Waste Wood Shredder

What is Waste Wood Shredder?

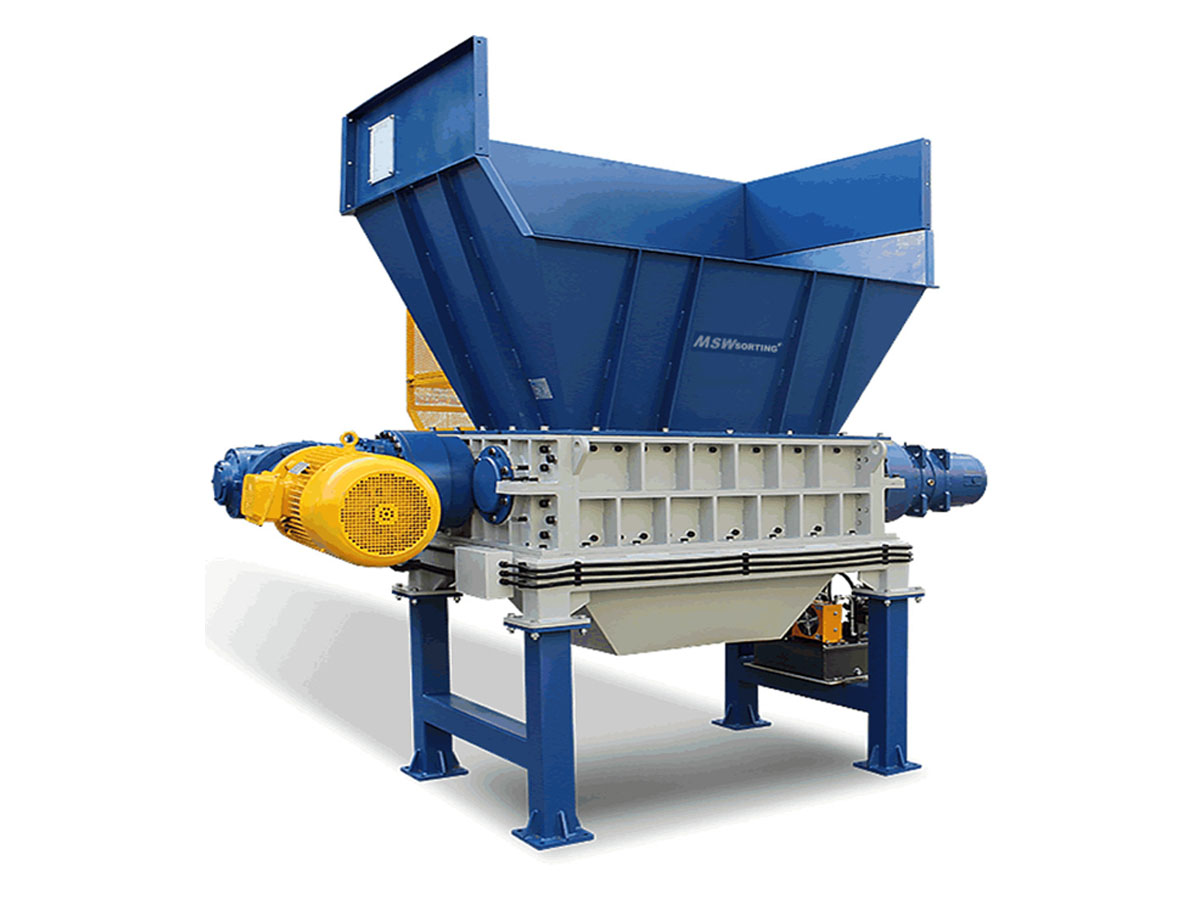

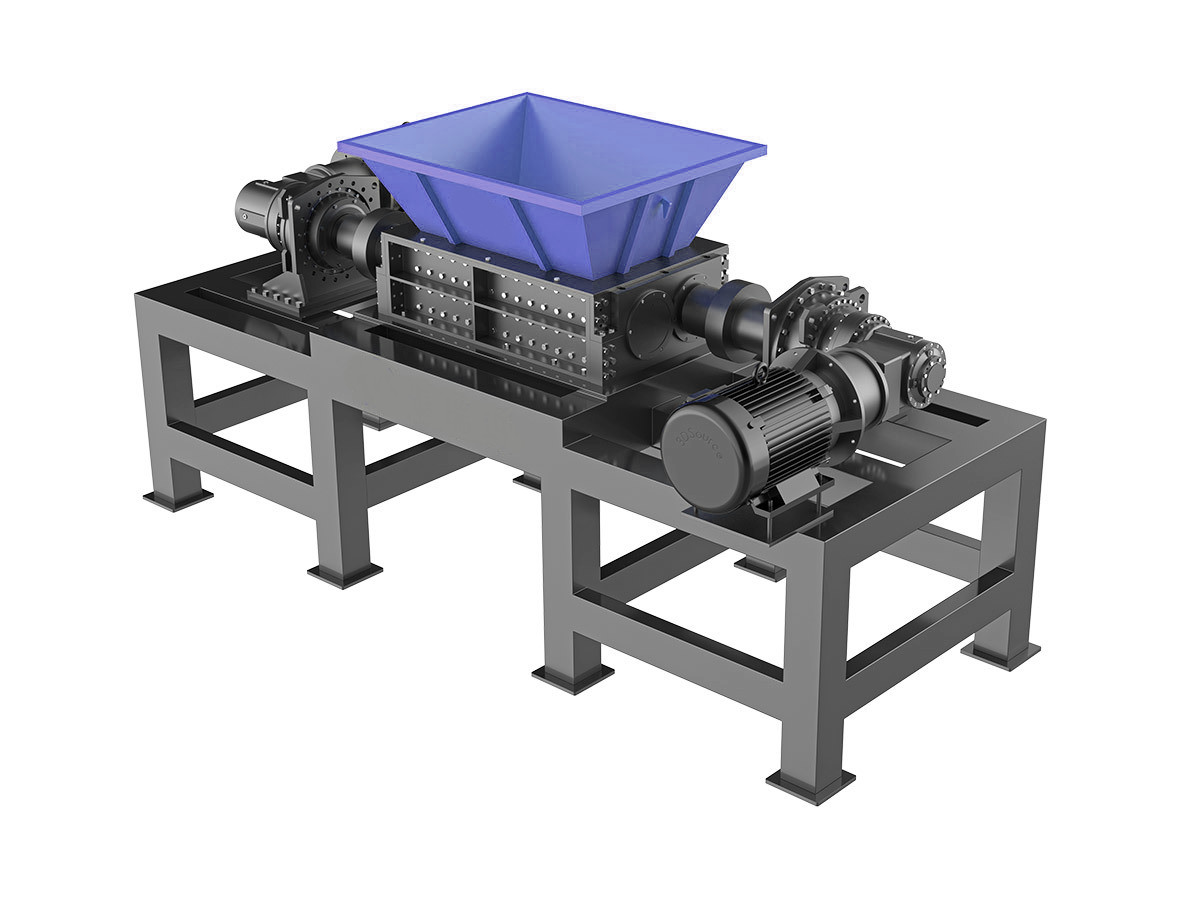

Waste Wood Shredder is a powerful machine designed to break down wood materials into smaller, more manageable pieces. It is widely used in forestry, agriculture, and recycling industries to process branches, logs, and other wood waste into chips or mulch. Waste wood shredders play a crucial role in waste reduction and sustainable resource management.

These machines are essential for converting wood waste into useful materials, such as biomass fuel, landscaping mulch, or raw materials for wood-based products. By shredding wood efficiently, businesses and individuals can reduce disposal costs and promote eco-friendly practices.

Waste wood shredders come in various sizes and designs, from small electric models for home use to large industrial machines capable of processing bulk wood waste. The choice of a waste wood shredder depends on the type and volume of wood materials being processed.

Working Principle of Waste Wood Shredder

Waste Wood Shredder operates through a high-powered motor that drives a system of rotating blades or hammers. When wood materials are fed into the machine, the blades cut, tear, and crush the material into smaller pieces, which are then expelled through an output chute.

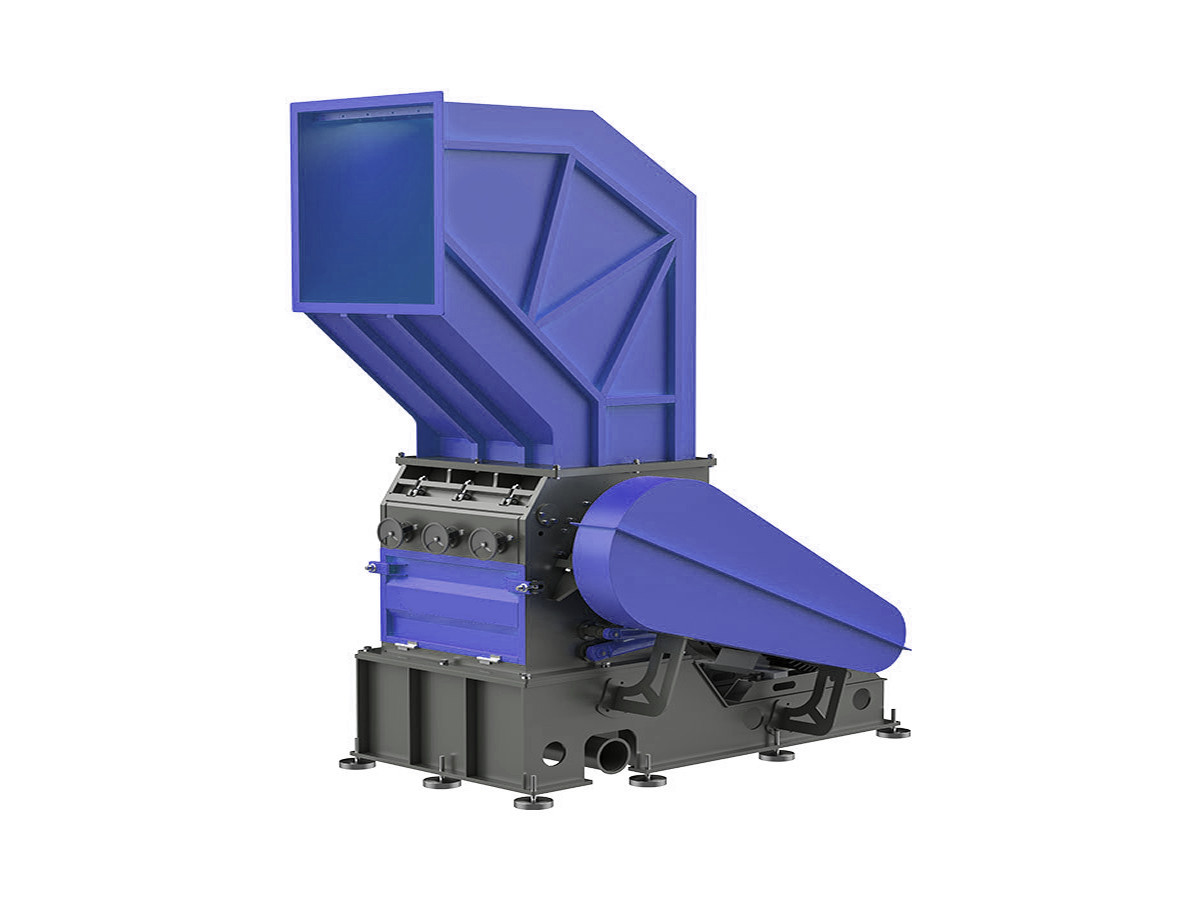

Some waste wood shredders use a drum-style cutting system, where sharp knives mounted on a rotating drum slice through the wood. Others use a disc or hammermill mechanism, where hammers repeatedly strike the wood to break it down into fine particles.

The efficiency of a waste wood shredder depends on factors such as blade sharpness, motor power, and feeding speed. Many models are equipped with automatic feeding mechanisms and safety features to enhance performance and protect the operator.

How to Choose the Right Waste Wood Shredder?

Choosing the right Waste Wood Shredder depends on the type of wood materials you need to process and the intended application. Key considerations include shredding capacity, motor power, and the desired output size.

For light-duty applications, such as home gardening or small-scale landscaping, an electric waste wood shredder with a moderate cutting capacity may be sufficient. However, for heavy-duty tasks, such as forestry waste management or commercial mulch production, a powerful gas-powered or industrial-grade shredder is recommended.

Additional factors to consider include the shredder’s portability, ease of maintenance, and energy efficiency. It is also important to select a model with safety features, such as an automatic shutoff system or overload protection, to ensure safe operation.

Applications of Waste Wood Shredder

Waste Wood Shredder is widely used in various industries to process wood waste and create valuable byproducts. In the forestry industry, waste wood shredders help break down branches and logs, making it easier to transport and repurpose wood waste.

In landscaping and agriculture, shredded wood is often used as mulch to enhance soil quality and retain moisture. This helps reduce weed growth and improve plant health, making waste wood shredders valuable tools for gardening and farming.

Additionally, waste wood shredders are used in biomass energy production, where shredded wood is processed into fuel for heating and power generation. Recycling facilities also use waste wood shredders to convert discarded wood products into raw materials for new wood-based products.

Maintenance of Waste Wood Shredder

Proper maintenance of a Waste Wood Shredder is essential to ensure long-term performance and efficiency. Regular maintenance helps prevent breakdowns, extends the machine’s lifespan, and keeps it operating at peak performance.

Key maintenance tasks include sharpening or replacing the blades, lubricating moving parts, and inspecting the motor and belts for signs of wear. Keeping the feeding and output areas clean is also important to prevent blockages and maintain smooth operation.

It is recommended to follow the manufacturer’s maintenance guidelines and perform routine checks on the shredder’s components. Proper storage and handling also help prolong the lifespan of the machine and ensure safe and reliable operation.

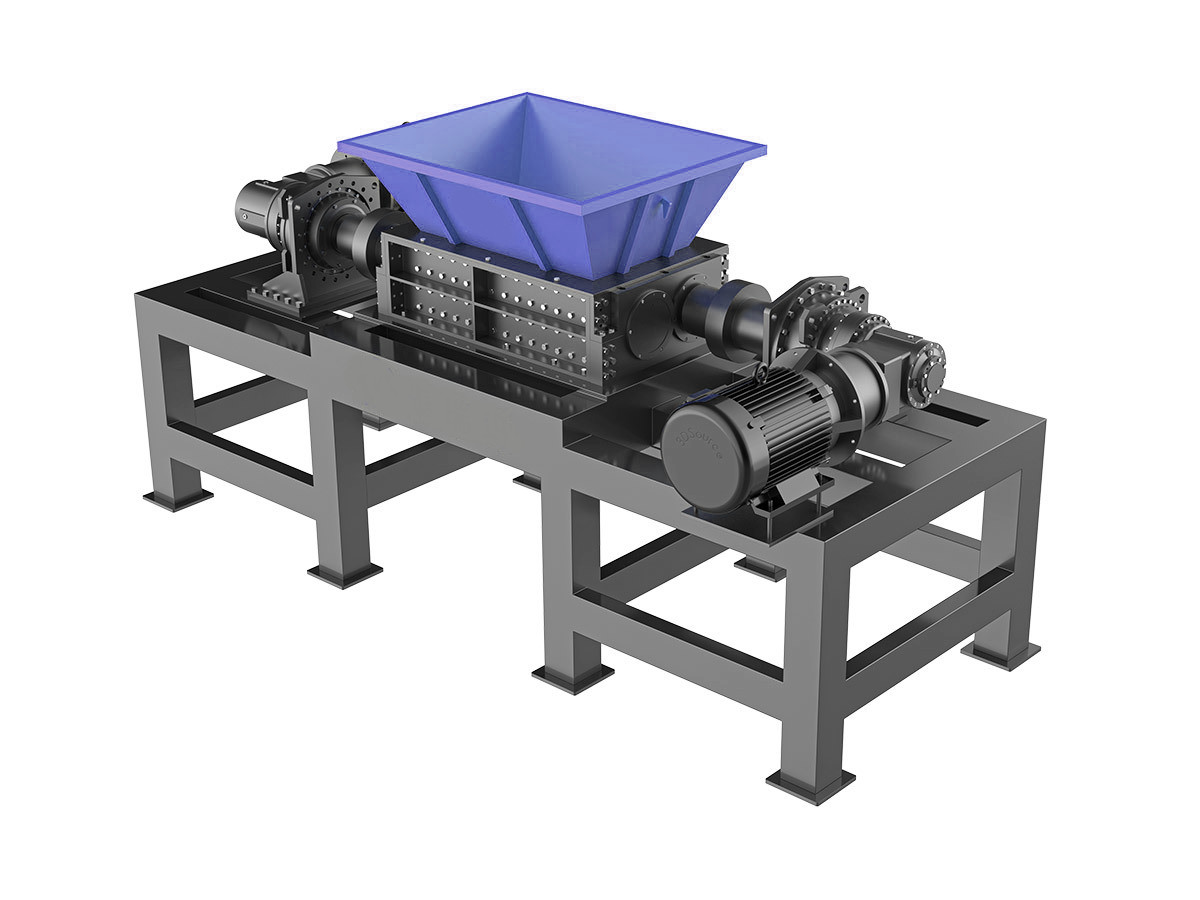

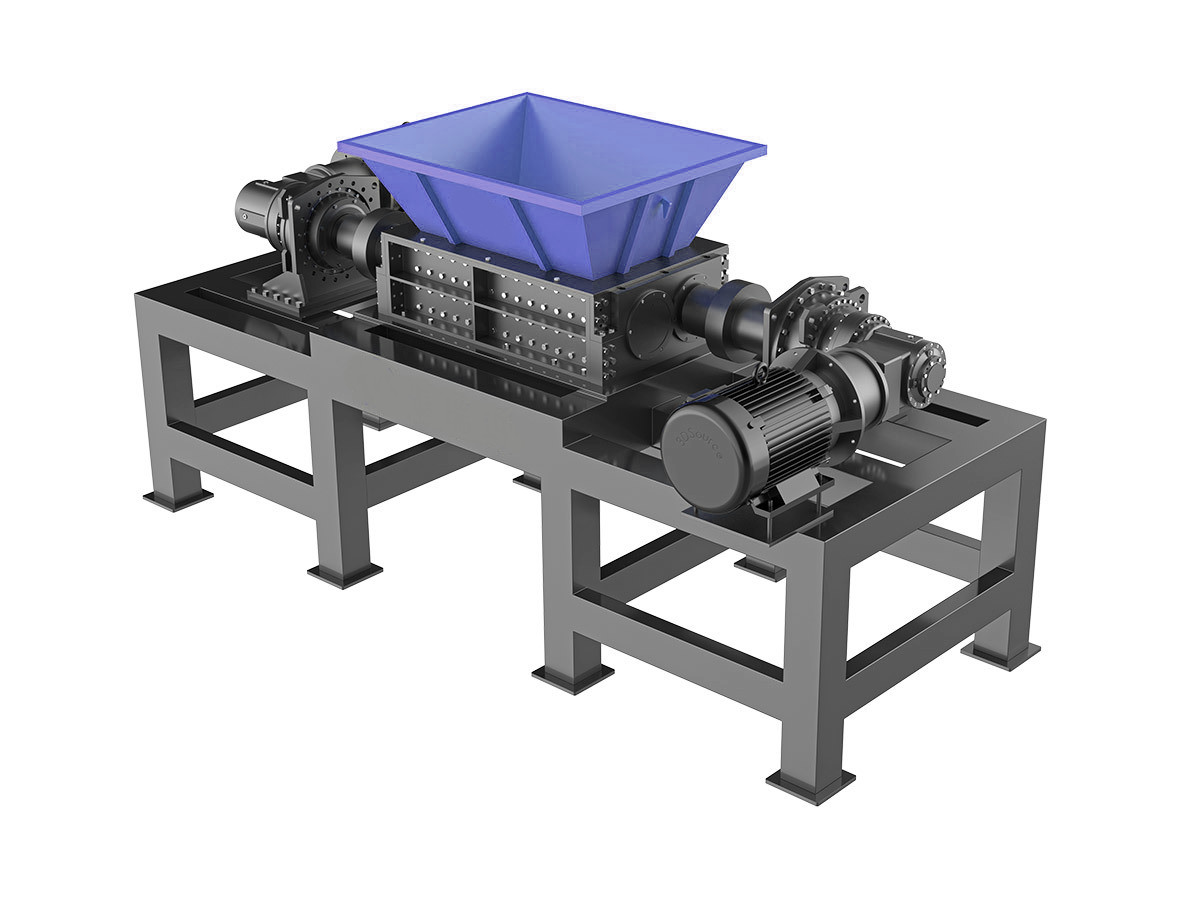

Main Components of Waste Wood Shredder

Waste Wood Shredder Types

Types of Waste Shredder Machine

Solid Waste Shredder

Efficiently process municipal and industrial waste into smaller, manageable sizes, aiding in recycling and waste disposal efforts.

Learn more >>

E-Waste Shredder

Specially engineered for electronic waste, this waste shredder handles materials like phones, computers, and circuit boards, ensuring secure disposal and recycling.

Learn more >>

Waste Metal Shredder

Our waste metal shredders efficiently process materials like aluminum, copper, and steel, making it easier to recycle and repurpose metal scrap.

Learn more >>

Waste Plastic Shredder

Built for recycling plastics like PE, PP, and PET, this waste shredder helps reduce plastic waste into manageable pieces for further processing.

Learn more >>

Waste Tire Shredder

Efficiently process used tires into reusable materials, including crumb rubber, for recycling and environmental sustainability.

Learn more >>

Waste Wood Shredder

Ideal for recycling wood waste like branches, pallets, and wooden furniture, this waste shredder helps create chips, mulch, or compost for eco-friendly disposal.

Learn more >>

Waste Paper Shredder

Ensure confidential document destruction with our secure waste paper shredders, designed for both small offices and large businesses.

Learn more >>

RDF Shredder

Transform waste into refuse-derived fuel (RDF) with this efficient waste shredder, perfect for waste-to-energy applications and reducing landfill dependency.

Learn more >>