Choosing the right wood chipper is a critical decision for any sawmill operation aiming to maximize profit from its waste stream. This guide provides a detailed comparison between two dominant machine types: the drum wood chipper and the disc wood chipper. We will examine how their fundamental designs lead to different performances in handling typical sawmill residues like slabs, edgings, and off-cuts. By understanding the advantages and limitations of each, you can select the equipment that best aligns with your production goals, desired chip quality, and operational budget.

Fundamental Differences in Cutting Action

The core distinction between these chippers lies in their mechanical approach to breaking down wood. This fundamental difference in action dictates every aspect of their performance, from the chip quality they produce to the types of material they can handle most effectively. The design philosophy behind each machine addresses the challenge of reducing wood to chips in uniquely different ways.

A drum chipper employs a large, rotating cylinder, or drum, mounted with multiple knives. The wood is fed parallel to the axis of the drum. The cutting action is a combination of shearing and tearing, as the knives engage the material along the length of the drum. In contrast, a disc chipper features a massive, heavy steel disc that spins at high speed, with knives mounted radially on its face. The wood is fed perpendicular to the disc, and the cutting action is primarily a high-speed impact or chopping motion.

The Shearing and Tearing Mechanism of a Drum Chipper

The rotating drum pulls the wood through the cutting chamber with a continuous, gripping action. This design provides a high torque, allowing it to process wider and sometimes more irregular pieces without stalling. The engagement of multiple knives along the material's length contributes to its ability to handle long, stringy waste like edgings.

The High-Speed Impact Cutting of a Disc Chipper

The disc chipper relies on the immense kinetic energy of the spinning disc to strike the wood and slice off chips. The high rotational speed, often exceeding 1,000 RPM, creates a clean, cutting action. This method is highly efficient for processing uniform logs and blocks but can be less effective with flexible or tangled materials.

How Infeed Systems Differ Between the Two Designs

Drum chippers often use a series of powered feed rollers to grip and forcefully pull material into the drum. This positive feed mechanism is crucial for their high-torque operation. Disc chippers may use a gravity-fed chute or a hydraulic feed wheel. The feed system must work in harmony with the cutting action to ensure a consistent and safe flow of material.

Why the Core Mechanism Dictates Material suitability

The drum chipper's tearing action makes it robust for mixed sawmill waste that may include bark and some contaminants. The disc chipper's precise impact cutting excels with clean, uniform wood, producing chips of a more consistent size and shape, which is often a requirement for pulp and paper mills.

Processing Capacity and Efficiency for Sawmill Residues

When evaluating capacity, it's essential to consider not just the volume of wood processed per hour but also the efficiency in handling the specific forms of waste generated in a sawmill. Sawmill residues are not homogeneous; they range from long, thin edgings to large, heavy slabs. The right chipper must maintain high throughput across this variety without frequent jams or downtime.

Drum chippers are renowned for their high-volume throughput, often processing over 100 tons of waste per hour in industrial settings. Their design is particularly adept at consuming long, stringy edgings and slabs continuously. The powerful feed rollers prevent the material from bouncing away, ensuring a steady flow. Disc chippers can also achieve high throughputs, but they are most efficient when the feedstock is pre-sized to fit the feed opening, minimizing the need for manual feeding or pre-breaking.

Handling Long Slabs and Edgings: A Comparison of Efficiency

For long, flexible edgings, the drum chipper has a distinct advantage. The material is drawn smoothly into the rotating drum, reducing the risk of tangling or "whipping" that can occur at the infeed of a disc chipper. This results in fewer interruptions and a more consistent feed rate for this specific type of waste.

Performance with Irregular Off-Cuts and Blocky Waste

Both machines can handle irregular blocks, but the disc chipper often produces a more uniform chip from this feedstock. The key is ensuring the pieces are small enough to enter the feed chute. A drum chipper's larger opening can accommodate bigger blocks, but the chip may show more variation in size.

Tolerance for Contaminants like Bark and Dirt

Sawmill waste is rarely perfectly clean. Drum chippers, with their robust construction and tearing action, generally have a higher tolerance for incidental bark, dirt, or even small embedded metals, though contaminants always increase wear. Disc chippers are more sensitive, as contaminants can quickly damage the precisely set knives on the disc, leading to costly downtime for repairs and blade changes.

Analyzing Real-World Throughput Data

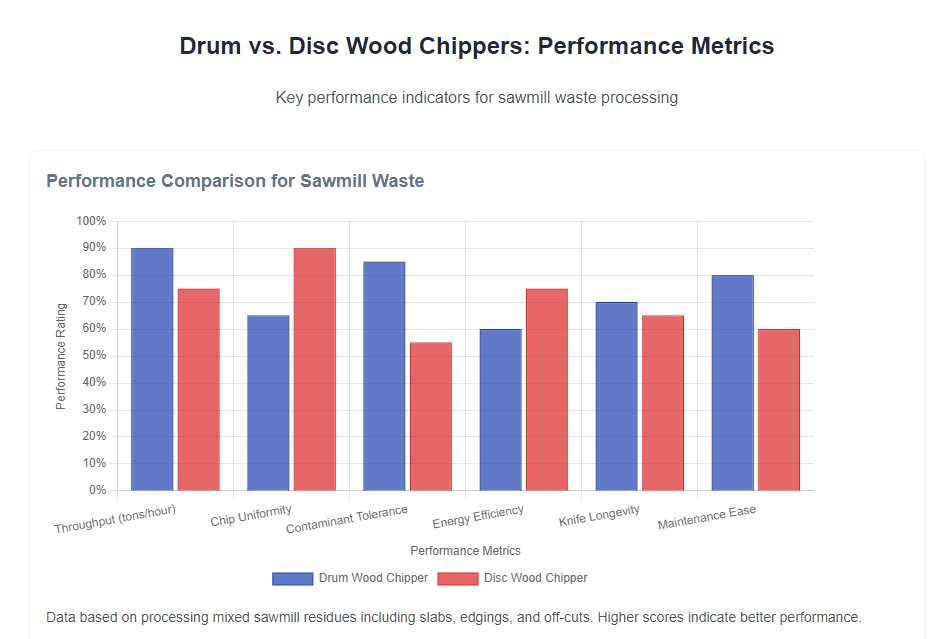

Industry data indicates that for processing a mixed stream of sawmill residues, a large drum wood chipper can maintain an average throughput of 80-120 green tons per hour. A comparable disc wood chipper might achieve 70-100 tons per hour on similar material but could exceed that range if the feedstock consists primarily of uniform log rounds.

An In-Depth Look at Final Chip Quality

Chip quality is a paramount concern, as it directly influences the market value of the output. High-quality chips command premium prices from pulp mills, board plants, and bioenergy facilities. The definition of quality includes consistency in size and shape, a low percentage of fines (dust), and a minimal presence of oversize particles.

The controlled, shearing action of a drum chipper can produce good-quality chips. However, the chip geometry may be less uniform compared to a disc chipper. The disc chipper is often considered the gold standard for chip quality in industries like pulp production. Its scissor-like cutting action, where the knife passes closely against a bed knife, creates chips of remarkably consistent length and thickness.

Chip Uniformity: Why Disc Chippers Often Excel

The design of a disc chipper allows for very precise adjustment of the knife-to-bed-knife gap and the knife extension from the disc face. These two settings directly control the length and thickness of the chip. This level of control is more difficult to achieve on a drum chipper, where chip size is influenced by the feed speed and the geometry of the drum knives.

Comparing the Control Over Chip Size Specifications

Operators can change the screen or grate size on a wood shredder or chipper to control maximum chip size. However, for inherent chip geometry, the disc chipper offers superior adjustability. By simply changing the knife projection, the operator can alter chip length without stopping the machine, a feature not available on drum chippers.

The Proportion of Fines and Oversized Chips in the Output

The high-speed impact in a disc chipper can generate more fines if the knives are dull. A well-maintained drum chipper typically produces a lower percentage of fines but may create more "overs," or long, sliver-like chips, especially if the knives are worn. Proper maintenance is crucial for both machines to minimize undesirable fractions.

Which Chip Type is Preferred by Different Industries?

The pulp and paper industry heavily favors the uniform chips from a disc chipper for optimal digester performance. For biomass fuel, where energy density is the primary concern, the chip quality from a drum chipper is often perfectly acceptable. The hard material shredding solutions used for pallets and demolition wood produce a different output altogether, more suited for fuel than for pulp.

Operating and Maintenance Costs Analysis

The initial purchase price is only one part of the total cost of ownership. Operating expenses, including power consumption, knife maintenance, and unplanned downtime, can significantly impact the long-term profitability of the equipment. A machine with a lower sticker price but higher operational costs may prove more expensive over its lifespan.

Drum chippers consume

substantial power due to the high torque required to rotate the heavy drum and pull material. Disc chippers require high rotational speed, which also translates to significant

energy use, though often of a different character (high RPM vs. high torque). The true cost difference often emerges in maintenance. Drum chipper knives are typically less

expensive and easier to change, but they may require more frequent sharpening or replacement due to the abrasive nature of their tearing action on dirty wood.

Knife Wear Patterns, Replacement Frequency, and Cost

Drum chipper knives wear more evenly along their entire length because the entire knife edge engages the wood. A set of knives might need rotation or replacement every 200-400 operating hours. Disc chipper knives wear most heavily at the tip. While they often last longer in clean wood, the cost per knife is higher, and the precision required for setting them adds labor time. The tungsten carbide cutters used in some high-end chippers extend life but increase initial cost.

Complexity and Time Required for Routine Maintenance

The maintenance schedule for a drum chipper is generally considered less complex. Gaining access to the knives and anvil is often straightforward. Disc chipper maintenance can be more involved, requiring careful locking out of the system and sometimes removing the entire feed assembly to access the knife disc. The lubrication system for the large bearings supporting the disc is also critical and must be meticulously maintained.

Energy Consumption: A Comparative Overview

Specific energy consumption (kWh per ton) is a key metric. For processing similar sawmill waste, a drum chipper might average 15-25 kWh per ton, while a disc chipper could range from 12-20 kWh per ton. These figures are highly dependent on wood species, moisture content, and desired chip size. The efficiency of the motor thermal protection system also plays a role in maintaining optimal energy use.

Comparing Common Failure Points and Mean Time to Repair

Common failures for drum chippers include wear on feed rollers and the drum bearings. For disc chippers, the primary concerns are the disc bearings and the precise alignment of the knives. The Mean Time To Repair (MTTR) for a disc chipper can be longer due to the complexity of realigning the cutting geometry, whereas drum chipper issues are often resolved more quickly.

Decision-Making Guide: Selecting the Right Machine

There is no one-size-fits-all answer. The optimal choice depends on a careful analysis of your specific operational needs, feedstock characteristics, and financial constraints. This section provides a framework to guide your decision-making process, helping you weigh the critical factors that should influence your final purchase.

If your primary goal is to process a high volume of mixed, potentially dirty sawmill waste with minimal pre-sorting and you are targeting the biomass fuel market, a drum chipper is likely the more robust and cost-effective choice. If your operation produces clean, uniform waste and your revenue depends on producing premium chips for the pulp market, the investment in a high-quality disc chipper is probably justified.

Key Factors That Favor Choosing a Drum Chipper

Choose a drum chipper if your feedstock consists of long, stringy edgings, wide slabs, and mixed construction waste. It is also the preferred choice if operational simplicity, lower knife cost, and high tolerance for contaminants are priorities. The double shaft wood shredder is another option for very bulky or contaminated wood waste, though it produces a shredded product rather than a clean chip.

When a Disc Chipper is the Undisputed Best Choice

A disc chipper is the best choice when the final chip quality specification is strict, such as for pulp production. It is also ideal for operations that primarily process log rounds, trimmings, and other uniform wood sources. Its ability to quickly adjust chip length online is a significant advantage for mills supplying multiple customers with different requirements.

Exploring Solutions for Mixed and Complex Waste Streams

For sawmills dealing with extremely heterogeneous waste, including metals or other non-combustibles, a two-stage system might be optimal. A primary solid waste primary shredder could reduce the entire waste stream, followed by a secondary separation and cleaning process before final chipping. This approach falls under high toughness material shredding solutions.

Comprehensive Considerations for Long-Term ROI

Calculating Return on Investment (ROI) requires looking beyond the invoice. Factor in the expected maintenance costs, energy consumption, labor requirements, and the potential revenue increase from selling higher-quality chips. A slightly more expensive machine with lower operating costs and higher output value will often deliver a better ROI over a five-to-ten-year period.

Conclusion and Final Summary

The choice between a drum and a disc wood chipper is a strategic decision that hinges on the specific nature of your sawmill waste and your business objectives. The drum chipper stands out as a high-capacity, robust workhorse ideal for processing a mixed stream of residues where ultimate chip uniformity is less critical. The disc chipper shines as a precision instrument, delivering superior chip quality that can open doors to higher-value markets.

By carefully considering the principles outlined in this guide—from the fundamental mechanics to the long-term financial implications—you can make an informed investment that enhances your operation's efficiency and profitability for years to come. The technology continues to evolve, with advancements in control panel PLC HMI systems improving the efficiency and ease of operation for both types of machines.

Quick-Reference Table: Core Characteristics at a Glance

A summary table comparing key attributes like ideal feedstock, typical chip quality, maintenance complexity, and capital cost provides a useful at-a-glance reference for decision-makers.

Future Trends in Wood Chipping Technology

The future points towards greater automation and intelligence. We can expect to see more chippers equipped with sensors that monitor knife wear in real-time and automated systems that adjust feed rate based on power consumption to optimize throughput and reduce jams.