Hard Material Shredding Solutions

Hard Material Shredding Solutions are specialized shredding systems designed to handle tough, dense materials such as metals, wood, construction debris, and e-waste. These shredders are built to withstand the stress of cutting through hard, abrasive materials, ensuring efficient size reduction and material processing.

In industries such as recycling, waste management, and manufacturing, hard material shredders are essential for breaking down large, bulky items into smaller, more manageable pieces. This facilitates transportation, disposal, and further processing, such as metal recovery, wood recycling, or energy production from waste.

Unlike soft material shredders, which are designed for flexible, lightweight materials, hard material shredders are equipped with heavy-duty mechanisms capable of withstanding high levels of stress and impact. These solutions ensure that even the most challenging materials can be processed with precision and minimal wear on the machine.

Efficient hard material shredding solutions are vital for reducing landfill waste, optimizing resource recovery, and improving the overall sustainability of industries that rely on these materials for production or energy generation.

What is Hard Material Shredding Solutions?

Hard Material Shredding Solutions refer to powerful shredding systems designed to process dense and tough materials. These solutions are engineered to handle a wide range of hard materials, including scrap metal, wood, concrete, glass, and construction waste.

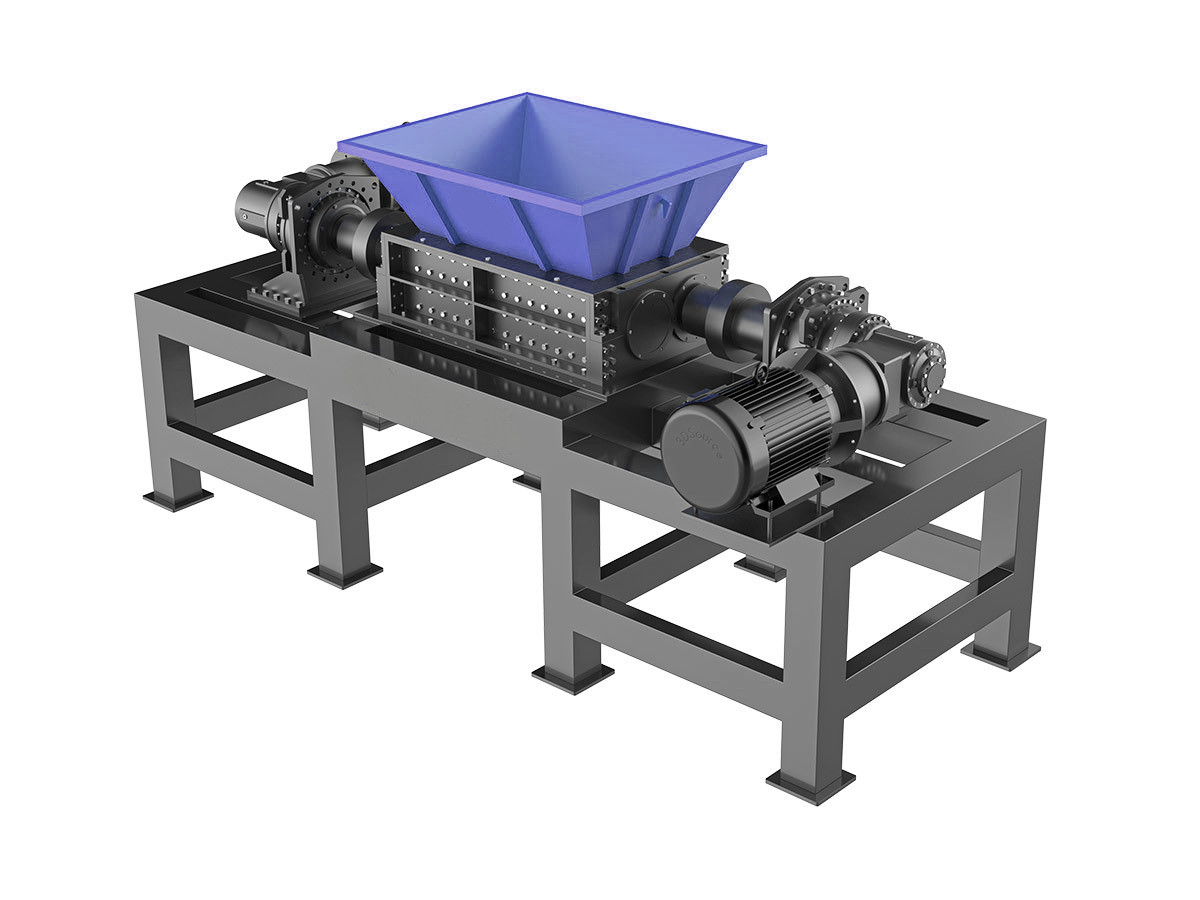

The shredding process involves breaking down large and rigid materials into smaller, uniform pieces that are easier to manage and further process. Depending on the application, hard material shredders may be equipped with high-torque motors, robust cutting blades, and reinforced chambers to ensure durability and performance.

Hard material shredders are available in various configurations, including single-shaft, dual-shaft, and high-speed hammer mills, each suited for different materials and processing requirements. These machines are used in industries such as metal recycling, wood processing, and construction demolition.

Why is Efficient Hard Material Shredding Important?

Efficient Hard Material Shredding is crucial for optimizing material processing, reducing operational costs, and improving sustainability. Hard materials, such as metal, concrete, and wood, can be challenging to process without the right equipment, but proper shredding ensures effective size reduction and resource recovery.

In industries like metal recycling, efficient shredding is essential for maximizing the recovery of valuable metals, which can be reused in manufacturing. Similarly, in construction and demolition, shredding large debris into smaller pieces facilitates easier disposal and recycling of materials like concrete, brick, and wood.

Additionally, efficient shredding reduces the wear and tear on machinery, improves throughput, and ensures that the final shredded material meets the specifications required for downstream processes, such as material sorting or energy production.

How Do Shredders Enhance Hard Material Recycling?

Hard Material Shredders enhance recycling by breaking down dense materials into smaller, more manageable pieces, which facilitates further sorting, separation, and repurposing. For example, in metal recycling, shredders reduce scrap metal into smaller fragments, making it easier to extract valuable metals like aluminum and steel.

In the case of wood and construction debris, shredding reduces large, bulky items into smaller chips that can be processed into wood pellets for energy production or used in the manufacture of composite materials.

Shredders also contribute to waste reduction by converting hard-to-recycle materials into useful secondary raw materials. For instance, shredded concrete can be repurposed as aggregate in construction, reducing the need for new raw materials.

Types of Shredders Used in Hard Material Processing

There are several types of Hard Material Shredders designed for different materials and processing needs:

Single-Shaft Shredders: These are commonly used for processing large volumes of materials such as wood, plastics, and construction debris. They are equipped with one central shaft and robust blades for continuous, efficient shredding.

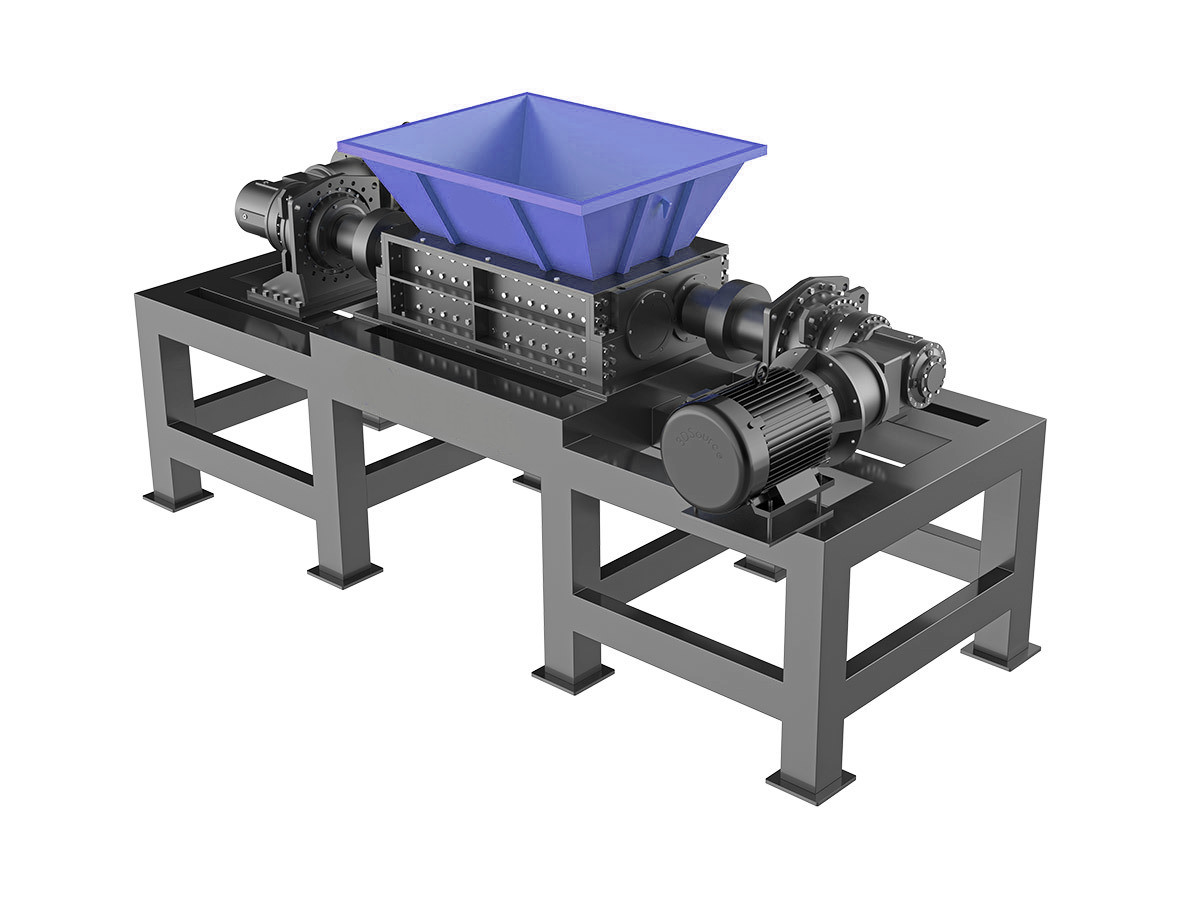

Dual-Shaft Shredders: Ideal for tougher materials like scrap metal, these shredders use two interlocking shafts to tear through materials with higher torque and cutting power, making them effective for processing heavy-duty materials.

High-Speed Hammer Mills: These are used for materials like concrete or glass, where high-speed impact is required to break the materials into smaller fragments. They are efficient for producing finely ground materials.

Granulators: These machines are ideal for processing smaller hard materials into consistent granules, suitable for reuse in various manufacturing applications.

Key Factors in Choosing the Right Shredders for Hard Materials

When selecting the right Hard Material Shredder, several factors must be considered to ensure optimal performance:

Material Type: Different materials require specific shredding technologies. For instance, scrap metal shredding requires a shredder with high torque and durable cutting tools, while wood shredding may need a different configuration to handle fibrous materials.

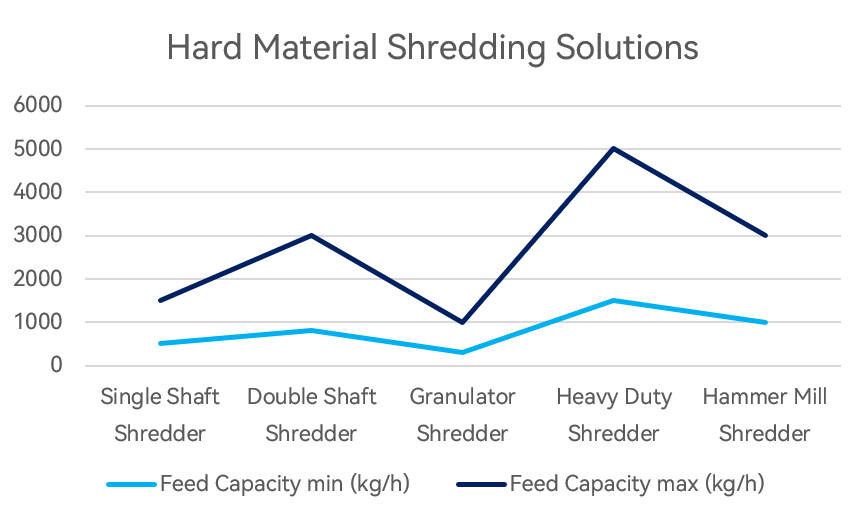

Throughput Capacity: The size of the shredder and its processing capacity are essential factors, especially for large-scale operations. Higher throughput ensures efficient processing of large quantities of materials.

Durability and Maintenance: The shredder's ability to handle tough materials without excessive wear is crucial. It's also important to choose a machine with easy maintenance features, such as accessible parts and simple blade replacement.

Energy Efficiency: Energy consumption is a significant cost in industrial shredding. Choosing a shredder with energy-efficient motors and low power consumption can help reduce operational costs.

FAQ

Q: What types of hard materials can be shredded?

A: Hard materials that can be shredded include metals, wood, concrete, glass, and construction debris. These materials are often recycled for reuse in manufacturing or energy production.

Q: How do I choose the right shredder for my materials?

A: The right shredder depends on factors such as the type of material, desired output size, throughput capacity, and durability. For tough materials like scrap metal, dual-shaft shredders or high-speed hammer mills are ideal.

Q: What is the difference between a single-shaft and dual-shaft shredder?

A: Single-shaft shredders are typically used for lighter materials, while dual-shaft shredders offer higher torque and are more suited for tougher, heavier materials such as scrap metal or dense plastics.

Q: How do I maintain my hard material shredder?

A: Regular maintenance includes checking the blades, lubricating moving parts, and inspecting the motor and belts. It's also essential to clean the shredder regularly to prevent material buildup and ensure optimal performance.

Main Components of Solid Waste Shredder

Shredding Solutions

Soft Material Shredding Solutions

Efficiently handle and process soft materials with our specialized soft material shredding solutions. Designed for materials like rubber, textiles, foam, and soft plastics, our shredders offer precise size reduction while ensuring optimal throughput and minimal downtime. Ideal for industries requiring soft material processing for recycling, waste management, and material recovery, our shredding machines are built for durability, energy efficiency, and high performance.

Learn more >>

Hard Material Shredding Solutions

Tackle tough materials with our advanced hard material shredding solutions. Engineered to process metal, concrete, wood, stone, and dense plastics, our shredders provide powerful performance for efficient size reduction and recycling. Designed for industries handling heavy-duty waste, our shredders ensure durability, precision, and high throughput, helping businesses optimize waste management and material recovery.

Learn more >>

High Toughness Material Shredding Solutions

Efficiently shred and process high toughness materials with our specialized shredding solutions. Designed for materials such as thick rubber, hard plastics, reinforced composites, and industrial metal alloys, our machines provide powerful cutting performance and exceptional durability. Built to handle the toughest materials, our shredders ensure optimal size reduction for recycling, waste management, and material recovery.

Learn more >>

Composite Material Shredding Solutions

Efficiently process and recycle composite materials with our specialized shredding solutions. Designed for fiber-reinforced plastics, carbon composites, and other complex materials, our shredders offer precision cutting and exceptional durability to handle tough and intricate substances. Ideal for industries such as automotive, aerospace, and construction, our machines ensure effective size reduction for reuse or disposal.

Learn more >>