Material clogging is one of the most frequent and disruptive issues faced in the operation of drum wood chippers. These blockages lead to significant downtime, reduce overall productivity, and can cause severe damage to the machine's internal components if not addressed correctly and promptly. Understanding the root causes of clogging is the first step toward developing effective solutions and preventive measures. This guide provides a systematic approach for operators and maintenance engineers to troubleshoot, resolve, and prevent material jams, ensuring safe and efficient chipper operation.

A clogged chipper not only halts production but also poses serious safety risks to personnel attempting to clear the blockage. The forces involved in a drum chipper are immense, with rotors spinning at high speeds and generating tremendous torque. Therefore, a methodical and safety-first approach is non-negotiable. This resource covers the entire lifecycle of a clogging event, from early detection to long-term prevention strategies, incorporating industry best practices and technical insights.

Understanding the Critical Moments and Locations of Clogging

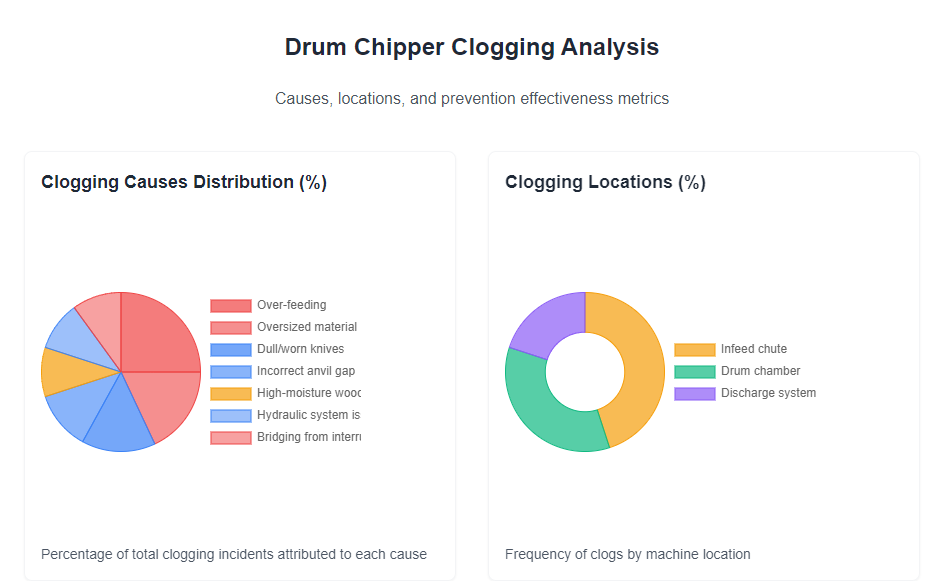

Clogging does not occur randomly; it typically happens at specific points within the material flow path of the chipper. Identifying the exact location of a blockage is crucial for diagnosing the underlying cause and applying the correct remedy. Each section of the machine, from the infeed to the discharge, has unique characteristics that contribute to different types of jams. Recognizing the early signs of a developing clog can allow an operator to intervene before a complete shutdown is necessary.

The material's journey through the chipper involves several transitions where the risk of blockage increases. These include the point of entry, where the geometry of the feed system can cause material to bridge; the cutting chamber, where inadequate cutting force can lead to a buildup of partially processed wood; and the discharge chute, where chip density and airflow issues can cause plugging. A thorough understanding of these critical zones enables a more targeted maintenance and operation strategy.

Signs of an Initial Clog at the Infeed Chute

The infeed chute is the first point where material enters the chipper. Early signs of trouble here often include unusual noises, such as a grinding or scraping sound, as the material struggles to be pulled in by the feed rollers. The engine may begin to lug or slow down significantly as it strains against the resistance. Visually, operators might see material stopping its forward progress or even bouncing slightly at the entrance, indicating that the feed rollers are losing their grip.

Another key indicator is the behavior of the hydraulic system. If the pressure gauges for the feed roller circuit show erratic spikes or consistently high readings, it suggests that the rollers are exerting excessive force to move material that is not flowing freely. This can be a precursor to a full-scale jam. In many modern chippers, the control system may trigger an alarm or automatically reduce the feed rate in response to these pressure anomalies, providing a valuable window for intervention.

Characteristics of an Internal Clog within the Drum Chamber

A clog within the drum chamber itself is often more severe and harder to clear than an infeed issue. The primary symptom is a complete cessation of chip output from the discharge chute, accompanied by the machine's engine either stalling completely or the drive system slipping (e.g., a belt squealing) as the rotor becomes locked. The machine may also emit a low, heavy humming sound if the rotor is jammed but the engine is still attempting to drive it.

This type of blockage typically occurs when a piece of wood is not cleanly sheared by the knives. Instead, it becomes wedged between the rotating drum and the stationary anvil or housing. The root cause is often related to blunt knives, an incorrect anvil gap, or an attempt to process a piece of wood that is far beyond the machine's designed capacity, such as a large, knotty log or a foreign object like a rock or metal.

How to Identify a Clog in the Discharge System

Discharge system clogs are characterized by a reduction or complete stop in the flow of chips from the spout, while the machine continues to run and the engine does not appear to be under excessive strain. Operators might notice chips backing up and becoming visible around the edges of the discharge chute or even spilling out from the infeed area. The sound of the machine may change, becoming more muffled as the internal airflow is restricted by the plugged chute.

These blockages are frequently caused by attempting to discharge chips into a full or poorly positioned trailer, where the chip pile obstructs the spout. They can also result from processing wood with a very high moisture content, which creates a dense, sticky chip that does not flow easily. In some cases, a failure in the fan or blower that propels the chips through the discharge system will lead to an immediate plug, as the chips lack the necessary kinetic energy to exit the machine.

Different Causes Associated with Clogs in Different Locations

The location of a clog provides a direct clue to its origin. An infeed clog is predominantly an issue of material handling and feed mechanics. Causes include oversized material, irregular feeding rates, or worn feed roller teeth. A drum chamber clog is primarily a cutting efficiency problem, pointing to knife sharpness, anvil gap, or the presence of contaminants. A discharge clog is often a material flow or system output issue, related to chip characteristics, blower power, or external obstructions.

Diagnosing the problem correctly saves valuable time. For instance, repeatedly trying to reverse the feed rollers to clear a discharge clog will be ineffective. Similarly, attempting to force more material through the machine to push out a drum chamber jam can cause catastrophic damage to the rotor assembly or drive train. A systematic approach that correlates the clog's location with its probable cause is the foundation of effective troubleshooting.

Clogging Caused by Improper Operation and Corrective Actions

Human factors are responsible for a significant percentage of all chipper clogs. Even the most robustly designed machine can be overwhelmed by incorrect operating practices. Operator training is therefore a critical investment for minimizing downtime. The most common operational errors involve exceeding the machine's physical limits, feeding inappropriate materials, and failing to maintain a consistent workflow. Addressing these behaviors through standardized procedures is highly effective.

Corrective actions focus on establishing and enforcing clear operational guidelines. These guidelines should be based on the manufacturer's specifications for the machine's capacity and capabilities. Visual aids, such as placards near the infeed chute indicating maximum log diameter, can serve as constant reminders for operators. Furthermore, fostering a culture where operators feel empowered to stop the process when they observe potential issues can prevent minor problems from escalating into major blockages.

Over-Feeding: The Consequences of Exceeding Machine Capacity

Feeding material too quickly is a primary cause of clogging. Each drum wood chipper has a maximum volumetric throughput, measured in cubic meters or tons per hour. When this limit is exceeded, the cutting chamber becomes overloaded. The knives cannot effectively shear the excessive volume of wood, leading to a buildup of partially cut material that eventually jams the rotor. The hydraulic system powering the feed rollers will show sustained high pressure, and the engine RPM will drop noticeably.

The corrective action is to establish a consistent, measured feed rate. The operator of the material handler should feed one log at a time, allowing it to be fully drawn into the machine before introducing the next. The sound of the engine and the chipper's rhythm are good indicators of a proper pace; a smooth, constant roar is ideal, while a labored, fluctuating sound suggests over-feeding. Using a machine with an auto-feed system that modulates the feed rate based on engine load can automate this optimization.

Oversized Feed Material: Risks of Un-processed Large Logs

Every chipper model is designed to handle a maximum log diameter, typically specified by the manufacturer. Attempting to process logs that exceed this diameter is a direct path to a severe clog. An oversized log may not fit properly between the feed rollers and the upper housing, causing it to become stuck at the infeed. If it does enter, it can strike the cutting drum with excessive force, potentially damaging knives and causing a jam in the chamber.

The solution is strict adherence to the machine's size limitations. Logs that are too large should be pre-processed with a different machine, such as a double-shaft wood shredder, which can break them down into smaller, manageable pieces. Operators should be trained to visually assess log size and have measuring tools available at the landing to confirm dimensions when in doubt. Implementing a quality control check before material reaches the chipper is a highly effective preventive measure.

Incorrect Material Types: Precautions for High-Moisture and Contaminated Wood

The physical properties of the feedstock greatly influence the chipping process. Wood with very high moisture content, such as green logs or timber saturated from rain, produces a heavy, sticky chip that does not flow well through the discharge system. This type of chip is prone to clumping and can adhere to the walls of the discharge chute, gradually building up until a plug forms. Contaminants like sand, dirt, or mud accelerate wear on the cutting components, reducing their efficiency and increasing clogging risk.

When processing high-moisture wood, operators should be especially vigilant about discharge flow. Periodic inspections of the chute during operation can help identify buildup early. Allowing wood to season or dry for a period before chipping can mitigate this issue. To handle contamination, a preliminary cleaning step, such as shaking or brushing off loose dirt from logs before feeding, can significantly extend knife life and maintain cutting performance. A chipper is a wood-processing tool, not a soil or rock crusher.

Bridging Phenomenon Caused by Interrupted Feeding

Bridging occurs when multiple pieces of wood interlock above the feed rollers, creating an arch that prevents any material from descending into the cutting chamber. This is a common issue when processing slash or branched material. The chipper may appear to be running normally, but no material is being consumed. If feeding is then resumed forcefully, the sudden collapse of the bridge can cause a shock load that overwhelms the cutting drum, leading to a jam.

Preventing bridging requires careful feeding technique. The material handler operator should avoid dumping large, tangled piles directly into the infeed hopper. Instead, the material should be broken up and fed in a controlled manner to maintain a steady flow. If bridging does occur, the correct response is to use the chipper's reverse function on the feed rollers to carefully break the arch. Manually poking at the bridge with a long tool is extremely dangerous and must be strictly prohibited.

Clogging Problems Triggered by Poor Equipment Condition

Even with perfect operating techniques, a chipper in poor mechanical condition will be prone to frequent clogging. The machine's ability to efficiently pull in, cut, and eject material depends on the integrity of its key components. Regular maintenance is not merely about preventing breakdowns; it is fundamental to ensuring consistent, clog-free performance. A proactive maintenance schedule that focuses on the components most critical to the cutting process is essential.

The state of the cutting mechanism is the heart of the issue. Dull knives, a misaligned anvil, or a weakened drive system cannot generate the clean, powerful shearing action required. The machine will struggle, leaving ragged cuts that are more likely to jam. Other systems, such as the hydraulics that power the feed rollers, must also be in optimal condition to provide the consistent force needed to present wood to the drum at the correct rate.

The Critical Impact of Worn or Damaged Knives on Cutting Efficiency

Sharp knives are the single most important factor for clean chipping. A sharp knife shears the wood fibers cleanly, producing uniform chips with minimal effort. A dull knife, in contrast, tears and crushes the wood. This requires more power from the engine, generates excessive heat, and produces irregular, splintered chips. More critically, the torn wood fibers are more likely to form a tangled mass that can clog the drum chamber or discharge system.

Knives have a finite lifespan and must be replaced on a schedule based on operating hours or the volume of wood processed. A common industry practice is to rotate the knives periodically to expose a fresh, sharp edge, and then replace them once all edges are worn. The use of high-quality, hardened steel knives can extend service intervals. Regularly inspecting the knives for nicks, cracks, and blunt edges is a core part of a preventive maintenance routine. Dull knives increase the risk of hitting the anvil block, causing damage to both components.

How Incorrect Anvil Gap Leads to Incomplete Cutting

The anvil is a hardened steel block that serves as the counter-surface against which the rotating knives shear the wood. The gap between the knife tips and the anvil must be set to a precise tolerance, usually specified by the manufacturer (e.g., 1 to 3 millimeters). If this gap is too wide, the knives will not make clean contact with the wood, failing to sever it completely. This can result in long, stringy pieces that wrap around the rotor or clog the discharge.

If the gap is too narrow, the knives will strike the anvil, causing immediate and severe damage to both components. This misalignment can occur over time due to vibration or after replacing knives or the anvil itself. Checking and adjusting the anvil gap is a critical maintenance task that should be performed regularly according to the service manual. Using a feeler gauge to ensure accuracy is standard practice. A correctly set gap is vital for efficient chipping and preventing jams.

Insufficient Pressure in the Hydraulic Feed System Causing Weak Feeding

The hydraulic feed system is responsible for generating the force needed to grip and pull wood into the cutting drum. If the hydraulic pressure is too low, the feed rollers will not be able to maintain a firm grip on the material, especially on slippery, barkless wood or large-diameter logs. This results in the logs slipping in the rollers instead of being advanced, a condition known as "chatter." This intermittent feeding disrupts the smooth cutting action of the drum and can lead to a jam.

Low hydraulic pressure can stem from several issues: a worn hydraulic pump, internal leaks in the cylinders or valves, a clogged hydraulic filter, or low fluid level. Regular monitoring of hydraulic pressure gauges can alert operators to a developing problem. Maintenance should include periodic fluid analysis, filter changes, and inspections for leaks. A well-maintained hydraulic system ensures consistent feed force, which is crucial for preventing infeed-related clogs.

Drive System Slippage Leading to Reduced Drum Speed

The cutting drum must maintain a high, constant rotational speed to effectively chip the wood. This speed is typically transmitted from the engine via a V-belt drive or a direct gearbox. If the V-belts are worn or improperly tensioned, they can slip under load, especially when a tough section of wood enters the drum. This slippage causes a sudden drop in drum RPM, preventing the knives from achieving the necessary cutting velocity and greatly increasing the likelihood of a clog.

Regular inspection of the drive system is essential. Belts should be checked for cracks, glazing, and proper tension. The manufacturer's specifications will provide the correct deflection measurement for tensioning. A gearbox drive requires checking the oil level and condition. Any unusual noises or vibrations from the drive train should be investigated immediately. A loss of drum speed is a direct indicator of a power transmission problem that must be rectified to avoid operational issues.

Safety First! Standard Operating Procedure for Clearing Clogs

Clearing a chipper clog is one of the most hazardous tasks an operator can perform. The potential for the machine to suddenly restart or for stored energy to be released makes strict safety protocols absolutely mandatory. Under no circumstances should safety be compromised for the sake of speed. A standardized, step-by-step procedure ensures that every clog clearance operation is conducted with maximum regard for personnel safety.

The foundation of safe clog clearance is ensuring the machine is completely de-energized and isolated from all power sources before any physical contact is made. This process must be systematic and verifiable. All personnel involved must be trained in these procedures and understand the grave consequences of taking shortcuts. The goal is to make the machine safe for the worker, eliminating any possibility of accidental activation during the clearing process.

Emergency Stop and Lockout-Tagout Process

The first action upon suspecting a clog is to immediately press the emergency stop button. This halts all machine motion. However, simply stopping the machine is insufficient for safety. The next critical step is to implement a Lockout-Tagout (LOTO) procedure. This involves physically isolating the chipper from all energy sources. The operator must disconnect and lock the main electrical power switch and isolate any hydraulic or pneumatic energy sources using specialized locks and tags.

Each person working on the machine places their own personal lock on the energy isolation device, ensuring that the machine cannot be re-energized until they have removed it. The keys to these locks must remain in the possession of the individual who applied them. This system prevents accidental or unauthorized restarting of the equipment. Verifying that the machine is truly de-energized by attempting to start it (after ensuring the area is clear) is the final check before work begins. This process is a non-negotiable safety standard.

Correct Use of the Jog/Reverse Function

Before proceeding to manual clearing, operators should attempt to use the machine's built-in functions to clear the blockage remotely. Many chippers are equipped with a jog or reverse mode for the feed system. After ensuring the discharge area is clear of personnel, the operator can momentarily engage the reverse function. This may be enough to dislodge a minor jam or a bridge at the infeed. The reverse function should be used in short, controlled bursts.

It is crucial to understand that this step should only be attempted after the initial emergency stop but before applying LOTO. If the clog does not clear after a few attempts, the operator must then proceed to full LOTO before any manual intervention. Relying solely on the reverse function without subsequent LOTO for a persistent clog is extremely dangerous, as it may not resolve the issue and creates a false sense of security. The control panel's PLC/HMI system often provides the interface for these functions.

Steps for Manual Clearing Using Specialized Tools

If automated methods fail, manual clearing is necessary. This must only be done with specialized, non-conductive tools designed for this purpose, such as a pry bar or a clearing tool with a hooked end. Under no circumstances should any part of the operator's body be placed inside the infeed chute, discharge chute, or any access panel. The tool is used to carefully break up and pull out the jammed material from the outside.

Work should proceed slowly and methodically. Starting from the discharge end (if accessible) is often safer, as it can relieve pressure on the jam. If working from the infeed, operators must be aware that dislodging the clog could cause the material to suddenly fall into the still-engaged cutting chamber. The machine must remain locked out throughout this entire process. Using a flashlight to inspect the interior can help identify the exact nature and location of the blockage.

Prohibited Behaviors: Never Use Hands or Feet Inside the Machine

This point cannot be overstated: it is absolutely forbidden to use hands, feet, or any other body part to probe or push a clog inside a chipper. The cutting mechanisms are under extreme tension when jammed, and a sudden release can cause them to move with explosive force. Furthermore, there is always the risk of the machine being accidentally re-energized by another person. Tragic accidents have occurred due to this fundamental violation of safety rules.

Training must emphasize that no amount of production urgency justifies such a risk. Company policy should mandate strict disciplinary action for anyone violating this rule. If a clog cannot be cleared with the available tools from outside the machine, the next step is to contact a qualified service technician. Safety takes precedence over all other concerns. Creating a culture where workers feel supported in refusing unsafe tasks is critical for preventing life-altering injuries.

Targeted Preventive Maintenance Plan to Avoid Clogging

The most effective and economical strategy for dealing with chipper clogs is to prevent them from occurring in the first place. A comprehensive preventive maintenance plan is far less costly than the downtime, repair expenses, and safety risks associated with frequent jams. This plan should be proactive, scheduled, and documented, focusing on the components and systems most critical to the chipping process. It transforms maintenance from a reactive activity into a strategic function.

A well-structured plan is based on the manufacturer's recommendations but is also tailored to the specific operating conditions, such as the type of wood processed and the environment. It consists of daily checks performed by the operator, weekly inspections by a lead operator, and more thorough monthly or quarterly services by a qualified mechanic. Documentation through checklists and maintenance logs is essential for tracking the machine's health and predicting component failure before it causes a problem.

Establishing a Knife Inspection and Replacement Cycle Based on Operating Hours

Knife maintenance is the cornerstone of clog prevention. A predetermined schedule for inspecting and replacing knives should be established based on the machine's operating hours. For example, a common schedule might require a visual inspection every 40 hours of operation, rotation of the knives every 120 hours, and full replacement every 500 hours. However, these intervals can vary significantly based on the abrasiveness of the wood (e.g., sandy soil contamination will dull knives faster).

Using a sharpness gauge or simply visually inspecting for a rounded cutting edge can determine when action is needed. Keeping a log of knife changes helps identify patterns and optimize the replacement schedule. Maintaining an inventory of sharp, pre-set knives reduces downtime when a change is required. Investing in high-quality knives with tungsten carbide tips can extend service life considerably, offering a strong return on investment through reduced changeover frequency and better performance.

Daily, Weekly, and Monthly Maintenance Checklists

Maintenance tasks should be organized into frequencies that ensure consistent oversight without being overly burdensome. A daily checklist, to be completed by the operator at the start of each shift, includes visual inspections for loose bolts or leaks, checking hydraulic fluid levels, ensuring the discharge chute is clear, and verifying the sharpness of the knives. This takes only a few minutes but can catch early signs of trouble.

A weekly checklist involves more detailed inspections. Tasks might include checking and adjusting V-belt tension, cleaning hydraulic suction filters, inspecting the anvil gap, and examining the wear on feed roller teeth. A monthly or quarterly service, performed by a mechanic, would encompass tasks like changing hydraulic filters, checking gearbox oil, inspecting bearings for play, and calibrating pressure sensors. This tiered approach ensures that all aspects of the machine receive attention at appropriate intervals.

Regular Monitoring of Hydraulic System Fluid Level, Pressure, and Filters

The hydraulic system is the lifeblood of the feed mechanism. Preventive maintenance for this system is critical. Daily checks of the fluid level in the reservoir are essential; low fluid can lead to pump cavitation and system failure. Monitoring pressure gauges during operation provides a real-time health indicator. A gradual drop in pressure may signal pump wear or an internal leak.

Hydraulic fluid and filters must be changed at intervals specified by the manufacturer, which are often based on operating hours. Contaminated fluid is a major cause of valve and pump failure. Using oil analysis kits can help determine the condition of the fluid and the presence of water or metal particles, allowing for predictive maintenance. A clean, well-maintained hydraulic system ensures reliable feed roller operation, which is fundamental to preventing infeed clogs.

Preventive Replacement Strategy for Key Components

Beyond knives, other components have a predictable lifespan and should be replaced proactively before they fail. Waiting for a component like a V-belt or a bearing to fail catastrophically during operation will cause unplanned downtime and potentially more extensive damage. A preventive replacement strategy involves identifying these components and replacing them after a certain number of operating hours or calendar time.

Components suitable for this strategy include drive belts, hydraulic hoses with a known service life, and bearings in high-stress locations like the rotor shaft. Keeping a maintenance history for the machine allows for accurate forecasting of these replacements. While this approach has an upfront cost, it is far cheaper than the emergency repairs and production losses associated with a breakdown. It also allows for scheduling the work during planned downtime, minimizing disruption.

Advanced Troubleshooting: When Conventional Methods Fail

Some clogging issues are persistent and recur despite adherence to standard operating and maintenance procedures. These problems often point to more subtle or complex underlying faults that require a deeper level of diagnostics. Advanced troubleshooting involves a systematic investigation of the machine's systems and components to identify root causes that are not immediately apparent. This process requires a methodical approach and a good understanding of the machine's mechanics.

When faced with a recurring clog, it is important to document the circumstances each time it occurs. Note the type of material being processed, the weather conditions, the specific sounds or machine behaviors preceding the clog, and the exact location of the jam. This data can reveal patterns that point to a specific cause. Advanced troubleshooting often involves using diagnostic tools like vibration analyzers, laser alignment tools, or pressure transducers to measure parameters that are not visible to the naked eye.

How to Determine if Rotor Dynamic Imbalance is Causing Excessive Vibration

An unbalanced rotor is a serious condition that can lead to a host of problems, including premature bearing failure, structural damage to the frame, and irregular cutting that promotes clogging. Imbalance can occur if a knife breaks off, if a heavy piece of material becomes lodged on the drum, or due to uneven wear. The primary symptom is excessive vibration that increases with rotor speed and is felt throughout the machine.

To diagnose imbalance, operators can run the chipper empty and listen and feel for vibration. If the vibration is significant without any load, it strongly suggests a rotor issue. A professional technician can use a vibration analysis tool to pinpoint the severity and location of the imbalance. Correcting this requires specialized equipment to dynamically balance the rotor, a task that must be performed by a qualified service engineer. Operating a chipper with a severely unbalanced rotor is unsafe and will lead to further damage.

Inspecting the Wear Condition and Grip Force of the Feed Rollers

The feed rollers must have sharp, aggressive teeth to grip the wood effectively. Over time, these teeth can become worn down, rounded, or even broken off. This reduces the roller's bite, leading to slippage and inefficient feeding. Visually inspecting the rollers regularly is important. If the teeth appear significantly worn, the rollers may need to be rebuilt or replaced.

Grip force can be quantitatively checked by measuring the hydraulic pressure applied to the feed roller circuit under load and comparing it to the manufacturer's specification. If the pressure is within range but the rollers still slip, the problem is likely mechanical wear on the rollers themselves. If the pressure is low, the issue is within the hydraulic system. Ensuring the rollers can exert sufficient force is critical for maintaining a consistent feed rate and preventing infeed-related clogs.

Potential Problems Caused by Control System Sensor Failures

Modern chippers rely on a network of sensors monitored by a Programmable Logic Controller to operate efficiently and safely. Faulty sensors can provide incorrect data to the control system, leading to operational issues that mimic clogging. For example, a malfunctioning engine RPM sensor might cause the PLC to incorrectly reduce the feed rate, making the chipper sluggish and prone to jamming. A faulty pressure transducer in the hydraulic system could prevent the auto-feed from functioning correctly.

Troubleshooting sensor failures requires accessing the machine's diagnostic menu through the HMI interface, which often displays error codes and real-time sensor values. A technician can compare these values to known good parameters to identify discrepancies. Wiring harnesses should also be inspected for damage or loose connections. While complex, diagnosing control system issues is essential for resolving problems that cannot be explained by mechanical condition alone.

When to Contact a Professional Service Engineer Instead of Handling It In-House

There is a clear limit to what in-house operators and mechanics should attempt. Tasks that require specialized knowledge, proprietary software, or heavy calibration equipment should be left to factory-trained service engineers. Specific situations that warrant a professional call include: major rotor or bearing issues, complex hydraulic system diagnostics, electrical and control system faults, and any problem that persists after all standard troubleshooting steps have been exhausted.

Attempting complex repairs without the proper expertise can void warranties, lead to incorrect assembly, and create serious safety hazards. The cost of a service call is typically far lower than the cost of additional downtime or further damage caused by an incorrect repair. Establishing a relationship with a reliable service provider ensures that expert help is available when needed, safeguarding both the equipment investment and the safety of the workforce.