Composite Material Shredding Solutions

Introduction of Composite Material Shredding Solutions

Composite Material Shredding Solutions are designed to process advanced composite materials used in industries such as aerospace, automotive, and construction. These materials, including carbon fiber composites, fiberglass, and reinforced plastics, require specialized shredding equipment due to their high strength, durability, and complex structure.

Traditional shredding methods may struggle with composites due to their resistance to cutting and abrasion. Advanced shredding solutions utilize high-torque motors, reinforced cutting blades, and innovative shredding technologies to effectively break down these materials into smaller, reusable fractions.

Shredding composite materials is essential for improving recycling rates and ensuring that valuable materials are not wasted. By converting these materials into manageable pieces, industries can reduce waste disposal costs, recover raw materials, and contribute to sustainable manufacturing processes.

With the increasing use of composite materials across multiple sectors, the demand for efficient shredding solutions continues to grow. Implementing the right shredding system enhances productivity, reduces environmental impact, and facilitates the reuse of composite waste.

What is Composite Material Shredding Solutions?

Composite Material Shredding Solutions refer to shredding systems designed to process composite materials, which consist of multiple different substances combined to create a stronger or more lightweight material. These materials are widely used in industries that require high-performance materials with excellent durability.

Unlike single-material plastics or metals, composites often have fibers embedded within a resin or polymer matrix, making them harder to shred using conventional shredding equipment. Specialized shredders are required to cut, tear, and break down these tough materials efficiently.

The shredded composite material can be repurposed for secondary manufacturing processes, such as reinforcement fillers in plastic molding or as recycled fibers for construction applications. Proper shredding solutions ensure that these materials are effectively processed for reuse, reducing waste and optimizing resource recovery.

Why is Efficient Composite Material Shredding Important?

Efficient Composite Material Shredding is crucial for industries that rely on composite materials while aiming to reduce waste and enhance sustainability. Due to their complex structure, composites are difficult to recycle without proper shredding technology.

Without efficient shredding, composite waste can accumulate in landfills, contributing to environmental concerns and resource wastage. Proper shredding solutions allow for better material recovery, enabling industries to reuse shredded composite materials in various applications.

In addition, efficient shredding ensures that the composite materials are processed with minimal energy consumption and wear on machinery, reducing operational costs and improving the longevity of shredding equipment.

How Do Shredders Enhance Composite Material Recycling?

Composite Material Shredders enhance recycling by breaking down large, bulky composite waste into smaller pieces that can be more easily sorted, processed, and repurposed. These shredders help industries recover valuable fibers and resins from composite materials, reducing the need for virgin raw materials.

For instance, carbon fiber-reinforced polymers (CFRP) and glass fiber composites can be shredded into smaller fractions, which can then be reprocessed into new composite products, reducing material costs for manufacturers.

Additionally, shredding allows for better separation of composite components. Some advanced shredding solutions include separation technologies that extract fibers, plastics, and resins individually, improving the efficiency of the recycling process.

Types of Shredders Used in Composite Material Processing

Several types of Composite Material Shredders are designed to handle different types of composite waste efficiently:

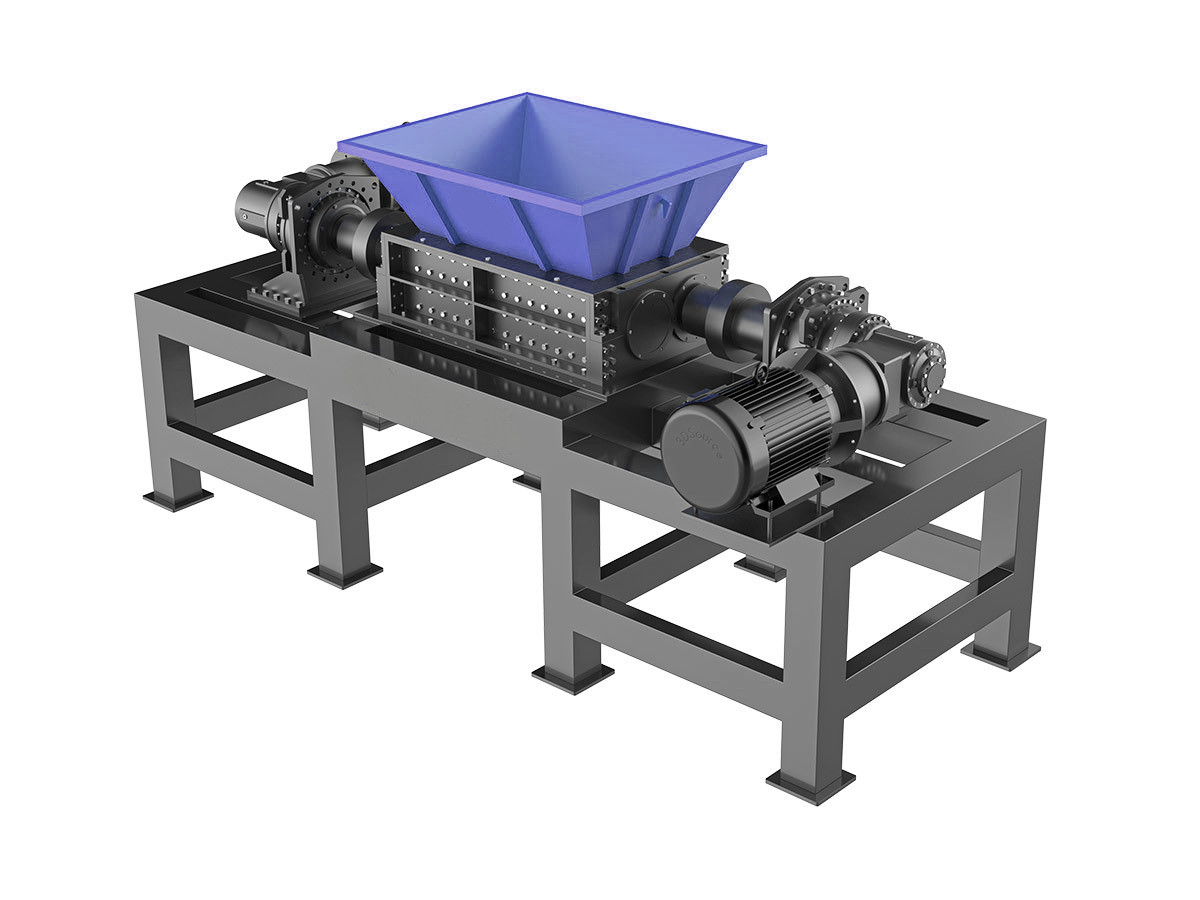

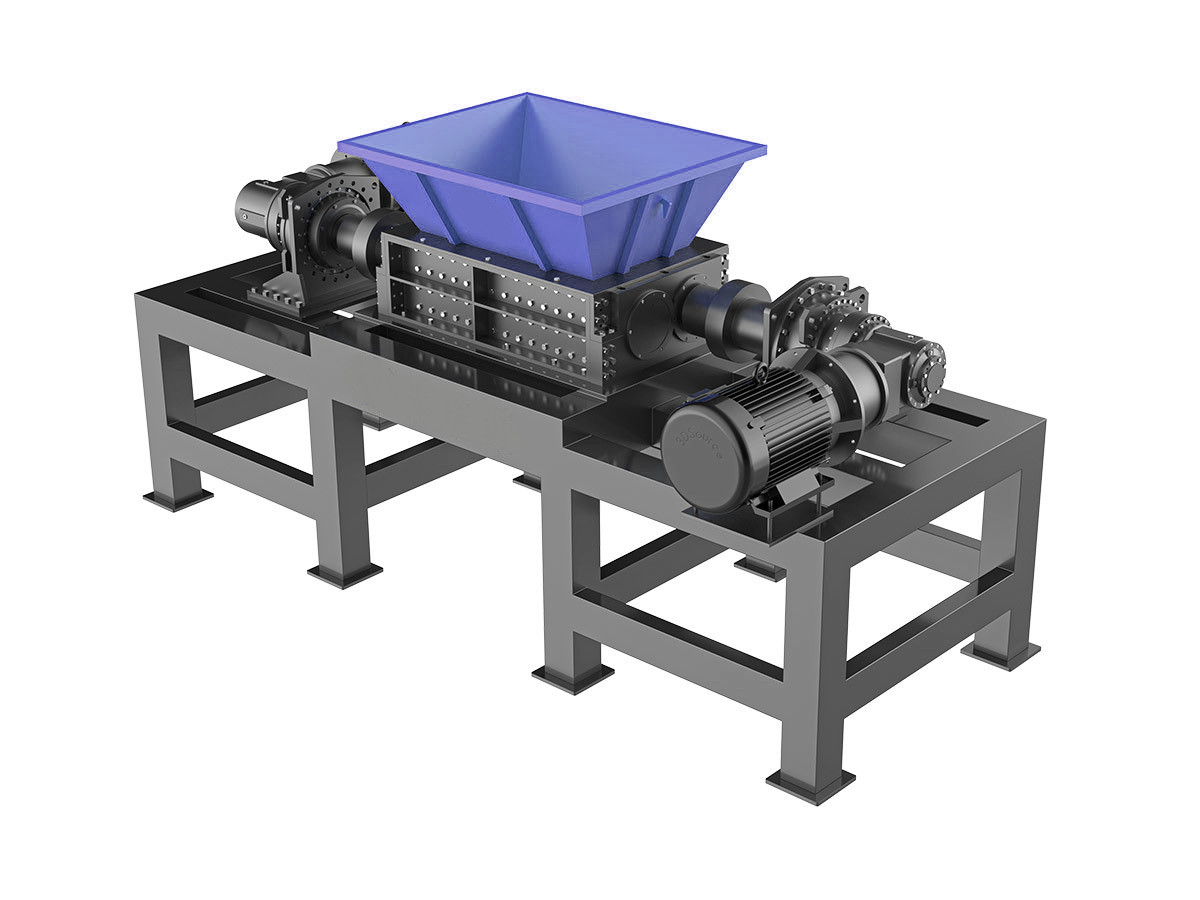

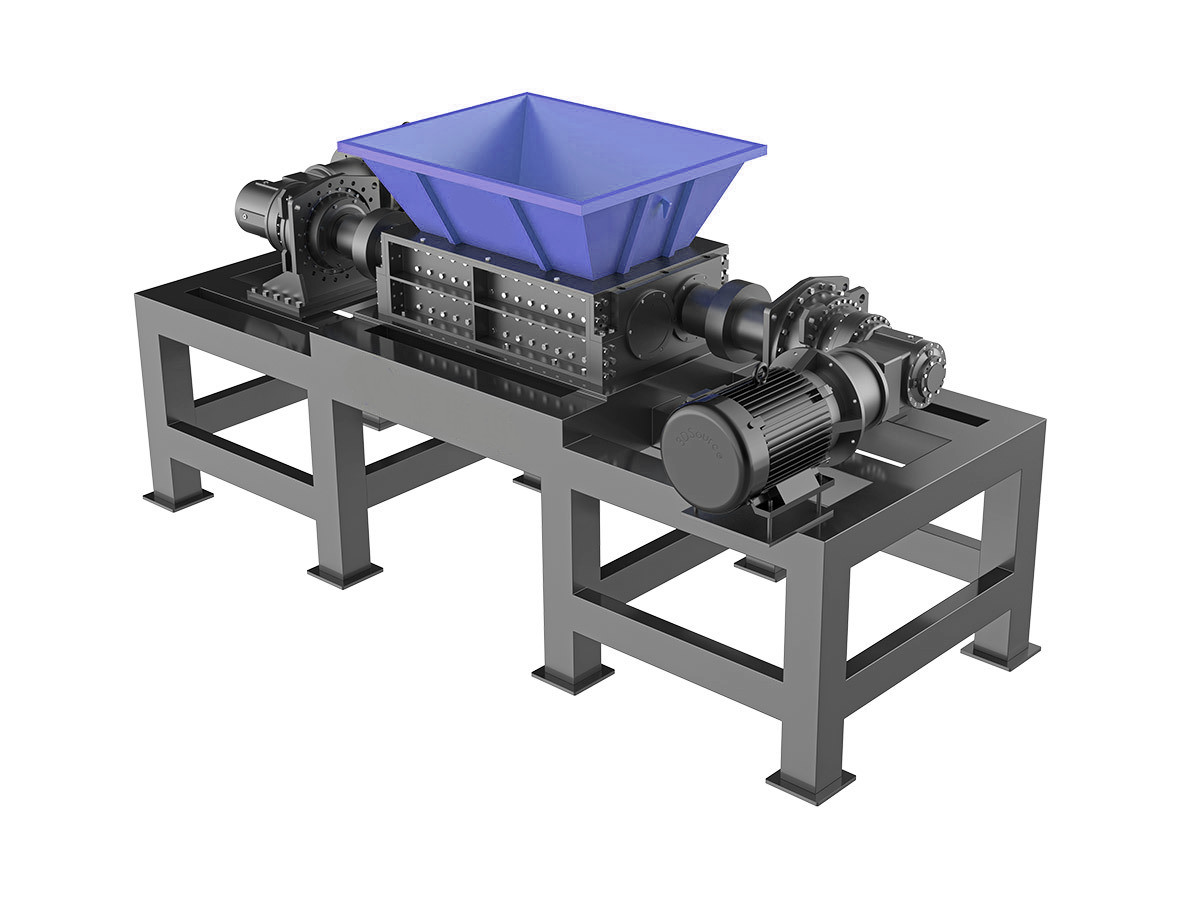

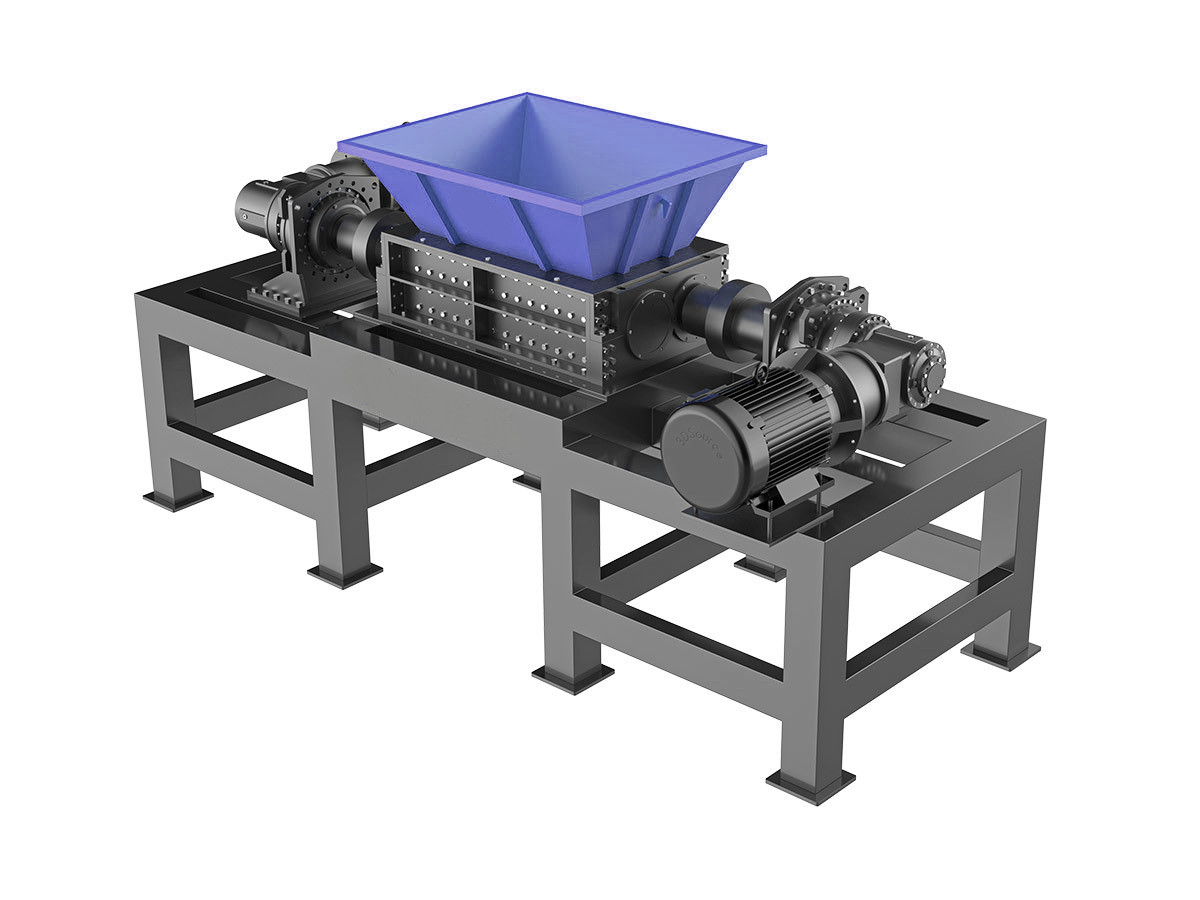

Dual-Shaft Shredders: These shredders use two interlocking shafts to tear through composite materials with high torque and slow-speed operation, reducing wear on cutting components.

Granulators: Granulators are ideal for processing smaller composite scraps into uniform granules, which can be used in secondary manufacturing processes.

Hammer Mills: These high-speed shredders use rotating hammers to break down composite materials into finer particles, often used in applications where further material separation is needed.

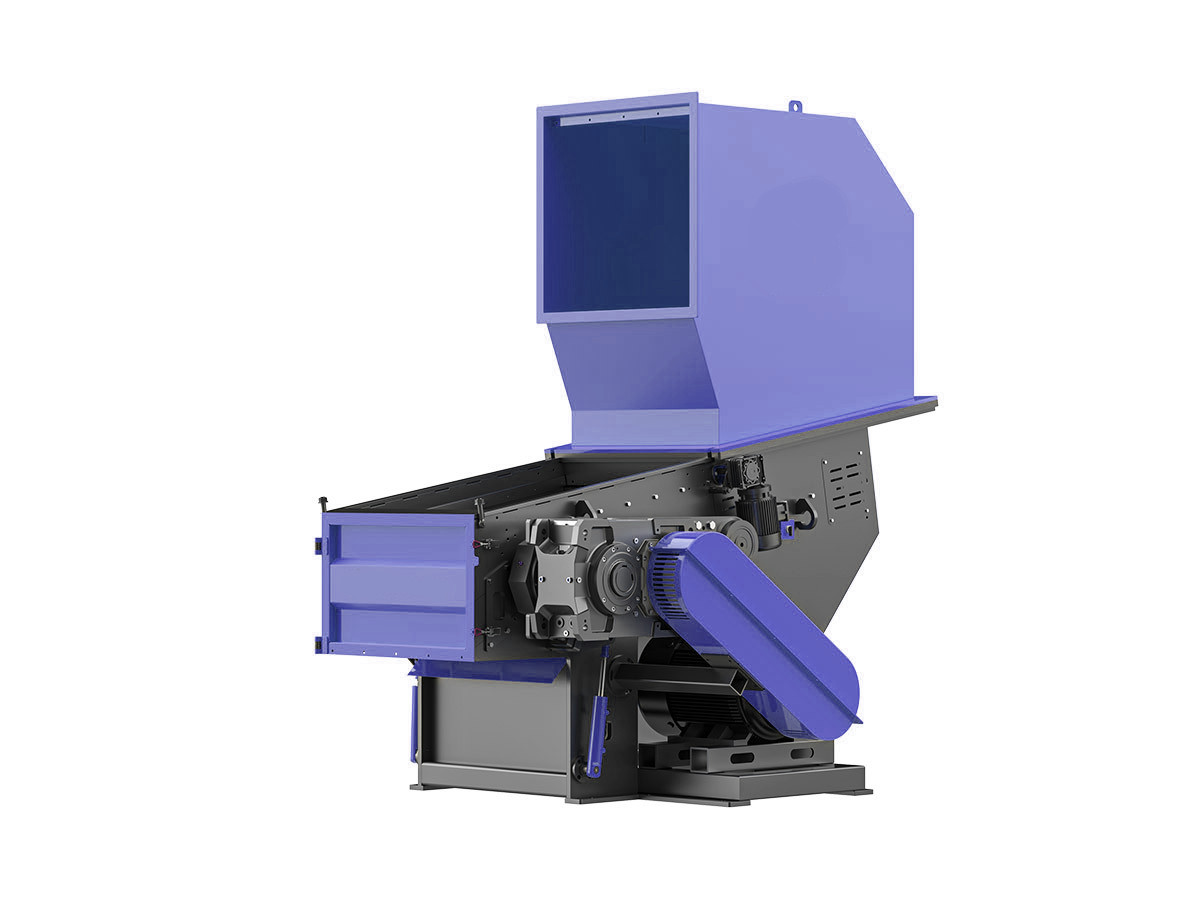

Single-Shaft Shredders: Equipped with reinforced cutting blades, these shredders are effective for processing lightweight to medium-density composite materials, such as fiberglass and reinforced plastics.

Key Factors in Choosing the Right Shredders for Composite Materials

Choosing the right Composite Material Shredder requires careful consideration of several key factors:

Material Composition: The type of composite material being processed (e.g., carbon fiber, fiberglass, reinforced plastics) will determine the most suitable shredding technology.

Shredder Durability: Since composite materials can be abrasive, shredders should have wear-resistant cutting blades and reinforced construction to ensure longevity.

Throughput Capacity: Industries processing large volumes of composite waste should invest in high-capacity shredders that can handle continuous operation efficiently.

Energy Efficiency: Given the challenges of shredding composite materials, selecting shredders with energy-efficient motors and optimized cutting mechanisms can help reduce power consumption and operational costs.

FAQ

Q: What types of composite materials can be shredded?

A: Composite materials such as carbon fiber-reinforced polymers (CFRP), fiberglass, thermoset plastics, and mixed-material composites can be shredded using specialized shredding equipment.

Q: Can composite shredding solutions recover valuable fibers?

A: Yes, advanced shredding technologies can extract valuable fibers from composite materials, allowing them to be reused in new manufacturing processes.

Q: What industries benefit from composite material shredding?

A: Industries such as aerospace, automotive, wind energy, and construction benefit from composite shredding, as it helps manage production waste and enhances material recycling.

Q: How do I maintain my composite material shredder?

A: Regular maintenance includes blade sharpening, lubrication, and inspecting cutting components for wear. Using the right shredder for the material type also helps reduce stress on the machine.

Q: What is the ideal output size for shredded composite materials?

A: The output size depends on the recycling or repurposing needs. Some applications require finely shredded particles, while others may need larger, uniform pieces.

Main Components of Solid Waste Shredder

Shredding Solutions

Soft Material Shredding Solutions

Efficiently handle and process soft materials with our specialized soft material shredding solutions. Designed for materials like rubber, textiles, foam, and soft plastics, our shredders offer precise size reduction while ensuring optimal throughput and minimal downtime. Ideal for industries requiring soft material processing for recycling, waste management, and material recovery, our shredding machines are built for durability, energy efficiency, and high performance.

Learn more >>

Hard Material Shredding Solutions

Tackle tough materials with our advanced hard material shredding solutions. Engineered to process metal, concrete, wood, stone, and dense plastics, our shredders provide powerful performance for efficient size reduction and recycling. Designed for industries handling heavy-duty waste, our shredders ensure durability, precision, and high throughput, helping businesses optimize waste management and material recovery.

Learn more >>

High Toughness Material Shredding Solutions

Efficiently shred and process high toughness materials with our specialized shredding solutions. Designed for materials such as thick rubber, hard plastics, reinforced composites, and industrial metal alloys, our machines provide powerful cutting performance and exceptional durability. Built to handle the toughest materials, our shredders ensure optimal size reduction for recycling, waste management, and material recovery.

Learn more >>

Composite Material Shredding Solutions

Efficiently process and recycle composite materials with our specialized shredding solutions. Designed for fiber-reinforced plastics, carbon composites, and other complex materials, our shredders offer precision cutting and exceptional durability to handle tough and intricate substances. Ideal for industries such as automotive, aerospace, and construction, our machines ensure effective size reduction for reuse or disposal.

Learn more >>