Waste Tire Shredder

What is Waste Tire Shredder?

Waste Tire Shredder is a specialized machine designed to break down used tires into smaller, manageable pieces. It plays a crucial role in tire recycling and waste management by converting old tires into shredded rubber, which can be repurposed for various applications such as fuel, construction materials, and artificial turf infill.

These machines are commonly used in recycling facilities, waste management plants, and rubber processing industries. By shredding tires, they help reduce landfill waste and contribute to sustainable resource management.

Waste tire shredders come in different types and sizes, from small units for light-duty operations to large, high-capacity industrial machines capable of processing thousands of tires per hour. Choosing the right shredder depends on the intended application and the volume of tires to be processed.

Working Principle of Waste Tire Shredder

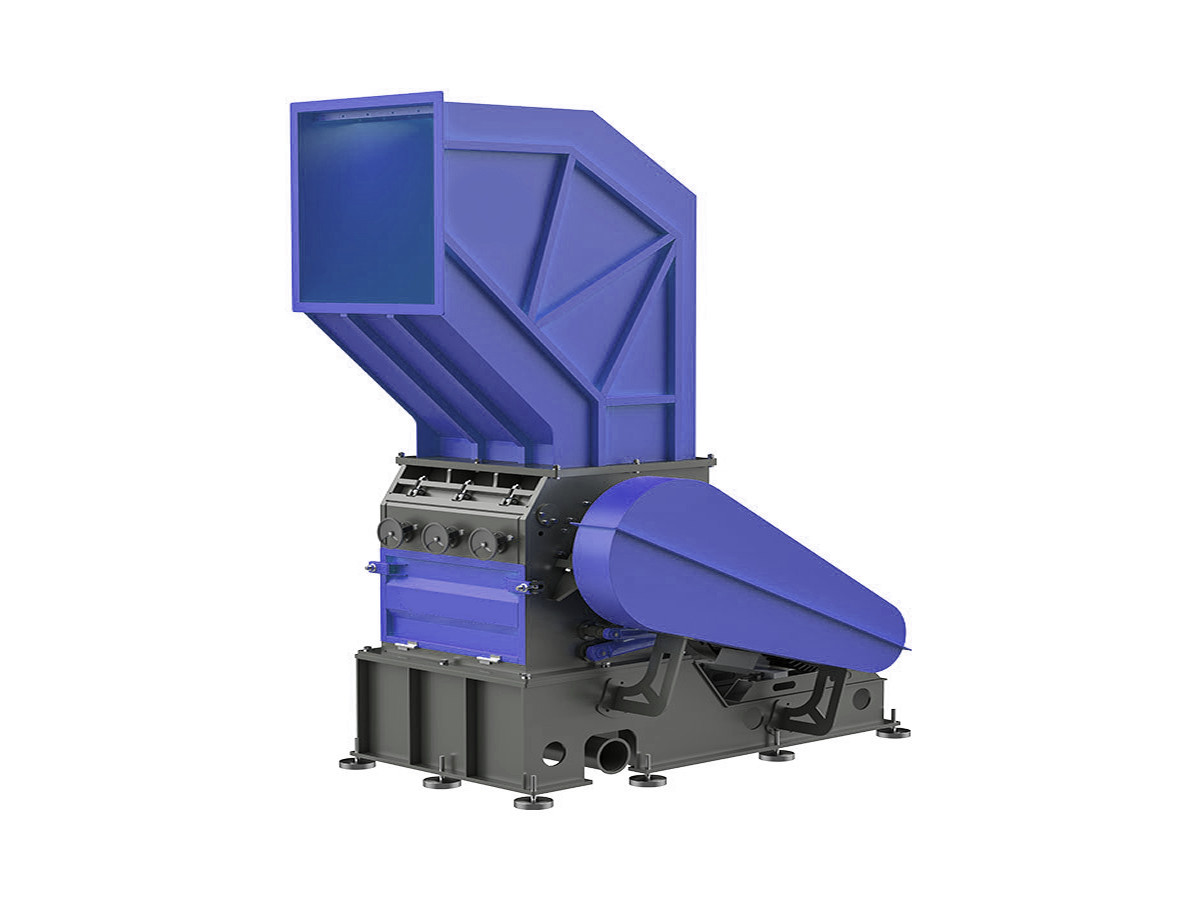

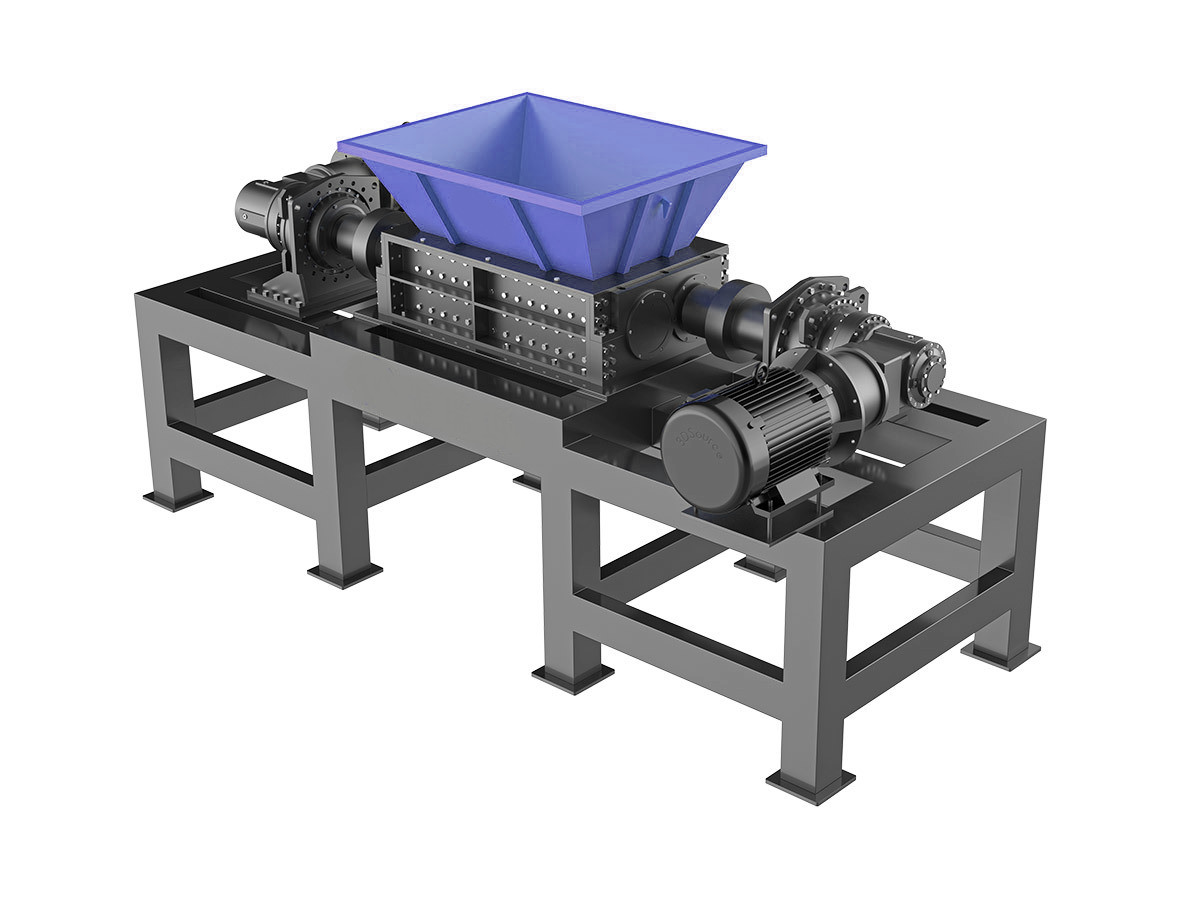

Waste Tire Shredder operates through a powerful cutting mechanism that breaks tires into smaller pieces. The shredding process typically involves rotating blades, shear cutters, or a combination of cutting and grinding mechanisms.

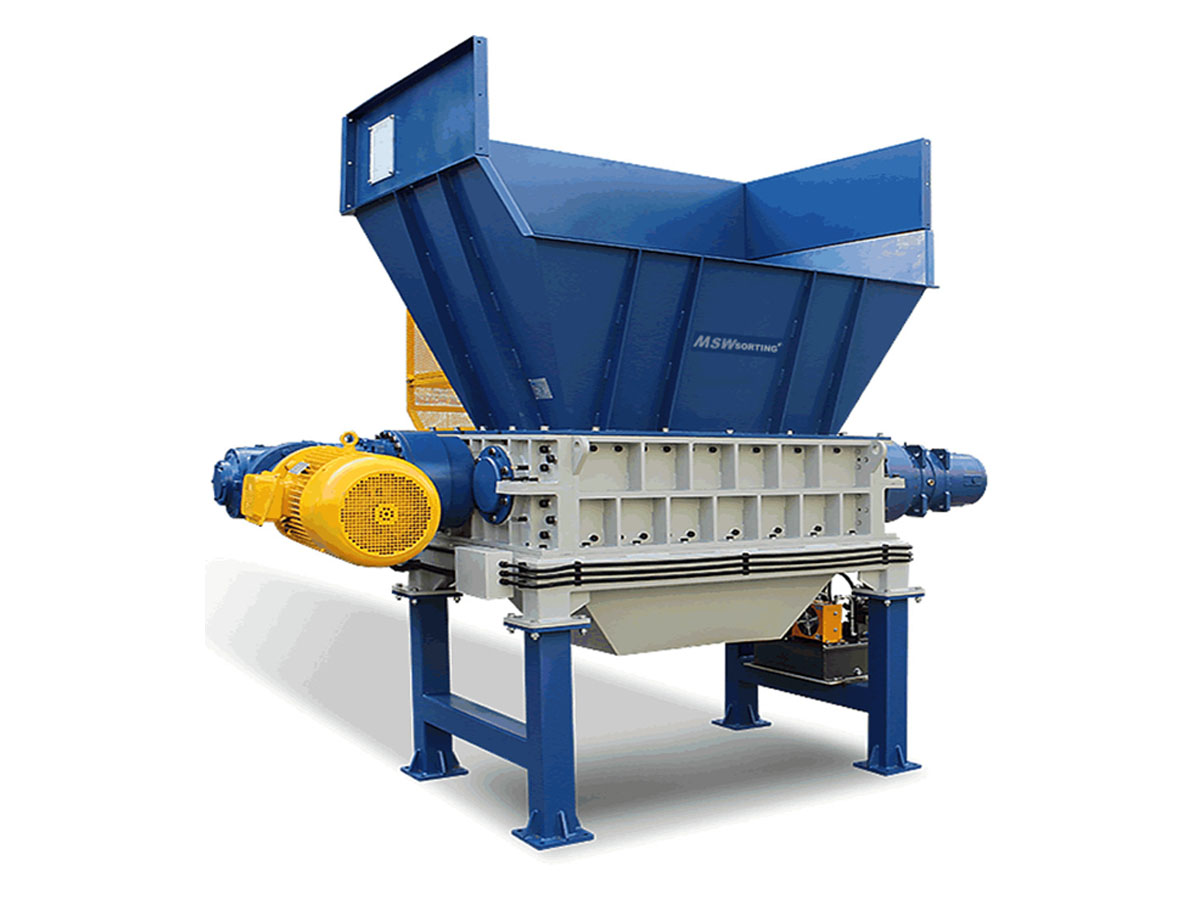

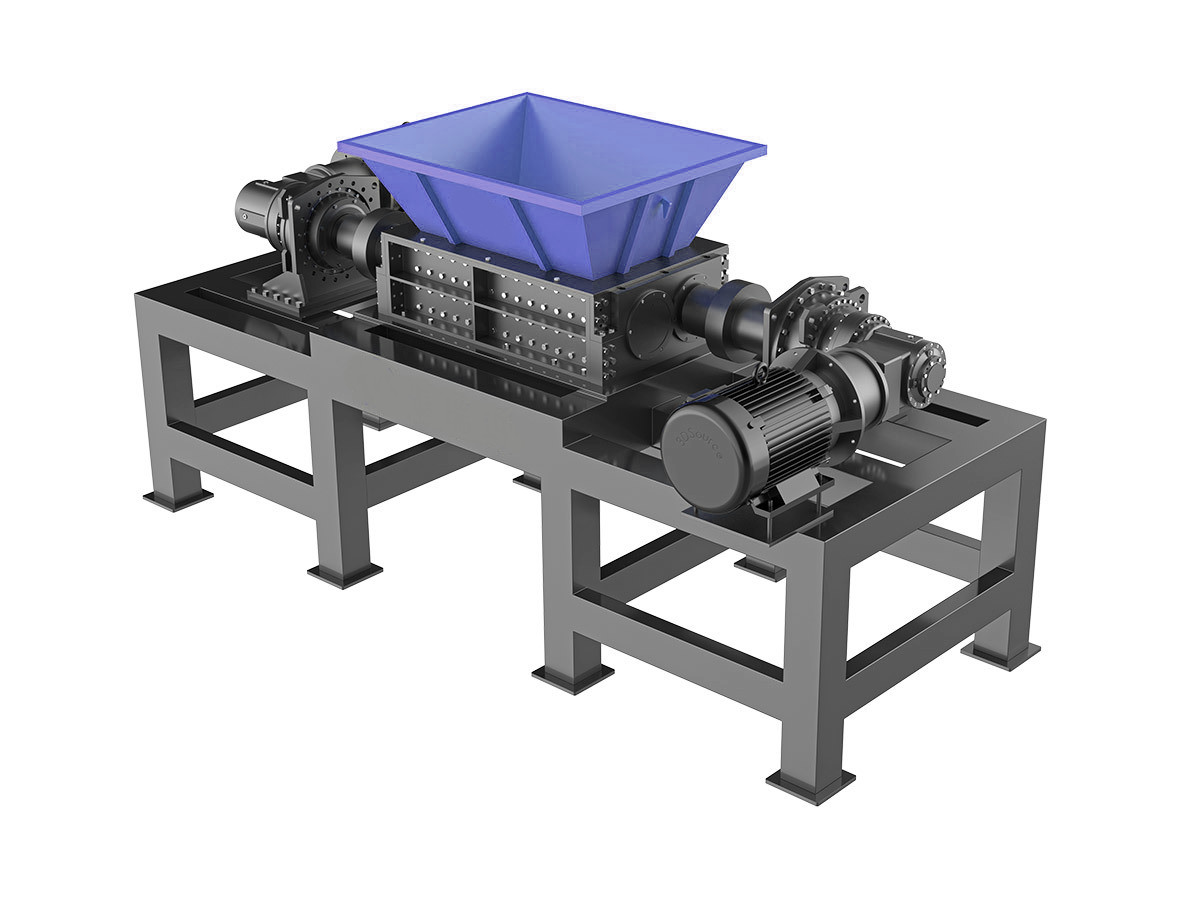

When a tire is fed into the shredder, the blades grip and pull it into the cutting chamber, where it is gradually shredded into the desired size. Some shredders use a dual-shaft system that tears apart the rubber, while others rely on high-torque, slow-speed cutting to ensure efficient processing.

Advanced waste Tire Shredders often include screening systems to separate rubber from steel wires and textiles, producing cleaner shredded material for further recycling. The final output size can be adjusted depending on the application, whether for rubberized asphalt, playground surfaces, or fuel.

How to Choose the Right Waste Tire Shredder?

Choosing the right Waste Tire Shredder depends on the volume of tires to be processed, the desired output size, and the end-use of the shredded rubber. Key considerations include shredding capacity, blade durability, and energy efficiency.

For small-scale operations, a single-shaft shredder may be sufficient, whereas large recycling facilities typically require dual-shaft or multi-stage shredders for higher efficiency and finer output. The hardness and quality of the shredder blades also affect performance, as tires contain steel reinforcements that require strong cutting mechanisms.

Other factors to consider include ease of maintenance, operational safety features, and the availability of customization options. Investing in a high-quality waste tire shredder can improve productivity and reduce long-term operational costs.

Applications of Waste Tire Shredder

Waste Tire Shredder is used in a wide range of applications, primarily in tire recycling and rubber repurposing. One of the main uses is the production of crumb rubber, which is used in playground surfaces, running tracks, and synthetic turf infill.

Shredded tire rubber is also used in civil engineering projects, such as road construction and drainage systems, where it serves as a lightweight, durable material. Additionally, tire-derived fuel (TDF) is a popular application, as shredded rubber can be burned in industrial boilers and cement kilns as an alternative fuel source.

Other applications include rubberized asphalt for road surfacing, eco-friendly construction materials, and innovative uses such as molded rubber products and insulation materials. Tire shredding helps reduce environmental pollution by giving discarded tires a second life.

Maintenance of Waste Tire Shredder

Proper maintenance of a Waste Tire Shredder is essential to ensure efficient operation and extend its lifespan. Regular maintenance helps prevent costly breakdowns and keeps the machine running at optimal performance.

Key maintenance tasks include inspecting and sharpening the cutting blades, as dull blades reduce shredding efficiency and increase energy consumption. It is also important to clean the machine regularly to prevent buildup of rubber particles that could clog the system.

Other important maintenance steps include lubricating moving parts, checking the motor and belts for wear, and ensuring that safety mechanisms are functioning properly. Following the manufacturer’s maintenance schedule and conducting routine inspections can help maximize the lifespan and efficiency of the shredder.

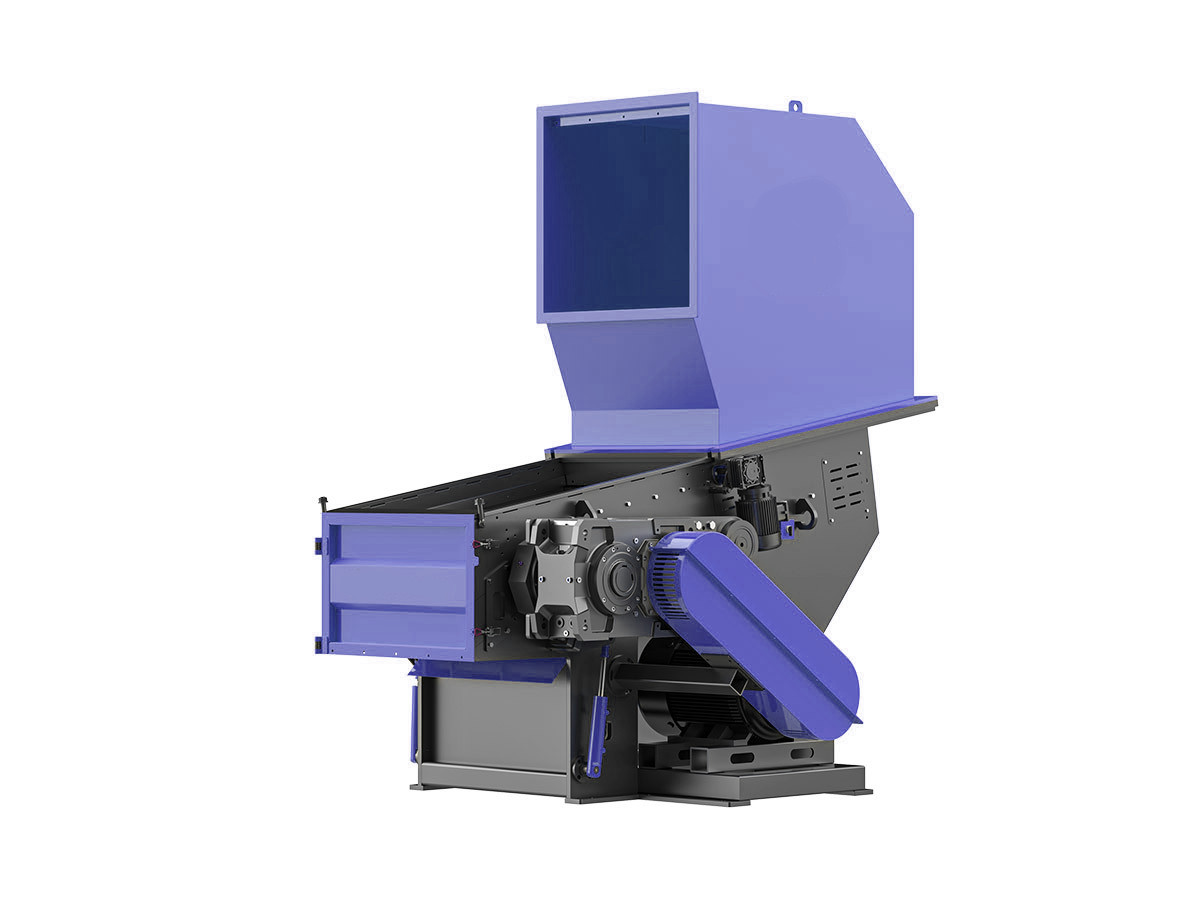

Main Components of Waste Tire Shredder

Waste Tire Shredder Types

Types of Waste Shredder Machine

Solid Waste Shredder

Efficiently process municipal and industrial waste into smaller, manageable sizes, aiding in recycling and waste disposal efforts.

Learn more >>

E-Waste Shredder

Specially engineered for electronic waste, this waste shredder handles materials like phones, computers, and circuit boards, ensuring secure disposal and recycling.

Learn more >>

Waste Metal Shredder

Our waste metal shredders efficiently process materials like aluminum, copper, and steel, making it easier to recycle and repurpose metal scrap.

Learn more >>

Waste Plastic Shredder

Built for recycling plastics like PE, PP, and PET, this waste shredder helps reduce plastic waste into manageable pieces for further processing.

Learn more >>

Waste Tire Shredder

Efficiently process used tires into reusable materials, including crumb rubber, for recycling and environmental sustainability.

Learn more >>

Waste Wood Shredder

Ideal for recycling wood waste like branches, pallets, and wooden furniture, this waste shredder helps create chips, mulch, or compost for eco-friendly disposal.

Learn more >>

Waste Paper Shredder

Ensure confidential document destruction with our secure waste paper shredders, designed for both small offices and large businesses.

Learn more >>

RDF Shredder

Transform waste into refuse-derived fuel (RDF) with this efficient waste shredder, perfect for waste-to-energy applications and reducing landfill dependency.

Learn more >>