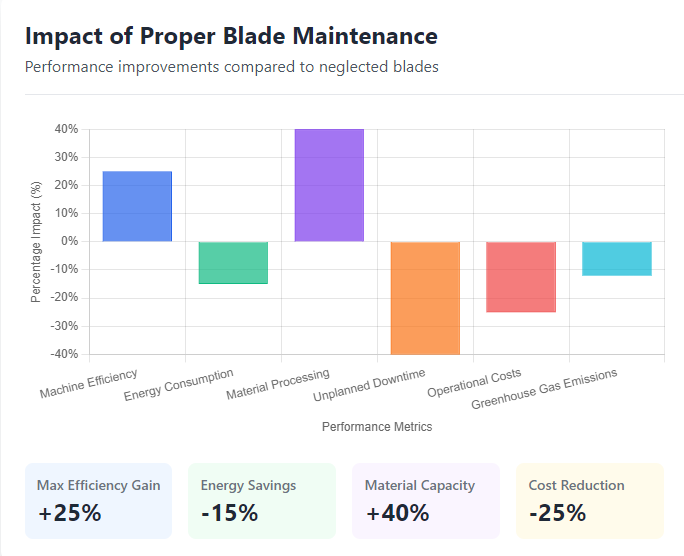

Disc wood chippers are essential machines in wood processing operations, designed to efficiently reduce wood waste into uniform chips for various applications. The performance and longevity of these machines heavily depend on proper blade maintenance, particularly regular inspection and timely replacement. Establishing optimal intervals for these maintenance activities ensures consistent output quality, minimizes unexpected downtime, and extends the equipment's operational life. Industry studies indicate that proper blade maintenance can improve overall machine efficiency by up to 25% and reduce energy consumption by approximately 15%. This comprehensive guide explores the critical aspects of blade maintenance, from inspection techniques to replacement procedures, providing wood processing facilities with actionable strategies to optimize their maintenance schedules. The information presented here applies to various disc wood chipper models used in recycling operations, biomass production, and landscaping applications.

Understanding the relationship between blade condition and machine performance is fundamental to developing effective maintenance protocols. Worn or damaged blades not only produce inferior quality wood chips but also place additional stress on other machine components, potentially leading to costly repairs. Research conducted by the Forest Products Laboratory shows that properly maintained blades can process up to 40% more material between replacements compared to neglected blades. The development of a systematic maintenance approach requires consideration of multiple factors, including operational frequency, wood species processed, environmental conditions, and specific machine specifications. By implementing the practices outlined in this guide, operators can significantly reduce maintenance costs while ensuring consistent production quality and workplace safety.

The Critical Importance of Blade Maintenance in Disc Wood Chippers

Blade

maintenance represents one of the most crucial aspects of disc wood chipper operation, directly influencing both machine performance and operational economics. The cutting blades

serve as the primary interface between the machine and processed material, determining the efficiency of the chipping  process and the quality of the final product. Regular maintenance ensures that

blades maintain their sharpness and structural integrity, which is essential for achieving clean, uniform cuts with minimal energy expenditure. Facilities that implement structured

blade maintenance programs typically experience 30-40% fewer unplanned shutdowns compared to those with reactive maintenance approaches. The financial implications of proper

maintenance extend beyond blade replacement costs, encompassing energy savings, reduced wear on other components, and improved productivity.

process and the quality of the final product. Regular maintenance ensures that

blades maintain their sharpness and structural integrity, which is essential for achieving clean, uniform cuts with minimal energy expenditure. Facilities that implement structured

blade maintenance programs typically experience 30-40% fewer unplanned shutdowns compared to those with reactive maintenance approaches. The financial implications of proper

maintenance extend beyond blade replacement costs, encompassing energy savings, reduced wear on other components, and improved productivity.

The consequences of neglected blade maintenance can be severe and far-reaching. Dull blades require significantly more power to achieve the same cutting results, increasing energy consumption and operational costs. Studies indicate that blades operating beyond their optimal sharpness can increase power consumption by up to 20% while reducing throughput by approximately 15%. Furthermore, compromised blades generate irregular wood chips that may not meet quality specifications for specific applications such as biomass fuel or landscaping mulch. From a safety perspective, properly maintained blades reduce the risk of kickbacks and other hazardous situations that can occur when the machine struggles to process material. The rotor assembly and connected components also experience less stress when blades are in optimal condition, extending the service life of these expensive parts.

Impact of Blade Condition on Chipper Performance

The condition of chipper blades directly affects multiple performance metrics, including output quality, processing speed, and energy efficiency. Sharp blades create clean cuts that produce uniformly sized wood chips with minimal fines and dust particles. This consistency is particularly important for applications requiring specific chip dimensions, such as biomass boiler fuel or oriented strand board manufacturing. When blades become dull, they tend to crush and tear wood fibers rather than cutting cleanly, resulting in irregular chip sizes and increased dust generation. Performance monitoring data shows that blade sharpness deterioration can reduce processing capacity by 1-2% for every 10 hours of operation under normal conditions, though this rate accelerates when processing abrasive materials or contaminated wood.

Energy consumption represents another critical performance indicator influenced by blade condition. Research conducted by the Department of Energy indicates that properly sharpened blades can reduce chipper energy requirements by 12-18% compared to moderately worn blades. This efficiency gain translates to substantial cost savings in facilities operating multiple shifts. The relationship between blade sharpness and power demand is nonlinear, with energy requirements increasing exponentially as blades approach the end of their useful life. Additionally, vibration levels typically rise as blades wear, potentially causing premature failure of bearings, seals, and other sensitive components. Regular blade inspection and maintenance help maintain optimal performance while protecting the broader machine system from excessive wear and damage.

Safety Considerations and Risk Mitigation

Proper blade maintenance plays a crucial role in ensuring operational safety and minimizing workplace hazards. Worn or damaged blades can create dangerous situations, including material kickback, projectile generation, and unexpected machine behavior. The kickback prevention device provides important protection, but its effectiveness depends on properly maintained cutting components. Statistics from occupational safety organizations indicate that approximately 25% of wood chipper accidents relate directly to improper blade condition or maintenance practices. Regular inspection and timely replacement of blades significantly reduce these risks by ensuring predictable machine behavior and consistent material feeding characteristics.

Beyond immediate safety concerns, blade maintenance affects long-term equipment reliability and operator confidence. Damaged blades can cause imbalances in the rotating assembly, leading to excessive vibration that stresses structural components and mounting systems. These vibrations not only accelerate wear on the heavy-duty frame and supporting structures but also create uncomfortable working conditions for operators. Furthermore, blades with chips or cracks can fail catastrophically during operation, sending high-velocity fragments through the machine housing. Implementing a systematic blade maintenance program that includes regular inspections, proper sharpening techniques, and scheduled replacements represents the most effective approach to mitigating these risks while maintaining a safe working environment.

Economic Benefits and Cost Optimization

The economic advantages of systematic blade maintenance extend far beyond simple replacement cost considerations. A comprehensive cost-benefit analysis must account for direct expenses such as blade purchases and sharpening services, as well as indirect costs including energy consumption, downtime, and related component wear. Industry data suggests that optimized blade maintenance programs can reduce total operating costs by 15-25% compared to reactive approaches that address issues only after problems become apparent. The most significant savings typically come from reduced energy consumption, extended component life, and minimized production interruptions. Facilities that track maintenance metrics often discover that preventative blade replacement proves more economical than waiting for complete failure.

Lifecycle cost analysis provides valuable insights for developing economically sustainable maintenance strategies. This approach considers not only the purchase price of replacement blades but also their expected service life, sharpening requirements, and impact on other machine components. Premium blades with advanced coatings or materials typically command higher initial prices but often deliver lower total cost per operating hour due to extended service intervals and maintained cutting efficiency. Additionally, proper maintenance scheduling helps optimize inventory management for replacement blades, balancing carrying costs against the risks of production stoppages. The economic benefits extend to improved product quality, which can command premium pricing in certain markets such as landscape mulch or specialized biomass applications.

Environmental Impact and Sustainability Contributions

Proper blade maintenance contributes significantly to environmental sustainability through multiple mechanisms, including energy conservation, material efficiency, and waste reduction. Sharp blades require less energy to process the same volume of material, directly reducing the carbon footprint of wood chipping operations. The Environmental Protection Agency estimates that maintaining optimal blade sharpness can reduce greenhouse gas emissions by 8-12% per ton of processed material in typical industrial chipping applications. This efficiency gain becomes increasingly important as organizations face growing pressure to minimize their environmental impact and improve sustainability metrics. Additionally, well-maintained blades produce more consistent chip sizes with less fine particulate matter, reducing dust suppression system requirements and associated environmental controls.

The sustainability benefits extend to resource conservation and waste minimization. Blades maintained at optimal sharpness generate less waste material in the form of oversize chips that require reprocessing or fines that may not meet product specifications. This material efficiency translates to higher utilization rates for raw materials and reduced waste handling requirements. Furthermore, extending blade life through proper maintenance reduces the frequency of replacements, conserving the energy and resources embedded in blade manufacturing. Some facilities have implemented blade reconditioning programs that further enhance sustainability by restoring used blades to serviceable condition rather than disposing of them. These approaches align with circular economy principles while delivering tangible economic benefits through reduced material costs.

Effective Blade Inspection Methods and Procedures

Systematic blade inspection represents the foundation of an effective maintenance program, enabling early detection of issues before they escalate into major problems. A comprehensive inspection protocol should incorporate multiple assessment techniques, including visual examination, dimensional verification, and performance monitoring. Industry best practices recommend establishing baseline measurements when blades are new or freshly sharpened to facilitate accurate comparison during subsequent inspections. The inspection frequency should reflect operational intensity, with high-volume facilities potentially requiring daily checks while lower-volume operations might implement weekly or biweekly schedules. Documentation represents a critical element of the inspection process, creating a historical record that supports trend analysis and maintenance interval optimization.

Modern inspection methodologies increasingly incorporate technological tools that enhance accuracy and efficiency. Digital imaging systems can capture detailed blade condition data for comparison over time, while specialized software helps track wear patterns and predict remaining useful life. Some advanced facilities employ automated measurement systems that quantify blade parameters without requiring disassembly, significantly reducing inspection time and labor requirements. Regardless of the specific techniques employed, the inspection process should evaluate multiple blade characteristics, including edge sharpness, surface condition, structural integrity, and mounting integrity. Consistent inspection protocols ensure that all critical aspects receive proper attention while facilitating reliable comparisons between inspection cycles.

Visual Inspection and Wear Pattern Identification

Visual inspection serves as the primary method for assessing blade condition during routine maintenance checks. This process involves examining the cutting edges for signs of dullness, chipping, cracking, or other damage that could affect performance. Proper lighting and, when necessary, magnification tools enable detection of subtle defects that might otherwise go unnoticed. Experienced technicians learn to recognize specific wear patterns that indicate particular issues, such as uneven wear suggesting misalignment or localized damage indicating foreign object impacts. The development of standardized inspection checklists helps ensure consistency and completeness, reducing the likelihood of overlooking important indicators. Many facilities supplement visual inspections with photographic documentation that creates a visual history of blade condition over time.

Advanced visual inspection techniques can provide early warning of developing problems before they significantly impact performance or safety. Dye penetrant testing, for instance, can reveal microscopic cracks that are invisible to the naked eye but could lead to catastrophic failure if undetected. Ultraviolet inspection methods similarly enhance defect detection capabilities, particularly for hard-to-see areas of the blade. These specialized techniques typically require additional training and equipment but can prevent costly downtime and repairs by identifying issues at their earliest stages. The anvil block should also receive visual inspection during blade checks, as its condition directly influences blade performance and wear patterns. Regular visual assessment of both components provides a more complete picture of the cutting system's condition.

Performance Monitoring and Output Quality Assessment

Performance monitoring provides valuable indirect information about blade condition through observation of operational parameters and output characteristics. Power consumption represents one of the most reliable indicators of blade sharpness, with increasing amperage draw typically signaling deteriorating cutting efficiency. Facilities equipped with power monitoring systems can track this parameter continuously, establishing baseline consumption levels for sharp blades and setting alert thresholds that trigger inspection or maintenance activities. Throughput rate provides another performance metric, with declining processing capacity often indicating blade wear. By correlating power consumption with production output, operators can develop sophisticated models that predict maintenance needs based on actual operating conditions rather than fixed time intervals.

Output quality assessment complements performance monitoring by evaluating the material produced by the chipper. Consistent chip size distribution represents one of the most important quality metrics, with increasing variability often signaling blade issues. Specialized screening systems can automatically analyze chip dimensions and provide quantitative data about size distribution, while manual sampling and measurement offer a lower-tech alternative for smaller operations. Other output characteristics such as fiber tear, surface texture, and fines generation also provide insights into blade condition. Facilities processing material for specific applications should establish quality tolerances that trigger maintenance activities when output begins to approach unacceptable limits. This proactive approach helps maintain product consistency while optimizing maintenance scheduling based on actual performance rather than theoretical calculations.

Measurement Techniques and Dimensional Verification

Precise dimensional measurement provides quantitative data about blade wear that supports objective maintenance decisions. Critical parameters typically include cutting edge thickness, blade width, and specific wear pattern dimensions that develop over time. Specialized measuring tools such as dial indicators, micrometers, and optical comparators enable accurate assessment of these parameters with resolution sufficient to detect incremental changes between inspections. Establishing wear limits for each critical dimension helps determine when blades require sharpening or replacement, removing subjectivity from maintenance decisions. Some facilities create custom gauges that quickly verify whether blades remain within specified tolerances, streamlining the inspection process during busy production schedules.

Advanced measurement technologies offer enhanced capabilities for blade assessment without requiring disassembly. Laser scanning systems can create detailed three-dimensional models of blade surfaces, identifying wear patterns that might escape detection using traditional methods. Coordinate measuring machines provide exceptionally precise dimensional data but typically require blade removal, making them more suitable for periodic comprehensive inspections rather than routine checks. For operations lacking access to sophisticated measurement equipment, simple template comparisons can still provide valuable information about blade condition. Regardless of the specific techniques employed, consistent measurement practices and thorough documentation create the foundation for data-driven maintenance interval optimization. This approach replaces guesswork with empirical evidence, resulting in more reliable performance and predictable maintenance requirements.

Documentation Systems and Maintenance History Tracking

Comprehensive documentation transforms occasional blade inspections into a strategic maintenance program with continuous improvement potential. Detailed records should include inspection dates, measured parameters, observed conditions, maintenance actions performed, and subsequent performance observations. This historical data enables trend analysis that identifies patterns not apparent from individual inspections, such as gradual changes in wear rates or correlations between specific wood types and blade longevity. Modern maintenance management systems facilitate this documentation through digital platforms that store inspection records, generate work orders, and provide analytical tools for optimizing maintenance schedules. Even simple spreadsheet-based tracking systems offer significant advantages over paper records or memory-based approaches.

The value of maintenance documentation extends beyond immediate blade management to broader operational improvements. Historical data helps justify capital investment decisions regarding blade quality, sharpening equipment, or even machine replacements. It provides evidence supporting maintenance budget requests and helps demonstrate regulatory compliance where required. Furthermore, well-documented maintenance histories typically enhance equipment resale value by providing prospective buyers with verifiable evidence of proper care. The feed rollers and other related components should be included in documentation efforts since their condition influences blade wear patterns. Integrating all relevant maintenance information creates a comprehensive picture that supports better decision-making across the entire wood processing operation.

Blade Replacement Procedures and Best Practices

Proper blade replacement procedures ensure optimal performance while maintaining safety standards throughout the process. The replacement process begins with thorough preparation, including machine isolation, workspace organization, and tool gathering. Safety considerations must remain paramount throughout all replacement activities, with proper lockout/tagout procedures implemented before any work begins. The specific steps vary depending on chipper design, but generally involve removing access panels, extracting worn blades, cleaning mounting surfaces, installing new blades, verifying proper alignment, and conducting post-installation testing. Following manufacturer recommendations precisely helps avoid common installation errors that could compromise performance or safety. Properly executed blade replacements typically require 2-4 hours for most industrial disc chippers, though this duration can vary significantly based on machine size and specific design features.

The quality of replacement blades significantly influences the success of the replacement procedure. Operators should source blades from reputable manufacturers that provide certification of material composition, heat treatment, and dimensional accuracy. Counterfeit or substandard blades may initially appear similar to genuine products but typically exhibit accelerated wear, unpredictable failure modes, and potential safety hazards. Before installation, each new blade should undergo inspection to verify absence of shipping damage and confirm compliance with specifications. The mounting hardware, including bolts, washers, and locking elements, should also receive careful inspection and replacement if any signs of wear or damage exist. Using proper torque values and sequences during installation ensures even clamping force distribution, which is essential for maintaining blade alignment under operational loads.

Safety Preparation and Equipment Isolation

Comprehensive safety preparation forms the essential foundation for any blade replacement activity. The process should begin with complete machine shutdown following established procedures that include clearing all material from the feed system and cutting chamber. Electrical isolation through lockout/tagout protocols prevents accidental startup during maintenance, while mechanical locking devices provide additional protection against rotation of the disc assembly. The workspace around the chipper should be cleared of tripping hazards and organized to provide unobstructed access to the blade compartment. Personal protective equipment, including cut-resistant gloves, safety glasses, and appropriate footwear, should be worn by all personnel involved in the replacement process. These preparations, while time-consuming, represent critical investments in personnel safety and replacement quality.

Additional safety considerations address specific hazards associated with blade replacement activities. The weight of chipper blades, particularly in larger industrial machines, presents lifting hazards that require proper equipment and techniques. Mechanical lifting devices should be used whenever blade weight exceeds approximately 25 pounds, with manual handling reserved for smaller blades only. The sharpness of both old and new blades represents another significant hazard, requiring careful handling and appropriate edge protection during removal and installation. The discharge conveyor area should be secured to prevent accidental entry during maintenance activities. Documenting safety preparations through checklists helps ensure consistency and completeness while providing valuable records for safety audits and training purposes.

Blade Removal and Component Cleaning

Systematic blade removal begins with identifying and accessing the fastening systems that secure blades to the disc assembly. Most modern chippers utilize specialized bolt configurations that may require specific tools for proper removal. Penetrating lubricants applied before disassembly can ease removal of fasteners that have become seized due to exposure to wood resins, moisture, and operational vibrations. The removal sequence should follow manufacturer recommendations, typically involving gradual, alternating loosening of fasteners to release clamping pressure evenly. Once fasteners are removed, blades should be carefully lifted straight out of their mounting positions to avoid damaging the precision mounting surfaces. Any resistance during removal should be investigated rather than forced, as misalignment or foreign material may require additional cleaning or inspection.

Thorough cleaning of all components represents a critical step often overlooked during blade replacement. The mounting surfaces on both the blade and disc assembly must be completely free of debris, corrosion, or residual material that could prevent proper seating of the new blade. Specialized cleaning tools, including plastic scrapers, brass brushes, and approved solvents, effectively remove contaminants without damaging precision machined surfaces. The fastener holes should receive particular attention, with thread chasers used to clean any accumulated debris that could affect torque accuracy during reassembly. All cleaning activities should be conducted with attention to environmental regulations regarding solvent use and waste disposal. The cleaned components should be inspected for any signs of damage or abnormal wear that might indicate underlying issues requiring correction before new blade installation.

New Blade Installation and Alignment Verification

Proper installation of new blades begins with verification of component compatibility and condition. Each blade should be matched to its specific mounting position, particularly in systems where blades are numbered or directional. The mounting surfaces should receive a final inspection to confirm complete cleanliness and absence of damage before blade placement. Positioning the blade carefully in its mounting location ensures proper initial alignment before fastener installation. Fasteners should be installed by hand initially to verify free movement and proper threading, with any resistance indicating potential alignment issues or thread damage requiring correction. The installation sequence typically follows a star pattern that distributes clamping force evenly across the blade mounting area, preventing distortion and ensuring uniform contact.

Alignment verification represents one of the most critical aspects of proper blade installation. Even minor misalignment can cause accelerated wear, vibration issues, and reduced cutting efficiency. Visual inspection should confirm that blades seat fully against their mounting surfaces without gaps or rocking. Dial indicator measurements provide quantitative verification of blade positioning relative to the disc face and cutting circle. Manufacturer specifications typically provide tolerance ranges for various alignment parameters, with premium installations aiming for the tighter end of these ranges. The relationship between blade tips and the screen grate or anvil requires particular attention, as improper clearance directly impacts chip quality and machine efficiency. Documenting alignment measurements creates baseline data for future maintenance reference and helps identify developing trends between replacements.

Post-Replacement Testing and Operational Verification

Comprehensive testing following blade replacement ensures proper installation and identifies any issues before returning the chipper to full production. Initial testing should begin with a visual inspection confirming that all access panels are properly secured and tools removed from the work area. The first start-up should occur without material feed, allowing operators to verify normal sound characteristics and absence of unusual vibrations. Vibration analysis using portable meters can provide quantitative data comparing post-replacement conditions to established baselines. Once no-load operation confirms proper mechanical function, gradual material introduction begins with easy-to-process wood types before progressing to more challenging materials. This stepped approach helps identify any installation issues under controlled conditions rather than during full production.

Operational verification extends beyond simple mechanical function to include performance and output quality assessments. Power consumption should be monitored during initial operation to establish baselines for the new blades, with significant deviations from expected levels potentially indicating installation issues. Output quality should be evaluated through systematic chip sampling and size distribution analysis, comparing results to quality standards for the specific application. Operators should document these initial performance characteristics for future reference during routine maintenance inspections. The first several hours of operation typically represent a critical period when any installation issues become apparent, warranting more frequent monitoring than during normal production. This thorough verification process, while requiring additional time, prevents minor installation errors from developing into significant problems affecting production quality or equipment reliability.

Determining Optimal Inspection and Replacement Intervals

Establishing appropriate inspection and replacement intervals requires consideration of multiple operational factors rather than relying on fixed time-based schedules. The most effective maintenance programs utilize condition-based approaches that respond to actual blade wear rather than theoretical calculations. Historical maintenance data provides the foundation for developing initial interval recommendations, which are then refined based on continuous monitoring of blade performance and wear patterns. Statistical analysis of failure modes and wear progression helps identify the optimal point for maintenance activities, balancing the costs of premature replacement against the risks of excessive wear. Facilities that implement data-driven interval determination typically achieve 15-20% longer blade life while maintaining better performance consistency compared to those using generic time-based schedules.

Modern maintenance strategies increasingly incorporate predictive technologies that forecast blade condition based on operational parameters rather than direct measurement. These approaches monitor indirect indicators such as power consumption, vibration patterns, and output quality to detect subtle changes that signal developing wear. Machine learning algorithms can process these data streams to identify patterns preceding specific wear conditions, enabling maintenance scheduling before performance degradation becomes significant. The integration of these advanced approaches with traditional inspection methods creates a comprehensive maintenance strategy that maximizes blade life while minimizing unplanned downtime. Regardless of the specific techniques employed, the interval determination process should remain dynamic, adapting to changes in processed materials, operational intensity, and other variables affecting blade wear rates.

Operational Frequency and Workload Considerations

Operational frequency represents one of the primary factors influencing appropriate maintenance intervals for chipper blades. High-volume facilities processing multiple shifts daily typically require more frequent inspections and shorter replacement cycles compared to intermittent operations. However, the relationship between operational hours and blade wear is not strictly linear, as start-up and shutdown cycles create additional stress that accelerates wear. Facilities should track actual runtime hours rather than calendar time when determining maintenance needs, though both metrics provide valuable context. The distribution of operational intensity also influences wear patterns, with continuous operation often producing more predictable wear compared to frequent start-stop cycles that create varying thermal and mechanical stresses.

Workload characteristics beyond simple operational hours significantly impact blade maintenance requirements. The volume of material processed provides a more accurate wear indicator than time alone, with some facilities establishing maintenance triggers based on tons processed rather than hours operated. The concentration of operation—whether distributed evenly across shifts or concentrated in intensive production campaigns—also affects optimal maintenance scheduling. Seasonal variations common in wood processing operations require flexible maintenance approaches that accommodate changing production demands. Facilities implementing double-shaft wood shredder technology for preliminary size reduction may experience different blade wear patterns in their disc chippers due to changed material characteristics. Understanding these workload nuances enables development of maintenance schedules that reflect actual operational conditions rather than theoretical models.

Material Characteristics and Processing Variables

The specific characteristics of processed materials profoundly influence blade wear rates and maintenance requirements. Wood species variation represents perhaps the most significant factor, with hardwoods typically causing more rapid blade deterioration than softwoods due to their higher density and abrasive content. Research indicates that blades processing oak or hickory may require replacement 30-40% more frequently than those processing pine or poplar under similar conditions. Wood condition further modifies wear patterns, with frozen, dirty, or bark-heavy material accelerating blade deterioration. Moisture content creates complex effects, with very dry wood increasing abrasive wear while very wet wood promotes corrosion and material buildup. Facilities processing mixed material streams should document composition changes that might necessitate maintenance schedule adjustments.

Contaminant presence represents another critical variable affecting blade maintenance intervals. Metallic objects such as nails, wires, or equipment parts cause immediate damage requiring blade replacement, while less obvious contaminants like sand, soil, or stone dust create gradual abrasive wear. The increasing use of recycled wood from construction and demolition sources has amplified contamination challenges in many operations. Material size and consistency also influence blade wear, with very large or irregular pieces creating impact loads that differ from the steady cutting forces generated by uniform feedstock. Facilities operating both drum wood chipper and disc chipper systems often discover different wear patterns based on material preparation methods. Understanding these material variables enables development of maintenance schedules that respond to actual operating conditions rather than assuming consistent material characteristics.

Environmental Conditions and Operational Parameters

Environmental conditions significantly influence blade wear mechanisms and appropriate maintenance intervals. Temperature extremes affect both the processed material and the blade itself, with cold conditions increasing material hardness while hot conditions may accelerate corrosion processes. Humidity levels directly impact corrosion rates, particularly in coastal regions or facilities without climate control. Airborne contaminants such as dust, salt spray, or industrial emissions can accelerate blade deterioration through abrasive or chemical action. Outdoor installations typically experience more variable conditions than climate-controlled indoor facilities, necessitating more frequent inspections to detect environment-related issues before they compromise performance. Understanding these environmental factors helps explain variations in blade life between apparently similar operations in different locations.

Operational parameters established by equipment settings directly affect blade wear patterns and maintenance needs. Feed rate represents one of the most influential variables, with excessively high rates creating impact loads and accelerated wear while very low rates may allow blade vibration that creates different wear patterns. The relationship between blade speed and feed rate determines chip formation characteristics, with optimal combinations producing efficient cutting while suboptimal settings accelerate dulling. Machine adjustments such as anvil clearance and screen selection indirectly influence blade wear by changing cutting dynamics and material flow. Facilities operating multiple wood shredder types should recognize that optimal parameters may differ between machines despite similar applications. Documenting these operational settings alongside maintenance records helps identify correlations that support continuous improvement of both performance and maintenance efficiency.

Implementation Strategies for Maintenance Optimization

Successful implementation of optimized blade maintenance intervals requires systematic approaches that integrate technical knowledge, operational practicalities, and economic considerations. The development process should begin with comprehensive data collection establishing current performance baselines, including blade life, sharpening frequency, associated costs, and operational impacts. This historical perspective helps identify improvement opportunities and provides justification for proposed changes to maintenance protocols. Implementation typically proceeds through phased approaches that test modified intervals in controlled environments before full-scale adoption. Stakeholder engagement throughout the organization ensures that maintenance changes receive necessary support from operations, finance, and management personnel. Facilities that approach maintenance optimization as a continuous process rather than a one-time initiative typically achieve sustained improvements in both performance and economics.

Technology integration represents a powerful enabler for maintenance optimization through enhanced monitoring capabilities and data analysis. Modern sensor systems can track blade condition indicators continuously without requiring manual inspection, providing real-time insights into wear progression. Digital maintenance platforms facilitate data organization, analysis, and reporting, transforming raw operational information into actionable intelligence. Predictive maintenance algorithms can process multiple data streams to forecast optimal maintenance timing with increasing accuracy as historical data accumulates. The implementation process should include appropriate training ensuring that personnel understand both the technical aspects of new maintenance approaches and the underlying rationale supporting changed intervals. This comprehensive implementation strategy maximizes the benefits of maintenance optimization while minimizing disruption to ongoing operations.

Data Collection and Analysis Methodologies

Effective data collection forms the foundation for evidence-based maintenance interval optimization. The data collection framework should capture both direct blade measurements and contextual operational information that might influence wear patterns. Direct measurements typically include dimensional parameters, visual condition assessments, and performance indicators recorded during routine inspections. Contextual data encompasses operational hours, material volumes, wood types, power consumption, and any unusual occurrences that might affect blade condition. Standardized data collection protocols ensure consistency between different operators and inspection cycles, while digital data capture reduces transcription errors and facilitates analysis. The initial data collection phase should continue for several complete blade lifecycles to capture representative information across varying conditions.

Data analysis transforms collected information into actionable insights supporting maintenance decisions. Statistical techniques identify correlations between operational variables and blade wear rates, helping prioritize factors with the greatest influence on maintenance needs. Trend analysis reveals gradual changes in wear patterns that might indicate developing issues with machine condition or operational practices. Comparative analysis between different blade types, suppliers, or maintenance approaches provides objective evidence supporting procurement and methodology decisions. Facilities implementing four-shaft wood shredder technology alongside disc chippers can benefit from cross-equipment analysis identifying common factors affecting blade maintenance across different machine types. The analysis process should produce specific, measurable recommendations for maintenance interval adjustments, with implementation followed by continued monitoring to verify expected outcomes.

Preventive Maintenance Program Development

Systematic preventive maintenance program development creates structured approaches to blade care that maximize performance while minimizing costs. Effective programs balance comprehensive coverage with practical implementation, avoiding both insufficient maintenance that risks unexpected failures and excessive maintenance that wastes resources. Program development begins with risk assessment identifying the consequences of various blade-related failure modes, which helps prioritize maintenance activities based on potential impact. The resulting program should specify inspection frequencies, acceptable condition parameters, maintenance procedures, and replacement criteria with sufficient clarity for consistent execution. Integration with broader maintenance management systems ensures that blade maintenance receives appropriate priority alongside other equipment care activities.

Preventive maintenance programs evolve through continuous improvement processes that incorporate lessons learned from actual operational experience. Regular program reviews should assess effectiveness metrics including blade life, maintenance costs, unplanned downtime, and output quality. Feedback mechanisms capturing operator observations and maintenance technician insights provide valuable qualitative data complementing quantitative performance measures. The program should remain flexible enough to accommodate operational variations while maintaining core principles that ensure consistent blade care. Facilities operating multiple wood processing technologies including single-shaft wood shredder systems should identify common elements that can be standardized across equipment types while recognizing unique requirements for each machine. This balanced approach creates sustainable maintenance programs that deliver long-term value through optimized blade performance and reliability.