High Toughness Material Shredding Solutions

Introduction of High Toughness Material Shredding Solutions

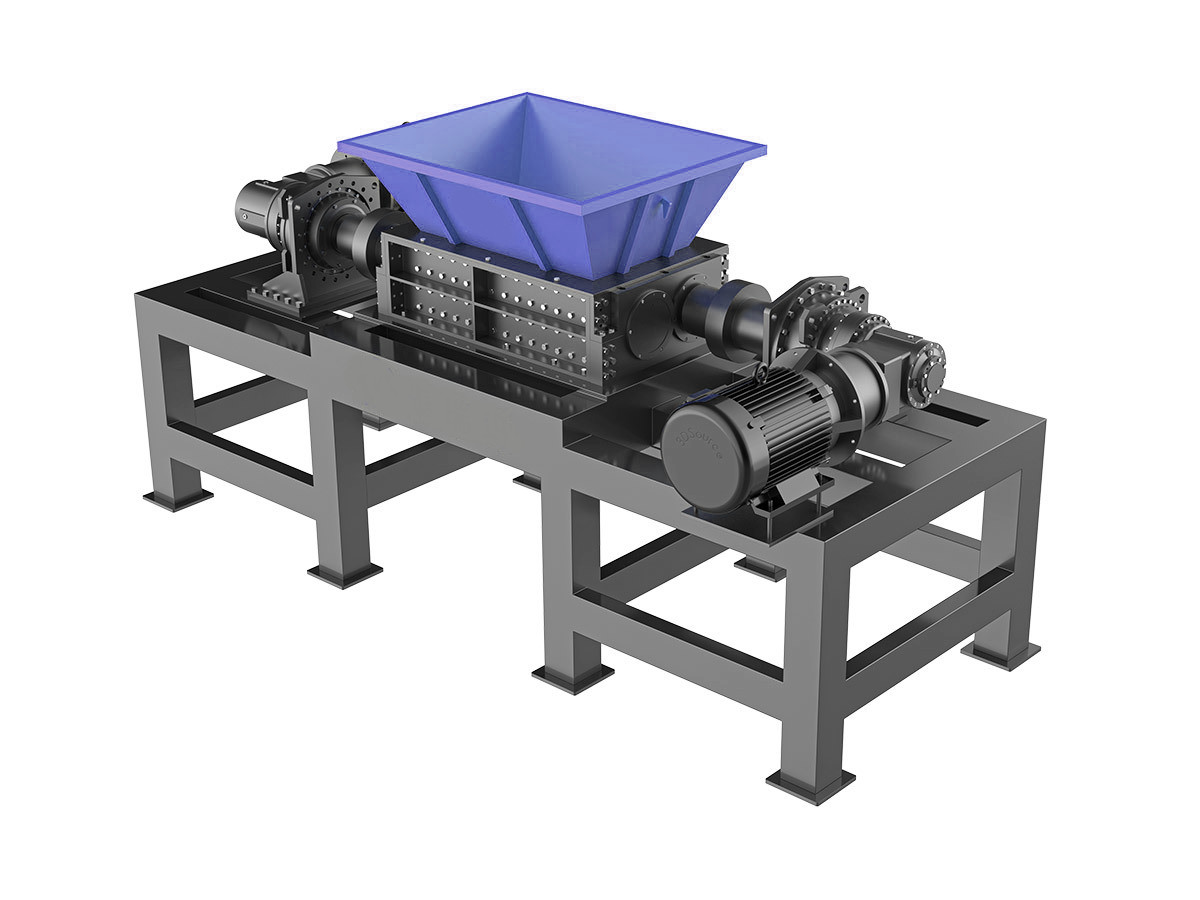

High Toughness Material Shredding Solutions are specifically designed to handle materials that possess significant strength, rigidity, and resistance to wear and tear. These materials, such as high-density plastics, composites, and tough metals, require shredding technologies that can withstand high levels of stress and maintain consistent performance over extended periods.

These shredding solutions are essential in industries where high-toughness materials are prevalent, such as aerospace, automotive manufacturing, and recycling of durable plastics and metals. The ability to break down these robust materials into smaller, manageable pieces is crucial for efficient processing and resource recovery.

Shredders designed for high toughness materials feature reinforced components, powerful motors, and precision cutting systems that ensure maximum durability and effective processing of even the toughest materials. Proper shredding not only enhances material handling but also helps in the recovery of valuable resources.

Investing in high-toughness material shredding solutions is key for industries that aim to minimize waste, enhance recycling rates, and create a more sustainable production cycle by repurposing these tough materials into reusable resources.

What is High Toughness Material Shredding Solutions?

High Toughness Material Shredding Solutions refer to shredding systems specifically engineered to process materials with high strength, durability, and toughness. These materials are often resistant to conventional shredding methods and require specialized equipment capable of withstanding heavy forces and intense abrasion.

These shredders are used to break down materials such as carbon fiber composites, reinforced plastics, metals like titanium, and industrial rubber. The shredding process typically involves high torque motors, multi-shaft cutting systems, and durable blades that are designed to maintain performance under extreme conditions.

The goal of high toughness material shredding is to reduce these resilient materials into smaller, uniform particles that can be reused in manufacturing processes or repurposed for recycling. This process ensures that valuable materials are not wasted and can be recycled or reformed into new products.

Why is Efficient High Toughness Material Shredding Important?

Efficient High Toughness Material Shredding is critical for industries that process or recycle durable materials. Shredding tough materials like composites, reinforced plastics, and high-strength metals requires advanced technology to ensure optimal performance and prevent equipment damage.

Without efficient shredding, these tough materials can cause excessive wear on machinery, reduce processing speeds, and increase operational costs. Specialized shredding solutions allow for the effective and cost-efficient breakdown of these materials, ensuring minimal downtime and optimal throughput.

Moreover, efficient shredding enhances sustainability efforts by ensuring that tough materials are properly processed and recycled. These materials can often be reused in manufacturing, reducing the need for new raw materials and lowering environmental impact.

How Do Shredders Enhance High Toughness Material Recycling?

High Toughness Material Shredders play a vital role in the recycling process by breaking down durable materials into smaller, manageable pieces, which can then be reused or reprocessed. The effective shredding of these materials allows for the separation of valuable components, making them easier to recycle or repurpose in manufacturing.

For instance, shredding carbon fiber composites into smaller particles helps separate the carbon fibers, which can then be used in the production of new composite materials or as filler in various industries. Similarly, high-toughness metal shredding helps recover valuable metals such as aluminum or titanium, reducing the need for new metal mining.

Advanced shredding technologies also incorporate features that minimize material loss, reduce energy consumption, and enhance the quality of the final shredded output, contributing to more efficient recycling processes and reduced environmental impact.

Types of Shredders Used in High Toughness Material Processing

There are several types of High Toughness Material Shredders designed to handle tough and resilient materials. These include:

Heavy-Duty Single-Shaft Shredders: Ideal for tough plastics and composites, these shredders feature reinforced cutting tools and a high-torque drive system for efficient material breakdown.

Dual-Shaft Shredders: These are perfect for processing high-strength materials like metals and industrial rubber. The dual-shaft configuration provides additional cutting power and torque for handling dense and rigid materials.

Granulators: Used for high-toughness plastics and composite materials, granulators break down materials into uniform granules, which can then be used in further manufacturing or recycling processes.

Hammer Mills: High-speed hammer mills are effective for processing hard materials, such as metals or tough plastics, by applying high impact forces to break them down into smaller pieces.

Key Factors in Choosing the Right Shredders for High Toughness Materials

When selecting the right High Toughness Material Shredder, several key factors should be taken into account to ensure optimal performance:

Material Strength: The strength and composition of the material being shredded directly affect the choice of shredder. Tougher materials like metals and composites require more powerful shredders with robust components.

Shredding Capacity: It's important to choose a shredder that can handle the volume of high-toughness material you need to process. High-throughput machines are essential for industrial applications with large amounts of material to be processed.

Durability: Since high toughness materials are often abrasive, it's crucial to select shredders that are designed with durable, wear-resistant components such as hardened steel blades and reinforced chambers.

Energy Efficiency: High-toughness material shredding can be energy-intensive, so selecting energy-efficient shredders with optimized motors and low power consumption can help reduce operational costs.

FAQ

Q: What types of materials are considered high toughness materials?

A: High toughness materials include metals (e.g., aluminum, titanium), carbon fiber composites, reinforced plastics, and industrial rubber. These materials are known for their resistance to wear, impact, and deformation.

Q: Can a shredder process a combination of high toughness materials?

A: Yes, some advanced shredders are capable of processing multiple types of high toughness materials, provided they are equipped with the appropriate cutting mechanisms and have the necessary power and durability.

Q: How do I ensure my high toughness material shredder lasts longer?

A: Regular maintenance, such as blade sharpening, lubrication, and checking for signs of wear, can help extend the life of the shredder. Additionally, using the correct shredder for the material type reduces the strain on the machine.

Q: What is the ideal output size for high toughness materials?

A: The output size depends on the intended application. For recycling, the material may need to be shredded into smaller granules or particles, while for disposal, larger, more uniform pieces may be required.

Main Components of Solid Waste Shredder

Shredding Solutions

Soft Material Shredding Solutions

Efficiently handle and process soft materials with our specialized soft material shredding solutions. Designed for materials like rubber, textiles, foam, and soft plastics, our shredders offer precise size reduction while ensuring optimal throughput and minimal downtime. Ideal for industries requiring soft material processing for recycling, waste management, and material recovery, our shredding machines are built for durability, energy efficiency, and high performance.

Learn more >>

Hard Material Shredding Solutions

Tackle tough materials with our advanced hard material shredding solutions. Engineered to process metal, concrete, wood, stone, and dense plastics, our shredders provide powerful performance for efficient size reduction and recycling. Designed for industries handling heavy-duty waste, our shredders ensure durability, precision, and high throughput, helping businesses optimize waste management and material recovery.

Learn more >>

High Toughness Material Shredding Solutions

Efficiently shred and process high toughness materials with our specialized shredding solutions. Designed for materials such as thick rubber, hard plastics, reinforced composites, and industrial metal alloys, our machines provide powerful cutting performance and exceptional durability. Built to handle the toughest materials, our shredders ensure optimal size reduction for recycling, waste management, and material recovery.

Learn more >>

Composite Material Shredding Solutions

Efficiently process and recycle composite materials with our specialized shredding solutions. Designed for fiber-reinforced plastics, carbon composites, and other complex materials, our shredders offer precision cutting and exceptional durability to handle tough and intricate substances. Ideal for industries such as automotive, aerospace, and construction, our machines ensure effective size reduction for reuse or disposal.

Learn more >>