Mobile drum chippers represent a significant advancement in forestry technology, enabling the processing of wood directly at the harvest site or landing. This approach transforms bulky, low-density logging residues and whole trees into uniform, high-density wood chips that are far more economical to transport. By eliminating the need to haul entire logs over long distances, forestry operations can achieve substantial reductions in fuel consumption, trucking cycles, and labor expenses. Industry studies indicate that on-site chipping can lower overall transport volumes by up to 60%, turning a cost center into a profit-generating activity. This guide provides a comprehensive overview for forestry companies and land managers seeking to optimize their operations through mobile wood processing.

The integration of a drum wood chipper into the wood supply chain fundamentally changes the logistics equation. Instead of allocating resources to move material with a high air-to-wood ratio, companies can focus on transporting a finished product. This method is particularly effective for managing forest residuals that were previously considered waste, thereby promoting sustainable forest management practices and contributing to a circular bioeconomy.

Why Mobile Drum Chippers are the Ideal Choice for On-Site Processing?

Mobile drum chippers offer a distinct set of advantages that make them superior to fixed-site plants for many forestry applications. Their primary benefit lies in their ability to bring the processing facility to the raw material, which is a paradigm shift from traditional forestry models. This mobility eliminates the logistical challenges and expenses associated with transporting unprocessed wood over potentially rough and long-distance terrain. The machinery is engineered for robustness and efficiency in demanding field conditions.

The economic rationale for deploying this technology is compelling. Fixed installations require a constant and costly flow of raw material to be viable, whereas mobile units can be moved to where the wood is most abundant, maximizing utilization rates. The design of the drum chipper itself is highly efficient for reducing various forms of wood waste into a consistent product suitable for biomass energy, pulp, or mulch.

From Transporting Air to Transporting Products: Changing the Economics of Wood Logistics

Conventional log transportation involves moving a significant amount of air and water contained within the wood structure. A freshly cut log can have a moisture content exceeding 50%, meaning half the weight being transported is water. Furthermore, the irregular shapes of logs and branches lead to inefficient stacking on trucks, resulting in trailers often hauling more void space than solid wood. This inefficiency directly translates into higher costs per unit of dry fiber delivered to the mill.

On-site chipping addresses this fundamental inefficiency. A mobile chipper processes the wood into small, uniform chips that can be densely packed into trailers. This increases the payload capacity significantly; a single truckload of chips can contain the fiber equivalent of multiple truckloads of whole logs. This density improvement reduces the number of required truck trips, which in turn lowers fuel costs, vehicle wear and tear, and associated emissions by a considerable margin.

The Inherent Advantages of Drum Design in Handling Forest Residuals

The drum chipper design features a large, rotating cylindrical drum equipped with hardened steel knives. As wood is fed into the machine, the drum pulls the material through and shears it against a fixed anvil. This mechanism is exceptionally effective at processing a wide variety of feedstocks, including crooked logs, slash, tops, and limbs that are typically left in the forest. The consistent, high-torque action of the drum minimizes jamming and ensures a steady output of chips.

This design is particularly suited for forest residues because it does not require pre-sorting or uniform piece size. Unlike disc chippers, which can be sensitive to feedstock geometry, drum chippers can handle the heterogeneous nature of logging slash with greater reliability. The result is a higher recovery rate of usable fiber from each harvest site, reducing waste and maximizing the value extracted from the forest.

Adaptability and Passability of Mobile Chassis

Mobile chippers are mounted on robust chassis designed for off-road conditions. There are two primary types: truck-mounted units for easier road travel and tracked carriers for superior mobility on soft, wet, or steep terrain. Tracked carriers exert a lower ground pressure than wheeled vehicles, allowing them to operate on sensitive soils without causing significant rutting or damage, which is crucial for complying with sustainable forestry practices.

The choice of chassis directly impacts the operational window of the equipment. Truck-mounted chippers offer faster relocation speeds between sites on public roads but may be limited in extreme terrain. Tracked models, while slower to transport between distant sites, provide unparalleled access to wood piles deep within a harvest area, ensuring that processing can occur close to the felling operation, which further minimizes the distance residual material must be moved.

How Rapid Deployment and Transfer Capabilities Enhance Equipment Utilization

The ability to quickly set up, operate, and then move to a new location is a key factor in the profitability of mobile chipping. Modern mobile drum chippers are designed for rapid deployment; many models can be operational within an hour of arriving on site. Hydraulic outriggers provide stable leveling on uneven ground, and integrated feed and discharge systems require minimal setup time.

This mobility allows a single machine to serve multiple harvest sites or landowners within a region, spreading the capital cost over a greater volume of wood. High equipment utilization is critical for achieving a positive return on investment. By moving the chipper to concentrated wood piles, the machine operates at or near its designed capacity more consistently than a fixed-site plant that depends on a continuous flow of delivered wood.

Planning Successful On-Site Chipping Operations: Key Preparations

Thorough planning is essential for the safe, efficient, and environmentally sound operation of a mobile drum chipper. A well-planned operation minimizes downtime, ensures product quality, and mitigates potential impacts on the surrounding ecosystem. The planning phase involves logistical coordination, site assessment, and resource allocation to create a seamless workflow from the forest to the chip truck.

Key considerations include the geographic layout of the harvest area, the volume and type of wood to be processed, and the sequencing of harvesting and chipping activities. Effective planning also involves communication with logging crews, truck drivers, and land managers to align expectations and schedules. A detailed plan serves as a roadmap that anticipates challenges and outlines solutions before machinery is ever mobilized.

Key Points for Site Selection: Flatness, Drainage, Proximity to Main Roads

Selecting an appropriate location for the chipping operation is a critical first step. The ideal site is relatively flat and well-drained to provide a stable foundation for the heavy equipment and to prevent operational delays due to muddy conditions. A slight slope can be beneficial for natural drainage, but excessive incline can complicate machine stabilization and chip handling. The site should be clear of overhead obstacles like power lines and have sufficient space for maneuvering support equipment and chip vans.

Proximity to main roads is another vital factor. While the chipper itself is mobile, the trucks that haul the chips away require safe and easy access. The chosen landing area should be as close as possible to public roads to minimize the construction of temporary access routes. This reduces site preparation costs and limits the environmental footprint of the operation. A central location within the harvest area also shortens the distance that material must be forwarded, saving time and fuel for the skidders or forwarders.

How to Estimate the Volume of Wood to be Processed to Plan the Operation Cycle

Accurately estimating the volume of wood available for chipping is necessary to schedule the operation efficiently. This estimation can be derived from harvest plans, which often include data on the merchantable volume per hectare. For residues, a common method is to use allometric equations or volume tables that relate tree diameter and species to the amount of slash produced. Modern technology, such as LiDAR scanning, can also provide detailed biomass maps of a harvest area.

Once the total volume is estimated, the production rate of the specific drum wood chipper model can be used to calculate the required operating time. For example, a chipper with a capacity of 100 green tons per hour would need approximately 10 hours to process 1,000 tons of material. This calculation helps in planning the number of chip trucks needed, labor shifts, and fuel supplies, ensuring a continuous workflow without bottlenecks.

Necessary Auxiliary Equipment List: Such as Grapples, Loaders, etc.

A mobile chipping operation cannot function in isolation; it requires a suite of supporting machinery to be efficient. A primary piece of auxiliary equipment is a material handler, such as a grapple-equipped excavator or a front-end loader. This machine is responsible for feeding the chipper consistently and safely, separating the operator from the dangerous feed zone. The handler should have sufficient reach and lifting capacity to manage large piles of wood.

Other essential equipment includes chip vans or live-bottom trailers for transporting the finished product, and possibly a water truck for dust suppression on dry sites. A service truck with tools and spare parts is also crucial for performing routine maintenance and addressing minor repairs on site, preventing prolonged downtime. The coordinated operation of this equipment fleet is what enables high-volume, continuous chipping.

Safety Plans and Environmental Impact Assessment

Safety is paramount in any industrial operation, and forest-based chipping presents unique hazards. A comprehensive safety plan must address risks such as flying debris, noise exposure, heavy equipment movement, and potential fire hazards from the chipper's engine or hot materials. Operators and ground personnel must wear appropriate Personal Protective Equipment (PPE), including hearing protection, safety glasses, hard hats, and high-visibility clothing.

An environmental impact assessment should be conducted to identify and mitigate potential effects on soil, water, and air quality. Measures for controlling dust may include misting systems or strategically positioning the chipper relative to the wind direction. Noise mitigation can involve using newer, quieter engine models or creating temporary sound barriers. Spill prevention plans for fuel and hydraulic fluids are also essential to protect the forest floor and any nearby waterways.

Core Configuration Choices for Mobile Drum Chippers

Selecting the right configuration for a mobile drum chipper is crucial for matching the machine's capabilities to the specific demands of the operation. Manufacturers offer various options for power, feeding, and discharge systems, allowing buyers to customize a chipper for optimal performance in their working environment. The choices made during selection will directly influence productivity, operating costs, and versatility.

The core configuration determines the machine's fundamental operating parameters. A well-chosen configuration will handle the expected feedstock efficiently, while a poor match can lead to frequent breakdowns, high fuel consumption, and unsatisfactory chip quality. Understanding the trade-offs between different options is key to making an informed investment that will deliver long-term value.

Power Source Selection: Independent Diesel Engine vs. Tractor PTO

Mobile drum chippers are typically powered in one of two ways: by a dedicated onboard diesel engine or by a tractor's Power Take-Off (PTO) system. Chippers with independent engines are self-contained units that generate their own power for the drum and hydraulic systems. These engines are often high-horsepower industrial models designed for continuous heavy-duty operation, providing consistent performance regardless of the prime mover.

PTO-driven chippers draw power from the tractor that tows them. This configuration can be more cost-effective initially and leverages the existing investment in a farm or forestry tractor. However, the chipper's performance is limited by the tractor's PTO horsepower, and the tractor engine must run at a high RPM to deliver sufficient power, which may not be as fuel-efficient as a dedicated engine optimized specifically for the chipping task.

Feed System Specifications: Size and Power Requirements of Hydraulic Rollers

The feed system is responsible for grabbing incoming material and drawing it steadily into the cutting drum. This is typically accomplished through a set of hydraulically powered rollers. The size, number, and grip strength of these rollers are critical specifications. Larger-diameter rollers with aggressive teeth can handle bigger, more irregular logs and prevent kickbacks. A system with multiple feed rollers provides better control over the material, leading to a more consistent chip size and reducing the risk of jams.

The hydraulic system that powers the feed must deliver high pressure and flow to maintain a constant pulling force. A weak feed system will struggle with large-diameter wood or tangled limbs, causing frequent stoppages. The best systems are reversible, allowing the operator to back out material if a blockage is detected, which is a vital safety and efficiency feature. The entire feed rollers assembly must be built from wear-resistant materials to withstand the abrasive nature of wood and dirt.

Discharge System: The Importance of a 360-degree Rotating Throw Arm

The discharge system directs the flow of chips from the machine into a waiting container. A key feature on modern mobile chippers is a 360-degree rotating spout or throw arm. This allows the operator to precisely direct the chip stream into different areas of a chip van or onto a pile without needing to reposition the entire chipper. This flexibility is invaluable for evenly loading trailers and for managing chip storage on the landing.

The discharge spout is often equipped with a deflector to control the trajectory and reduce dust generation. Some advanced models feature telescopic spouts that can extend to reach the far corners of a large trailer. The ability to swivel the spout away from the chipper also enhances safety during maintenance or if a truck is not immediately present. An efficient discharge system minimizes chip loss and ensures a clean work area.

Comparison of Advantages and Disadvantages between Tracked and Truck-mounted Mobile Chassis

The choice between a tracked or truck-mounted chassis is a fundamental decision based on terrain and operational tempo. Truck-mounted chippers are ideal for operations that require frequent relocation over public highways. They can travel at road speeds, reducing transit time between sites. Their primary limitation is ground pressure; they can become stuck in soft, wet, or uneven terrain, restricting their use to well-prepared landings.

Tracked carriers excel in challenging field conditions. Their wide tracks distribute the machine's weight over a larger area, providing excellent flotation on soft ground. This allows them to operate on slopes and in wet weather that would immobilize a wheeled vehicle. The trade-off is that tracked carriers are slow and require a low-bed trailer for transport between distant sites, adding complexity and cost to logistics. The decision often hinges on the typical soil conditions and the size of the individual work sites.

Standard Operating Procedure for On-Site Chipping Operations

Establishing a Standard Operating Procedure (SOP) is essential for ensuring that chipping operations are conducted safely, efficiently, and consistently. A well-defined SOP minimizes the risk of accidents, reduces equipment wear, and ensures the production of high-quality chips. It provides a clear set of instructions for all personnel involved, from the machine operator to the ground crew.

The SOP should cover all phases of the operation, from initial site arrival to final cleanup and departure. Adherence to the SOP helps create a predictable routine that maximizes productivity while safeguarding both people and machinery. Regular training and reviews of the procedure are necessary to incorporate lessons learned and maintain a high safety standard.

Equipment Entry, Positioning and Stabilization Process

Upon arriving at the designated landing, the first step is to carefully position the chipper. The operator should survey the area to identify the best location, considering the direction of the wind to blow dust away from the work zone, the proximity to the wood pile, and the access route for chip trucks. The chipper should be positioned on level ground to ensure stable operation and even wear on the cutting components.

Once in position, the chipper must be stabilized before operation. This is typically done by extending hydraulic outriggers or stabilizer legs until the machine is firmly planted and level. This prevents rocking or shifting during the high-vibration chipping process, which could lead to premature mechanical failure or unsafe operating conditions. A quick visual inspection of the immediate area for trip hazards or debris is also performed at this stage.

Best Practices from Piling Branchwood to Continuous Feeding

The efficiency of the chipping process depends heavily on how the raw material is prepared and fed. Logging residues should be piled in an organized manner that allows the material handler to maintain a steady supply to the chipper. Tangled piles should be broken up to facilitate smooth feeding. The operator of the feed machine should present the wood to the chipper butt-end first, aligning it with the feed tray to prevent skewing.

Continuous, steady feeding is the goal. The chipper operator and the material handler must communicate effectively, often via radio, to regulate the feed rate. Overfeeding can cause the engine to lug down and potentially stall, while underfeeding reduces productivity. The ideal is a consistent flow that keeps the engine operating at its peak torque RPM, resulting in optimal chip quality and fuel efficiency. Avoiding rocks and metal contaminants is critical to protect the expensive cutting knives.

On-site Stacking and Storage Techniques for Wood Chips

When chips are not loaded directly into a truck, they must be piled correctly to maintain quality and prevent hazards. Chips should be stacked in a well-drained area, and the pile should be compacted to reduce air pockets. Fresh wood chips undergo biological degradation, which generates heat. Without proper management, this can lead to spontaneous combustion.

To mitigate this risk, chip piles should not be excessively large if they are to be stored for more than a few days. Regularly monitoring the internal temperature of the pile is a prudent practice. For long-term storage, piles are often turned to dissipate heat. The use of a discharge conveyor can help shape the pile and achieve better density than simply relying on the chipper's blower.

Equipment Cleaning, Maintenance and Transfer after Operation Completion

At the end of each shift or upon completion of work at a site, a thorough cleaning and inspection routine must be followed. The chipper should be run without feed for a short period to clear any residual material from the chamber and discharge chute. The exterior and the feed system should be cleaned of mud and debris to prevent corrosion and allow for proper inspection.

A post-operation maintenance check includes inspecting knives for wear, checking hydraulic lines for leaks, and ensuring all guards are secure. Any issues should be logged and addressed promptly. Before transferring the chipper to a new site, it must be secured properly for transport, with the discharge spout locked and all stabilizers fully retracted. This disciplined approach to shutdown and transfer ensures the equipment is ready for immediate operation at the next location.

Economic Benefit Analysis: Cost Savings and Value Creation

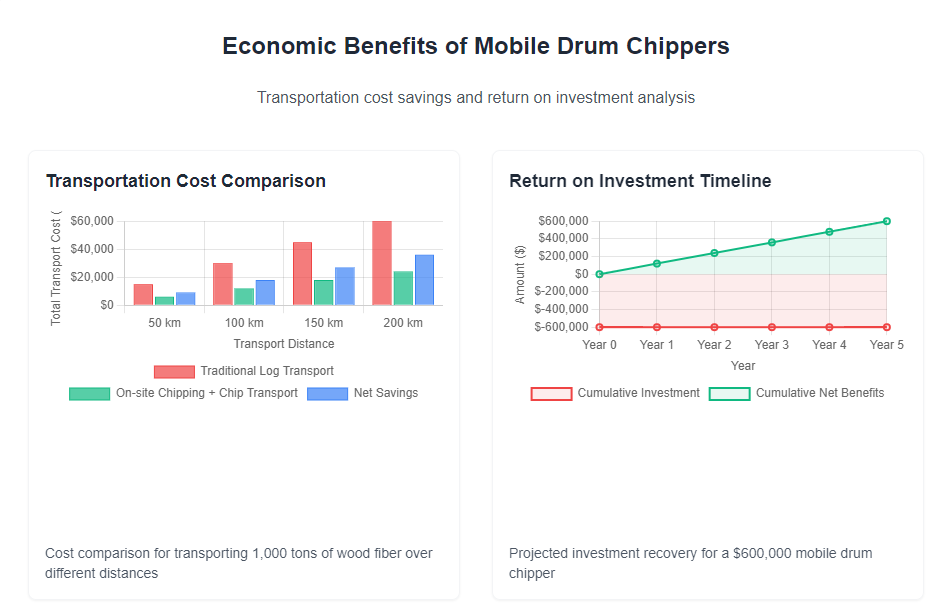

The decision to invest in mobile chipping technology must be justified by a clear economic analysis. The primary financial benefits arise from dramatic reductions in transportation costs and the conversion of low-value biomass into a marketable product. A comprehensive analysis looks beyond simple purchase price to consider the total cost of ownership and the new revenue streams enabled by the equipment.

Quantifying these benefits requires modeling the specific operational context, including haul distances, residue volumes, and local chip markets. The

analysis should account for both direct cost savings and indirect value creation, such as improved site cleanup and reduced fire risk. For many operations, the return on investment

is achieved within a few years, after which the cost savings translate directly to improved profitability.

Transportation Cost Saving Model Calculation

A fundamental saving comes from the increased density of chips compared to unprocessed logs. For example, a standard log truck might carry 25 tons of whole logs, whereas a chip van can carry 25-30 tons of wood chips. The critical difference is that the chips represent the fiber from a much larger volume of whole trees because the air and space are eliminated. It is common for chipping to reduce the number of truckloads needed by 50% to 60%.

To calculate savings, consider a haul distance of 100 kilometers. If transporting logs requires 100 truckloads at a cost of $300 per load, the total transport cost is $30,000. By chipping on-site, the number of loads may be reduced to 40. At the same per-load cost (which might be slightly higher due to tarps and specialized trailers), the cost becomes $12,000, resulting in a direct saving of $18,000 for that volume of wood. This model clearly demonstrates the financial impact.

Revenue Growth from Converting Low-Value Residuals into High-Value Wood Chips

Forest residues, such as slash, often have little to no value if left in the forest. In some cases, landowners must pay for their disposal through burning or other methods. A mobile chipper transforms this liability into an asset. The produced chips can be sold as boiler fuel for biomass energy plants, as raw material for pulp and paper mills, or as landscape mulch.

The revenue generated depends on local market prices for wood chips, which can vary significantly. For instance, biomass chips might sell for $25 per green ton, while higher-quality pulp chips could command $40 or more. By processing 10,000 tons of residues annually, an operation could generate $250,000 to $400,000 in new revenue. This revenue turns a cost center (residue management) into a profit center, fundamentally improving the economics of the harvest.

Analysis of Investment Return Period for a Mobile Chipper

The capital cost of a new mobile drum chipper can range from $500,000 to over $1,000,000, depending on size and specifications. The return on investment (ROI) period is calculated by comparing this initial outlay against the annual net savings and new revenue. Annual benefits include transport cost savings, revenue from chip sales, and avoided costs like residue disposal fees.

If the total annual benefit is $200,000 and the annual operating costs (fuel, maintenance, labor) are $80,000, the net annual saving is $120,000. For a chipper costing $600,000, the simple payback period would be five years ($600,000 / $120,000/year). Many operators find that with high utilization, the payback period can be as short as three to four years, making it a sound financial investment.

Other Benefits Beyond Money: Such as Forest Land Cleaning, Fire Risk Reduction

The economic analysis should not overlook significant non-monetary benefits. Effective removal of logging residues through chipping results in a cleaner forest floor after harvest. This improves aesthetics, facilitates replanting operations, and reduces the habitat for pests like bark beetles. A clean site is also easier and safer for forestry workers to navigate.

Perhaps the most critical ancillary benefit is the reduction of wildfire fuel. Dense piles of dry slash left in the forest represent a severe fire hazard. By chipping this material and removing it, the overall fuel load is dramatically decreased, protecting the remaining forest stands and nearby communities. This contributes to broader forest health and resilience, aligning forestry operations with public safety and environmental stewardship goals.

Challenges, Limitations and Coping Strategies

While mobile drum chipping offers substantial advantages, it is not without its challenges. Acknowledging these limitations and developing strategies to manage them is key to a successful operation. The primary challenges often relate to environmental conditions, the capital intensity of the equipment, and regulatory compliance.

A proactive approach to these challenges involves careful planning, investing in operator training, and maintaining flexible operational plans. By anticipating potential problems, managers can develop contingency plans that minimize disruption. Understanding the limitations also helps in setting realistic expectations for productivity and profitability.

Dependence on Weather and Terrain and Response Plans

Mobile chipping operations are highly dependent on favorable weather and ground conditions. Persistent heavy rain can render access roads and landing areas impassable, halting operations. Even if the chipper itself is tracked, the support vehicles and chip trucks may be unable to navigate muddy terrain. Extreme cold can also pose challenges, such as frozen material jamming the feed system.

To mitigate weather dependence, operations should be scheduled for drier seasons whenever possible. Having well-maintained, all-weather access roads is crucial. A flexible schedule that allows for shifting operations to different sites within a region based on local weather forecasts can maximize annual productivity. For winter operations, storing wood piles under cover or using cold-weather engine pre-heaters can help maintain efficiency.

Professional Requirements for Equipment Investment and Maintenance

Mobile drum chippers are complex industrial machines that require skilled operators and mechanics for proper operation and upkeep. An unskilled operator can cause rapid wear to cutting components, produce poor-quality chips, and create unsafe conditions. Similarly, a lack of proper maintenance can lead to unexpected breakdowns that are costly to repair and cause significant downtime.

The coping strategy is to invest comprehensively in human resources. This includes providing certified training for operators and ensuring a maintenance team is trained on the specific model. Establishing a rigorous preventive maintenance schedule is non-negotiable. Keeping an inventory of critical spare parts, such as a rotor assembly or knife sets, on the service truck can drastically reduce repair time during a failure.

How to Ensure Operations Comply with Environmental Regulations

Forest operations are subject to a web of environmental regulations concerning soil disturbance, water quality, and air emissions. Chipping activities can generate noise and dust that may be regulated, especially near residential areas. Non-compliance can result in fines, work stoppages, and damage to a company's reputation.

The best strategy is to engage with regulatory agencies early in the planning process. Obtaining all necessary permits and understanding the specific requirements is essential. On-site, best management practices must be implemented diligently. These can include using a dust suppression system on the chipper, operating within designated noise limits, and establishing buffer zones around streams. Documenting all environmental protection measures demonstrates due diligence.

Synergistic Effects with Other Processing Methods

Mobile chipping is not always a standalone solution; it can be effectively combined with other wood processing methods. For example, in a whole-tree harvesting system, merchantable stems are sent to a sawmill, while the entire remaining tree (tops, limbs) is chipped on-site for biomass. This integrated approach maximizes the value recovered from each tree.

Another synergy exists with grinding operations. While chippers produce uniform chips, a double-shaft wood shredder might be used first to process very contaminated or oversized waste wood before it is fed into a chipper for final sizing. Understanding how different technologies complement each other allows land managers to select the most efficient and profitable toolchain for their specific feedstock and end-product goals.