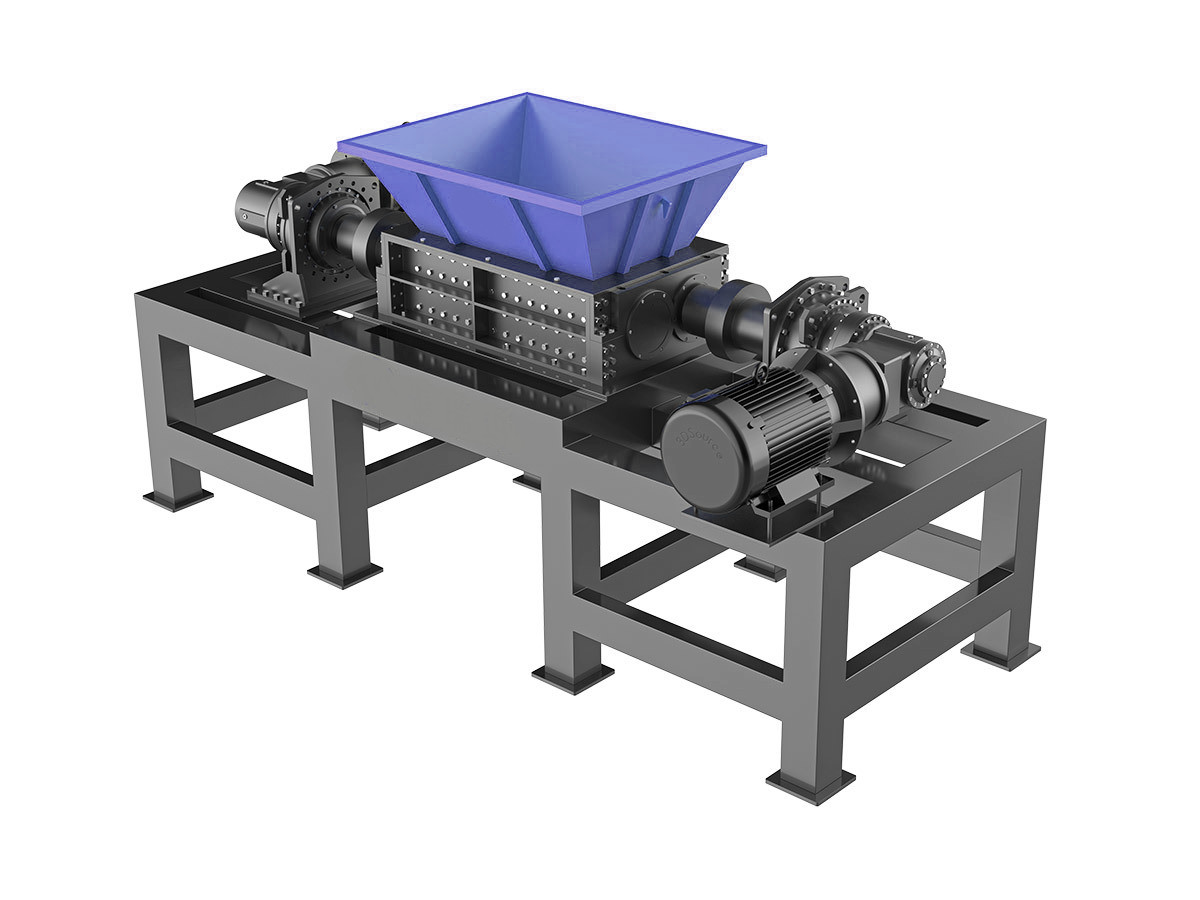

Double Shaft Waste Wood Shredder

A double shaft wood shredder is a robust industrial machine designed to handle high-volume wood waste processing. Unlike single shaft shredders, which rely on a single cutting mechanism, double shaft shredders utilize two counter-rotating shafts with high-torque cutting blades. This dual-shaft configuration allows for greater shredding efficiency, making it ideal for processing bulky wood materials such as pallets, tree branches, furniture waste, and construction debris.

Industries such as recycling, biomass energy production, and waste management depend on double shaft wood shredders to reduce wood waste into manageable pieces. By efficiently breaking down large wood structures, these shredders help optimize transportation, recycling, and material repurposing processes, contributing to sustainable waste management.

With their durable construction, high processing capacity, and ability to handle various wood types, double shaft wood shredders offer businesses a reliable and long-lasting solution for wood waste disposal. Their ability to process tough materials with minimal maintenance makes them a preferred choice for heavy-duty industrial applications.

Key Advantages of a Double Shaft Waste Wood Shredder

One of the most significant advantages of a double shaft wood shredder is its superior material handling capability. The dual-shaft system allows the machine to grip, pull, and tear apart large pieces of wood without the risk of clogging or jamming. This ensures continuous operation, even when processing dense or oversized wood waste.

Another key benefit is the ability to process a wide range of wood materials. Whether it's thick wooden pallets, tree trunks, or mixed construction debris, double shaft shredders can handle tough wood waste efficiently. Their high-torque operation enables them to shred even the most stubborn materials without excessive wear on the blades.

Additionally, double shaft wood shredders are designed for low maintenance and long-term durability. The high-quality cutting blades are resistant to wear and tear, and many models include self-cleaning mechanisms to prevent material buildup. Advanced features such as automatic overload protection, reverse operation, and adjustable shredding speeds help enhance efficiency and extend the machine’s lifespan.

How a Double Shaft Wood Waste Shredder Works

The shredding process in a double shaft wood shredder is based on two synchronized, counter-rotating shafts equipped with hardened steel blades. As wood waste is fed into the machine, the dual shafts work together to grip, crush, and tear the material into smaller pieces. This method ensures thorough and efficient shredding, even for large or irregularly shaped wood pieces.

Unlike high-speed grinders that rely on impact cutting, double shaft shredders operate at low speeds with high torque. This slow-speed, high-power cutting process reduces noise and dust production while increasing the efficiency of material breakdown. The controlled shredding action also helps maintain consistent particle sizes, making it easier to transport and recycle the shredded wood.

Modern double shaft wood shredders feature intelligent control systems that optimize performance and safety. Features such as automatic load sensing, hydraulic ram feeding, and customizable output size settings allow for greater operational flexibility. With their powerful shredding capabilities and advanced automation, double shaft wood shredders provide an efficient and eco-friendly solution for managing wood waste in industrial and commercial applications.