Selecting an appropriate low-noise waste wood shredder is essential for urban community recycling projects where space constraints and noise sensitivity are significant concerns. This guide explores the critical factors involved in choosing such equipment, including compliance with local noise regulations, advanced noise reduction technologies, motor efficiency, safety considerations, and long-term maintenance strategies. By understanding these elements, communities can achieve sustainable wood waste management while minimizing disturbances to residents and adhering to environmental standards.

Noise Regulations and Restrictions for Urban Community Wood Recycling

Urban areas impose strict noise limits to maintain residential tranquility, typically requiring daytime noise levels to remain below 55 decibels measured on the A-weighted scale. These regulations are designed to prevent public nuisance and ensure that industrial activities like wood shredding do not disrupt daily life. Compliance with these rules is not optional; failure to adhere can result in legal penalties, community complaints, and operational shutdowns. Understanding the specific noise thresholds in your locality is the foundational step in selecting a shredder that aligns with urban living requirements.

Noise restrictions vary based on the time of day and the type of operation, with nighttime limits often being more stringent than daytime standards. For instance, many cities mandate that continuous noise from equipment like shredders must not exceed 50 dB(A) during night hours to protect sleep quality. Intermittent operations might have slightly higher allowances but still require careful management. Communities must consult municipal codes or environmental agencies to obtain precise data, as these standards are enforced through periodic monitoring and resident reporting.

Community Noise Standards and Measurement Methods

Noise levels are commonly measured using the A-weighted decibel scale, which approximates human hearing sensitivity by filtering out low-frequency sounds. The C-weighted scale is sometimes used for assessing broader environmental noise but is less relevant for community compliance. Accurate measurement involves placing sensors at designated points, such as property boundaries, and applying time-weighted averages to account for fluctuations. Urban noise assessments typically follow guidelines from organizations like the World Health Organization, which recommends average exposure levels of 55 dB(A) for daytime residential areas to prevent health impacts.

Local authorities provide noise limit data through online databases or public documents, enabling residents to verify compliance before purchasing equipment. Measurements should be conducted over representative periods, such as during peak shredder operation, to ensure accuracy. Standardized procedures, including the use of calibrated sound level meters, help in generating reliable reports that can be submitted for regulatory approval. Communities can also hire acoustic consultants to perform assessments and recommend mitigation strategies if initial readings exceed limits.

Differences in Noise Limits for Continuous and Intermittent Operation

Continuous operation of wood shredders is subject to stricter noise controls because sustained sounds are more likely to cause annoyance and health issues. Urban regulations often cap continuous noise at 55 dB(A) during the day, while intermittent noise might be allowed up to 60 dB(A) for short durations. The equivalent continuous noise level is a calculated metric that averages noise over time, accounting for both peak and quiet periods. This calculation helps determine whether a shredder's operational pattern meets legal requirements without necessitating constant monitoring.

Intermittent shredding, such as batch processing of wood waste, may have higher permissible levels due to its non-persistent nature. However, communities must still ensure that sudden noise spikes do not violate regulations. Tools like sound exposure level calculators can assist in predicting compliance based on shredder usage schedules. Operators should document run times and noise outputs to demonstrate adherence during inspections. Understanding these distinctions allows for better planning of shredding activities around community-sensitive hours, such as avoiding early mornings or late evenings.

Consequences of Violations and Complaint Handling Procedures

Violating noise regulations can lead to immediate fines, forced equipment cessation, or legal actions from affected residents. Penalties often escalate with repeated offenses, potentially resulting in permanent operational bans. The complaint process typically involves residents reporting disturbances to local authorities, who then conduct investigations and may issue corrective orders. Proactive measures, such as installing noise barriers or adjusting run times, can prevent such scenarios and foster positive community relations.

Communities should establish clear communication channels with neighbors to address concerns before they escalate into formal complaints. Documenting compliance efforts, such as regular noise checks and community meetings, can serve as evidence of due diligence. In some cases, mediation services are available to resolve disputes without legal intervention. Implementing a noise management plan that includes preemptive shutdowns during quiet hours demonstrates commitment to cooperative coexistence and reduces the risk of penalties.

Noise Mitigation Strategies for Community Compliance

Effective noise control involves combining equipment selection with operational practices to stay within regulatory limits. Enclosing shredders in sound-absorbing structures or positioning them away from residential boundaries can significantly reduce noise propagation. Regular maintenance of moving parts, such as blades and motors, prevents wear-induced noise increases. Communities might also invest in real-time noise monitoring systems that alert operators when levels approach thresholds, allowing for immediate adjustments.

Strategic scheduling of shredding activities during less sensitive times, like mid-morning or afternoon, minimizes disruption. Educational initiatives that inform residents about recycling benefits and noise control efforts can build tolerance and support. Some municipalities offer incentives for using low-noise equipment, such as reduced permit fees or grants. By integrating these strategies, urban wood recycling projects can operate efficiently while maintaining harmonious community relations.

Technical Principles of Low-Noise Waste Wood Shredders

Low-noise shredders incorporate multiple engineering innovations to reduce sound emissions without compromising performance. These designs focus on minimizing vibrations, optimizing cutting mechanisms, and containing noise within the equipment structure. Key components include advanced motor systems, precision-balanced blades, and robust enclosures that collectively lower acoustic output. Understanding these principles helps buyers distinguish genuinely quiet models from those with superficial marketing claims.

Noise reduction in shredders often stems from material science and mechanical design. For example, using composite materials for certain parts can dampen vibrations more effectively than metal alone. The integration of noise-absorbing foams or rubber isolators in critical areas further attenuates sound. Manufacturers conduct extensive testing to refine these elements, resulting in shredders that operate at noise levels 10-15 dB below conventional models, making them suitable for noise-sensitive urban settings.

Low-Noise Motors and Variable Speed Drives

Brushless DC motors and variable speed drives are central to noise reduction, as they operate more smoothly and quietly than traditional alternatives. These motors reduce mechanical friction and electromagnetic noise, contributing to overall sound levels as low as 50 dB(A) under optimal conditions. Variable speed technology allows the shredder to adjust power based on load, avoiding the high-noise peaks associated with fixed-speed operation during startup or heavy processing.

The efficiency of these motors also lowers energy consumption, with some models achieving noise reductions of up to 20% compared to standard engines. However, balancing noise control with power output requires careful engineering; undersized motors may strain and produce more noise when overloaded. Performance curves provided by manufacturers illustrate how noise levels change with speed, enabling users to select configurations that maintain quiet operation across typical workloads. Regular maintenance, such as lubrication and alignment checks, ensures sustained low-noise performance over time.

Blade Design and Vibration Dampening Structures

Optimized blade geometry, such as helical or staggered tooth patterns, reduces impact noise during wood cutting by distributing force more evenly. High-strength alloys or carbide-tipped blades maintain sharpness longer, minimizing the high-pitched sounds caused by dull edges. Vibration dampening is achieved through components like rubber-mounted bearings or suspended bases, which isolate shocks from the machine frame. These features can lower operational noise by 5-10 dB, making a noticeable difference in community environments.

Advanced shredders may include rotor assemblies with dynamic balancing to prevent wobble-induced noise. The use of anvil blocks or counter-knives in the cutting chamber further stabilizes the process, reducing erratic vibrations. Structural enhancements, such as reinforced frames, also contribute to noise control by preventing resonance. Buyers should request demonstration videos or on-site tests to verify these claims, as actual performance can vary based on wood type and moisture content.

Enclosure Soundproofing and Sealing Techniques

Double-walled enclosures with sound-absorbing fillers like mineral wool or polyurethane foam are effective at containing shredder noise. Seals around doors and joints prevent sound leakage, maintaining internal noise levels that are 10-15 dB lower than external readings. The choice of materials impacts both cost and durability; for instance, rubber gaskets offer better longevity than foam but may require more frequent inspections. Properly designed enclosures can reduce noise to below 55 dB(A) at a distance of one meter, meeting most urban standards.

Ventilation systems within enclosures must be engineered to allow airflow without compromising noise control, often using baffles or acoustic louvers. Regular checks for wear or damage to seals ensure ongoing effectiveness. In community settings, enclosures also serve safety functions by preventing access to moving parts. Manufacturers may provide noise certification reports, such as those based on ISO 3744 standards, to validate performance claims. Investing in high-quality enclosures typically adds 15-20% to equipment costs but is justified by long-term compliance and community acceptance.

Noise Testing and Certification Standards

International standards like ISO 3744 define procedures for measuring shredder noise in controlled environments, ensuring consistent and comparable data. These tests involve positioning microphones at specific angles and distances to capture sound power levels, which are then reported in decibels. Third-party certifications provide credibility, as they confirm that a shredder's noise output aligns with manufacturer specifications. Buyers should prioritize models with such certifications to avoid non-compliant equipment.

Interpreting test reports requires attention to details like measurement uncertainty and operating conditions during testing. For example, a shredder might be rated at 53 dB(A) under ideal lab settings but produce higher noise in real-world use due to variable wood types. Requesting supplementary data from field tests can offer a more accurate picture. Awareness of common misleading practices, such as reporting noise at idle instead of full load, helps in making informed decisions. Reliable suppliers will transparently share comprehensive test results upon request.

Material Selection for Noise Absorption

The use of viscoelastic materials in shredder construction enhances noise absorption by converting sound energy into heat. Components like polymer-lined hoppers or composite discharge chutes reduce reverberation and impact noise. These materials are chosen for their acoustic properties as well as durability, with some offering resistance to moisture and wear from wood debris. Innovations in material science have led to shredders that operate 8-12 dB quieter than earlier models.

Cost considerations often influence material choices; for instance, advanced composites may increase initial investment but reduce long-term maintenance needs. Suppliers might offer customization options to optimize noise control for specific community requirements. Regular inspections ensure that noise-absorbing materials remain intact and effective, as degradation can lead to gradual increases in sound levels. By prioritizing quality materials, users can extend the shredder's lifespan while maintaining low-noise operation.

Motor and Power Selection: Balancing Performance and Noise

Selecting the right motor is crucial for achieving a balance between shredding efficiency and noise control in community settings. Motors account for a significant portion of operational sound, and their design directly influences overall acoustic footprint. Factors such as power rating, speed variability, and cooling mechanisms must be evaluated to ensure compatibility with urban noise limits. An appropriately sized motor prevents overloading, which can cause excessive noise and premature wear.

Power requirements depend on the volume and type of wood waste processed; for example, hardwoods may demand higher torque than softwoods. Undersized motors struggle with heavy loads, leading to increased noise and energy consumption. Conversely, oversized motors operate inefficiently at partial capacity, wasting electricity and generating unnecessary sound. Energy-efficient models, though costlier upfront, can reduce operational expenses by 15-25% over their lifespan, making them economically viable for community projects.

Noise Differences Between Single-Phase and Three-Phase Motors

Single-phase motors are common in small-scale shredders due to their compatibility with standard residential power outlets, but they tend to produce more noise and vibration than

three-phase alternatives. Three-phase motors offer smoother operation and lower acoustic output, often by 3-5 dB, making them preferable for noise-sensitive areas. However, they

require access to industrial electrical systems, which may not be available in all communities. An assessment of local power infrastructure is necessary before selection.

Three-phase motors also exhibit better efficiency, with power factors exceeding 0.9 compared to 0.7-0.8 for single-phase models. This efficiency translates to reduced energy costs and heat generation, indirectly contributing to noise control. Communities should consult electricians to evaluate wiring upgrades if needed. In cases where three-phase power is impractical, single-phase motors with noise-dampening features can still meet regulations if paired with proper enclosures and operational controls.

Variable Speed Motors and Noise Curves

Variable speed motors allow shredders to adjust rotational speed based on the load, minimizing noise during light processing while maintaining power for dense materials. Noise curves graphically represent how sound levels change with speed, typically showing lower decibels at reduced RPMs. For instance, a shredder might operate at 58 dB(A) at full speed but drop to 52 dB(A) at half capacity, providing flexibility for community noise management.

Interpreting these curves requires understanding of typical workloads; selecting a motor that spends most of its time in quieter speed ranges optimizes noise compliance. Advanced models include programmable settings that automatically limit speed during sensitive hours. The initial cost of variable speed systems is offset by energy savings and extended equipment life. Buyers should request noise curve data from manufacturers and verify it through independent testing if possible.

Motor Efficiency and Energy Cost Considerations

High-efficiency motors, such as those meeting IE3 or IE4 standards, consume less electricity and produce less waste heat, reducing both operational costs and noise from cooling fans. Energy costs can account for up to 30% of a shredder's lifetime expenses, so investing in efficient models yields long-term savings. Simple calculations involving local electricity rates and annual usage hours help estimate payback periods, which often range from 2 to 5 years for premium motors.

Efficiency gains also contribute to noise reduction by minimizing strain on the motor and associated components. For example, a 10% improvement in efficiency might lower noise by 1-2 dB due to reduced vibration. Communities can leverage utility rebates or green incentives to offset higher upfront costs. Maintaining motors with regular servicing, such as bearing replacements and alignment checks, ensures that efficiency and noise performance remain optimal over time.

Motor Cooling Systems and Thermal Noise

Cooling fans are a common source of motor noise, particularly in air-cooled systems. Liquid cooling alternatives circulate coolant through sealed loops, operating more quietly and efficiently in confined spaces. Air-cooled motors might generate noise levels of 60-65 dB(A) from fans alone, whereas liquid-cooled versions can reduce this by 5-8 dB. The choice depends on the shredder's duty cycle and installation environment.

Thermal management is critical for noise control, as overheating can cause motors to labor and produce additional sound. Proper ventilation around the shredder prevents heat buildup, especially in enclosed areas like garages. Some models integrate temperature sensors that adjust cooling intensity based on real-time needs, avoiding constant high-noise fan operation. Communities should factor in cooling system maintenance, such as filter cleaning or coolant replacement, to sustain low-noise performance.

Safety Features and Community Suitability

Safety is paramount in community settings where shredders may be accessed by untrained individuals or located near public spaces. Designs that incorporate child-proof locks, low vibration, and electrical safeguards reduce accident risks and enhance public acceptance. These features not only protect users but also minimize liability and insurance costs for community organizations. A thorough evaluation of safety standards ensures that the shredder aligns with urban living requirements.

Vibration control is particularly important for installations in residential buildings, as excessive shaking can damage structures or cause discomfort. Shredders with balanced rotors and isolation mounts limit vibration transmission to floors and walls. Electrical safety measures, such as ground fault circuit interrupters, prevent shocks in damp environments. By prioritizing these aspects, communities can foster a safe recycling culture while complying with occupational health regulations.

Child-Proof Operation Designs

Safety locks and interlock systems prevent unauthorized operation by requiring keys or codes to start the shredder. Protective covers over moving parts, such as the feed opening or discharge chute, eliminate access to hazardous areas. These designs often comply with standards like EN 13857, which specifies safety distances to keep hands and tools away from danger zones. In community gardens or shared spaces, such features are essential for preventing accidents involving children or pets.

User interfaces with clear warning labels and emergency stop buttons enhance operational safety. Regular inspections ensure that safety mechanisms remain functional, as wear or tampering could compromise their effectiveness. Educational programs that teach proper shredder use to community members further reduce risks. Investing in robust safety designs may increase initial costs by 10-15% but is justified by the prevention of injuries and associated legal issues.

Low Vibration and Structural Integrity

Low-vibration shredders use dynamically balanced components and shock-absorbing materials to minimize force transfer to supporting surfaces. This is crucial for installations in basements or attached garages, where excessive vibration could crack walls or disturb neighbors. Structural integrity is maintained through heavy-duty frames and reinforced mounting points that distribute loads evenly. Vibration levels below 2.5 mm/s are generally acceptable for residential settings, as per industry guidelines.

Assessing a building's vibration tolerance involves consulting engineering reports or conducting simple tests before installation. Anti-vibration pads or floating foundations can be added to further isolate the equipment. Long-term vibration monitoring helps detect imbalances early, preventing damage and noise escalation. Communities should prioritize shredders with certified low-vibration ratings to ensure compatibility with urban infrastructure.

Electrical Safety and Grounding Requirements

Proper grounding and leakage protection are non-negotiable for community shredders, as they prevent electrical hazards in potentially wet or crowded environments. Ground fault circuit interrupters automatically cut power upon detecting current imbalances, reducing shock risks. Wiring should adhere to national electrical codes, with periodic inspections by qualified electricians to ensure ongoing compliance. These measures are especially important for outdoor or semi-outdoor installations.

Weatherproof enclosures protect electrical components from moisture and debris, extending their lifespan and maintaining safety. Communities should verify that shredders carry certifications like UL or CE, indicating conformity with international safety standards. Training operators on basic electrical safety, such as avoiding extension cords or overloading circuits, minimizes risks. Although safety features add to equipment costs, they prevent costly accidents and ensure uninterrupted recycling operations.

Noise and Vibration Monitoring Interfaces

Integrated sensors that track noise and vibration levels in real time provide data for compliance reporting and proactive maintenance. These interfaces can connect to community monitoring systems, alerting operators when thresholds are approached. For example, a dashboard might display live decibel readings, allowing adjustments before complaints arise. Such technology is increasingly affordable, with basic systems costing under $500 and offering substantial benefits in urban settings.

Data logged by these interfaces can be used to generate reports for regulatory bodies or community meetings. Wireless connectivity enables remote monitoring, reducing the need for on-site checks. Calibration of sensors ensures accuracy over time, with annual verifications recommended. By adopting monitoring solutions, communities demonstrate commitment to transparency and environmental stewardship, strengthening public trust in recycling initiatives.

Cost-Benefit Analysis and Budget Planning

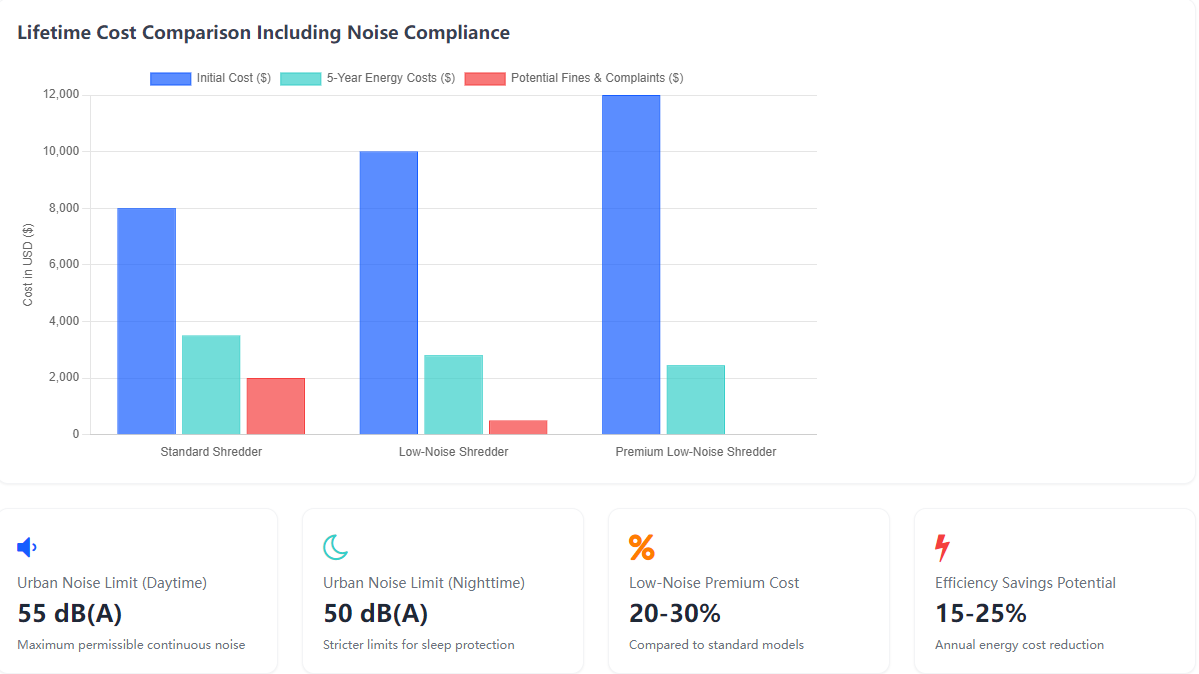

Low-noise shredders typically command a price premium of 20-30% over standard models, but their long-term benefits include regulatory compliance, reduced energy costs, and lower complaint-related expenses. A comprehensive cost-benefit analysis weighs these factors against initial investment to determine financial viability. Budget planning should account for installation, operation, and maintenance costs over the equipment's lifespan, which can exceed 10 years with proper care.

Indirect savings, such as avoided fines or enhanced community goodwill, are harder to quantify but equally important. For instance, a single noise violation fine might range from $500 to $2000, justifying the extra cost of a quieter model. Energy-efficient shredders can save hundreds of dollars annually in electricity bills, accelerating return on investment. Communities should use simple calculation tools to compare total cost of ownership across different options.

Initial Investment and Long-Term Savings

The upfront cost of a low-noise shredder includes the base price, taxes, and any customization fees. Long-term savings arise from lower energy consumption, reduced maintenance, and avoidance of penalties. A model costing $10,000 might save $1,500 per year in energy and compliance costs, yielding a payback period of 6-7 years. These calculations should be tailored to local utility rates and regulatory environments.

Durability also influences savings; high-quality shredders require fewer repairs and part replacements, lowering lifetime expenses. Warranties covering noise-related components provide additional financial security. Communities can use online calculators or consult vendors to generate personalized cost projections. Investing in a reliable shredder ultimately supports sustainable budgeting by minimizing unexpected costs.

Installation and Commissioning Expenses

Professional installation ensures that noise control features function as intended, with costs varying based on site complexity. Urban installations might require soundproofing modifications or electrical upgrades, adding $500 to $2000 to the budget. Commissioning involves testing the shredder under real conditions to verify noise levels and safety compliance. Skipping this step risks non-compliance and operational issues.

Obtaining multiple quotes from certified installers helps control costs while ensuring quality. Some suppliers offer package deals that include installation and initial training. Communities should factor in time delays for permits or inspections, which can extend project timelines. Proper planning prevents budget overruns and ensures a smooth transition to operational status.

Operational and Maintenance Costs

Annual operational costs include electricity, lubricants, and routine part replacements like blades or seals. Low-noise models may require specialized maintenance, such as replacing acoustic insulation every 3-5 years, at a cost of $200-$500 per service. Predictive maintenance schedules, based on usage hours, optimize spending by addressing issues before they escalate.

Maintenance contracts with suppliers can stabilize costs by covering regular servicing and emergency repairs. Communities should budget 2-3% of the initial equipment cost annually for upkeep. Tracking expenses through software or logs identifies trends and opportunities for savings. Efficient maintenance not only controls costs but also preserves noise performance over time.

Financing and Subsidy Opportunities

Grants, loans, or subsidies for green equipment are available from municipal programs or environmental organizations. These can cover 20-50% of the shredder's cost, making low-noise models more accessible. Applications typically require documentation of noise compliance and community benefits, such as reduced waste sent to landfills.

Financing options include leasing or installment plans that spread payments over several years. Interest rates and terms vary, so comparing offers is essential. Communities should research local incentives early in the planning process to incorporate them into budgets. Successful funding applications often highlight how the shredder supports broader sustainability goals, such as carbon reduction or public education.

Installation, Commissioning, and Community Communication

Proper installation is critical for achieving the advertised noise levels of a wood shredder. Site selection, foundation preparation, and acoustic enhancements all influence final sound emissions. Commissioning involves rigorous testing to ensure the equipment operates within specified parameters before regular use. Effective communication with residents addresses concerns preemptively, building support for the recycling initiative.

Installation in areas shielded from homes by barriers or distance reduces noise propagation. For example, placing the shredder in a rear yard with a solid fence can lower perceived noise by 3-5 dB. Commissioning tests should replicate real-world conditions, using typical wood types and load sizes. Sharing results with the community through meetings or reports fosters transparency and trust.

Site Selection and Soundproofing Measures

Choosing an installation site away from bedrooms and common areas minimizes noise impact. Soundproofing measures include erecting barriers made of mass-loaded vinyl or installing the shredder on vibration-damping pads. These steps can reduce external noise levels by up to 10 dB, ensuring compliance even in dense neighborhoods. Site assessments by acoustic experts identify optimal locations based on topography and building layouts.

Temporary soundproofing during installation prevents disturbances from construction noise. Permanent solutions, such as enclosing the shredder in a shed with acoustic lining, offer long-term benefits. Costs for these enhancements range from $1000 to $5000, depending on complexity. Communities should prioritize sites with existing infrastructure, like concrete pads, to reduce preparation expenses.

Commissioning and Noise Testing Procedures

Commissioning includes calibrating the shredder and verifying noise outputs using standardized methods. Third-party noise tests provide impartial data, with reports detailing measurements at multiple points around the equipment. These tests should be conducted during peak operation to capture worst-case scenarios. Results below local limits, such as 55 dB(A), confirm readiness for community use.

Adjustments based on commissioning findings, like tightening bolts or adding seals, fine-tune performance. Operators receive training on optimal settings to maintain low noise during routine use. Documenting the commissioning process creates a benchmark for future comparisons. Communities can use these records to demonstrate due diligence in regulatory reviews.

Community Engagement and Operational Agreements

Open dialogue with neighbors through meetings or newsletters explains the shredder's purpose and noise control measures. Agreements on run times, such as avoiding early mornings or weekends, prevent conflicts. Sample templates for these pacts include clauses for periodic reviews and conflict resolution. Positive engagement turns potential opponents into allies, enhancing project sustainability.

Educational tours or demonstrations show residents how the shredder benefits the community through waste reduction. Feedback mechanisms, like suggestion boxes or online forums, allow continuous improvement. Celebrating milestones, such as achieving noise compliance, reinforces positive relationships. Effective communication requires ongoing effort but pays dividends in community harmony.

Long-Term Monitoring and Compliance Documentation

Continuous noise monitoring using installed sensors or periodic manual checks ensures ongoing compliance. Data logs should be stored securely and reviewed monthly to identify trends. Compliance documentation includes noise reports, maintenance records, and community communication logs. These materials are invaluable during inspections or dispute resolutions.

Automated alerts notify operators of deviations, enabling prompt corrections. Cloud-based systems facilitate remote access to data for stakeholders. Communities should update monitoring protocols as regulations change. Proactive documentation not only ensures legal adherence but also builds a reputation for responsibility and innovation.

Maintenance Strategies and Long-Term Performance Retention

Regular maintenance is essential for preserving the low-noise characteristics of a wood shredder over its operational life. Scheduled inspections, part replacements, and performance checks prevent gradual increases in sound levels due to wear or misalignment. A well-maintained shredder can operate within 2-3 dB of its original noise rating for decades, providing consistent community benefits.

Maintenance plans should be tailored to usage intensity; for example, high-volume processing may require monthly checks, while occasional use might suffice with quarterly servicing. Key components like blades, motors, and enclosures need particular attention. Investing in predictive maintenance technologies, such as vibration analysis tools, detects issues early, reducing repair costs and downtime.

Inspection and Replacement of Sound-Absorbing Materials

Acoustic linings and seals degrade over time due to exposure to dust, moisture, or UV radiation. Visual inspections every six months identify cracks, gaps, or compression that reduce effectiveness. Replacing worn materials with identical or upgraded versions restores noise control performance. Costs for replacement parts vary but typically represent a small fraction of the initial investment.

Choosing durable materials, such as closed-cell foam or rubber, extends replacement intervals to 3-5 years. Proper installation during replacement ensures seamless integration with existing components. Communities can stock spare parts to minimize downtime. Documenting material conditions in maintenance logs tracks degradation rates and informs future budgeting.

Motor and Bearing Maintenance Protocols

Lubricating bearings according to manufacturer specifications reduces friction-related noise and extends lifespan. High-quality lubricants suitable for low-noise applications minimize viscosity changes under load. Motor inspections include checking alignment, cleaning cooling vents, and testing electrical connections. These steps prevent efficiency losses that could increase noise by 1-2 dB.

Bearing replacement schedules depend on operating hours; for instance, continuous-use shredders might need new bearings every 2000 hours. Using precision-balanced bearings ensures smooth operation. Maintenance records should note lubrication dates and any unusual sounds. Proactive care reduces the risk of catastrophic failures that could halt community recycling activities.

Blade Balancing and Sharpening Impact on Noise

Unbalanced blades cause vibrations that amplify noise and strain other components. Dynamic balancing machines detect imbalances and guide corrections. Sharp blades cut cleanly with less resistance, lowering operational noise by 3-5 dB compared to dull edges. Sharpening should follow original angle specifications to maintain efficiency.

Regular sharpening intervals depend on wood hardness; for mixed waste, every 50-100 hours of use is typical. Blade inspection includes checking for chips or warping that affect balance. Proper storage prevents corrosion or damage between services. Maintaining blade integrity is a cost-effective way to sustain low-noise performance without major investments.

Long-Term Performance Monitoring and Record-Keeping

Performance tracking using simple sensors or manual measurements provides data for trend analysis. Key metrics include noise levels, vibration amplitudes, and energy consumption. Records stored in digital formats allow easy retrieval for audits or troubleshooting. Consistent monitoring identifies gradual changes that might otherwise go unnoticed.

Mobile apps or cloud platforms enable real-time data sharing with maintenance teams. Setting performance benchmarks during commissioning facilitates comparisons. Communities should review records annually to update maintenance strategies. This systematic approach ensures that the shredder remains a reliable, quiet asset for urban recycling efforts.