An industrial wood shredder is a significant capital investment for any recycling or waste management operation. These powerful machines, designed to shear and tear through tough woody biomass, are subjected to extreme forces and abrasive materials daily. Without a proper maintenance strategy, the lifespan of these critical assets can be drastically shortened, leading to frequent breakdowns, costly repairs, and unexpected downtime that disrupts entire operations. Proactive and preventive maintenance is not merely a recommendation; it is an essential practice that ensures operational reliability, protects your investment, and maximizes the return over the machine's entire service life. A well-maintained shredder can often operate efficiently for over 15,000 hours before requiring a major overhaul.

The Importance and Strategy of Preventive Maintenance

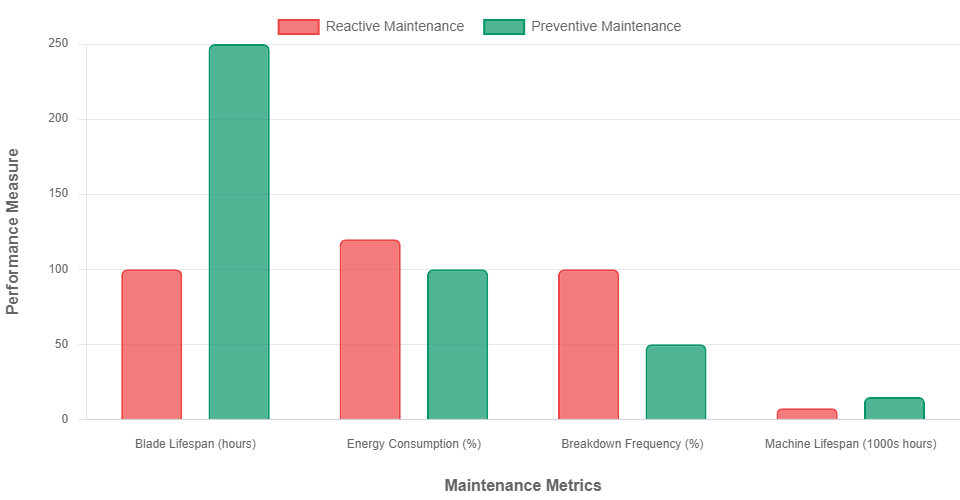

Preventive maintenance is a systematic approach focused on preventing equipment failure before it actually occurs. For a wood shredder, this involves a scheduled plan of inspections, servicing, and parts replacement based on either time intervals or hours of operation. This strategy contrasts sharply with reactive maintenance, where actions are only taken after a failure has happened. The core philosophy is that the small, planned cost of regular upkeep is vastly preferable to the large, unplanned costs associated with major breakdowns, which can include not just repair bills but also lost production and rushed shipping fees for parts.

Implementing a robust preventive maintenance program requires careful planning and documentation. It begins with understanding the machine's critical components and their expected lifespans under normal operating conditions. This program should be a living document, accessible to all relevant personnel, and integrated into the daily workflow. The ultimate goal is to create a predictable rhythm of care that aligns with production schedules, minimizing disruption and creating a culture of responsibility and awareness around equipment health.

The Necessity of Regular Inspection and Wear Parts Replacement

The cutting components of a shredder, such as the cutting blades and the screen grate, are consumable items designed to be replaced. These parts are in constant contact with abrasive material, and their sharp edges gradually dull, while their physical mass decreases due to wear. Operating a shredder with worn-down blades forces the motor to work harder, increasing energy consumption by up to 20% and putting undue stress on the rotor assembly and drive train. Regular inspection allows operators to monitor this wear and schedule replacements during planned downtime.

Predicting the lifespan of these wear parts depends on the material being processed. Shredding clean softwood may allow blades to last for 200-250 operating hours, while processing contaminated construction debris or hardwoods might reduce that to 100 hours or less. By tracking hours of operation and periodically visually inspecting these components, a reliable replacement cycle can be established. Keeping a stock of critical wear parts on hand is a best practice that ensures a quick swap-out, often completing the replacement in a few hours rather than waiting days for a shipped part.

Methods for Monitoring Machine Operating Status and Performance Indicators

Modern industrial shredders are increasingly equipped with sophisticated monitoring systems that provide a continuous stream of data on machine health. Sensors can track amperage draw of the main motor, which directly indicates the load on the system. A sudden, sustained spike in amperage could signal a jam or an attempt to process an overly large or dense load. Vibration sensors mounted on bearings can detect anomalies long before a human operator would hear or feel a problem, providing an early warning of impending bearing failure.

Analyzing this data over time reveals valuable trends. For instance, a gradual increase in the average amperage required to process the same type of material might indicate that the blades are dulling and need to be rotated or replaced. Monitoring hydraulic pressure and temperature can prevent catastrophic system failures. This data-driven approach transforms maintenance from a subjective, experience-based task into an objective, predictive science, enabling interventions to be scheduled at the most optimal time, maximizing part life without risking a breakdown.

Key Measures for Timely Repair and Adjustment

Even with an excellent preventive maintenance program, unexpected issues can arise. The difference between a minor incident and a major disaster is often the speed and quality of the response. Timely repair involves addressing small problems before they escalate into large ones. This requires a keen eye from operators and a protocol that empowers them to act when they notice abnormalities, such as unusual noises, smells, or changes in the sound of the machine's operation.

Adjustments are a key part of optimizing shredder performance. Machine settings are not "set it and forget it." Factors like changes in the moisture content of the wood (e.g., fresh green waste vs. seasoned dry pallets) or variations in the size and type of feedstock can necessitate adjustments to the feed rate, rotor speed, or even the clearance between cutting blades. These fine-tuning adjustments ensure the machine is always operating at its peak efficiency, producing a consistent output size while minimizing wear and energy use.

Quick Action in Response to Fault Alarms and Abnormal Phenomena

When a shredder's control system triggers a fault alarm, immediate action is required. The first and most critical step is to safely and immediately stop the feed system and then stop the shredder rotor. Ignoring an alarm and continuing to run the machine can turn a simple fix into a catastrophic failure. For example, an overload alarm might be resolved by simply reversing the rotor to clear a minor jam. If ignored, it could lead to a stalled rotor, potentially shearing a critical pin or damaging the gearbox, resulting in repairs that cost tens of thousands of dollars.

After shutdown, operators should follow a logical troubleshooting procedure to identify the root cause. Consulting the machine's manual is essential. Once the issue is identified, temporary measures might be necessary to safely remove the offending material or isolate the problem before full repairs can be made. This process should always prioritize safety, ensuring all energy sources are locked out before any hands-on inspection or work is performed inside the cutting chamber.

Optimizing Performance and Efficiency by Adjusting Machine Parameters

The efficiency of a shredder is highly dependent on how it is fed and configured. For instance, feeding a mix of large branches and fine twigs simultaneously can cause uneven loading and inefficient processing. Adjusting the feed rate to match the density and size of the material is crucial; dense hardwoods should be fed more slowly than light, bulky softwoods. Many modern shredders feature hydraulic or variable frequency drive systems that allow the rotor speed to be adjusted, providing another lever to optimize performance for different materials.

The physical setup of the machine is equally important. The clearance between the tips of the rotating knives and the stationary anvil block is a critical setting that affects both output size and wear. A smaller clearance produces a finer grind but increases wear and energy consumption. Conversely, a larger clearance reduces wear but may result in an unacceptably coarse output. Similarly, changing the screen grate size is necessary to achieve different final product specifications. Regularly checking and adjusting these parameters ensures the shredder is always working as intended.

Operational Best Practices to Reduce Wear and Failure

How a shredder is operated on a daily basis has the single greatest impact on its long-term health and maintenance costs. Proper operation is the first and most effective line of defense against premature wear and unscheduled downtime. Best practices are designed to keep the machine operating within its designed parameters, avoiding the extreme stresses that lead to accelerated component failure. Training every operator to a high standard creates a culture of ownership and care that permeates the entire operation.

These practices extend beyond the act of shredding itself. They encompass the entire environment around the machine, including housekeeping, material preparation, and even how the machine is started up and shut down at the beginning and end of a shift. Consistent application of these simple, yet effective, routines can double the lifespan of wear parts and prevent up to 50% of common mechanical issues, delivering significant savings on maintenance and operational costs.

Methods and Precautions for Correct Feeding

Uniform feeding is the golden rule of shredder operation. The hopper should be loaded in a way that allows the feed rollers to grab material consistently and evenly. Overloading the hopper can overwhelm the system, leading to jams and erratic operation. Conversely, trickle-feeding the machine underutilizes its capacity and can cause the cutting elements to rub against each other without material, leading to unnecessary wear. Using equipment like a wheel loader or a conveyor to maintain a steady, even flow of material into the hopper is ideal.

The physical characteristics of the feed material must also be considered. Most shredders have maximum allowable dimensions; feeding oversize logs can damage the feed mechanism and the rotor. Material should also be inspected for contaminants like metals, rocks, or large amounts of soil, which are highly abrasive and can cause immediate and severe damage to the cutting chamber. Pre-processing or pre-sorting feedstock to remove these contaminants is a crucial step in protecting the shredder.

The Importance of Maintaining a Clean and Dry Environment

Wood dust and debris are more than just a housekeeping issue; they are a operational hazard. Accumulated dust around bearings can trap heat, causing them to overheat and fail prematurely. Dust infiltrating hydraulic systems can contaminate fluid and damage sensitive valves and pumps. Perhaps most seriously, fine wood dust is highly combustible. A spark from a metal contaminant or an overheated bearing can ignite a dust cloud, leading to a flash fire or explosion. Therefore, regularly cleaning the machine, its immediate surroundings, and its cooling fins is a critical safety and maintenance task.

Moisture is the enemy of any industrial machinery. Operating a shredder in a consistently wet or humid environment accelerates corrosion on the frame, electrical components, and the inside of the cutting chamber. Rust on the chamber walls adds a highly abrasive element to the processing stream, rapidly wearing down blades. Whenever possible, shredders should be operated under cover or in a well-ventilated building. If outdoor operation is necessary, using protective covers when the machine is not in use and ensuring water cannot pool on or in the machine will significantly extend its life.

Key Maintenance Points During Long-Term Storage and Idle Periods

Properly preparing a shredder for an extended period of inactivity is just as important as maintaining it during active use. A machine left sitting without preparation is vulnerable to corrosion, lubricant degradation, and vermin infestation, which can lead to significant problems when it's time to restart. Whether the downtime is for a seasonal closure or a prolonged market shift, a deliberate preservation process will ensure the shredder is ready for reliable service when needed.

The storage environment plays a crucial role. An ideal location is a clean, dry, and well-ventilated indoor space. If outdoor storage is the only option, the machine should be elevated on blocks to keep it off the damp ground and covered with a breathable, waterproof tarp to protect it from the elements while allowing moisture to escape. The goal of storage preparation is to create a stable, protected state that halts the processes of wear and decay until the machine is called back into action.

Steps and Methods for Cleaning the Machine and Applying Anti-Rust Oil

The first step in long-term storage is a thorough and complete cleaning. All residual wood chips, dust, and debris must be removed from the hopper, the cutting chamber, the discharge conveyor, and all external surfaces. High-pressure air or water can be used, but if water is used, it is critical to allow the machine to dry completely afterward to prevent trapping moisture. Pay special attention to hidden areas where material can accumulate, such as around bearings and inside guards.

Once the machine is clean and dry, the next step is to protect all exposed metal surfaces from corrosion. This is done by applying a thin layer of anti-rust oil or a specialized preservative spray. Key areas to focus on include the polished surfaces of the rotor shaft, the interior of the cutting chamber, the hydraulic cylinder rods, and any other unpainted or vulnerable metal parts. This coating acts as a barrier, preventing air and moisture from reaching the metal surface and initiating rust.

Strategy for Regularly Starting the Machine to Prevent Component Rust

For storage periods longer than a month, a periodic starting and running schedule is highly beneficial. The goal is not to process material but to circulate fluids and protect internal components. Every four to six weeks, start the shredder and allow it to run at idle speed until it reaches normal operating temperature. This process accomplishes several important tasks: it circulates oil to coat and protect internal engine and hydraulic components, prevents seals from drying out and cracking, and charges the battery.

This running period also provides an opportunity to exercise the machine's functions. Slowly engage the feed system and rotor (ensuring the chamber is empty) to circulate hydraulic fluid through all valves and cylinders. Listen for any unusual noises and monitor instrument readings for any anomalies. This "exercise" helps identify any issues that may have developed during storage, allowing them to be addressed before the machine is needed for full production. Keeping a log of these maintenance runs ensures the schedule is adhered to and provides a valuable history of the machine's idle period.