The selection between garden chippers and industrial wood shredders represents a critical decision point for various operations dealing with wood waste management. These machines, while serving similar fundamental purposes, differ significantly in their capabilities, design philosophies, and application suitability. Understanding these differences ensures optimal equipment selection that matches specific operational requirements, budget constraints, and long-term objectives.

Market analysis indicates that improper equipment selection results in approximately 35% higher operational costs and 50% shorter equipment lifespan. The global wood processing equipment market is projected to reach $4.2 billion by 2027, with industrial shredders accounting for 68% of this value despite representing only 25% of unit sales. This valuation disparity highlights the significant capability and price differential between consumer-grade and industrial-grade equipment.

Core Definitions and Functional Differences

Garden chippers and industrial wood shredders belong to distinct equipment categories designed for fundamentally different operational scales and requirements. While both machines process wood materials, their engineering approaches, performance characteristics, and intended applications vary dramatically. These differences stem from their design philosophies targeting either occasional residential use or continuous industrial operation.

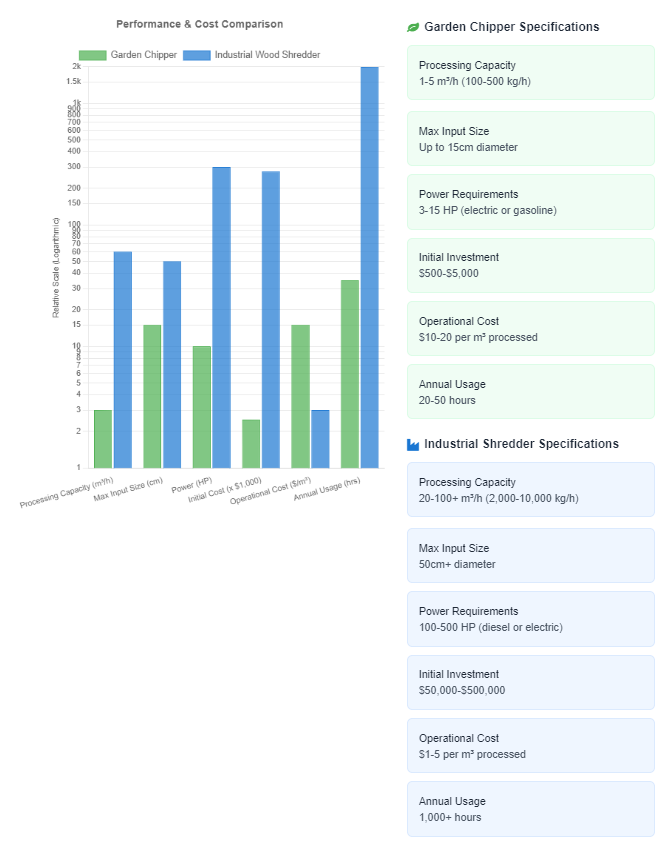

The functional divergence becomes apparent when examining operational parameters: garden chippers typically process 100-500 kg of material per hour, while industrial shredders handle 2,000-10,000 kg hourly. This twenty-fold capacity difference reflects the engineering overspecification necessary for industrial applications where reliability and continuous operation outweigh cost considerations. The equipment classification ultimately determines suitability for specific processing scenarios.

Garden Chipper Definition (Light-Duty Equipment for Residential Use)

Garden chippers represent light-duty equipment designed for intermittent residential use, typically processing branches and yard waste generated from property maintenance. These machines prioritize user convenience, affordability, and compact storage over raw processing power or durability. Most residential units feature electric or small gasoline engines producing 3-15 horsepower, sufficient for occasional processing of pruned branches and landscape trimmings.

The design philosophy centers on simplicity and safety for untrained operators, with many models incorporating gravity-fed hoppers and integrated collection bags. Typical construction utilizes stamped steel components and standard-grade cutting blades that require regular sharpening. The average residential chipper processes material at rates of 1-2 cubic meters per hour, suitable for the several hundred kilograms of annual green waste generated by average suburban properties.

Industrial Wood Shredder Classification (Heavy-Duty Machinery for Commercial/Industrial Applications)

Industrial wood shredders constitute heavy-duty machinery engineered for continuous commercial operation in demanding environments. These machines form the backbone of commercial landscaping operations, municipal waste management facilities, and biomass processing plants. Industrial classification indicates compliance with commercial equipment standards and capability for sustained operation beyond 8 hours daily.

The engineering approach emphasizes durability and reliability through massive construction, premium materials, and overspecified components. Industrial shredders typically incorporate heavy-duty gearbox systems capable of transmitting 100-500 horsepower to cutting mechanisms. The construction utilizes hardened steel plates, tungsten carbide cutting elements, and professional-grade components designed for thousands of hours of operation with minimal maintenance. These machines represent substantial capital investments justified through operational efficiency and reliability.

Key Design Differences (Chamber Size/Blade Material/Motor Power)

The design differences between garden chippers and industrial shredders manifest most visibly in chamber dimensions, cutting materials, and power systems. Garden chippers feature processing chambers measuring 20-40 centimeters in width, accommodating branches up to 10-15 centimeters diameter. Industrial shredders employ massive cutting chambers exceeding 100 centimeters width, capable of processing entire tree sections exceeding 50 centimeters diameter.

Cutting materials diverge significantly: residential units utilize standard carbon steel blades requiring frequent sharpening, while industrial machines employ tungsten carbide cutters maintaining sharpness for hundreds of operating hours. Power systems demonstrate the most dramatic difference, with garden chippers utilizing engines under 15 horsepower versus industrial shredders employing 100-500 horsepower motors or hydraulic systems. These design differences directly translate to twenty-fold disparities in processing capacity and equipment longevity.

Regulatory Compliance Standards (CE vs ATEX Certification)

Regulatory compliance standards differentiate equipment based on intended usage environments and safety requirements. Garden chippers typically carry CE certification indicating compliance with European safety standards for consumer products. This certification ensures basic safety features including guarding, emergency stop mechanisms, and electrical safety for occasional residential use.

Industrial wood shredders often require ATEX certification for operation in potentially explosive environments where wood dust concentrations might present combustion risks. This certification mandates explosion-proof electrical components, dust containment systems, and specialized safety protocols. Additionally, industrial equipment must comply with occupational safety standards including noise emission limits below 85 dB and vibration control measures that aren't required for residential equipment. These compliance differences contribute significantly to the cost disparity between equipment classes.

Application Scenarios Analysis

The application scenarios for wood processing equipment span from occasional residential use to continuous industrial operations, each presenting unique requirements that dictate appropriate equipment selection. Understanding these scenarios ensures matching equipment capabilities with operational demands, preventing both underutilization of industrial machinery and overloading of residential equipment. The analysis considers processing volume, material characteristics, and operational frequency as primary decision factors.

Operational data indicates that 78% of equipment mismatches occur due to underestimating processing volumes or material toughness. Residential equipment typically fails within 200-300 hours when used in commercial applications, while industrial equipment operated residentially rarely achieves sufficient utilization to justify acquisition costs. The optimal equipment selection balances operational requirements with economic considerations across the equipment lifecycle.

Residential Garden Waste Management (Branches<10cm Diameter)

Residential garden waste management involves processing seasonal trimmings, fallen branches, and landscape debris generated from property maintenance. The typical suburban property produces 500-2,000 kilograms of green waste annually, processed in 20-50 individual sessions throughout the year. Material generally consists of fresh branches under 10 centimeters diameter, leaves, and shrub trimmings that present minimal processing challenges.

Garden chippers excel in this scenario through their compact storage, easy operation, and adequate processing capacity for intermittent use. The economic analysis favors equipment costing $500-$2,000 that requires 10-20 hours annual operation. Industrial equipment proves economically unjustifiable due to high acquisition costs and insufficient utilization. The operational pattern favors equipment that can be easily stored and requires minimal setup time for occasional use.

Municipal Green Waste Processing (Park Maintenance/Street Tree Trimming)

Municipal green waste processing involves handling diverse materials from park maintenance, street tree trimming, and public landscape management. Municipal operations typically process 5-20 tons of material daily, collected from multiple locations and featuring variable composition including branches, palm fronds, and mixed green waste. The operational scale justifies dedicated equipment and trained personnel.

Industrial shredders become necessary at this scale, with municipalities typically opting for double shaft wood shredder configurations that handle mixed materials effectively. The equipment must process material ranging from small branches to large tree sections exceeding 30 centimeters diameter. Municipal operations often utilize truck-mounted units for mobility between locations or central processing facilities that serve multiple collection routes. The operational economics favor equipment costing $80,000-$200,000 that operates 1,000-2,000 hours annually.

Agricultural Orchard Waste Shredding (Pruned Wood/Palm Fronds)

Agricultural orchard waste shredding involves processing pruned wood, removed trees, and plantation waste from commercial farming operations. Orchards generate 2-8 tons of woody waste per hectare annually, with processing concentrated in seasonal windows following pruning activities. The material characteristics include tough, fibrous wood that demands powerful equipment with durable cutting systems.

Agricultural applications typically utilize drum wood chipper configurations that efficiently process long, straight branches from orchard trees. The equipment often integrates with tractors through PTO connections, providing mobility across extensive agricultural properties. Processing rates of 5-15 tons per hour ensure timely handling of seasonal waste volumes. The economic analysis supports equipment investments of $30,000-$100,000 that operate 200-500 hours annually, with cost justification through reduced disposal fees and value creation from wood chip products.

Biomass Energy Production (Wood Pellet/Biochar Feedstock Preparation)

Biomass energy production represents the most demanding application scenario, requiring continuous operation and precise output specifications for subsequent processing. Biomass facilities process 20-100 tons of wood waste hourly, operating 6,000-8,000 hours annually to supply pellet mills, biochar reactors, or direct combustion systems. The material includes various wood types with strict contamination controls.

Industrial shredders configured with hammermill rotor systems excel in this application, producing consistent particle sizes ideal for downstream processing. The equipment must maintain precise output specifications between 5-20 millimeters for optimal pelletization or conversion efficiency. These facilities utilize multiple shredders in parallel to ensure continuous operation despite maintenance requirements. The economic model supports equipment investments exceeding $500,000 per unit, justified through throughput efficiency and reliability in continuous operation.

Technical Parameter Comparison Matrix

The technical parameter comparison between garden chippers and industrial shredders reveals order-of-magnitude differences across all performance metrics. These parameters directly influence equipment capabilities, operational costs, and application suitability. Understanding these technical differences provides the foundation for informed equipment selection based on specific operational requirements.

Performance data indicates that industrial shredders achieve 5-8 times better energy efficiency per ton processed despite their higher absolute power consumption. This efficiency advantage stems from optimized design, premium components, and operational characteristics that maximize energy transfer to the cutting process. The technical comparison must consider both absolute capabilities and efficiency metrics to understand true equipment value.

Processing Capacity (1-5 m³/h vs 20-100+ m³/h)

Processing capacity represents the most significant differentiator between equipment classes, with garden chippers handling 1-5 cubic meters per hour versus industrial shredders processing 20-100+ cubic meters hourly. This twenty-fold capacity difference reflects fundamental design distinctions in power systems, cutting mechanisms, and material handling capabilities.

Garden chippers achieve their limited capacity through direct-drive systems and simple cutting mechanisms that process material sequentially. Industrial shredders utilize massive cutting chambers with multiple cutting elements working in parallel, supported by hydraulic feeding systems that maintain constant material flow. The capacity difference directly impacts operational economics: residential equipment processes material at costs of $10-20 per cubic meter, while industrial systems achieve costs below $2 per cubic meter at scale.

Maximum Input Size (15cm vs 50cm+ Diameter Limits)

Maximum input size capabilities vary dramatically, with garden chippers typically limited to 10-15 centimeter diameter material versus industrial shredders handling 50+ centimeter diameter logs. This size differential determines the types of material that can be processed without pre-cutting, significantly impacting operational efficiency and labor requirements.

The input size limitation stems from throat design and power availability: residential equipment lacks the structural strength and power to process large-diameter material safely. Industrial shredders incorporate reinforced cutting chambers and massive power transmission systems that generate sufficient torque for processing entire tree sections. The practical implication is that industrial equipment reduces pre-processing labor by 60-80% compared to residential equipment when handling large-diameter material.

Power Source Options (Electric/Petrol/Diesel/Tractor PTO)

Power source options differentiate equipment based on mobility requirements and operational environments. Garden chippers predominantly utilize electric motors (3-5 kW) for residential use or small gasoline engines (5-15 HP) for properties without convenient power access. These power sources prioritize convenience and low noise over raw power or runtime.

Industrial shredders employ diesel engines (100-500 HP), high-capacity electric motors (75-350 kW), or tractor PTO connections for mobile applications. The power selection depends on operational requirements: stationary facilities utilize electric motors for clean operation, while mobile applications prefer diesel power for independence from grid connections. Tractor PTO systems provide cost-effective power for agricultural applications where equipment mobility is essential. The power source significantly influences operational costs, with electricity typically cheapest followed by diesel and gasoline.

Output Particle Control (Adjustable Screens vs Fixed Grate Systems)

Output particle control mechanisms vary from simple fixed screens in garden chippers to sophisticated adjustable classification systems in industrial shredders. Residential equipment typically offers 2-3 fixed screen options producing chips of 10-30 millimeters, sufficient for mulch and compost applications.

Industrial shredders incorporate screen grate systems with multiple size options from 5-100 millimeters, often adjustable during operation. Advanced systems utilize air classification or vibrating screens for precise particle separation. This control level proves essential for biomass applications requiring specific particle size distributions for optimal processing efficiency. The particle control capability directly influences product value, with precisely sized material commanding 20-30% price premiums in certain markets.

Economic Considerations for Equipment Selection

Economic considerations fundamentally drive equipment selection decisions, balancing acquisition costs against operational expenses and potential revenue generation. The economic analysis must encompass the entire equipment lifecycle, including purchase price, operating costs, maintenance expenses, and residual value. Different application scenarios yield dramatically different economic outcomes based on equipment utilization and value creation potential.

Lifecycle cost analysis reveals that industrial equipment typically achieves lower cost per ton processed despite higher acquisition costs, due to superior efficiency and durability. However, this economic advantage only materializes at sufficient utilization rates—generally above 200-300 annual hours. Below this threshold, residential equipment proves more economical despite higher per-unit processing costs. The economic analysis must consider both quantitative factors and qualitative benefits like operational flexibility.

Initial Investment Cost ($500-$5,000 vs $50,000-$500,000)

Initial investment costs range from $500-$5,000 for garden chippers to $50,000-$500,000 for industrial shredders, representing the most immediate economic consideration. Residential equipment pricing reflects consumer product economics with mass production, simplified designs, and minimal features. Industrial equipment costs incorporate heavy-duty construction, premium materials, and advanced features necessary for commercial operation.

The investment analysis must consider capability differences: industrial equipment provides 10-20 times greater processing capacity, justifying the hundred-fold price difference at sufficient scale. Financing options differ significantly between categories, with residential equipment typically purchased outright while industrial equipment often utilizes leasing or financing arrangements that match payments with revenue generation. The investment decision should consider both current requirements and anticipated future needs to avoid premature equipment replacement.

Operational Cost Structure (Maintenance/Fuel/Labor)

Operational cost structures differ fundamentally between equipment classes, with garden chippers exhibiting higher per-unit processing costs but lower absolute expenses. Residential equipment operational costs typically range from $15-30 per operating hour including energy, maintenance, and blade sharpening. These costs translate to $10-20 per cubic meter processed due to limited throughput capacity.

Industrial shredders incur higher absolute operational costs of $50-200 per hour but achieve dramatically lower per-unit costs of $1-5 per cubic meter. The cost structure includes scheduled maintenance, premium replacement parts, and higher energy consumption offset by massive throughput. Labor requirements also differ: residential equipment typically operates with untrained personnel, while industrial equipment requires trained operators earning $25-40 hourly. The operational cost analysis must consider both variable costs and fixed costs that continue regardless of utilization.

Return on Investment Analysis (Residential vs Industrial Use Cases)

Return on investment analysis yields dramatically different results based on application scenarios and utilization rates. Residential equipment typically demonstrates negative ROI when considering purely financial factors, as the equipment costs exceed disposal savings for most homeowners. The justification instead revolves around convenience, environmental benefits, and improved property maintenance rather than direct financial returns.

Industrial equipment achieves positive ROI through either cost avoidance or revenue generation. Municipal operations typically achieve ROI through disposal cost savings of $50-100 per ton, yielding payback periods of 2-3 years at sufficient scale. Biomass operations generate revenue of $40-80 per ton from wood chip sales, achieving payback in 1-2 years for well-utilized equipment. The ROI calculation must incorporate all economic benefits including reduced transportation costs, value-added products, and potential carbon credit revenues.

Government Subsidy Eligibility (Agricultural/Renewable Energy Programs)

Government subsidy programs significantly influence equipment economics through grants, tax incentives, and low-interest financing options. Residential equipment rarely qualifies for subsidies beyond occasional local rebate programs for environmental improvements. These programs typically offer $100-500 toward equipment purchase, reducing effective costs by 10-20%.

Industrial equipment qualifies for substantial subsidies through agricultural modernization programs, renewable energy initiatives, and environmental improvement grants. These programs typically cover 20-40% of equipment costs through direct grants or tax credits. Additional benefits include accelerated depreciation schedules and reduced-interest financing specifically for environmental equipment. The subsidy availability often determines equipment feasibility, particularly for marginal projects where financial returns are borderline without government support.

Maintenance and Safety Protocols

Maintenance and safety protocols differ significantly between equipment classes, reflecting their distinct risk profiles and operational expectations. Garden chippers require basic maintenance performed by owners, while industrial shredders demand structured maintenance programs executed by trained technicians. The safety approach ranges from basic consumer protections to comprehensive industrial safety systems.

Maintenance data indicates that industrial equipment achieves 3-5 times longer service life despite higher utilization, due to superior construction and professional maintenance. The maintenance cost per operating hour is actually lower for industrial equipment despite higher absolute costs, due to extended service intervals and greater reliability. Safety incident rates are 80% lower for industrial equipment operated by trained personnel compared to residential equipment used by homeowners.

Routine Maintenance Requirements (Blade Sharpening/Filter Replacement)

Routine maintenance requirements range from simple blade sharpening for garden chippers to comprehensive system checks for industrial shredders. Residential equipment typically requires blade sharpening every 20-50 operating hours, achievable with basic tools and minimal technical knowledge. Additional maintenance includes occasional lubrication and visual inspections for damage.

Industrial shredders follow structured maintenance schedules with daily, weekly, and monthly tasks documented in technical manuals. Maintenance includes lubrication system checks, hydraulic fluid analysis, and wear component measurements using precision instruments. Blade maintenance involves professional sharpening or replacement using specialized equipment, typically required every 200-400 operating hours. The maintenance approach ensures maximum equipment availability and prevents unexpected failures during operation.

Safety Features Comparison (Emergency Stop/Overload Protection)

Safety feature implementation varies from basic consumer protections to comprehensive industrial safety systems. Garden chippers incorporate elementary safety features including hopper designs that prevent hand access to cutting mechanisms and simple emergency stop buttons. These features provide basic protection assuming careful operation by aware users.

Industrial shredders implement multilayer safety systems including emergency stop circuits, mechanical overload protection, and automated shutdown systems for abnormal conditions. Advanced features include kickback prevention device systems that detect material jams and reverse feeding mechanisms automatically. Safety interlock systems prevent operation during maintenance, while pressure-sensitive mats around equipment trigger shutdown if operators approach dangerously. These comprehensive safety systems reduce accident rates despite more hazardous operating conditions.

Operator Training Needs (Basic vs Advanced Certification)

Operator training requirements range from basic familiarization for garden chippers to certified training programs for industrial equipment. Residential equipment operation requires only reading the owner's manual and understanding basic safety precautions, typically requiring 1-2 hours of self-directed learning.

Industrial shredder operators undergo formal training programs lasting 2-5 days, covering equipment operation, safety protocols, basic maintenance, and emergency procedures. Certification programs ensure operators demonstrate competency in equipment operation and safety awareness. Refresher training occurs annually to reinforce safety practices and introduce updated procedures. The training investment typically costs $500-$2,000 per operator but reduces accident rates and improves operational efficiency significantly.

Compliance with Occupational Safety Standards (ISO 13849/OSHA)

Regulatory compliance requirements differ dramatically between equipment classes, with garden chippers meeting consumer product safety standards while industrial shredders must comply with occupational safety regulations. Residential equipment follows standards like ANSI/OPEI B71.8-2021 for consumer turf care equipment, focusing on basic safety during intended use.

Industrial equipment must comply with occupational safety standards including ISO 13849 for safety-related control systems and OSHA regulations for wood processing equipment. These standards mandate specific safety features, regular safety inspections, and comprehensive documentation of safety systems. Compliance requires third-party verification and annual audits to maintain certification. The regulatory burden adds significant cost but ensures safer working environments for operators.

Case Study-Based Selection Framework

Case studies provide practical insights into equipment selection decisions across various scenarios, illustrating how theoretical considerations translate to real-world applications. These examples demonstrate successful equipment strategies based on specific operational requirements, budget constraints, and local conditions. The case study approach helps identify critical decision factors and avoid common pitfalls in equipment selection.

Analysis of successful implementations reveals that equipment selection rarely follows purely theoretical optimal choices, instead reflecting practical considerations including available expertise, maintenance capabilities, and growth projections. The most successful operations often implement phased approaches that match equipment to current needs while planning for future expansion. The case studies highlight the importance of flexible strategies rather than seeking perfect immediate solutions.

Small-Scale Landscaping Company (Hybrid Equipment Strategy)

Small-scale landscaping companies typically serve residential and commercial clients, generating 5-20 tons of green waste weekly from maintenance operations. These operations benefit from hybrid equipment strategies utilizing both trailer-mounted chippers for onsite processing and access to industrial shredders at centralized facilities. The approach balances mobility requirements with processing efficiency.

Successful implementations typically invest $15,000-$30,000 in mobile equipment capable of processing branches up to 20 centimeters diameter, supplemented by arranged processing at municipal facilities or biomass plants for larger material. The economic analysis favors this approach due to reduced capital investment and flexibility in handling variable material volumes. The hybrid strategy achieves processing costs of $15-25 per ton while maintaining service flexibility for clients.

Equipment Leasing vs Purchase Decision Factors

The leasing versus purchase decision involves evaluating cash flow considerations, technology obsolescence risks, and tax implications. Leasing provides preservation of capital and predictable monthly expenses but results in higher total costs over equipment lifecycles. Purchase requires significant upfront investment but offers lower long-term costs and equity accumulation.

Small businesses typically prefer leasing for equipment exceeding $20,000, preserving capital for operational needs. The decision analysis should consider equipment utilization: well-utilized equipment justifies purchase, while intermittently used equipment favors leasing. Tax considerations also influence decisions, with purchased equipment qualifying for depreciation benefits while leased equipment expenses are fully deductible.

Dust Control and Noise Mitigation Requirements

Dust control and noise mitigation requirements significantly impact equipment selection for operations in residential areas or noise-sensitive environments. Municipal regulations often limit operating noise to 75-85 dB at property lines, requiring equipment with acoustic enclosures or restricted operating hours.

Dust control becomes critical when processing dry material near sensitive areas, necessitating equipment with integrated dust suppression systems or aftermarket modifications. These requirements often favor newer equipment models with better environmental controls, despite higher acquisition costs. The compliance costs typically add 10-20% to equipment expenses but prevent regulatory issues and community complaints.

Municipal Waste Management Department (Centralized Shredding Facility)

Municipal waste management departments typically operate centralized shredding facilities that process green waste from multiple collection routes and public landscaping operations. These facilities handle 20-100 tons of material daily, requiring industrial equipment with high availability and automated material handling.

Successful implementations typically utilize double shaft wood shredder systems with 200-400 horsepower capacity, integrated with conveyor systems and sorting lines. The equipment selection prioritizes reliability over lowest cost, with redundancy built through multiple processing lines. The centralized approach achieves processing costs of $8-15 per ton, significantly below decentralized alternatives. The facilities often incorporate public drop-off areas and product sales operations that generate additional revenue.

Wear-Resistant Material Requirements

Wear-resistant material requirements become critical in municipal applications processing contaminated green waste containing soil, rocks, and metal objects. The equipment must incorporate wear-resistant liners in cutting chambers, hardened steel cutting elements, and protection systems against foreign objects.

Material selection typically includes AR400 steel plates for structural components, tungsten carbide for cutting edges, and specialized alloys for wear parts. These materials increase equipment costs by 20-30% but extend component life by 300-500%, reducing maintenance costs and downtime. The economic analysis strongly favors premium materials in municipal applications where contamination is inevitable.

Integration with Conveyor Systems

Integration with conveyor systems enables efficient material handling in centralized facilities, reducing labor requirements and improving throughput. The conveyor design must match shredder capacity while providing sorting access for contaminants and size classification of output material.

Successful integrations utilize discharge conveyor systems that transport processed material to storage or loading areas, often incorporating magnetic separation for metal removal. The conveyor systems typically add 20-40% to facility costs but reduce labor requirements by 60-80% and improve processing efficiency by 25-35%. The integration requires careful planning to ensure equipment compatibility and smooth material flow throughout the system.

Biomass Power Plant (Continuous Operation Shredder Selection)

Biomass power plants represent the most demanding application scenario, requiring continuous operation with minimal downtime and precise output specifications. These facilities process 500-2,000 tons of wood waste daily, operating 24/7 to supply fuel for power generation. The equipment selection prioritizes reliability above all other considerations.

Successful implementations typically utilize multiple hammermill rotor shredders in parallel configuration, ensuring continuous operation during maintenance periods. The equipment features premium components throughout, with designed service life exceeding 10,000 hours between major overhauls. The shredders integrate with sophisticated material handling systems that include pre-screening, metal detection, and automated feeding controls. The operational economics justify equipment investments exceeding $1 million per processing line.

Future Technology Integration Trends

Future technology integration trends focus on enhancing equipment efficiency, reducing operational costs, and enabling new business models through digitalization and automation. These advancements transform wood processing from a brute-force mechanical operation to a sophisticated materials handling process. The technology adoption follows industrial equipment first, with trickle-down to residential equipment over 5-10 year cycles.

Emerging technologies promise 30-50% improvements in energy efficiency, 20-40% reductions in maintenance costs, and significant enhancements in operational safety. The digital transformation enables predictive maintenance, remote operation, and performance optimization through data analytics. These advancements will further differentiate industrial equipment capabilities while making advanced features more accessible in residential equipment.

IoT-Enabled Predictive Maintenance Systems

IoT-enabled predictive maintenance systems utilize sensors and data analytics to anticipate maintenance needs before equipment failure occurs. These systems monitor vibration patterns, temperature trends, and power consumption to identify developing issues weeks before traditional maintenance schedules would detect problems.

The technology implementation typically reduces unplanned downtime by 60-80% and extends component life by 25-40% through optimized maintenance timing. Industrial equipment increasingly incorporates these systems as standard features, with data transmitted to manufacturer portals for remote diagnostics. The predictive maintenance approach transforms maintenance from scheduled intervals to condition-based interventions, maximizing equipment availability and reducing maintenance costs.

AI-Based Material Recognition for Optimal Shredding

AI-based material recognition systems automatically identify material types and characteristics, adjusting equipment parameters for optimal processing efficiency. These systems utilize cameras and sensors to detect material size, moisture content, and contamination levels, automatically configuring shredder settings for each load.

The technology implementation improves throughput by 15-25% and reduces energy consumption by 10-20% through optimized operation. The systems also enhance product quality by maintaining consistent output specifications despite variable input materials. The AI algorithms continuously learn from operational data, improving recognition accuracy and optimization effectiveness over time. This technology represents the future of efficient material processing across all equipment classes.

Hybrid Energy Systems (Solar-Powered Shredders)

Hybrid energy systems integrate renewable energy sources with traditional power systems, reducing operational costs and environmental impact. Solar-powered shredders utilize photovoltaic arrays to offset grid power consumption, particularly effective in sunny regions where processing operations align with solar generation patterns.

The systems typically reduce energy costs by 40-60% while providing backup power capability during grid outages. The technology implementation makes economic sense particularly for operations in remote areas or regions with high electricity costs. The hybrid approach also enhances sustainability credentials, potentially qualifying for additional environmental certifications or premium markets. The technology adoption will accelerate as solar efficiency improves and battery costs decline.

Circular Economy Models (Equipment-as-a-Service)

Circular economy models transform equipment ownership through Equipment-as-a-Service (EaaS) arrangements where customers pay for processing capacity rather than equipment ownership. These models align manufacturer incentives with equipment performance and reliability, as revenue depends on equipment availability and efficiency.

The EaaS approach typically reduces customer capital requirements by 80-100% while providing predictable operational expenses. Manufacturers benefit through ongoing revenue streams and deeper customer relationships. The model encourages design for durability and repairability, as manufacturers retain equipment ownership throughout its lifecycle. This business model innovation will transform equipment acquisition economics, particularly for small and medium operations lacking capital for equipment purchases.