Waste Plastic Shredder

What is Waste Plastic Shredder?

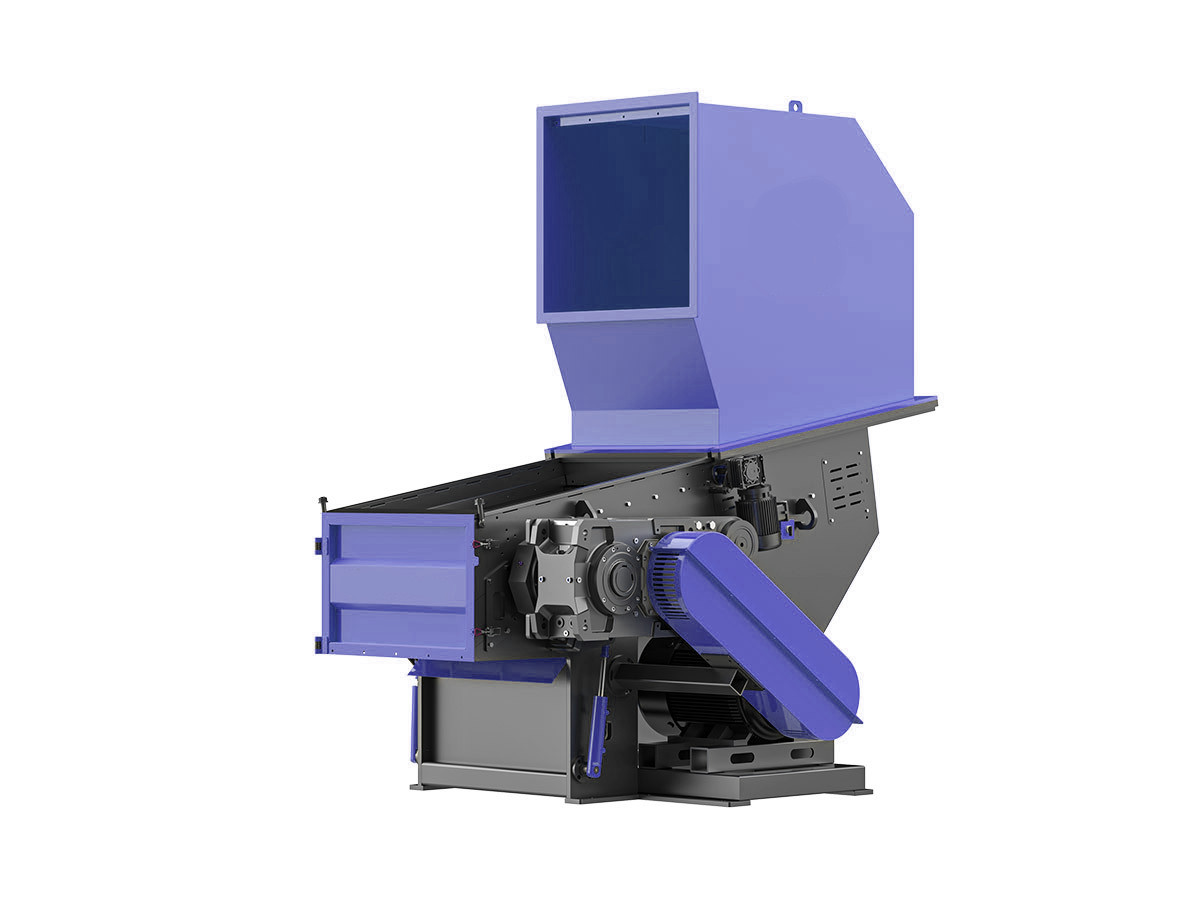

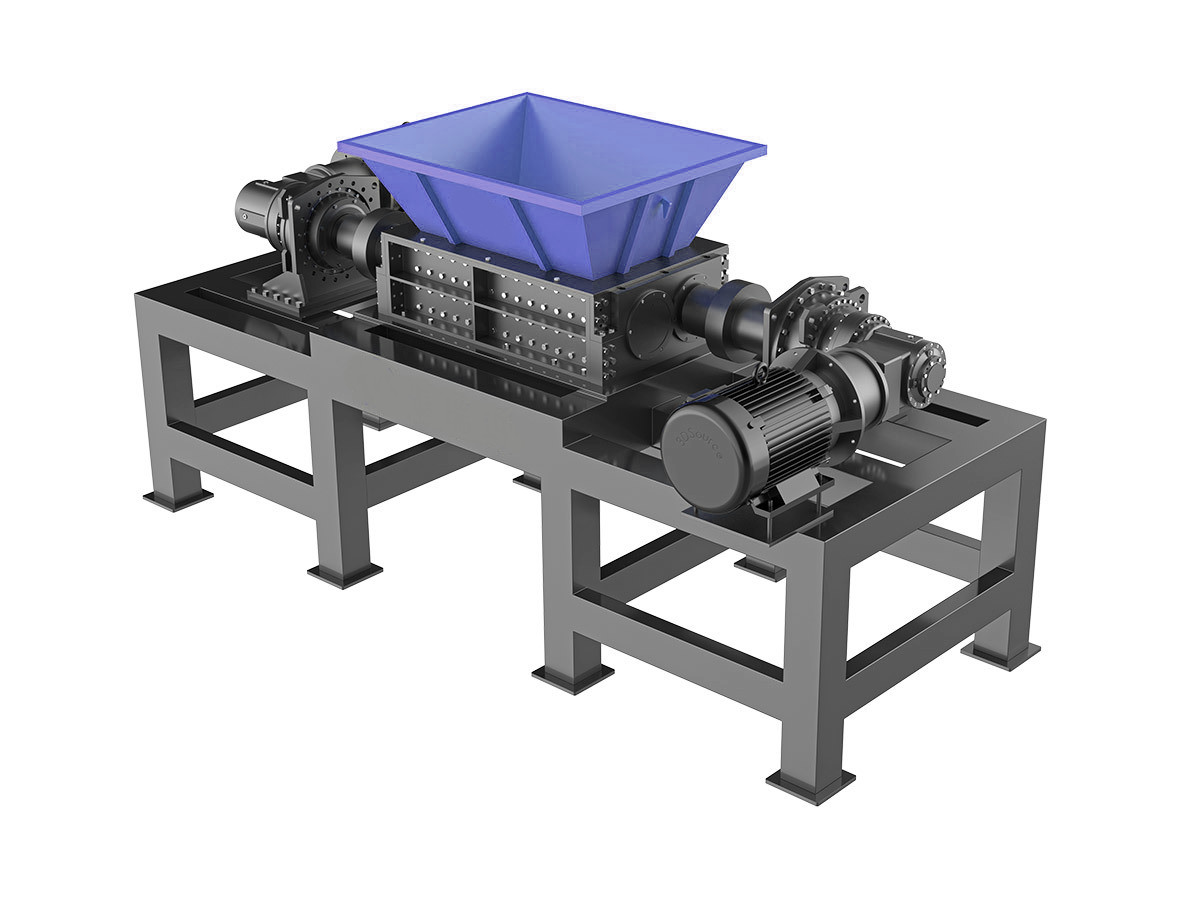

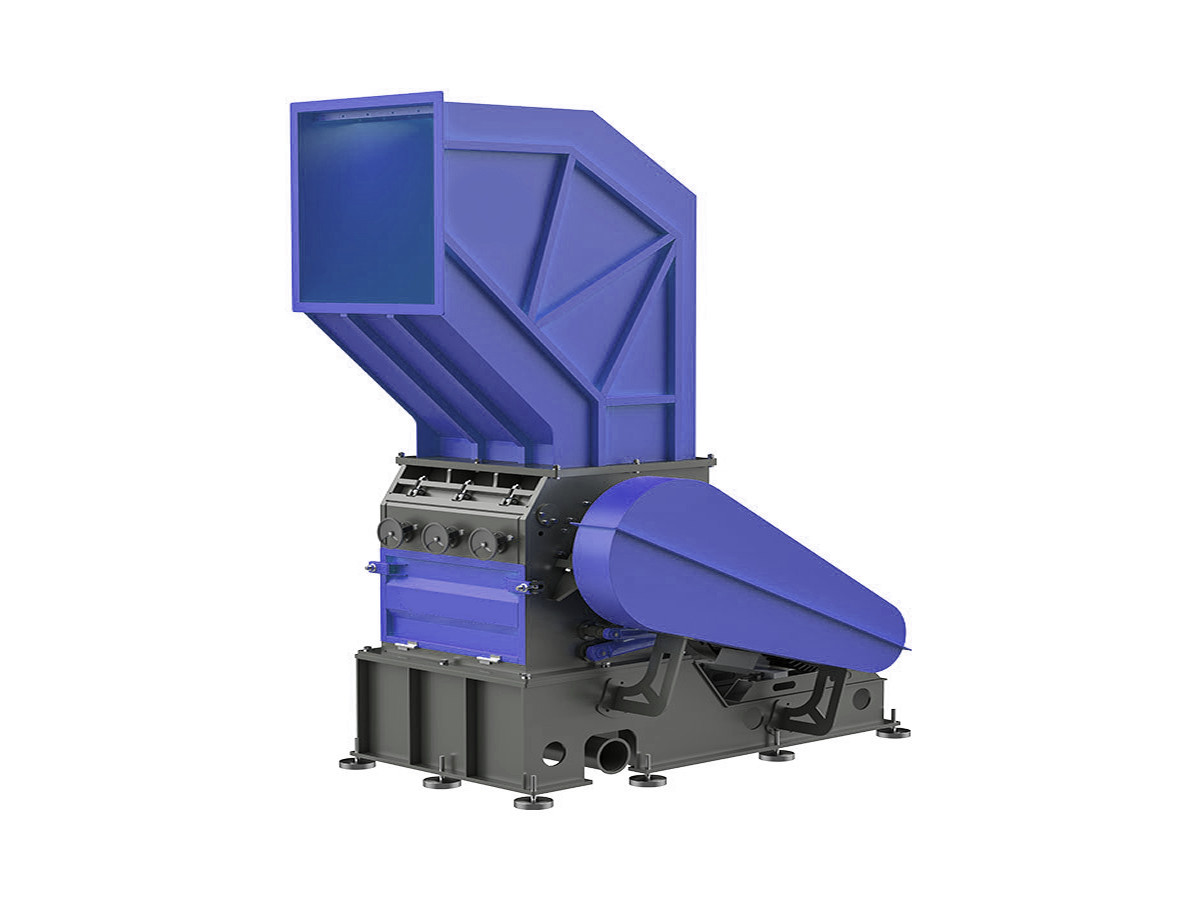

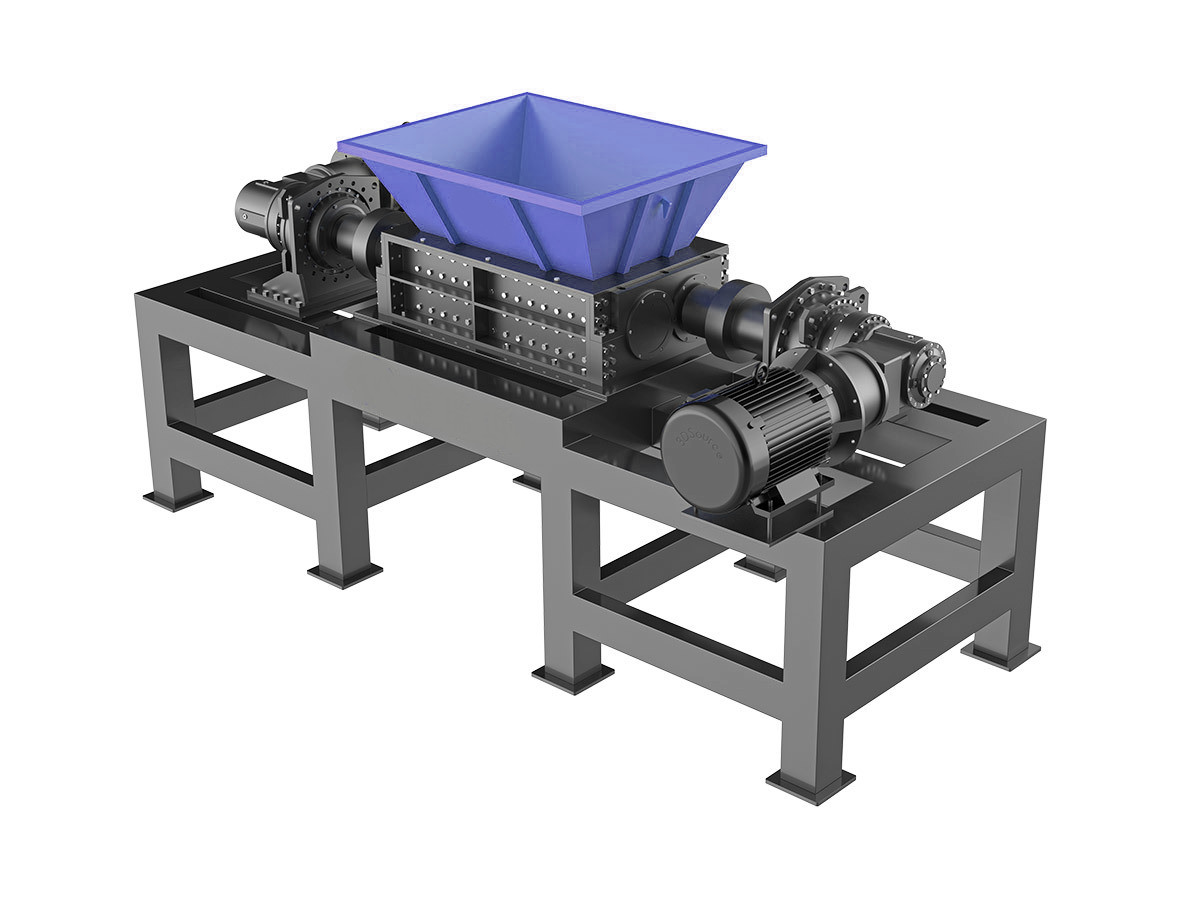

Waste Plastic Shredder is a machine designed to break down plastic materials into smaller pieces, making them easier to recycle or dispose of. It is commonly used in recycling facilities, plastic manufacturing plants, and waste management operations. Waste plastic shredders help reduce the volume of plastic waste and prepare it for further processing, such as extrusion, molding, or reprocessing into new plastic products.

The machine works by using sharp, rotating blades to cut and crush plastic items into smaller fragments. These small pieces can then be reused in various industrial processes, reducing the need for new plastic production and promoting environmental sustainability.

Waste plastic shredders are available in different sizes and configurations, ranging from small units for household or light-duty use to large industrial machines capable of processing large volumes of plastic waste. The choice of shredder depends on factors like the type of plastic, the volume of waste, and the desired output size.

Working Principle of Waste Plastic Shredder

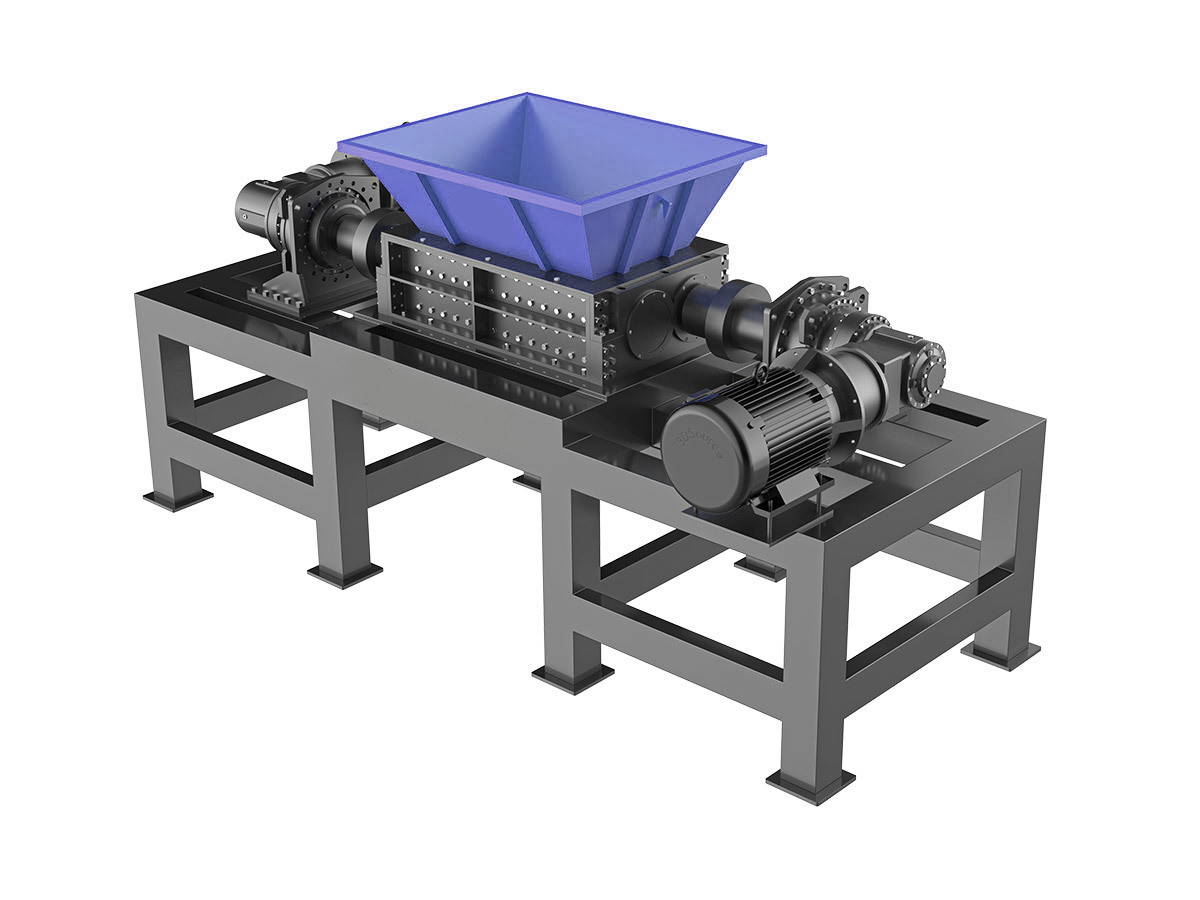

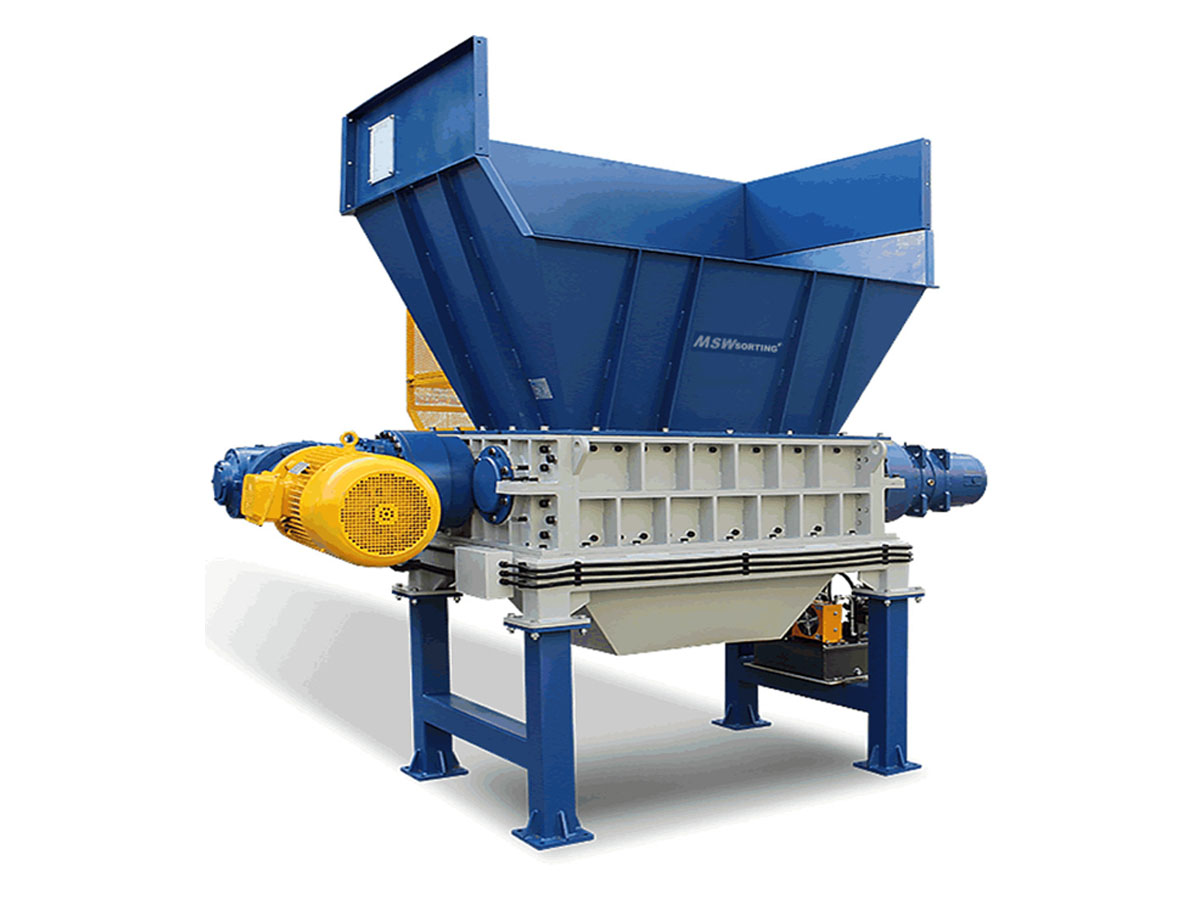

Waste Plastic Shredder works by using powerful rotating blades or hammers to cut, crush, and shear plastic materials into smaller pieces. These blades are powered by a high-performance motor that allows them to break down tough plastic materials with ease.

The plastic waste is fed into the shredder through a hopper, where the rotating blades grab and pull the material into the shredding chamber. The blades then tear apart the plastic, reducing it to the desired size. The size of the output depends on the type of shredder and the settings used.

Waste plastic shredders can be designed with various configurations to suit different types of plastic, such as soft plastic, hard plastic, or mixed plastic materials. The process is efficient and quick, making it ideal for large-scale recycling operations or industrial applications where high volumes of plastic need to be processed.

How to Choose the Right Waste Plastic Shredder?

Choosing the right Waste Plastic Shredder depends on several factors, including the type of plastic waste you need to process, the size of the material, and the desired output size. It is essential to choose a shredder that is designed for the specific type of plastic you are working with, as different plastics have different properties and require different shredding mechanisms.

The size of the shredder is another critical factor. Smaller shredders are suitable for light-duty applications, such as shredding plastic bottles or packaging materials. On the other hand, larger industrial shredders are necessary for processing bulk plastic waste or larger items, such as plastic containers or scrap from manufacturing operations.

Other important considerations include the shredder’s energy efficiency, ease of maintenance, and the speed of operation. Make sure to assess the total cost of ownership, which includes initial purchase cost, operational costs, and maintenance requirements, to ensure you are making the best investment for your needs.

Applications of Waste Plastic Shredder

Waste Plastic Shredder is widely used in many industries to manage plastic waste and promote recycling efforts. In recycling centers, waste plastic shredders break down plastic waste into smaller, uniform pieces that can be easily processed into new plastic products. This helps reduce the environmental impact of plastic waste by giving it a second life.

Waste plastic shredders are also used in the manufacturing of plastic products, where they are used to process scrap plastic from the production line. This scrap can then be reused in the production of new items, contributing to a circular economy and reducing the need for virgin plastic materials.

In addition, waste plastic shredders play a crucial role in managing plastic waste in municipal waste management systems, helping to reduce the volume of plastic that ends up in landfills. They are used in the automotive industry, the electronics sector, and many other industries where plastic waste needs to be managed and recycled.

Maintenance of Waste Plastic Shredder

Proper maintenance of a Waste Plastic Shredder is essential to ensure its efficiency and extend its lifespan. Regular maintenance helps to prevent breakdowns, reduce downtime, and ensure that the machine operates at optimal performance. Key maintenance tasks include inspecting and sharpening the blades, as well as lubricating the moving parts to minimize friction and wear.

The motor and electrical components should also be checked periodically for wear and tear. Dust and debris can accumulate over time, so it is important to keep these parts clean to prevent overheating or malfunctions. Regular cleaning of the shredder is essential to maintain smooth operation and avoid any build-up of material that could cause blockages.

In addition, operators should monitor the machine during use, paying attention to any unusual sounds, vibrations, or performance issues. By identifying potential problems early, you can avoid costly repairs and ensure the longevity of the shredder. Following the manufacturer’s recommended maintenance schedule is crucial for keeping the shredder in top working condition.

Main Components of Waste Plastic Shredder

Waste Plastic Shredder Types

Types of Waste Shredder Machine

Solid Waste Shredder

Efficiently process municipal and industrial waste into smaller, manageable sizes, aiding in recycling and waste disposal efforts.

Learn more >>

E-Waste Shredder

Specially engineered for electronic waste, this waste shredder handles materials like phones, computers, and circuit boards, ensuring secure disposal and recycling.

Learn more >>

Waste Metal Shredder

Our waste metal shredders efficiently process materials like aluminum, copper, and steel, making it easier to recycle and repurpose metal scrap.

Learn more >>

Waste Plastic Shredder

Built for recycling plastics like PE, PP, and PET, this waste shredder helps reduce plastic waste into manageable pieces for further processing.

Learn more >>

Waste Tire Shredder

Efficiently process used tires into reusable materials, including crumb rubber, for recycling and environmental sustainability.

Learn more >>

Waste Wood Shredder

Ideal for recycling wood waste like branches, pallets, and wooden furniture, this waste shredder helps create chips, mulch, or compost for eco-friendly disposal.

Learn more >>

Waste Paper Shredder

Ensure confidential document destruction with our secure waste paper shredders, designed for both small offices and large businesses.

Learn more >>

RDF Shredder

Transform waste into refuse-derived fuel (RDF) with this efficient waste shredder, perfect for waste-to-energy applications and reducing landfill dependency.

Learn more >>