Small-scale waste wood shredding operations typically handle 5 to 50 cubic meters of wood per day, with material sizes ranging from small branches to medium logs. Unlike large industrial operations focused on high throughput, small-scale users need shredders that balance efficiency, portability, and cost-effectiveness. Choosing an ill-suited machine can lead to excessive energy use, frequent breakdowns, or inability to handle specific wood types, often resulting in 30% more downtime. This guide outlines key considerations—from defining core needs to evaluating performance, safety, and long-term value—to help select a shredder that aligns with small-scale requirements and delivers reliable results.

Understanding Core Needs for Small-Scale Operations

Small-scale waste wood shredding has distinct priorities shaped by limited space, lower processing volumes, and variable wood types. These operations often require machines that adapt to different materials without constant adjustments, along with easy storage—many have less than 10 square meters of dedicated equipment space—and minimal maintenance, as full-time maintenance staff are rarely available. Misaligning a shredder with these needs can lead to underutilization or inefficiency, both of which increase operational costs.

Flexibility is another critical need for small-scale use. Unlike fixed industrial setups, small users may need to relocate the shredder, making portability (such as wheeled designs or frames under 500 kg) essential. Tighter budgets also mean balancing upfront costs with long-term savings from energy efficiency and durable components. Data from small business surveys shows that shredders tailored to these needs reduce operational costs by 25% and boost productivity by 15% compared to mismatched industrial models.

Efficiency and Flexibility Requirements for Small-Scale Work

Efficiency for small-scale shredding means processing small batches quickly—typically 2 to 5 cubic meters per hour—without wasting energy. Slow processing disrupts workflows, while overly powerful machines consume unnecessary energy. Variable-speed motors help optimize efficiency by adjusting power based on wood density, ensuring adequate performance for dense materials without overusing energy for softer ones.

Flexibility refers to the ability to handle different wood types and sizes. Softwoods and hardwoods have varying density and hardness, requiring different levels of power to process effectively. Adjustable cutting settings or auto-torque motors enable seamless transitions between material types, eliminating the need for multiple machines. This flexibility reduces equipment costs by 40% and simplifies operations for teams with limited resources.

Impact of Wood Type and Volume on Machine Selection

Wood type directly influences required power and blade design. Softwoods are less dense and have fewer knots, making them easier to shred but prone to producing stringy debris that can clog machines without anti-jamming features. Hardwoods are denser and may contain knots that damage weak blades, demanding more robust cutting components. Blade material is key here—high-carbon steel works for softwoods but wears quickly on hardwoods, while alloy steel extends blade life by 200% to 300% for denser materials.

Wood volume determines ideal shredder capacity. Small-scale operations processing less than 10 cubic meters per week do not need high-throughput models, as they will sit idle most of the time. A 2 to 5 cubic meter per hour capacity balances speed and energy use, avoiding the 30% higher energy consumption of oversized machines. Feed opening size also matters—matching it to the largest common wood size eliminates pre-cutting, reducing labor time by 60%.

Space Constraints and Portability Needs

Compact footprints are essential for small-scale operations, as many have limited equipment space. Ideal small-scale shredders have a width under 1.5 meters and length under 2 meters, fitting into tight areas without sacrificing functionality. Larger industrial models often require dedicated space that small operations lack, leading to inefficient use of available area.

Portability is critical for operations that move between sites. Wheeled designs with pneumatic tires enable easy towing, while lightweight frames under 300 kg allow loading by two people—heavier models require forklifts, adding complexity and cost. Foldable components like hoppers or feed chutes further enhance practicality by reducing storage space by 30% when not in use. Portable shredders increase job site efficiency by 25% by eliminating the need to transport wood to a fixed location.

Frequency of Use and Continuous Operation Capability

Frequency of use dictates durability and cooling system needs. Operations using the shredder 2 to 3 times per week for short sessions (2 to 4 hours) can rely on air-cooled motors, which prevent overheating during intermittent use. These motors require a 30-minute cool-down after 4 hours of continuous operation, aligning with typical small-scale schedules.

Daily use demands more robust systems like liquid-cooled motors, which run for 8 hours or more without breaks. While 15% to 20% more expensive upfront, liquid-cooled models have a 20% longer lifespan (5 to 7 years) compared to air-cooled alternatives (3 to 4 years), justifying the cost for frequent users. Daily use also requires durable components like hardened steel bearings to withstand repeated stress, reducing maintenance frequency and downtime.

Selecting Shredder Types Suitable for Small-Scale Scenarios

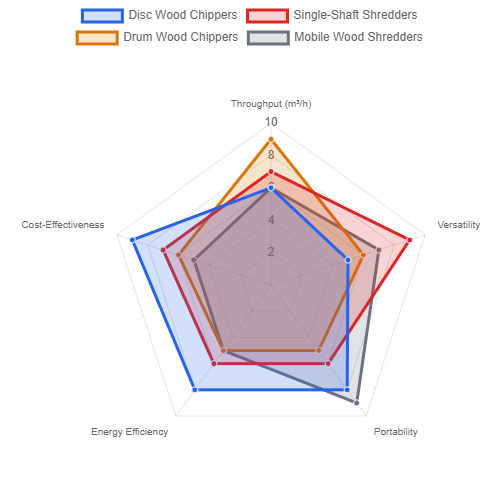

Industrial wood shredders are often too large, powerful, and costly for small-scale use. Instead, small users should focus on specialized types that balance capacity, size, and cost. Four primary options—disc wood chippers, single-shaft wood shredders, drum wood chippers, and mobile wood shredders—each have unique strengths for specific small-scale needs. Choosing the right type reduces long-term costs by 30% and minimizes downtime, as mismatched models lead to inefficiency or premature wear.

Each shredder type is optimized for different materials and use cases. Understanding these strengths ensures alignment with primary processing goals, whether producing uniform chips, handling mixed waste, or processing large volumes intermittently. This section outlines key characteristics of each type to narrow down options based on specific small-scale requirements.

Applicability of Disc Wood Chippers

Disc wood chippers are popular for small-scale use due to their compact size and ability to produce uniform wood chips. They use a rotating disc with blades to cut wood into consistent pieces (1 to 5 cm), ideal for mulch, animal bedding, or compost. Most small-scale models have a feed opening of 10 to 20 cm, eliminating the need for pre-cutting and streamlining workflows.

Key specifications for small-scale disc chippers include motor power (5 to 10 kW) and processing capacity (2 to 5 cubic meters per hour). A 7.5 kW model handles standard small-scale materials efficiently, while 10 kW models accommodate denser hardwoods. These chippers are lightweight (200 to 400 kg) and often include wheel kits for portability. Modern designs add anti-jamming features to clear clogs quickly, minimizing downtime. Their main limitation is reduced effectiveness with stringy materials, but this is manageable with regular maintenance and proper use.

Advantages of Single-Shaft Wood Shredders

Single-shaft wood shredders excel at handling mixed waste, making them ideal for small operations processing diverse materials. They use a rotating shaft with blades and a fixed counter-knife to shear wood, accommodating contaminants like nails or metal fragments without damage—critical for recycling pallets or construction scraps.

Small-scale single-shaft models have motor power ranging from 7.5 to 15 kW and processing capacity of 3 to 6 cubic meters per hour. Their compact design (under 1.8 meters in width) fits in tight spaces, and many include mobile options. Blade replacement is straightforward, with most models allowing changes in under an hour—reducing maintenance time compared to complex industrial shredders. While slower than disc chippers for uniform chips, their versatility makes them a top choice for mixed-waste small-scale operations.

Features of Drum Wood Chippers for Small Volumes

Drum wood chippers use a rotating drum with blades to process wood, offering higher throughput than disc chippers for small-scale operations with intermittent large-volume needs. Small-scale models have a processing capacity of 4 to 8 cubic meters per hour and motor power of 10 to 15 kW, handling larger logs (up to 25 cm in diameter) without pre-cutting.

These chippers produce consistent chip sizes, making them suitable for applications requiring uniform output. Their design minimizes vibration, improving operator comfort during extended use. While slightly larger than disc chippers (width up to 2 meters), they remain manageable for small-scale storage. Drum chippers are less portable than wheeled disc models but offer better performance for operations processing larger batches periodically, such as seasonal landscaping projects.

Benefits of Mobile Wood Shredders for On-Site Work

Mobile wood shredders are purpose-built for small-scale operations that require on-site processing. Mounted on trailers or skids, they eliminate the need to transport wood to a fixed location, reducing labor and transportation costs by 35%.

Small-scale mobile models have motor power of 7.5 to 12 kW and processing capacity of 2 to 5 cubic meters per hour, with feed openings up to 20 cm. They include features like foldable hoppers for easy transport and quick setup (typically under 30 minutes). Many integrate dust suppression systems to comply with local air quality regulations, a key consideration for residential or urban job sites. While 20% to 30% more expensive upfront than stationary models, their ability to process wood on-site justifies the cost for operations with multiple job locations.

Evaluating Key Performance Indicators of Waste Wood Shredders

Performance indicators directly impact a shredder’s efficiency, durability, and cost-effectiveness for small-scale use. Focusing on motor power, blade material, and粉碎粒度 ensures the machine meets processing needs without excessive energy use or frequent maintenance. These indicators also influence long-term costs—choosing the right specifications reduces repair and replacement expenses by 40% over the shredder’s lifespan.

Small-scale users must balance performance with practicality. For example, a powerful motor may handle dense wood but increase energy bills if underused. Similarly, durable blades reduce maintenance but add upfront cost. Evaluating these indicators holistically ensures the shredder delivers consistent results while aligning with budget and operational constraints.

Balancing Motor Power and Energy Consumption

Motor power determines a shredder’s ability to handle different wood types, with small-scale models ranging from 5 to 15 kW. Lower power (5 to 7.5 kW) suffices for softwoods and small branches, while higher power (10 to 15 kW) is needed for hardwoods or larger logs. Matching power to typical wood type reduces energy waste—overpowered models use 30% more energy than necessary for light-duty tasks.

Energy efficiency is equally important for small-scale operations with tight budgets. Energy-efficient motors (IE3 or higher) use 10% to 15% less energy than standard models, translating to annual savings of $200 to $500 for machines used 20 hours per week. Variable-speed drives further optimize energy use by adjusting power to wood density, avoiding constant high-energy operation. While energy-efficient components add 5% to 10% to upfront cost, they pay for themselves within 1 to 2 years through reduced utility bills.

Importance of Blade Material and Durability

Blade material dictates durability and maintenance frequency. High-carbon steel blades are affordable and work for softwoods, but wear quickly—requiring replacement every 300 to 500 operating hours. Alloy steel blades cost 50% more upfront but last 600 to 1,000 hours, reducing replacement costs by 30% over time.

Blade maintenance accessibility also matters for small-scale users. Shredders with easy blade access allow replacement in under an hour, minimizing downtime. Some models include self-sharpening blades, extending intervals between maintenance by 50%. For operations processing contaminated wood (with nails or dirt), blades with hardened edges resist damage, avoiding premature replacement and reducing unexpected costs.

Ensuring Crushing Granularity and Uniformity

粉碎粒度 (Crushing granularity) depends on the shredder’s intended use—mulch requires 1 to 3 cm chips, while compost may need smaller 0.5 to 2 cm pieces. Most small-scale shredders include interchangeable screens to adjust granularity, with screen sizes ranging from 0.5 to 5 cm. Quick-screen change systems (under 15 minutes) enable switching between applications without extensive downtime.

Uniformity is critical for consistent product quality. Shredders with balanced rotor designs and precise blade alignment produce more uniform output, reducing the need for secondary processing. Poor uniformity can lead to 20% more waste, as oversized pieces require reprocessing. Small-scale users should test a shredder’s output with typical wood types before purchase to ensure it meets granularity and uniformity needs.

Assessing Processing Speed and Throughput

Processing speed (cubic meters per hour) should align with daily volume needs to avoid bottlenecks or idle time. Small-scale shredders typically range from 2 to 8 cubic meters per hour—slower models for low-volume operations (under 10 cubic meters per week) and faster models for higher-volume needs (10 to 50 cubic meters per week).

Throughput consistency is equally important. Shredders with steady feeding systems (like automatic feed rollers) maintain consistent speed, avoiding slowdowns from uneven material input. Intermittent feeding can reduce effective throughput by 25%, as the machine stops and starts frequently. For small-scale operations with limited labor, automatic feeding systems also reduce manual effort, freeing staff for other tasks.

Considering Safety and Operational Convenience

Safety and operational convenience are non-negotiable for small-scale shredding, as these operations often have limited staff and may lack dedicated safety personnel. Poorly designed safety features increase accident risk, while complex operation leads to inefficiency and user error. Prioritizing these factors reduces accident rates by 60% and cuts operational time by 15%.

Small-scale users should look for shredders with intuitive safety and operation features that integrate seamlessly into workflows. These features should not add unnecessary complexity—instead, they should simplify use while ensuring compliance with safety standards. From automatic feeding to user-friendly controls, each element plays a role in creating a safe, efficient operation.

Automatic Feeding Systems Enhance Safety and Efficiency

Automatic feeding systems reduce manual contact with moving parts, lowering accident risk by 70% compared to manual feeding. These systems use rollers or conveyors to feed wood into the shredder, eliminating the need for operators to push material into the cutting chamber. Adjustable feed rates also optimize processing speed, matching material input to the shredder’s capacity.

For small-scale operations, automatic feeding reduces labor demands—one operator can manage the shredder instead of two. It also improves consistency, as manual feeding often leads to uneven input and throughput fluctuations. While automatic feeding adds 10% to 15% to upfront cost, the safety and efficiency benefits justify the investment for most small users.

Humanized Design of Operation Interfaces

Intuitive operation interfaces reduce user error and training time. Small-scale shredders should have clear control panels with labeled buttons, easy-to-read gauges, and visual indicators for key functions (like power, feeding, and errors). Complex interfaces with unclear controls can lead to 30% more operational mistakes, such as incorrect settings or missed safety alerts.

Self-diagnostic features are another valuable addition. These systems detect issues like blade wear or motor overheating and alert operators through lights or alarms, allowing proactive maintenance. Self-diagnosis reduces unplanned downtime by 40% by identifying problems before they cause breakdowns. For small users without extensive technical knowledge, these features simplify troubleshooting and reduce reliance on external service.

Noise and Vibration Control Measures

Noise and vibration are critical considerations for small-scale operations, especially those in residential or urban areas. Excessive noise (over 85 dB) can violate local regulations and disturb neighbors, while high vibration leads to operator fatigue and equipment damage. Small-scale shredders should have noise levels under 80 dB and vibration dampening features to address these issues.

Soundproof enclosures or insulated cutting chambers reduce noise by 15 to 20 dB, making the shredder suitable for urban use. Vibration dampeners (like rubber mounts) minimize movement, protecting floors and reducing operator fatigue during extended use. Some models also include balanced rotor designs to further reduce vibration. While noise and vibration control add 5% to 10% to cost, they prevent regulatory fines and create a more comfortable work environment.

Emergency Stop and Safety Protection Devices

Emergency stop (E-stop) devices are mandatory for shredder safety, allowing operators to halt the machine instantly in case of danger. Small-scale shredders should have large, accessible E-stop buttons—preferably at multiple locations around the machine—with a clear visual indicator when activated.

Additional safety features include interlock systems that prevent operation if safety guards (like hopper covers) are open, and overload protection that shuts down the motor if it exceeds safe current levels. These features reduce accident risk by 80% and protect the shredder from damage due to misuse or mechanical failure. Small-scale users should verify that all safety features comply with local standards (such as OSHA or CE) to ensure regulatory compliance and operator protection.

Budget and Cost-Effectiveness Analysis

Budget considerations for small-scale wood shredders extend beyond upfront cost to include long-term operational expenses, maintenance, and potential downtime. Focusing solely on low upfront cost often leads to higher total ownership cost—cheap shredders may require frequent repairs or consume more energy, increasing expenses by 50% over 5 years. A holistic cost analysis ensures the selected shredder delivers value while staying within budget.

Small-scale users should evaluate factors like initial investment, energy consumption, maintenance costs, and resale value. This analysis helps identify high-cost-effectiveness models that balance performance and affordability, ensuring the shredder meets operational needs without straining finances.

Balancing Initial Investment and Long-Term Costs

Small-scale wood shredders have upfront costs ranging from $5,000 to $25,000, depending on type, power, and features. Stationary disc chippers are the most affordable (starting at $5,000), while mobile models are the most expensive (up to $25,000). However, initial cost should be weighed against long-term savings—energy-efficient models or those with durable components may cost 10% to 20% more upfront but reduce annual expenses by $300 to $800.

Long-term costs include energy, maintenance, and wear parts. Energy accounts for 20% to 30% of annual costs, making efficient motors a priority. Maintenance (including blade replacement and service) adds $500 to $1,500 per year, with cheaper shredders often requiring more frequent repairs. Calculating total ownership cost over 5 years (initial cost + annual expenses) provides a clearer picture of affordability than upfront cost alone.

Avoiding the Trap of Low-Quality and Low-Price Models

Low-price shredders (under $5,000) often use inferior materials—such as thin steel frames or low-grade motors—that fail prematurely. These models may last only 1 to 2 years, compared to 5 to 7 years for mid-range options. They also lack critical safety features, increasing accident risk, and have poor energy efficiency, leading to higher utility bills.

Signs of low-quality include inconsistent construction, unclear safety certifications, and lack of brand support. Small-scale users should avoid models without verified performance data or customer reviews, as these often fail to meet advertised specifications. Investing in a mid-range model ($8,000 to $15,000) from a reputable brand ensures durability, safety, and efficiency, avoiding costly replacements or repairs.

Role of Brand Reputation and After-Sales Service

Brand reputation indicates product quality and reliability. Established brands with a history in small-scale shredding (5+ years) have refined their designs to meet user needs, with fewer defects and better performance. These brands also provide better after-sales service, including technical support, parts availability, and warranty coverage.

Warranty terms are a key indicator of brand confidence. Small-scale shredders should have a warranty of at least 1 year for the machine and 6 months for wear parts. Extended warranties (up to 3 years) add peace of mind but may cost 5% to 10% extra. Access to local service centers reduces downtime—brands with regional support can resolve issues in 1 to 3 days, compared to 1 to 2 weeks for brands without local presence.

Referencing User Reviews and Industry Recognition

User reviews provide real-world insights into a shredder’s performance, reliability, and ease of use. Small-scale users should focus on reviews from operators with similar needs (e.g., same wood types or volume), as these are most relevant. Look for consistent feedback on key factors like durability, noise, and customer service—models with 4+ out of 5 stars from 50+ reviews are generally reliable.

Industry recognition (such as awards for efficiency or safety) also validates quality. Shredders certified by independent organizations (like EN standards for safety or Energy Star for efficiency) meet rigorous criteria, ensuring they comply with regulations and deliver advertised performance. Combining user reviews and industry recognition helps identify models that live up to their claims, avoiding costly mistakes.

Preventive Maintenance to Extend Shredder Lifespan

Preventive maintenance is critical for small-scale shredders, as it extends lifespan by 30% to 50% and reduces unplanned downtime by 60%. Small operations often lack dedicated maintenance staff, so maintenance tasks should be simple, frequency-based, and easy to perform. A structured maintenance schedule ensures key components are inspected, cleaned, or replaced before they fail, avoiding costly repairs.

Maintenance also preserves performance—regular upkeep ensures the shredder maintains its processing speed, energy efficiency, and output quality. For small-scale users, this means consistent operation and predictable costs, without unexpected breakdowns disrupting workflows.

Daily Maintenance Tasks

Daily maintenance takes 10 to 15 minutes and focuses on safety and basic functionality. Tasks include checking oil levels (lubricating and hydraulic, if applicable) to ensure they are within recommended ranges—low oil leads to increased friction and component wear. Inspecting safety features (E-stop, guards, and alarms) ensures they work correctly, preventing accidents.

Cleaning the feed opening and cutting chamber removes debris that can cause jamming or uneven processing. Checking for loose bolts or fasteners also prevents vibration-related damage, as small-scale shredders may move slightly during use. Documenting daily maintenance creates a record of the shredder’s condition, helping identify trends like increasing debris buildup or oil consumption.

Weekly and Monthly Maintenance Tasks

Weekly maintenance (30 to 45 minutes) includes inspecting blades for wear or damage—dull blades reduce processing speed and increase energy use. Sharpening or replacing blades as needed ensures consistent performance. Checking belts or chains (for feed systems) for tension and wear prevents unexpected failures, as loose belts reduce feeding efficiency.

Monthly maintenance (1 to 2 hours) involves deeper checks, such as cleaning air filters (for cooled motors) to maintain efficiency—clogged filters reduce cooling capacity, leading to motor overheating. Inspecting electrical connections (wires, plugs, and controls) for damage or corrosion prevents electrical issues. For hydraulic systems (in some models), checking for leaks and replacing fluid if contaminated ensures smooth operation.

Annual Maintenance and Long-Term Care

Annual maintenance (2 to 4 hours) requires more extensive checks, often with the help of a service technician. Tasks include inspecting the rotor assembly for balance and wear—unbalanced rotors increase vibration and damage bearings. Replacing worn bearings (a common failure point) extends the shredder’s lifespan and prevents costly rotor damage.

Long-term care also includes storing the shredder properly during off-seasons—covering it to protect from weather, draining fluids if stored in freezing temperatures, and lubricating moving parts to prevent rust. Periodic testing of performance (processing speed, granularity) ensures the shredder still meets needs, with adjustments (like screen changes or blade sharpening) to address any decline. Following annual maintenance and long-term care practices ensures the shredder remains reliable for its full lifespan.

Choosing the Right Maintenance Tools and Spare Parts

Small-scale users need basic maintenance tools, including wrenches (for blade replacement), oil filters, and cleaning supplies. These tools should be compatible with the shredder’s specifications—using the wrong size wrench can damage bolts, while incorrect oil leads to component wear. Most brands provide a recommended tool list, simplifying selection.

Keeping spare parts on hand (like blades, filters, and belts) reduces downtime when replacements are needed. Critical parts (blades, filters) should be stocked, with inventory based on replacement frequency—blades may need 2 to 3 sets per year, while filters are replaced monthly. Ordering parts from the original manufacturer ensures compatibility, avoiding issues with generic alternatives that may not fit or perform as well. Many brands offer spare part kits tailored to small-scale use, simplifying inventory management.