E-waste Shredder

What is E-waste Shredder?

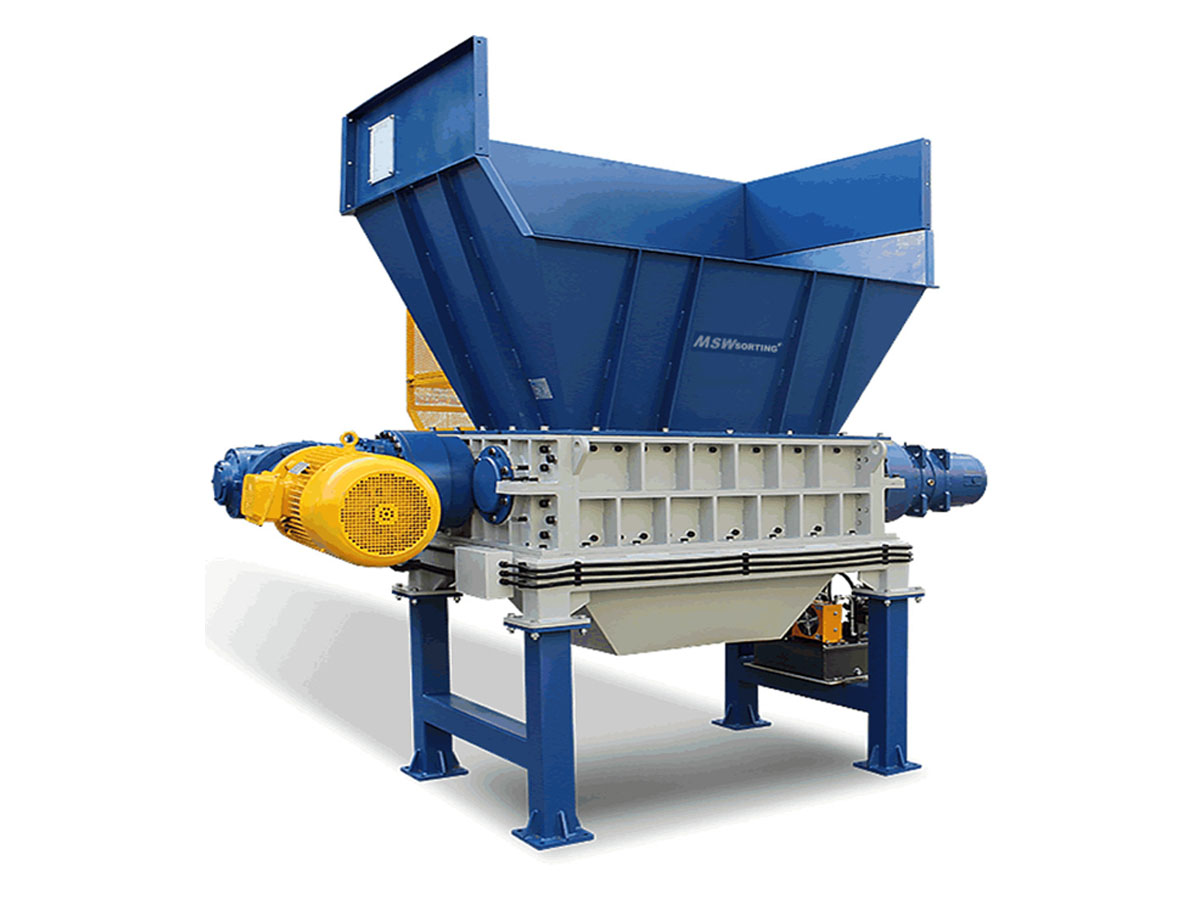

An E-waste Shredder is an industrial machine designed to process and reduce electronic waste into smaller, manageable pieces. It plays a crucial role in the recycling industry by breaking down discarded electronics such as computers, smartphones, circuit boards, and other e-waste components. By shredding e-waste, valuable materials like metals and plastics can be efficiently separated and recovered for reuse, minimizing environmental impact.

Working Principle of E-waste Shredder

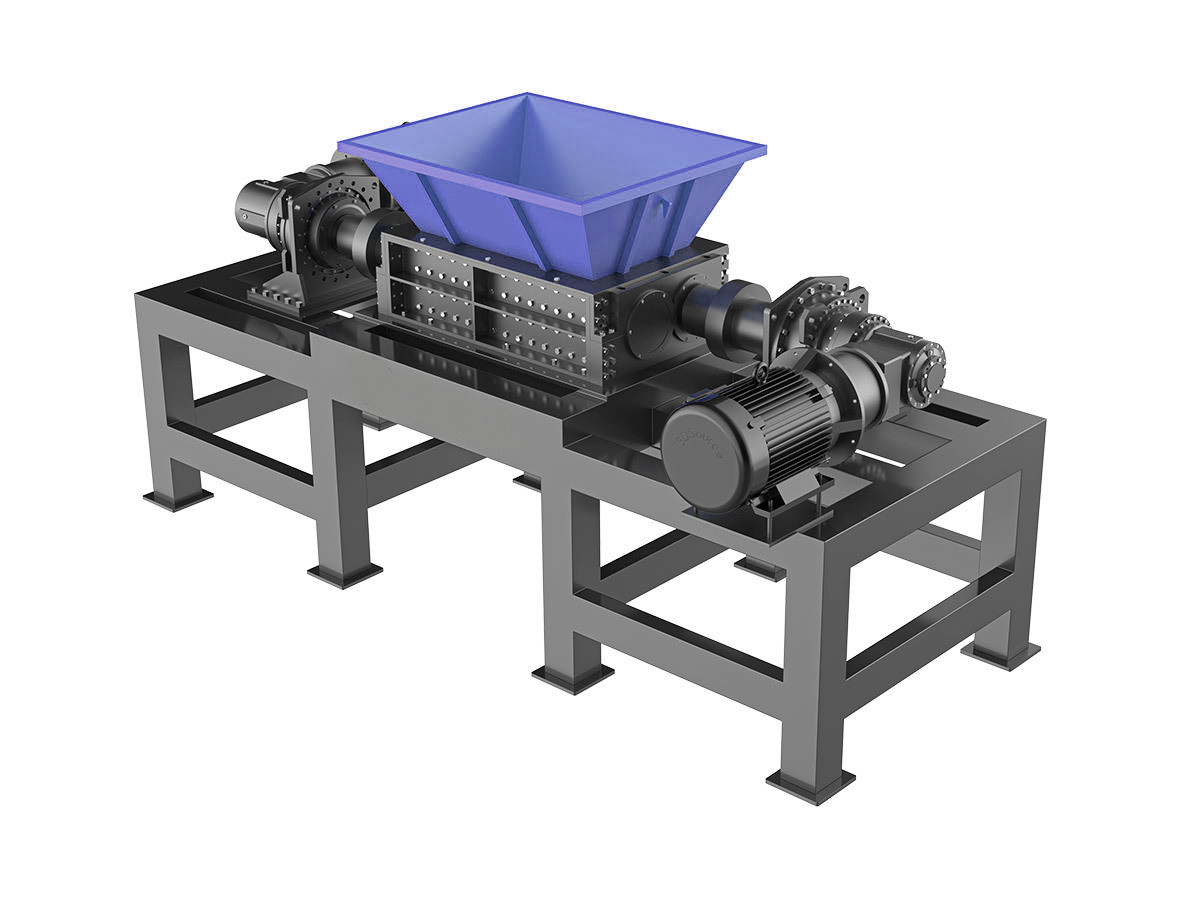

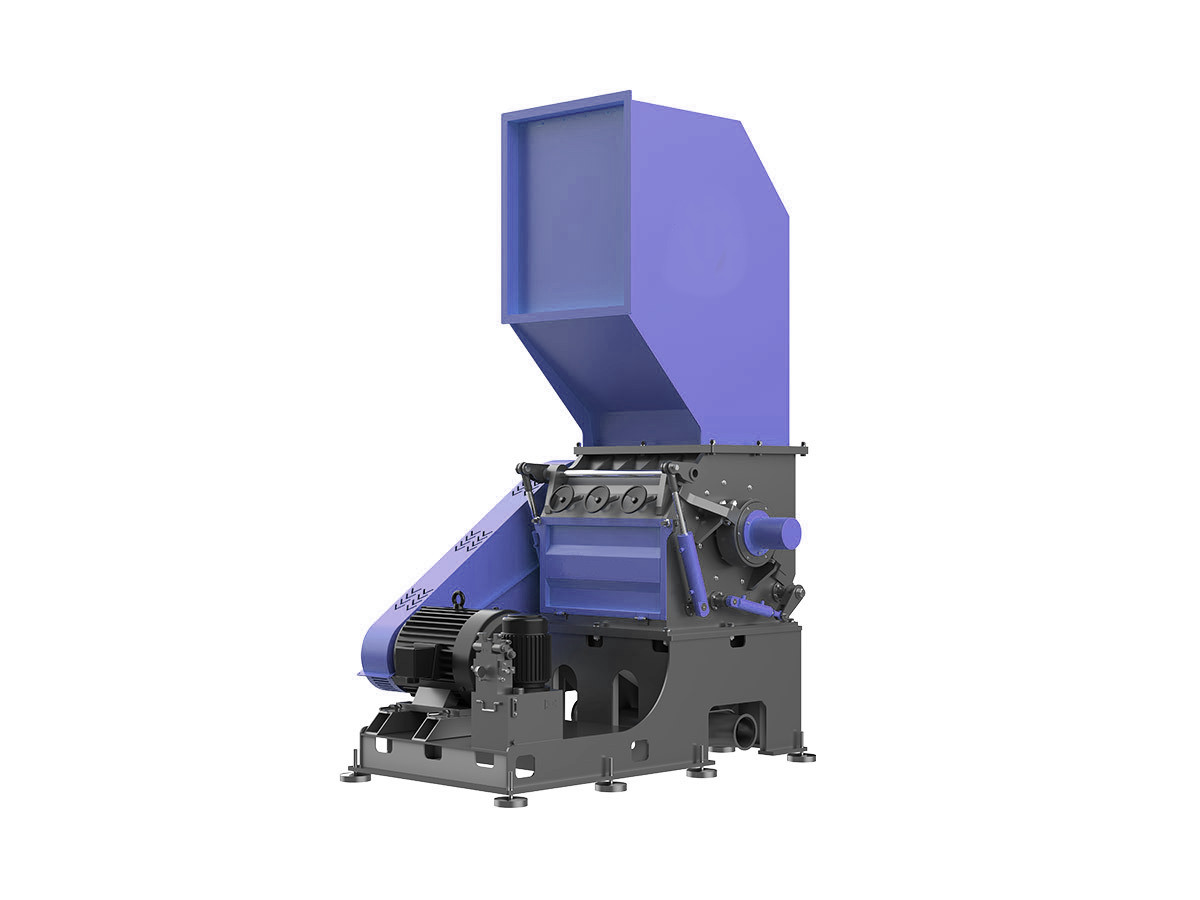

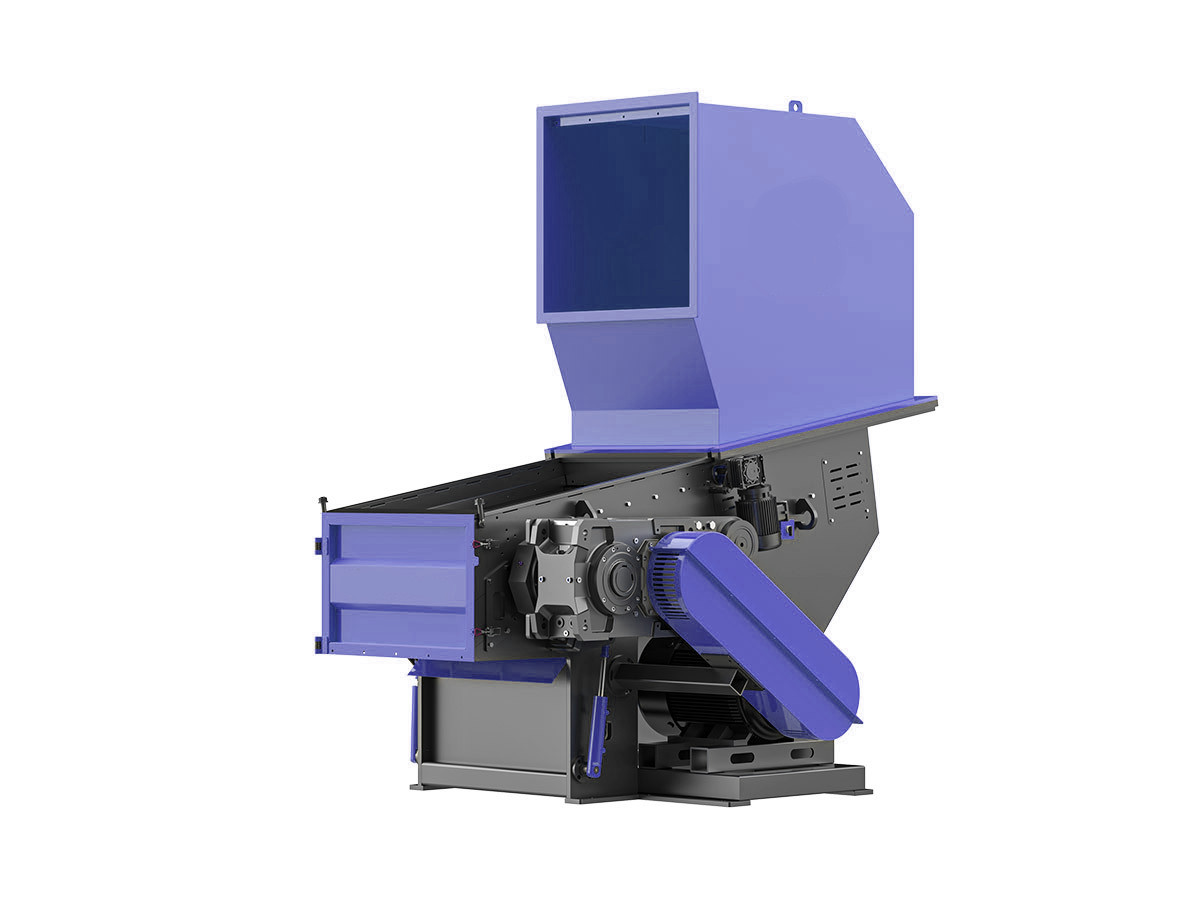

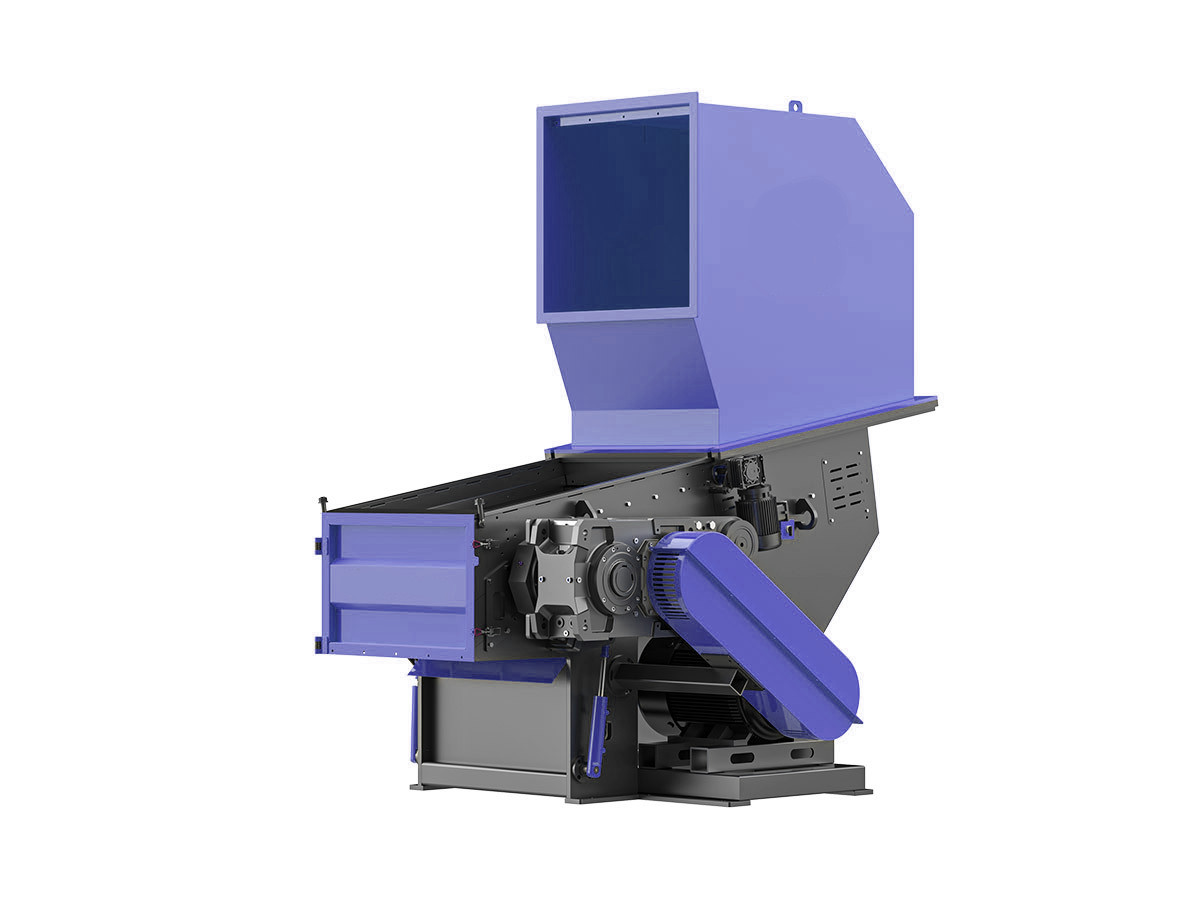

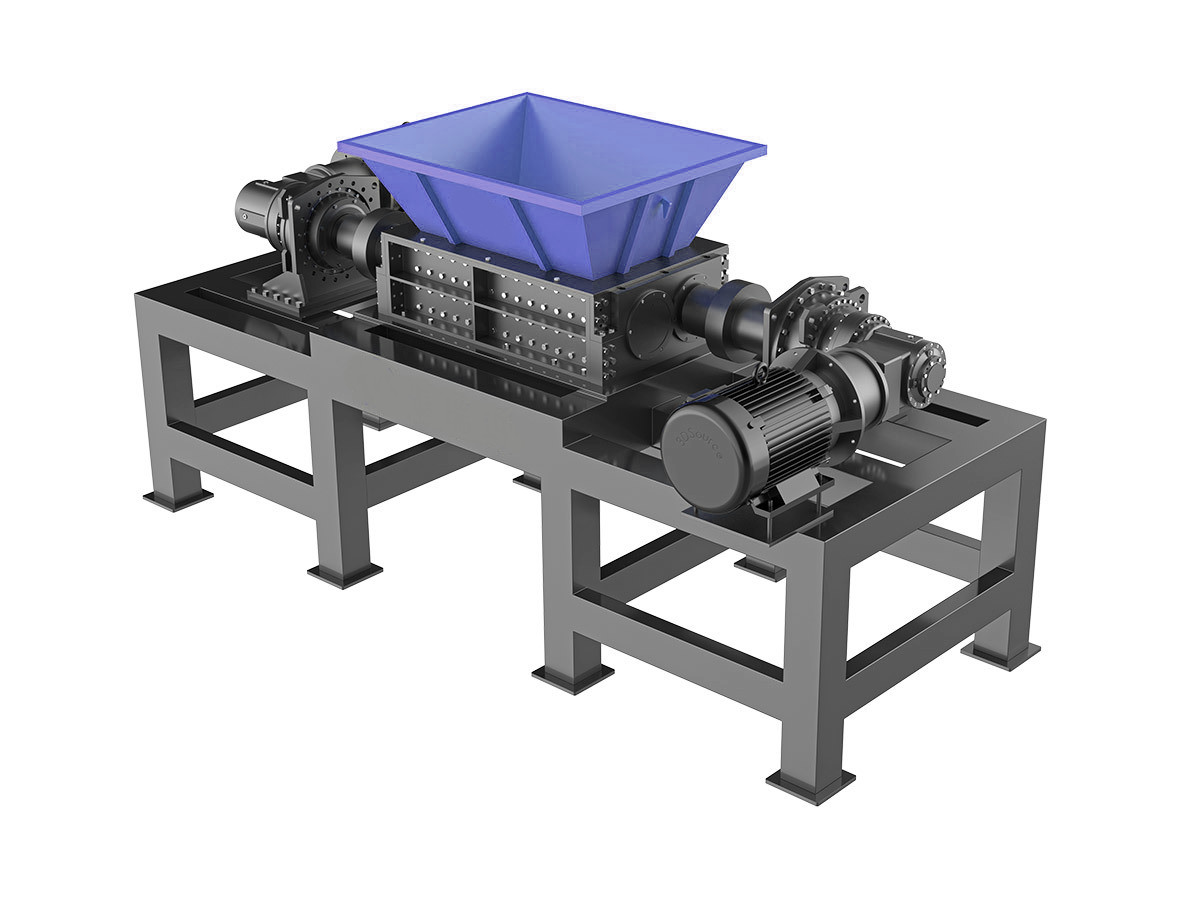

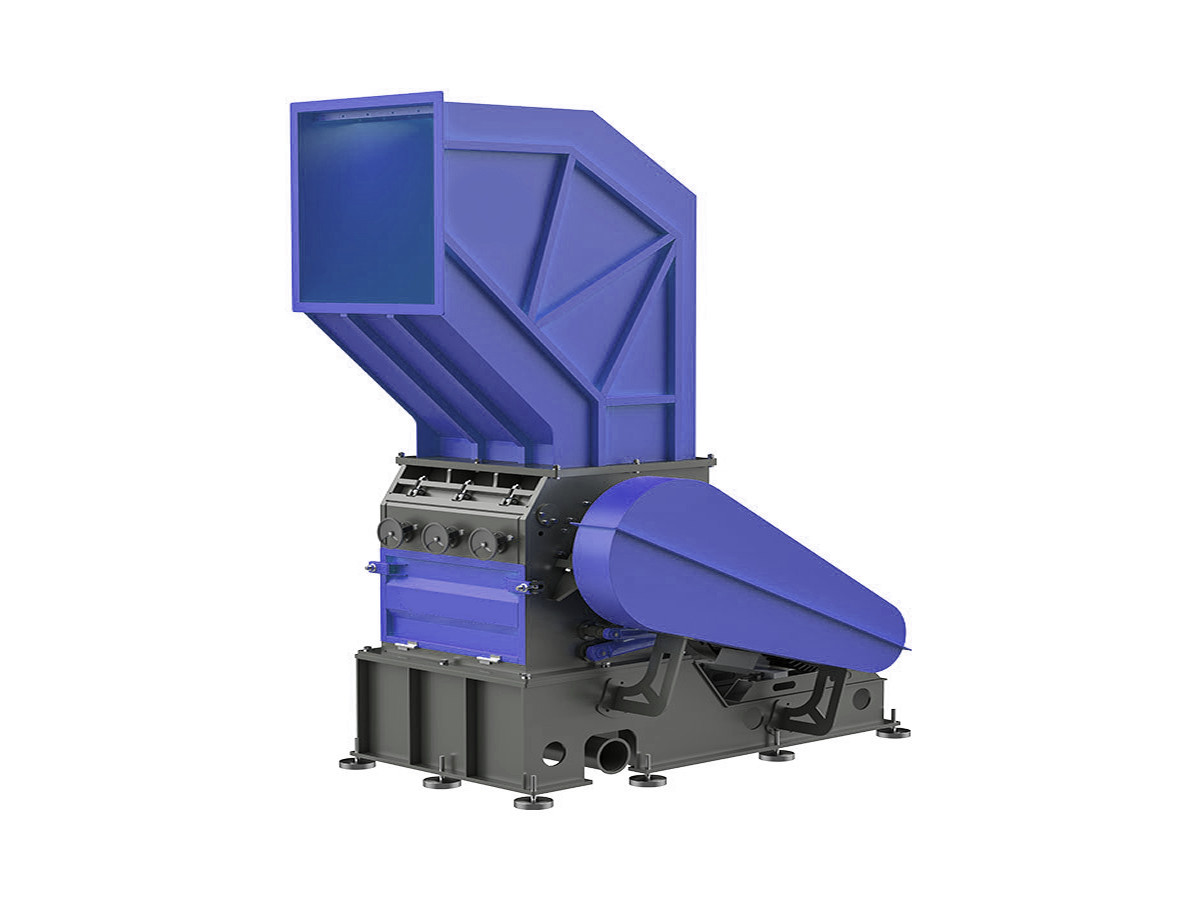

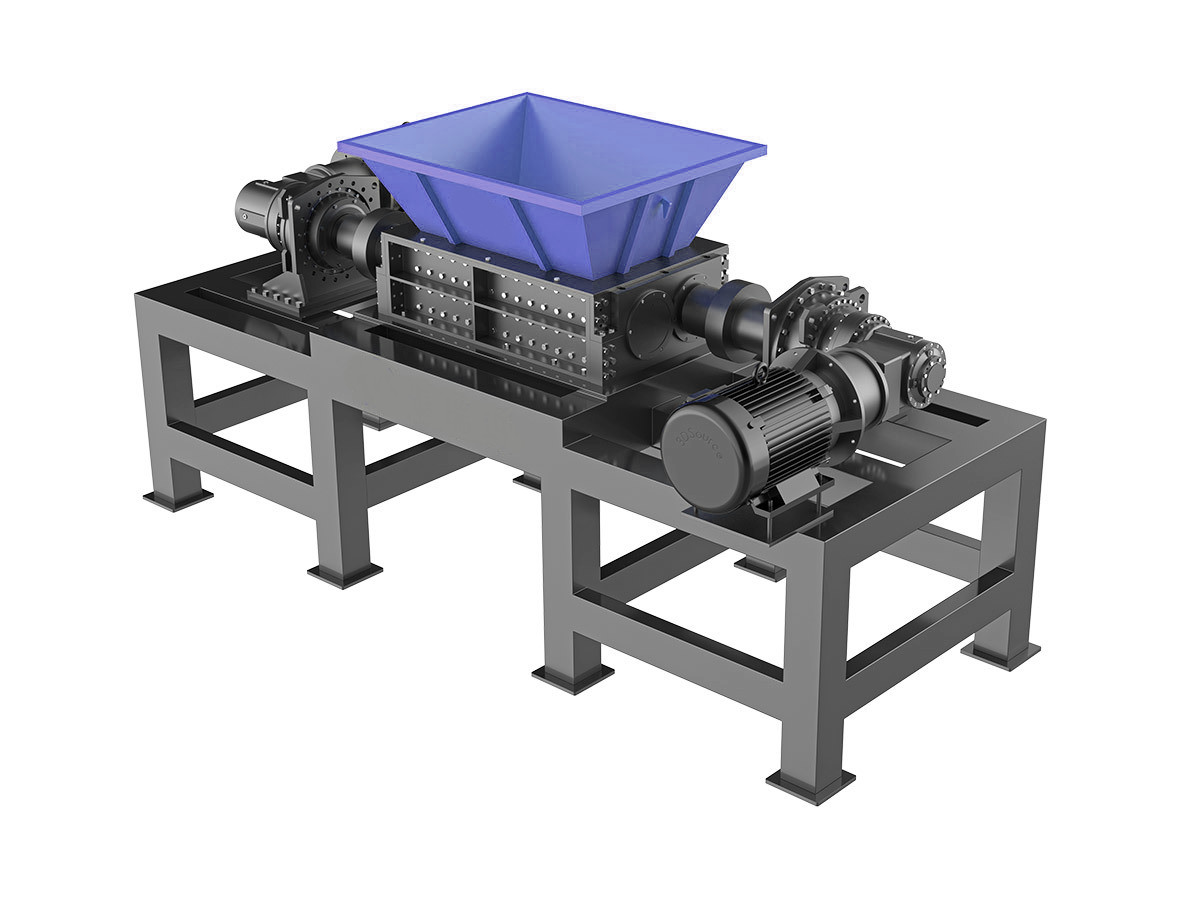

The working principle of an E-waste Shredder involves multiple cutting mechanisms such as rotary blades, hammer mills, or dual-shaft shredders. The e-waste is fed into the machine, where it is torn apart by high-torque cutting blades. These blades efficiently break down the materials into small particles, which can then be further processed for material recovery. Advanced shredders may also incorporate sorting systems to separate metals, plastics, and other materials.

How to Choose the Right E-waste Shredder?

Choosing the right E-waste Shredder depends on several factors, including the volume of e-waste to be processed, the type of materials involved, and the desired output size. Key considerations include shredding capacity, power consumption, durability, and the ability to handle different types of electronic waste. Businesses should also assess whether they need additional features such as dust control systems, automatic sorting, and compliance with environmental regulations.

Applications of E-waste Shredder

The E-waste Shredder is widely used in electronic waste recycling plants, IT asset disposal centers, and industrial recycling facilities. It helps recover valuable materials like copper, aluminum, and rare metals from discarded electronics. Additionally, shredding e-waste ensures data security by destroying sensitive information stored on old hard drives and electronic devices, making it an essential tool for businesses handling confidential data.

Maintenance of E-waste Shredder

Regular maintenance of an E-waste Shredder is essential for optimal performance and longevity. Key maintenance practices include routine blade sharpening or replacement, lubrication of moving parts, and clearing blockages to prevent overheating. Additionally, operators should inspect the machine for wear and tear and ensure compliance with safety standards. A well-maintained shredder increases efficiency and reduces downtime.

Main Components of E-waste Shredder

E-waste Shredder Types

Types of Waste Shredder Machine

Solid Waste Shredder

Efficiently process municipal and industrial waste into smaller, manageable sizes, aiding in recycling and waste disposal efforts.

Learn more >>

E-Waste Shredder

Specially engineered for electronic waste, this waste shredder handles materials like phones, computers, and circuit boards, ensuring secure disposal and recycling.

Learn more >>

Waste Metal Shredder

Our waste metal shredders efficiently process materials like aluminum, copper, and steel, making it easier to recycle and repurpose metal scrap.

Learn more >>

Waste Plastic Shredder

Built for recycling plastics like PE, PP, and PET, this waste shredder helps reduce plastic waste into manageable pieces for further processing.

Learn more >>

Waste Tire Shredder

Efficiently process used tires into reusable materials, including crumb rubber, for recycling and environmental sustainability.

Learn more >>

Waste Wood Shredder

Ideal for recycling wood waste like branches, pallets, and wooden furniture, this waste shredder helps create chips, mulch, or compost for eco-friendly disposal.

Learn more >>

Waste Paper Shredder

Ensure confidential document destruction with our secure waste paper shredders, designed for both small offices and large businesses.

Learn more >>

RDF Shredder

Transform waste into refuse-derived fuel (RDF) with this efficient waste shredder, perfect for waste-to-energy applications and reducing landfill dependency.

Learn more >>