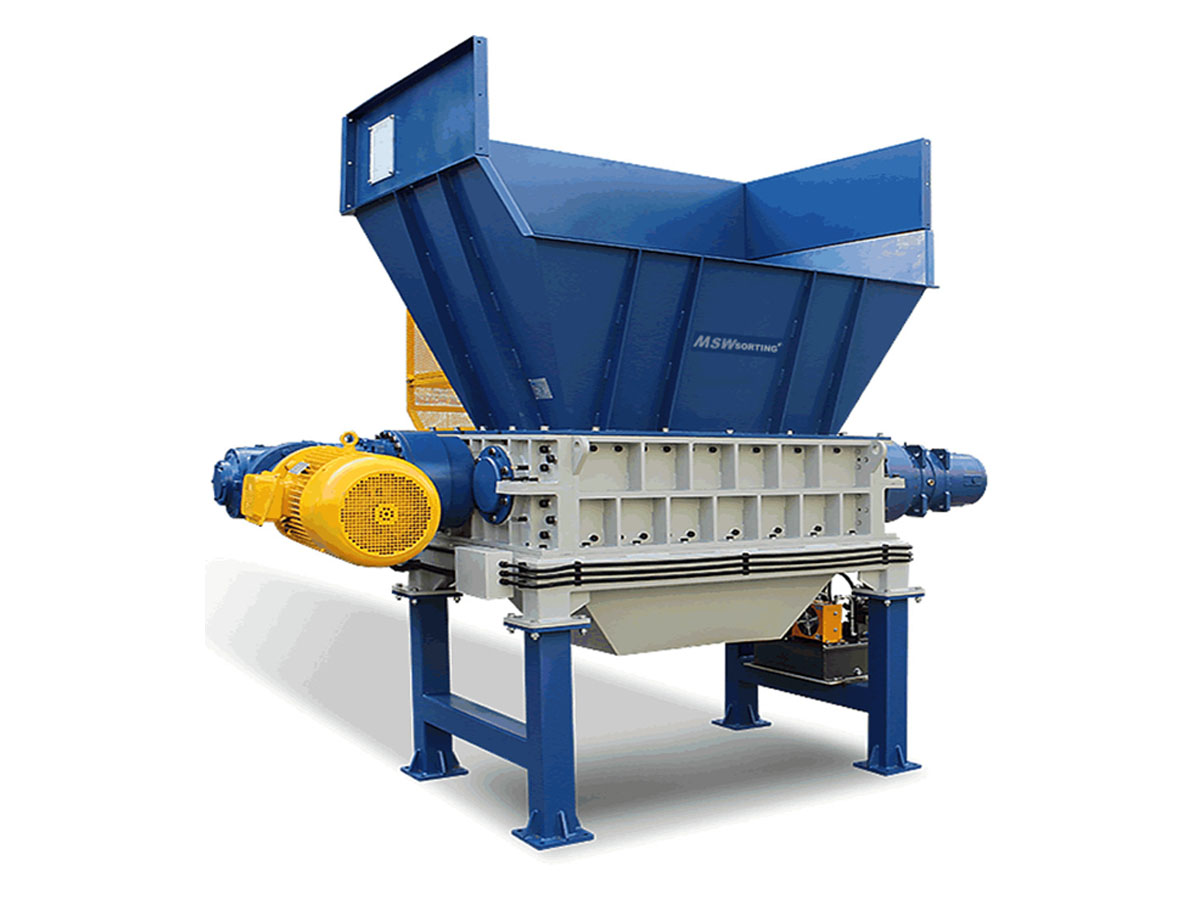

RDF Shredder

What is RDF Shredder?

RDF Shredder is a specialized machine designed to process waste materials into Refuse-Derived Fuel (RDF), an alternative fuel source used in cement kilns, power plants, and industrial boilers. It converts municipal solid waste (MSW), industrial waste, and commercial waste into small, uniform particles suitable for combustion.

By shredding waste into a consistent size, RDF shredders enhance the efficiency of waste-to-energy processes. They help reduce landfill waste while providing an environmentally friendly fuel alternative that reduces reliance on fossil fuels.

RDF shredders vary in size and design, with options ranging from single-shaft and dual-shaft shredders to high-capacity industrial machines. The choice of shredder depends on the type of waste being processed and the required output size.

Working Principle of RDF Shredder

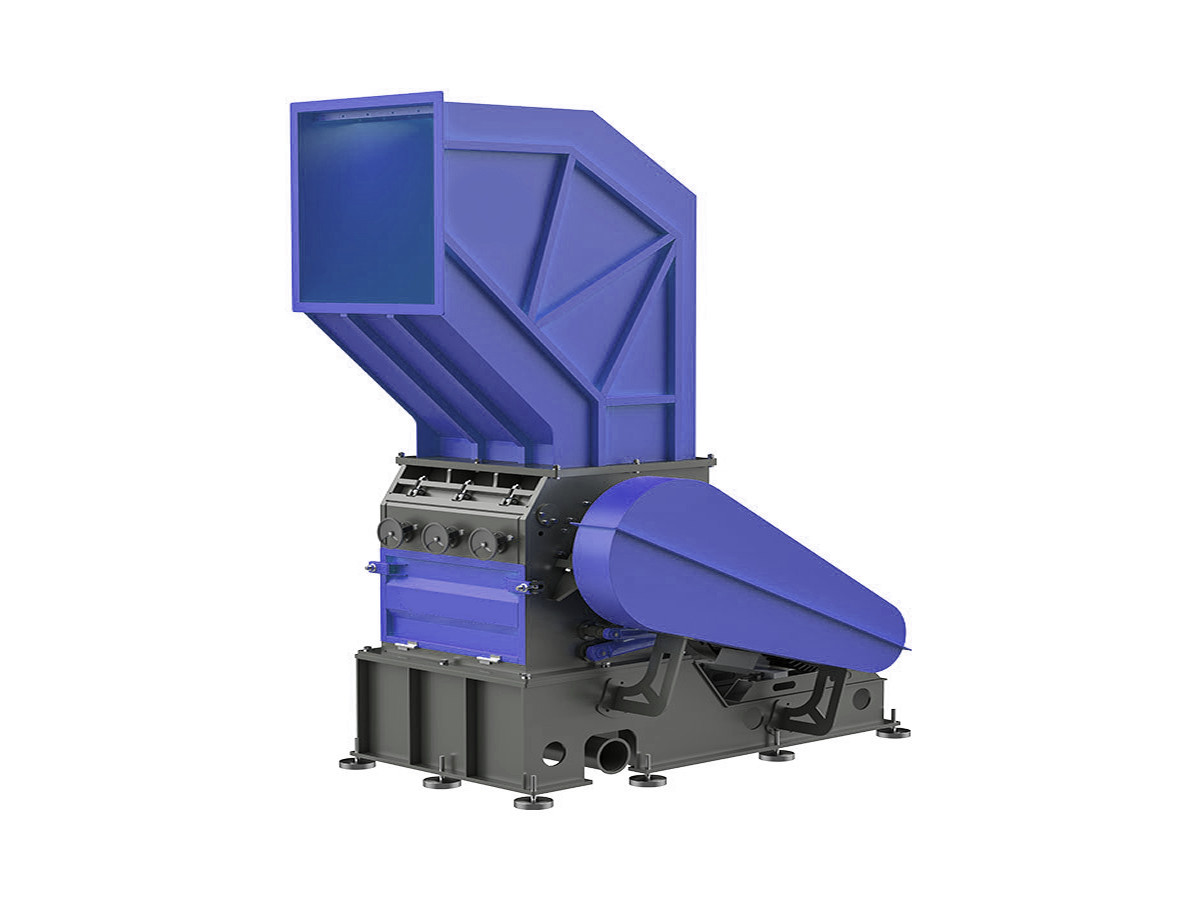

RDF Shredder operates by breaking down mixed waste materials into uniform fragments using high-torque cutting blades or hammers. The shredding process ensures that non-combustible components such as metal and glass are separated before producing the final RDF material.

When waste enters the shredder, rotating blades or cutting drums tear the material into smaller pieces. Some RDF shredders use a two-stage process, where an initial coarse shred is followed by a finer cut to achieve the desired particle size.

Advanced RDF shredders may include sorting mechanisms to separate recyclable materials from combustible waste, improving the efficiency and quality of the final RDF product. The process results in high-calorific-value material that can be used as an energy source.

1 Waste Intake

Mixed waste enters through heavy-duty conveyor belts or hopper feeding systems, designed to handle diverse material streams without clogging.

2 High-Torque Shredding

Rotating cutting blades or hammer mills reduce materials into uniform fragments, with configurations for single or multi-stage processing.

3 Material Separation

Integrated magnetic separators and air classifiers remove metals and non-combustibles, enhancing RDF quality for energy recovery.

4 Output Optimization

Final particle size screening ensures consistent 20-80mm RDF material with high calorific value, ready for waste-to-energy conversion.

How to Choose the Right RDF Shredder?

Choosing the right RDF Shredder depends on factors such as waste composition, required output size, and processing capacity. The type of waste being shredded—whether plastics, textiles, wood, or paper—affects the choice of cutting mechanism and shredder design.

For small-scale operations, a single-shaft shredder may be sufficient, while large industrial facilities may require dual-shaft or multi-stage shredders for higher efficiency. The durability of cutting blades is another key consideration, as RDF shredders must handle a variety of materials, including tough and abrasive waste.

Other important factors include energy efficiency, ease of maintenance, and automation features. Investing in a high-quality RDF shredder can optimize waste processing efficiency and reduce operational costs over time.

Applications of RDF Shredder

RDF Shredder is widely used in waste-to-energy facilities, cement plants, and industrial boilers to process waste into fuel. One of the primary applications is the production of RDF for co-incineration in cement kilns, where it serves as a cost-effective alternative to coal and other fossil fuels.

In power generation, RDF is used as a fuel source in waste-to-energy plants to generate electricity. It is also utilized in industrial heating systems, where it provides a sustainable energy solution for large-scale manufacturing operations.

Beyond energy production, RDF shredders contribute to sustainable waste management by reducing landfill waste and promoting recycling. The process helps recover valuable materials while converting non-recyclable waste into useful energy.

Maintenance of RDF Shredder

Regular maintenance of an RDF Shredder is essential to ensure consistent performance and longevity. Routine maintenance helps prevent breakdowns, minimizes downtime, and ensures efficient shredding operations.

Key maintenance tasks include inspecting and sharpening the cutting blades, as dull blades reduce shredding efficiency and increase power consumption. Cleaning the shredder regularly is also important to remove debris and prevent blockages.

Other essential maintenance steps involve lubricating moving parts, checking for wear on the motor and belts, and ensuring safety systems are fully functional. Following the manufacturer’s maintenance schedule helps maximize efficiency and prolong the machine’s lifespan.

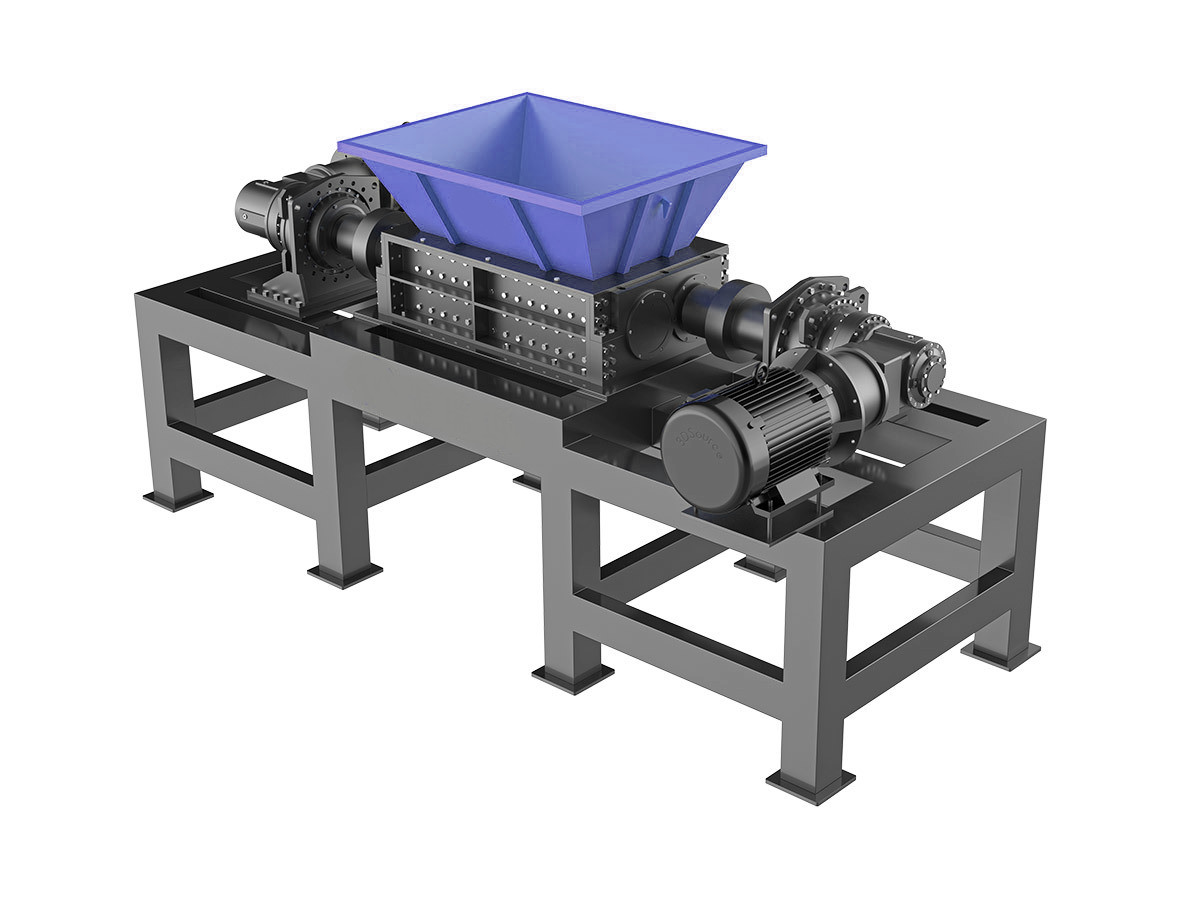

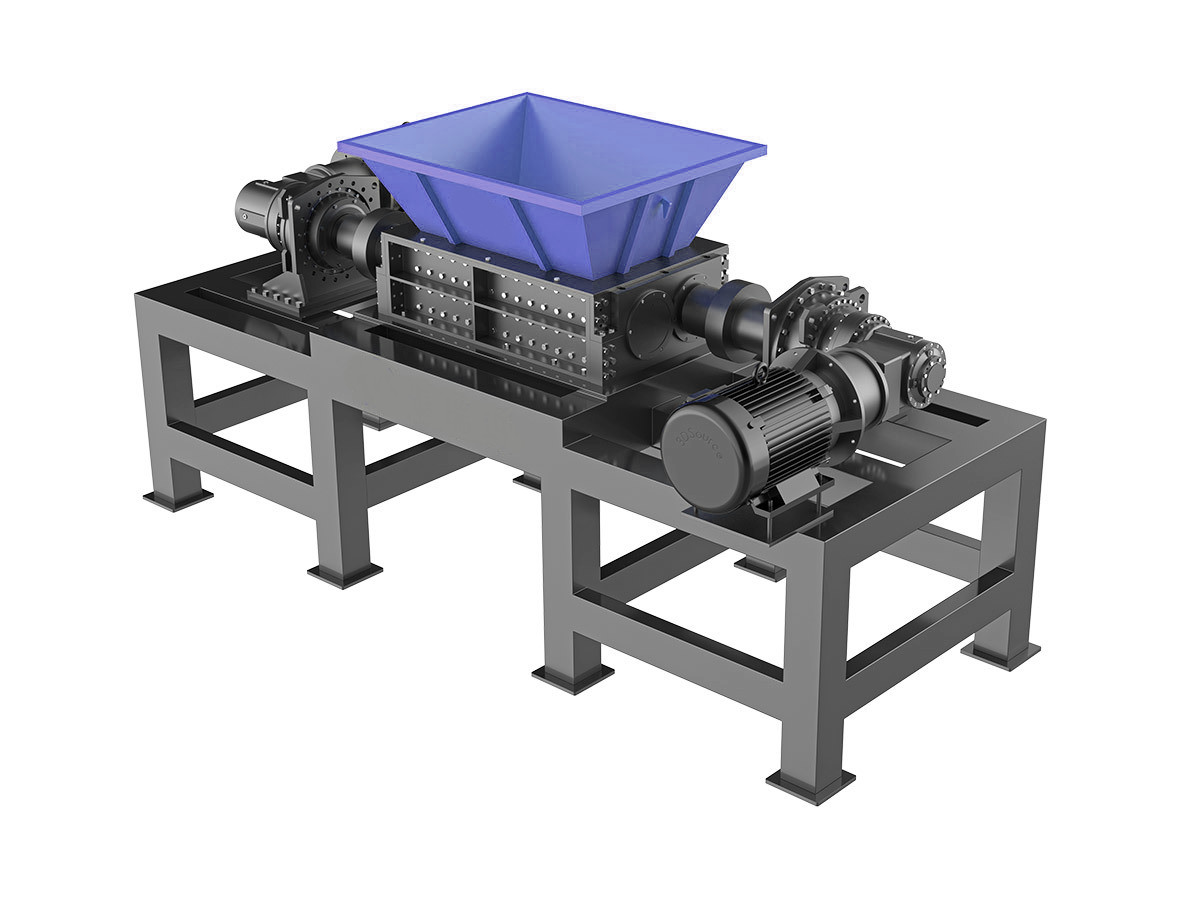

Main Components of RDF Shredder

RDF Shredder Types

Types of Waste Shredder Machine

Solid Waste Shredder

Efficiently process municipal and industrial waste into smaller, manageable sizes, aiding in recycling and waste disposal efforts.

Learn more >>

E-Waste Shredder

Specially engineered for electronic waste, this waste shredder handles materials like phones, computers, and circuit boards, ensuring secure disposal and recycling.

Learn more >>

Waste Metal Shredder

Our waste metal shredders efficiently process materials like aluminum, copper, and steel, making it easier to recycle and repurpose metal scrap.

Learn more >>

Waste Plastic Shredder

Built for recycling plastics like PE, PP, and PET, this waste shredder helps reduce plastic waste into manageable pieces for further processing.

Learn more >>

Waste Tire Shredder

Efficiently process used tires into reusable materials, including crumb rubber, for recycling and environmental sustainability.

Learn more >>

Waste Wood Shredder

Ideal for recycling wood waste like branches, pallets, and wooden furniture, this waste shredder helps create chips, mulch, or compost for eco-friendly disposal.

Learn more >>

Waste Paper Shredder

Ensure confidential document destruction with our secure waste paper shredders, designed for both small offices and large businesses.

Learn more >>

RDF Shredder

Transform waste into refuse-derived fuel (RDF) with this efficient waste shredder, perfect for waste-to-energy applications and reducing landfill dependency.

Learn more >>