Modern agriculture faces significant challenges in managing orchard waste, with traditional disposal methods becoming increasingly unsustainable and regulated. Wood shredders emerge as transformative technology that converts agricultural biomass from environmental liability into economic asset through circular economy principles. These industrial machines process pruned branches, woody debris, and organic waste into valuable products including mulch, compost, and biomass fuel, creating new revenue streams while addressing waste management challenges.

The global market for agricultural shredders is projected to reach $1.2 billion by 2027, driven by increasing regulatory pressure and growing recognition of biomass value. Farms implementing shredding technology report 40-60% reduction in waste management costs while generating additional revenue streams amounting to $50-150 per ton of processed material. This economic transformation positions wood shredders as essential equipment for sustainable orchard management worldwide.

Challenges of Orchard Waste Management in Modern Agriculture

Orchard waste management presents complex challenges due to the substantial volume, seasonal generation patterns, and heterogeneous composition of agricultural biomass. Traditional disposal methods struggle with the economic and environmental costs of handling woody materials that require specialized processing equipment. The increasing regulatory restrictions on burning and landfilling have created urgent needs for alternative solutions that align with sustainability principles.

Agricultural operations generate approximately 2-5 tons of woody waste per hectare annually, with variations depending on crop type, pruning intensity, and orchard age. This biomass represents both a disposal challenge and untapped economic opportunity, with current management practices often failing to capture the inherent value of these organic materials. The spatial distribution of orchards further complicates collection and transportation economics, particularly for smaller farming operations.

Volume and Composition of Orchard Waste (Branches/Leaves/Pruned Wood)

Orchard waste consists primarily of pruned branches, fallen trees, leaves, and occasional crop residues that vary significantly in size, density, and composition. Woody materials typically constitute 60-80% of total waste volume, with branch diameters ranging from 0.5cm to 15cm depending on pruning practices and tree species. The heterogeneous nature of this biomass requires robust processing equipment capable of handling varying material characteristics.

Moisture content fluctuates seasonally from 15-25% in dried branches to 45-60% in green waste, affecting both processing efficiency and potential end-uses. The bulk density of unprocessed orchard waste typically ranges between 80-150 kg/m³, which can be increased to 250-400 kg/m³ through shredding, dramatically improving transportation and handling efficiency. Nutrient analysis reveals carbon-nitrogen ratios of 60:1 to 120:1, indicating excellent potential for compost production with proper formulation.

Traditional Disposal Methods (Burning/Landfilling) and Environmental Impact

Traditional disposal methods predominantly involve open burning or transportation to landfills, both presenting significant environmental concerns. Open burning releases particulate matter, carbon monoxide, and volatile organic compounds, with agricultural burning contributing approximately 5-10% of regional air pollution in major farming areas according to environmental agency data.

Landfilling organic waste generates methane, a greenhouse gas 25 times more potent than carbon dioxide, while occupying valuable landfill space. Transportation costs for landfilling typically range from $25-50 per ton, with additional tipping fees of $30-70 per ton, making this economically unsustainable for many farming operations. The environmental costs extend beyond greenhouse gas emissions to include soil degradation and loss of valuable organic matter that could enhance agricultural sustainability.

Regulatory Pressures on Agricultural Waste Management (EU Landfill Directive/US EPA Rules)

Regulatory pressures have intensified globally, with the EU Landfill Directive requiring member states to reduce biodegradable municipal waste going to landfill to 35% of 1995 levels by 2025. The US EPA implements Clean Air Act regulations that restrict agricultural burning in many regions, with penalties exceeding $10,000 per violation for unauthorized burning incidents.

Many jurisdictions have implemented outright bans on agricultural burning during certain seasons or air quality conditions, with California's Air Resources Board restricting burning on 90-120 days annually. The European Green Deal's farm-to-fork strategy further encourages circular economy practices in agriculture, providing both regulatory pressure and financial incentives for sustainable waste management. These regulatory developments have created urgent needs for compliant waste management solutions throughout the agricultural sector.

Economic Losses from Unutilized Biomass Resources

Economic losses from unutilized biomass represent significant missed opportunities for agricultural operations. The inherent value of orchard waste includes potential revenue from biomass sales, cost savings from reduced fertilizer and mulch purchases, and avoided disposal costs that collectively amount to substantial economic benefits.

Research indicates that the average orchard operation loses $120-180 per hectare annually in unutilized biomass value, considering potential sales as biomass fuel ($40-80/ton), premium mulch ($60-120/ton), and compost feedstock ($25-50/ton). Additional losses occur through purchased inputs that could be replaced by processed biomass, including synthetic fertilizers ($80-120/hectare) and weed control materials ($30-60/hectare). These collective economic losses make traditional disposal methods increasingly unsustainable from financial perspectives.

Wood Shredders as Circular Economy Enablers

Wood shredders serve as fundamental technology enabling circular economy principles in agricultural operations by transforming waste into valuable resources. These machines facilitate the size reduction and homogenization of heterogeneous orchard waste, creating standardized materials suitable for various value-added applications. The technological evolution of agricultural shredders has produced specialized equipment capable of handling the unique challenges presented by orchard biomass.

Modern shredding equipment achieves throughput rates of 5-20 tons per hour depending on machine size and material characteristics, processing efficiency that enables real-time waste management during pruning operations. The versatility of output particle sizes allows farmers to tailor materials for specific applications from coarse mulch to fine biomass fuel, maximizing economic returns based on local market conditions and operational requirements.

Technical Specifications of Agricultural Wood Shredders (Chipper/Grinder Types)

Agricultural wood shredders encompass two primary technologies: drum chippers that utilize rotating drums with fixed knives for producing consistent chip sizes, and grinders that employ hammers or flails for more aggressive size reduction. Drum chippers typically produce uniform chips of 10-50mm suitable for biomass fuel and pulp production, while grinders generate more variable particle sizes ideal for mulch and compost applications.

Power requirements range from 30-100 horsepower for tractor-powered units to 100-500 horsepower for stationary industrial systems, with throughput capacities varying accordingly. Modern disc wood chipper designs incorporate hydraulic feeding systems that maintain consistent throughput regardless of material variations, achieving processing efficiencies of 2-5 tons per horsepower-hour. The selection between chipper and grinder technologies depends primarily on intended end-use applications and material characteristics.

Particle Size Control for Different End-Uses (Mulch/Compost/Biomass Fuel)

Particle size control represents a critical functionality that determines the economic value and appropriate applications of shredded biomass. Mulch applications typically require particle sizes of 15-75mm to provide effective weed suppression and moisture retention while allowing adequate air circulation. Compost production benefits from smaller particle sizes of 5-25mm that increase surface area for microbial activity and accelerate decomposition rates.

Biomass fuel production demands precise size control between 10-30mm for efficient combustion in automated boiler systems, with strict limitations on oversize particles that can cause feeding problems. Advanced wood shredder systems incorporate interchangeable screens and adjustable grinding elements that enable operators to produce specific particle size distributions for different markets. This flexibility allows farmers to maximize returns by targeting premium applications that command higher prices.

Integration with Existing Farm Infrastructure (Tractor-Powered/Stationary Units)

Shredder integration with existing farm infrastructure occurs through tractor-powered mobile units or stationary systems connected to material handling equipment. Tractor-powered models utilize power take-off (PTO) systems that provide mobility for in-field processing, typically requiring 50-150 horsepower tractors for adequate performance. These mobile units process material at the generation site, eliminating transportation costs for unprocessed biomass.

Stationary systems offer higher throughput capacities of 10-30 tons per hour and connect to conveyor systems for automated material handling. These installations require capital investment in infrastructure but provide superior processing efficiency and consistency for larger operations. The integration approach depends on farm size, material volume, and available infrastructure, with mobile units suitable for operations under 50 hectares and stationary systems preferred for larger enterprises.

Energy Consumption Optimization (Motor Efficiency/Load Management)

Energy consumption optimization focuses on motor efficiency, load management, and operational practices that minimize power requirements while maintaining throughput. Modern electric motors achieve efficiency ratings of 90-95% compared to 80-85% for older models, significantly reducing energy costs per ton processed. Variable frequency drives automatically adjust power consumption based on material load, reducing energy usage by 15-25% during light-load conditions.

Load management systems monitor current draw and automatically adjust feed rates to maintain optimal loading between 80-95% of capacity, maximizing energy efficiency while preventing overload situations. Operational practices including regular blade maintenance and proper material preparation further reduce energy consumption by 10-20%. These optimizations collectively reduce processing costs to $2-5 per ton, making biomass valorization economically viable even for lower-value applications.

Economic Value Creation Pathways

Wood shredders create economic value through multiple pathways that transform waste management from cost center to profit generator. These value creation mechanisms include direct cost savings, revenue generation from biomass sales, and secondary benefits from improved agricultural productivity. The comprehensive economic analysis demonstrates compelling returns on investment that justify equipment acquisition through both purchased and leased arrangements.

Economic modeling indicates typical payback periods of 2-4 years for shredder investments, with net present values exceeding $50,000 over 10-year equipment lifecycles for medium-sized operations. The value creation extends beyond direct financial returns to include risk reduction through regulatory compliance, improved sustainability credentials, and enhanced operational resilience through diversified revenue streams. These economic benefits have driven rapid adoption across agricultural sectors globally.

Cost Reduction in Waste Transportation and Disposal

Cost reduction in waste transportation and disposal represents the most immediate economic benefit, with shredding reducing biomass volume by 60-80% through increased bulk density. This volume reduction decreases transportation requirements by 3-5 times, lowering costs from $25-40 per ton for unprocessed material to $8-15 per ton for shredded biomass.

Elimination of tipping fees at landfills or waste facilities provides additional savings of $30-70 per ton, while avoiding costs associated with burning permits and environmental mitigation. The combined savings typically amount to $55-110 per ton of biomass that would otherwise require disposal, creating immediate economic benefits that partially or completely offset processing costs. These savings alone often justify equipment acquisition for operations generating more than 500 tons of biomass annually.

Revenue Generation from Shredded Biomass Sales (Landscaping/Power Plants)

Revenue generation from shredded biomass sales creates positive cash flow from material previously considered waste. Landscaping mulch markets offer prices of $60-120 per ton for colored or certified organic products, with standard agricultural mulch commanding $25-50 per ton depending on quality and region. Biomass fuel markets provide $40-80 per ton for material meeting specific moisture and quality specifications.

Specialty markets including playground surfacing, animal bedding, and filtration media offer premium prices of $100-200 per ton for carefully processed material with specific characteristics. The development of these markets requires investment in quality control and market development but provides superior returns compared to bulk biomass sales. Successful operations typically generate $35-90 per ton in net revenue after processing and transportation costs.

Carbon Credit Earnings Through Sustainable Waste Conversion

Carbon credit earnings provide additional revenue streams through certified emission reductions achieved by avoiding methane generation from landfilling and eliminating burning-related emissions. Methodology development under carbon standards including Verra and Gold Standard enables quantification and verification of emission reductions ranging from 0.5-1.2 tons CO2-equivalent per ton of biomass processed.

Current carbon prices of $15-30 per ton CO2-equivalent generate additional revenue of $7-36 per ton of biomass, with pricing projected to increase under climate policy developments. The certification process requires monitoring, reporting, and verification costs of $2-5 per ton, but net revenues remain significant particularly for larger operations. These carbon revenues enhance project economics while providing verifiable sustainability credentials valuable in consumer markets.

Government Subsidies for Circular Agriculture Practices

Government subsidies significantly improve investment economics through grants, tax incentives, and low-interest financing programs supporting circular economy practices. The EU Common Agricultural Policy provides grants covering 40-60% of equipment costs through rural development programs, while the US USDA offers similar support through EQIP and REAP programs.

Investment tax credits of 15-30% reduce net equipment costs, while accelerated depreciation provisions improve cash flow during initial investment periods. Specific programs including California's FARMER program provide additional incentives for agricultural equipment reducing air pollution. These subsidies typically reduce payback periods by 12-24 months and improve return on investment metrics by 25-40%, making projects economically attractive even for cautious investors.

Reduced Fertilizer Costs via Organic Mulch Application

Reduced fertilizer costs occur through nutrient recycling when shredded biomass is applied as mulch or incorporated into soils, slowly releasing nitrogen, phosphorus, and potassium while improving soil organic matter. Research demonstrates that proper application of woody mulch can reduce synthetic fertilizer requirements by 30-50% while improving water retention and soil structure.

The nutrient value of shredded biomass typically amounts to $15-30 per ton based on current fertilizer prices, with additional benefits from micronutrients and organic matter not captured in conventional fertilizer analysis. Soil health improvements including increased water infiltration, reduced erosion, and enhanced microbial activity provide further economic benefits though more difficult to quantify. These integrated benefits create compelling economic cases for on-farm utilization of processed biomass.

Shredder Technology Optimization for Orchard Waste

Shredder technology optimization focuses on addressing the unique challenges presented by orchard waste, including variable material size, contamination risks, and high fiber content. Modern equipment incorporates specialized designs that improve reliability, reduce maintenance requirements, and enhance processing efficiency for agricultural applications. These technological advancements have significantly increased equipment uptime and reduced operating costs compared to earlier generations.

Performance monitoring indicates that optimized shredders achieve availability rates exceeding 90% in agricultural applications, with maintenance costs reduced to $1.5-3.0 per ton processed. Throughput efficiencies have improved by 25-40% through advanced feeding mechanisms and cutting geometries that handle the specific material characteristics of orchard waste. These improvements have expanded the economic viability of biomass processing to smaller operations and more challenging material types.

Blade Design for Fibrous and Woody Materials (Carbide-Tipped/Flail Blades)

Blade design innovations address the abrasive nature of orchard waste through carbide-tipped cutting edges that maintain sharpness 3-5 times longer than conventional steel. The geometry of cutting edges has been optimized for fibrous materials, incorporating steep attack angles and specialized coatings that reduce energy consumption while preventing material wrapping.

Flail blade systems provide alternative processing for mixed materials containing soil and debris, sacrificing some cutting precision for greatly improved durability in contaminated conditions. The selection between fixed-blade and flail systems depends on material cleanliness and desired output quality, with fixed-blade systems producing more uniform products while flail systems offering superior durability. Advanced blade materials typically increase service life by 200-300%, reducing maintenance costs and downtime for blade changes.

Contamination Control (Rock/Metal Removal Systems)

Contamination control systems protect processing equipment from damage caused by rocks, metals, and other foreign materials commonly found in orchard waste. Magnetic separators effectively remove ferrous metals using permanent magnets generating fields up to 12,000 gauss, capturing nails, wire, and other metallic contaminants before they enter cutting chambers.

Stone detection systems utilize impact plates or acoustic sensors that identify non-metallic contaminants and trigger rejection mechanisms before damage occurs. The integration of these systems reduces damage-related downtime by 70-80% and extends component life by 2-3 times, significantly improving operational economics. Regular maintenance protocols including visual inspections and metal detector verification ensure continuous protection against costly contamination damage.

Dust Suppression Mechanisms (Water Spray/Enclosed Processing)

Dust suppression mechanisms address occupational health concerns and explosion risks associated with fine particle generation during shredding operations. Water spray systems incorporate fine mist nozzles that add 5-15% moisture content to processed material, effectively reducing dust generation by 80-90% without significantly affecting material handling properties.

Enclosed processing systems contain dust within sealed chambers equipped with filtration systems that capture particles above 99% efficiency. These systems typically incorporate HEPA filters for recirculating systems or baghouse filters for vented applications, maintaining airborne dust concentrations below occupational exposure limits. The implementation of dust control is particularly important for materials destined for animal bedding or other sensitive applications where dust content affects marketability.

Mobile vs Stationary Shredder Selection Criteria

Mobile versus stationary shredder selection involves evaluating multiple factors including material volume, transportation costs, infrastructure requirements, and operational flexibility. Mobile systems offer advantages for distributed processing across multiple locations, eliminating biomass transportation costs and enabling real-time processing during pruning operations.

Stationary systems provide higher throughput capacities, superior energy efficiency, and better integration with material handling and storage infrastructure. The economic analysis typically favors mobile units for operations under 100 hectares or multiple dispersed locations, while stationary systems prove more economical for larger centralized operations. Lifecycle cost analysis generally indicates 15-25% lower processing costs for stationary systems at sufficient scale, but mobile systems provide compensating benefits through operational flexibility.

Case Studies of Successful Implementations

Case studies of successful implementations demonstrate the practical application and economic benefits of wood shredders in diverse agricultural contexts. These real-world examples provide valuable insights into implementation challenges, operational practices, and economic outcomes that inform investment decisions. The documented experiences highlight both the versatility of shredding technology and the importance of context-specific implementation planning.

Analysis of successful projects reveals common factors including thorough pre-implementation planning, appropriate equipment selection, and development of markets for processed materials. The economic performance typically exceeds initial projections due to secondary benefits and market developments not fully captured in feasibility studies. These case studies provide compelling evidence for the economic and environmental benefits of integrating shredding technology into agricultural operations.

Mediterranean Olive Grove Waste Conversion (Pellet Fuel Production)

Mediterranean olive groves have implemented large-scale shredding operations that process pruning waste into pellet fuel for heating applications. Spanish operations typically process 5-10 tons per hour of olive wood, producing pellets that command premium prices due to high calorific value and low ash content. The integrated operations achieve production costs of €120-150 per ton for pellets sold at €220-280 per ton.

Italian implementations have developed specialized double shaft wood shredder configurations that handle the challenging geometry of olive wood branches, achieving throughput rates 20-30% higher than conventional designs. The economic analysis demonstrates payback periods of 2.5-3.5 years despite higher capital costs, with net present values exceeding €300,000 over 10-year project lifecycles. These successful implementations have created new revenue streams while addressing serious wildfire risks associated with accumulated pruning waste.

Citrus Farm Branch Mulching for Soil Conservation (California/Spain)

California citrus farms have implemented shredding systems that process pruning waste into mulch for in-orchard application, improving soil moisture retention and reducing irrigation requirements by 20-30%. The integrated approach eliminates disposal costs while providing agronomic benefits valued at $800-1200 per hectare annually through reduced water and fertilizer inputs.

Spanish citrus operations in Valencia have developed similar systems that additionally address soil erosion challenges on sloping terrain, reducing sediment loss by 60-70% compared to bare soil. The economic analysis demonstrates complete payback within 2-3 years even without considering revenue from biomass sales, with the combined benefits of disposal cost avoidance and production improvements creating compelling economics. These implementations demonstrate the value of integrated approaches that maximize on-farm utilization of processed biomass.

Apple Orchard Waste to Biogas Feedstock (Washington State/Germany)

Washington State apple orchards have partnered with anaerobic digestion facilities to supply shredded pruning waste as biomass feedstock for biogas production. The material provides structural composition that improves digestion efficiency when mixed with high-moisture substrates, increasing biogas yield by 15-20% compared to conventional feedstocks.

German implementations in the Bodensee region have developed specialized shredding protocols that optimize particle size distribution for anaerobic digestion, achieving methane yields of 250-300 m³ per ton of volatile solids. The economic model includes transportation costs to centralized digestion facilities but still demonstrates net returns of $40-60 per ton after processing and transportation. These partnerships create symbiotic relationships between agricultural operations and renewable energy producers while addressing waste management challenges.

ROI Analysis (2-5 Year Payback Periods)

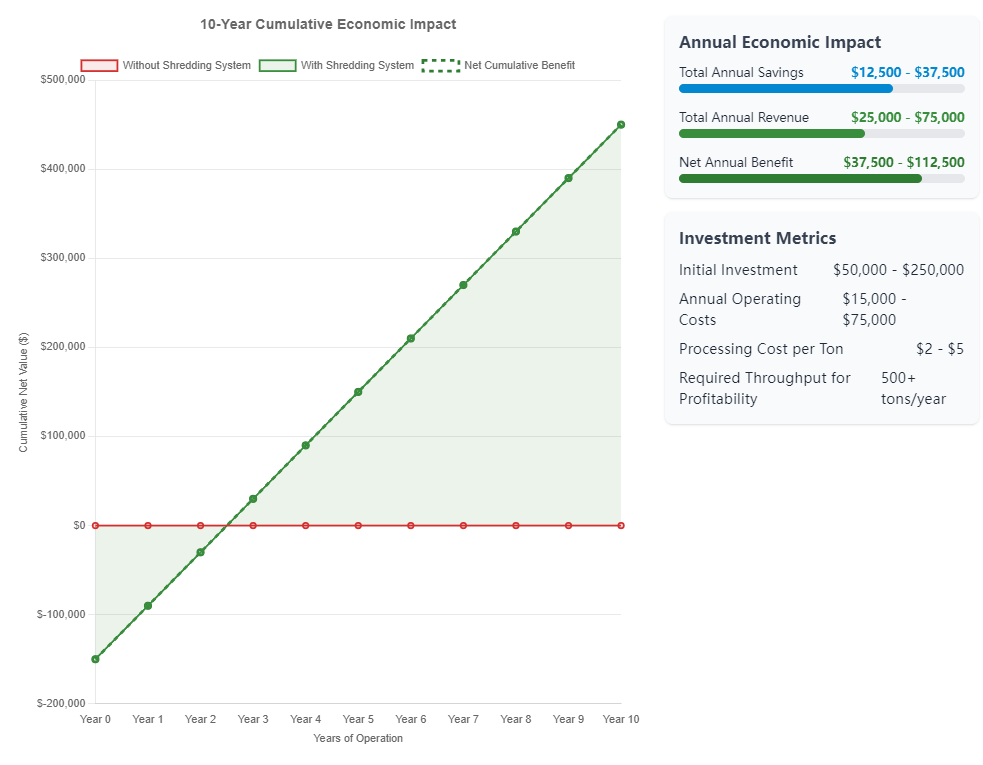

Comprehensive ROI analysis across multiple implementations reveals payback periods typically ranging from 2-5 years depending on scale, material characteristics, and market conditions. Smaller operations (under 50 hectares) generally achieve payback in 3.5-5 years due to higher per-ton processing costs, while larger operations (over 100 hectares) frequently achieve payback within 2-3 years.

The analysis considers capital costs ranging from $50,000-250,000 for equipment, annual operating costs of $15,000-75,000, and net revenues of $40-90 per ton processed. Sensitivity analysis indicates that biomass prices and transportation cost savings represent the most significant variables affecting economic outcomes. The consistent positive results across diverse conditions demonstrate the economic robustness of shredding investments for orchard waste management.

Policy and Market Drivers

Policy and market drivers have created favorable conditions for adoption of wood shredding technology in agricultural applications. Regulatory developments, sustainability initiatives, and market transformations collectively encourage circular economy practices that valorize agricultural waste streams. Understanding these drivers is essential for assessing investment opportunities and developing strategic implementation plans.

The convergence of environmental regulation, climate policy, and market demand for sustainable products has created unprecedented opportunities for biomass valorization. Policy developments typically provide both regulatory pressure for change and financial incentives for adoption, while market drivers create economic opportunities that enhance investment returns. These complementary drivers have accelerated technology adoption across global agricultural sectors.

EU Farm to Fork Strategy Impact on Agricultural Waste

The EU Farm to Fork Strategy establishes ambitious targets for reducing nutrient losses by 50% while increasing organic farming area to 25% of agricultural land by 2030. These targets create both regulatory pressure and financial incentives for circular economy practices that utilize organic waste streams within agricultural systems.

The strategy's emphasis on reducing synthetic fertilizer usage by 20% directly encourages nutrient recycling through processed biomass applications. Associated funding mechanisms including CAP strategic plans provide financial support for equipment investments that advance these objectives. The integrated policy approach has significantly accelerated adoption of shredding technology throughout European agricultural sectors.

USDA BioPreferred Program Certification Benefits

The USDA BioPreferred Program provides preferential procurement for biobased products across federal agencies and encourages private sector adoption through certification and labeling. Products containing shredded agricultural biomass qualify for certification when meeting minimum biobased content requirements, providing market access and price premiums.

The program's labeling initiative increases consumer recognition and acceptance of biobased products, creating market differentiation opportunities for materials derived from agricultural waste. Federal procurement requirements mandate purchase of biobased products when available, creating stable demand for qualified materials. These market development efforts significantly enhance the economic viability of biomass processing operations.

Carbon Pricing Mechanisms Affecting Waste Valorization

Carbon pricing mechanisms including emissions trading systems and carbon taxes have improved the economics of waste valorization by increasing the cost of traditional disposal methods and creating revenue opportunities for emission reductions. The EU Emissions Trading System prices have exceeded €80 per ton CO2-equivalent, making avoided emissions through biomass utilization increasingly valuable.

National carbon taxes in Canada, South Africa, and other jurisdictions similarly increase the cost of landfill disposal and burning while creating economic incentives for sustainable alternatives. Compliance carbon markets typically offer higher prices but require more rigorous quantification and verification, while voluntary markets provide flexibility for smaller operations. These pricing mechanisms collectively improve the economic returns on shredding investments by 15-25%.

Corporate Sustainability Commitments (Agribusiness Buyers)

Corporate sustainability commitments have created premium markets for agricultural products produced using circular economy practices. Major food processors and retailers including Unilever, Nestlé, and Walmart have established sourcing preferences for ingredients produced with sustainable waste management practices.

These commitments often include specific targets for reducing supply chain emissions and increasing circularity, creating demand for verifiable sustainable practices throughout agricultural supply chains. The price premiums typically range from 5-15% for certified sustainable products, providing additional economic benefits beyond direct biomass valorization. These market developments have significantly expanded the economic case for investing in shredding technology.

Future Innovation Directions

Future innovation directions promise to further enhance the economic viability and environmental benefits of wood shredders in agricultural applications. Technological advancements, business model innovations, and integration opportunities collectively drive continuous improvement in equipment performance and application diversity. These developments will expand adoption to broader agricultural sectors and create new value creation opportunities.

Emerging innovations focus on reducing costs, improving reliability, and creating higher-value products from agricultural biomass. The integration of digital technologies, advanced materials, and novel processing approaches will transform shredding from simple size reduction to sophisticated biomass preparation for diverse applications. These innovations will further strengthen the economic case for circular economy practices in agriculture.

IoT-Enabled Shredders with Predictive Maintenance

IoT-enabled shredders incorporate sensors that monitor equipment condition, performance parameters, and output quality in real-time, enabling predictive maintenance that reduces downtime and improves reliability. Vibration analysis detects bearing wear and imbalance weeks before failure, while motor current monitoring identifies developing mechanical problems.

Cloud connectivity enables remote monitoring and diagnostics, reducing service response times and improving first-time fix rates for maintenance issues. The data collected supports continuous improvement through performance benchmarking and operational optimization. These technologies typically reduce maintenance costs by 20-30% and increase equipment availability by 5-10 percentage points, significantly improving operational economics.

Biomass Pretreatment for Advanced Biofuels (Pyrolysis/Gasification)

Biomass pretreatment innovations optimize shredded material for advanced conversion technologies including pyrolysis, gasification, and hydrothermal processing. Specific particle size distributions, moisture content adjustments, and contamination removal create ideal feedstock characteristics for these conversion processes that produce higher-value energy products.

Integrated systems that combine shredding with drying, torrefaction, or pelletization enable entry into premium energy markets with prices 2-3 times higher than raw biomass. These advanced processing pathways typically require greater capital investment but offer superior returns for operations with sufficient scale and access to conversion facilities. The development of decentralized conversion technologies will further expand these opportunities for agricultural operations.

Circular Business Models (Lease-to-Own/Performance Contracts)

Circular business models including lease-to-own arrangements and performance-based contracts reduce barriers to adoption by minimizing upfront capital requirements. Equipment manufacturers and specialized service providers offer shredding services based on throughput or processed volume, creating predictable costs while eliminating capital investment.

Performance contracts guarantee specific outcomes including cost savings or revenue generation, with payments based on achieved results rather than equipment usage. These innovative business models typically increase adoption rates by 300-400% compared to traditional sales models, particularly among smaller operations with limited capital availability. The development of these models represents a significant innovation in agricultural equipment marketing and financing.

Integration with On-Farm Renewable Energy Systems

Integration with on-farm renewable energy systems creates synergies that improve overall economics and sustainability. Solar or wind power can operate electric shredders during periods of excess generation, effectively utilizing renewable energy that would otherwise be curtailed.

Processed biomass can fuel boilers for greenhouse heating or drying operations, displacing fossil fuels and improving energy independence. The integrated approach typically improves return on investment for both renewable energy and shredding investments by 15-25% through optimized energy utilization and enhanced value creation. These synergies will become increasingly important as renewable energy adoption expands in agricultural sectors.

Implementation Roadmap for Farmers

Implementation roadmap provides structured guidance for farmers considering adoption of wood shredding technology, outlining key steps from initial assessment through operational optimization. This systematic approach ensures thorough consideration of all relevant factors and maximizes probability of successful implementation. The roadmap addresses technical, economic, and operational aspects in an integrated manner.

Successful implementations typically follow a phased approach beginning with feasibility assessment, progressing through equipment selection and installation, and concluding with operational optimization and market development. Each phase requires specific expertise and considerations that should be addressed systematically rather than reactively. The comprehensive approach typically reduces implementation risks and improves economic outcomes by 20-30% compared to ad hoc approaches.

Waste Auditing and Shredder Capacity Planning

Waste auditing involves quantifying biomass availability, characterizing material properties, and identifying seasonal variations that affect equipment utilization. Detailed analysis typically includes weighing representative samples, mapping spatial distribution, and assessing contamination levels that influence equipment selection.

Capacity planning matches equipment specifications to biomass availability, considering both peak processing requirements during pruning seasons and annual utilization rates that affect economic viability. The analysis typically targets equipment utilization of 400-800 hours annually for economic viability, with larger operations justifying higher utilization rates. Proper planning ensures equipment selection matches operational requirements without excessive capital investment or capacity constraints.

Partnership Models with Bioenergy Producers

Partnership models with bioenergy producers create reliable markets for processed biomass while providing stable revenue streams that enhance investment economics. Long-term supply agreements typically guarantee minimum prices and volumes, reducing market risk and facilitating equipment financing.

Advanced partnership structures include revenue sharing arrangements where bioenergy producers contribute to equipment costs in exchange for preferential pricing, or joint venture models that create aligned economic interests. These partnerships typically improve project economics by 15-25% through reduced market risk and enhanced revenue stability. The development of strong partnerships represents a critical success factor for many implementations.

Training Programs for Equipment Operation and Safety

Training programs ensure safe and efficient equipment operation while maximizing equipment lifespan and minimizing downtime. Comprehensive training typically includes classroom instruction covering operational principles, hands-on operation practice, and maintenance procedures specific to the equipment implemented.

Safety training focuses on hazard identification, personal protective equipment requirements, and emergency procedures specific to shredding operations. Certification programs provide formal recognition of competency and ensure consistent operational practices across multiple operators. Proper training typically reduces operational costs by 10-15% through improved efficiency and reduced maintenance requirements while enhancing workplace safety.

Certification Schemes for Premium Biomass Products

Certification schemes enable access to premium markets by verifying sustainable production practices and product quality characteristics. Organic certification requires documentation of input materials and processing methods, typically commanding price premiums of 20-30% for mulch and soil amendment products.

Sustainability certifications including FSC and PEFC provide chain-of-custody documentation that verifies sustainable sourcing practices, increasingly required by corporate buyers and public procurement. Quality certifications ensure consistent product characteristics that meet specific market requirements, reducing buyer risk and enabling repeat sales. The implementation of appropriate certification typically enhances revenues by 15-25% while providing market differentiation.