What Are Waste Shredder Machines?

Understanding the Function of Waste Shredder Machines

Waste shredder machines are powerful mechanical devices designed to break down various materials into smaller, more manageable pieces. They are widely used across different industries for waste reduction, material recycling, and resource recovery.

By utilizing rotating blades, hammers, or cutting edges, waste shredders effectively process solid waste, metals, plastics, and other materials. Their primary function is to enhance material handling efficiency and facilitate further processing or disposal.

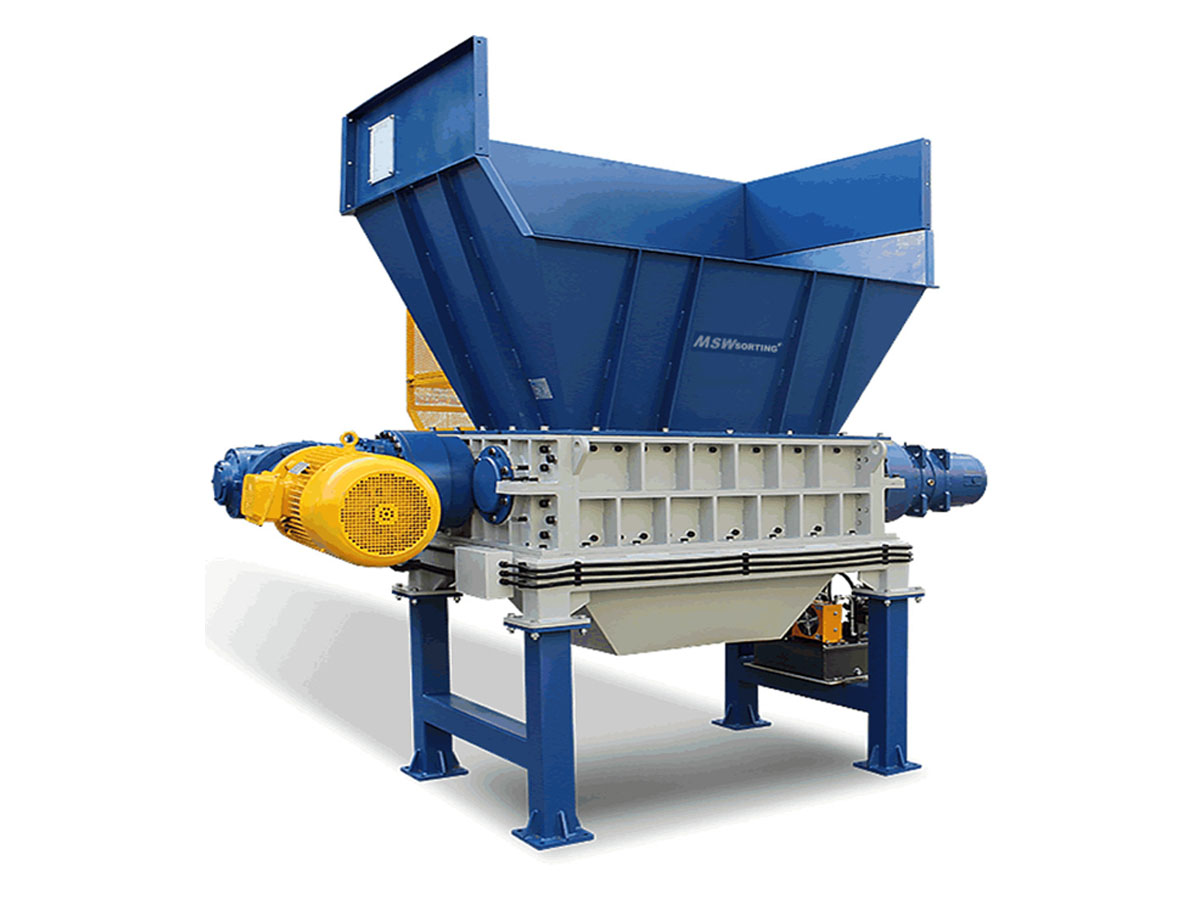

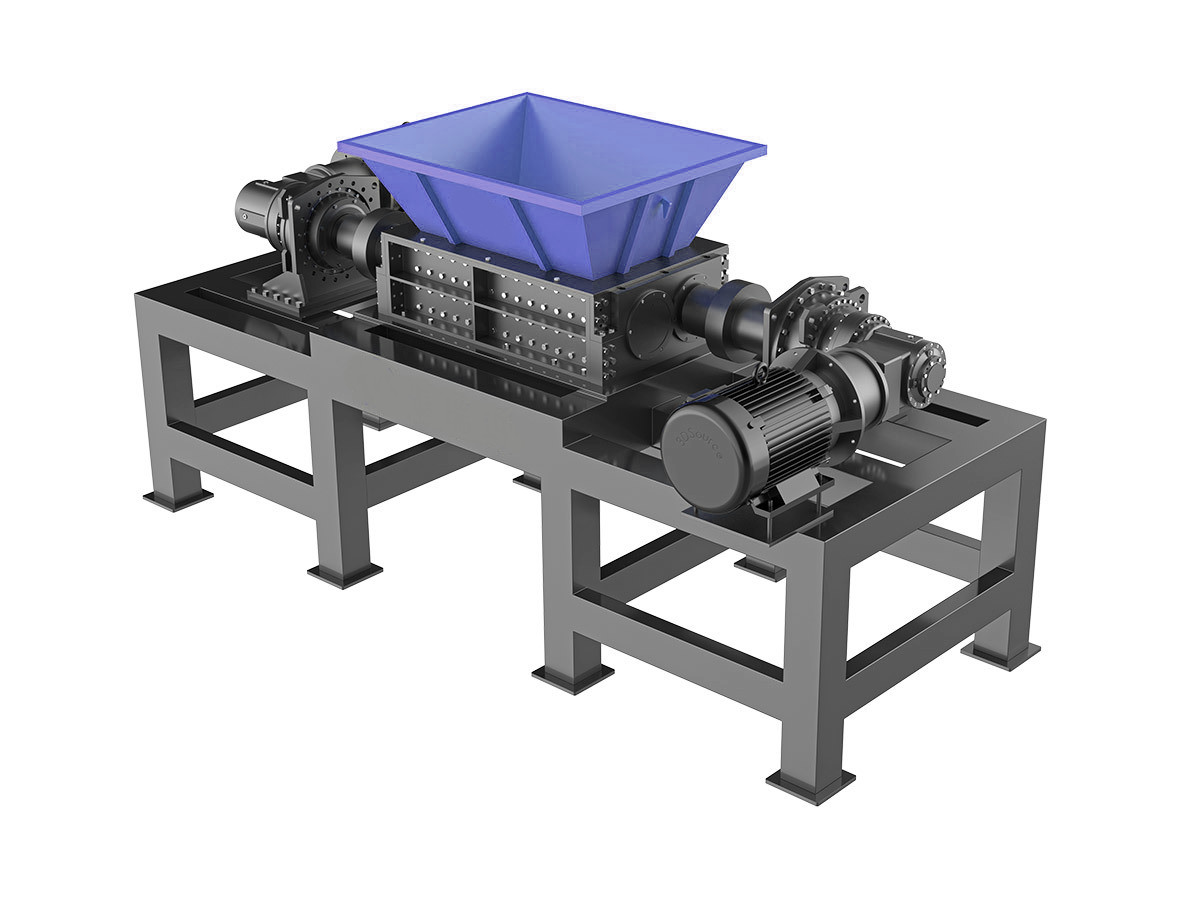

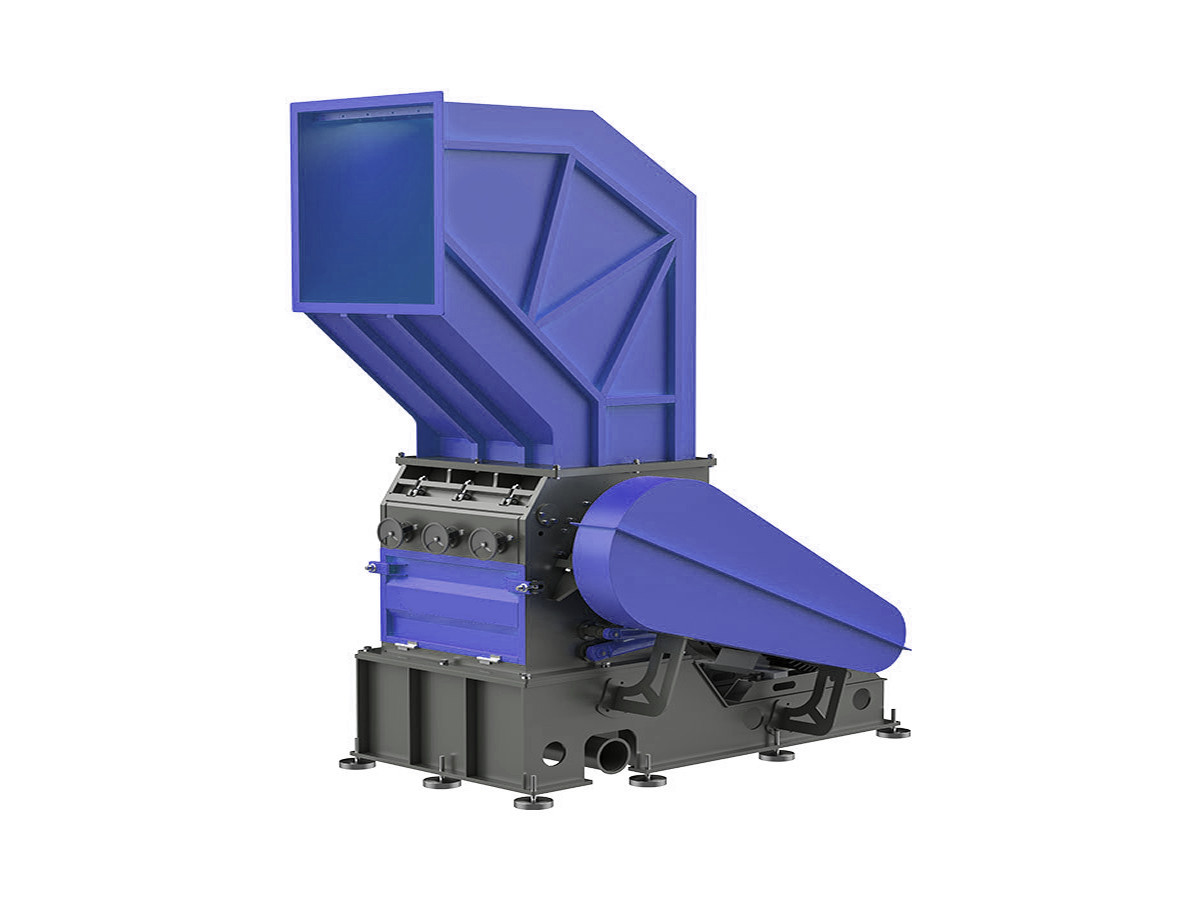

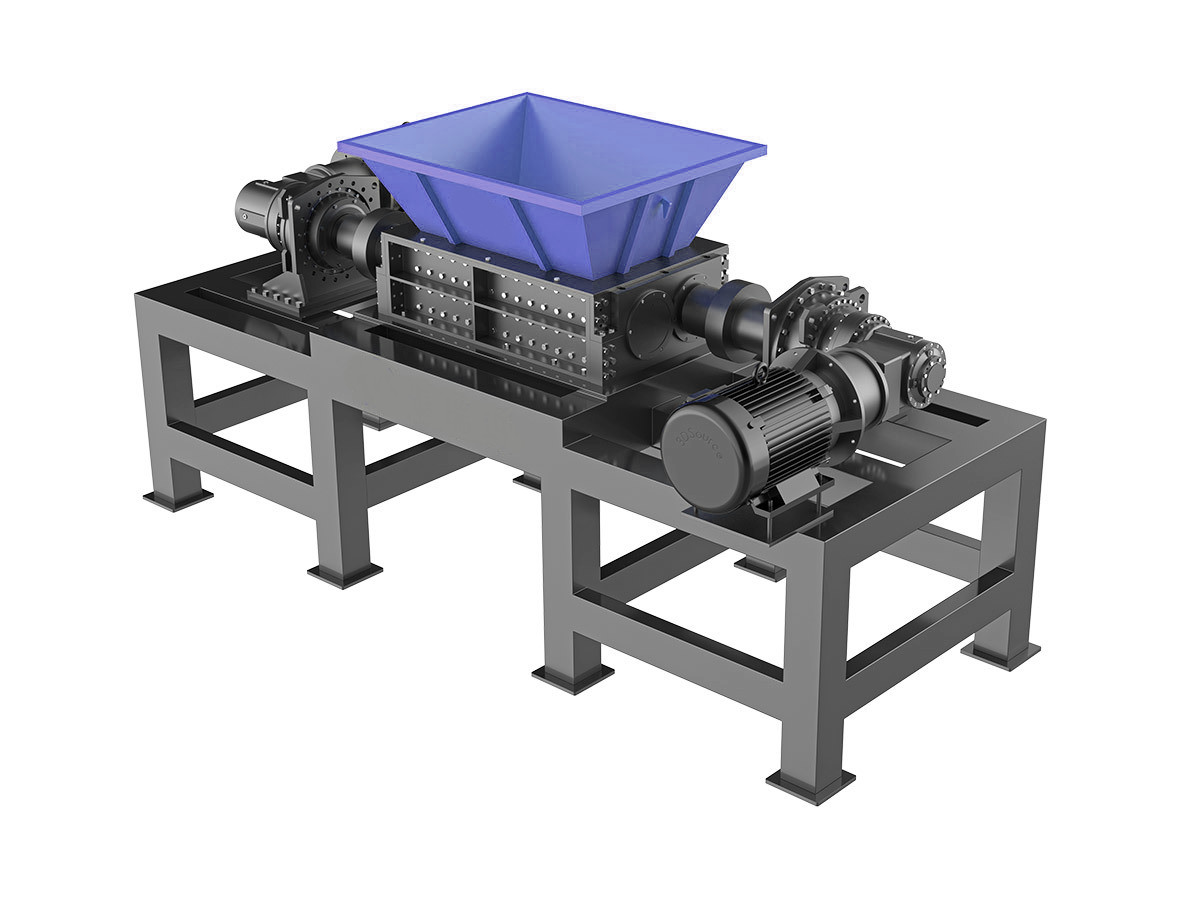

Waste shredders come in various types, each designed for specific applications. Common types include single-shaft, double-shaft, four-shaft, and hammer mill shredders, each offering unique advantages for different materials.

For example, single-shaft shredders are ideal for precise shredding and controlled particle size, while double-shaft shredders are preferred for high-capacity processing of bulky materials. Four-shaft shredders provide finer shredding results, whereas hammer mill shredders are excellent for crushing tough materials like metals and electronic waste.

Applications of Waste Shredder Machines

The versatility of waste shredder machines allows them to be used in various industries, including waste management, manufacturing, and resource recovery. They play a crucial role in processing municipal solid waste, plastic materials, scrap metal, and even hazardous waste.

In the recycling industry, waste shredders help break down discarded materials such as electronic waste, tires, and paper, making them easier to transport and repurpose. They also contribute to environmental sustainability by reducing landfill waste and promoting material reuse.

Key Benefits of Using Waste Shredder Machines

Waste shredder machines offer numerous benefits, including volume reduction, improved material handling, and cost savings in waste management. By shredding large items into smaller pieces, they optimize storage and transportation efficiency.

Additionally, waste shredders enhance security by destroying sensitive materials, such as confidential documents and electronic devices. Industries rely on these machines to ensure data protection and proper disposal of proprietary materials.

How to Choose the Right Waste Shredder Machine

Understand Your Material Type

The first step in choosing the right waste shredder machine is identifying the type of material you need to process. Different waste shredders are designed for specific materials, such as plastic, metal, wood, paper, or municipal solid waste.

For example, waste plastic shredders handle soft and rigid plastics efficiently, while waste metal shredders are built with reinforced blades to process scrap metals. Understanding your material helps in selecting the most effective shredding technology.

Determine the Desired Output Size

The required final particle size plays a crucial role in choosing the right waste shredder. Some applications require coarse shredding for easy transportation, while others need fine shredding for recycling and reprocessing.

Single-shaft shredders are ideal for producing uniform and smaller pieces, while double-shaft and four-shaft shredders are more suitable for rough cutting and heavy-duty shredding applications. Fine shredders may also be necessary for materials that require precise sizing.

Consider the Waste Shredder's Capacity and Throughput

Waste shredder machines vary in processing capacity, measured in tons per hour or kilograms per hour. If your operation requires handling large volumes of waste, a high-capacity waste shredder with a powerful motor is essential.

Overloading a waste shredder beyond its capacity can cause frequent breakdowns and increase maintenance costs. It is important to choose a machine that matches your operational demands to ensure smooth and efficient processing.

Evaluate the Cutting Mechanism

Waste shredders utilize different cutting mechanisms, including shear cutting, impact crushing, and grinding. The choice of mechanism depends on the toughness and density of the materials being processed.

For example, double-shaft shredders use a slow-speed, high-torque system that is ideal for tough materials like metal and rubber. On the other hand, high-speed hammer mill shredders are best suited for breaking down electronic waste and biomass.

Assess Power Consumption and Efficiency

Energy efficiency is a critical factor when selecting a waste shredder. Machines with high power consumption can lead to increased operational costs, while energy-efficient models help reduce expenses and environmental impact.

Look for waste shredders with advanced motor control systems that optimize power usage based on load conditions. Some models also feature automatic shut-off mechanisms to conserve energy when not in use.

Look for Safety Features

Waste shredding machines can pose safety risks, especially when handling large and tough materials. Safety features such as emergency stop buttons, automatic overload protection, and enclosed cutting chambers help prevent accidents.

Ensure that the waste shredder you choose complies with industrial safety standards and includes protective mechanisms to safeguard operators and the surrounding environment.

Check Maintenance and Durability

Regular maintenance is necessary to keep waste shredders in peak condition. Choosing a machine with easy-to-replace blades, wear-resistant components, and accessible maintenance points can help reduce downtime and repair costs.

High-quality waste shredders are made from durable materials such as hardened steel and are built to withstand continuous operation. Investing in a robust machine ensures long-term reliability and performance.

Consider Customization and Integration

Some industries require customized shredding solutions to fit specific production lines. Many manufacturers offer tailored waste shredder designs with adjustable cutting speeds, blade configurations, and discharge systems.

If your waste shredder needs to integrate with other machinery, such as conveyors, granulators, or compactors, make sure it is compatible with your existing setup for a seamless workflow.