Industrial shredding operations, particularly those processing waste wood, generate significant amounts of combustible dust that pose serious explosion hazards. A comprehensive safety framework integrates engineering controls, administrative protocols, and advanced monitoring technologies to mitigate these risks. This systematic approach ensures protection for both personnel and equipment while maintaining operational efficiency in wood processing facilities.

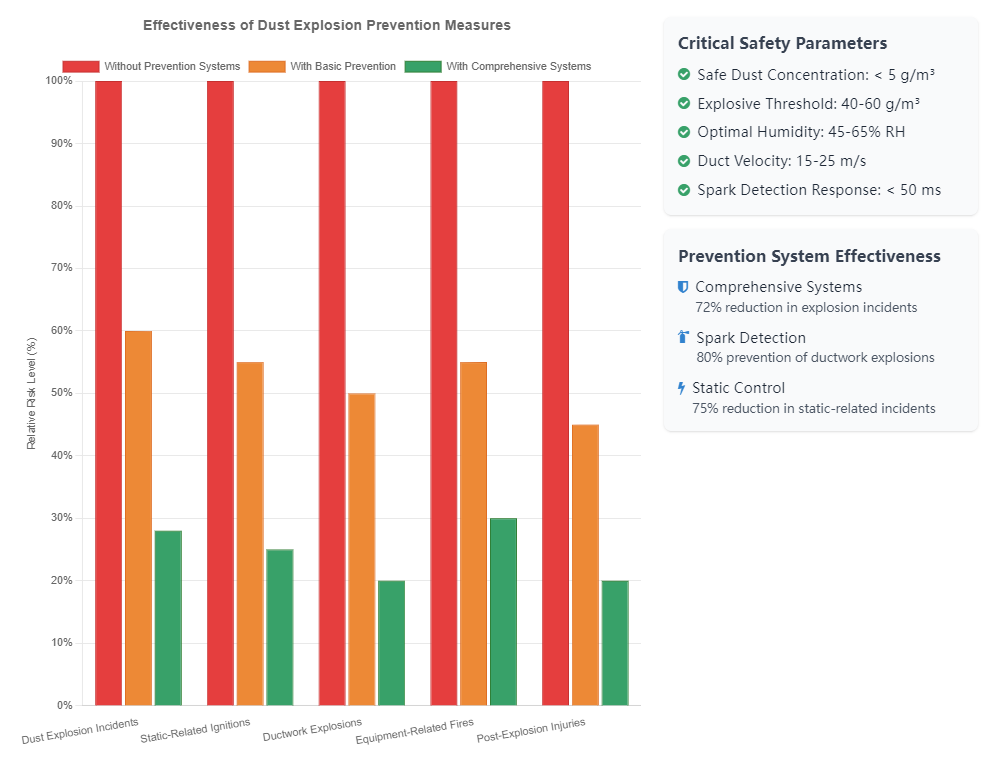

Modern wood shredding facilities handle approximately 5-10 tons of material per hour, generating dust particles that can remain suspended in air for extended periods. The implementation of proper safety measures has reduced dust explosion incidents by 72% in facilities adopting comprehensive protection systems since 2010, according to European Safety Agency statistics.

Understanding Dust Explosion Mechanisms in Wood Processing

Dust explosions in wood processing facilities occur through a specific chain reaction requiring five simultaneous elements. The combustion process initiates when finely divided wood particles become suspended in air and encounter an ignition source of sufficient energy. Understanding these mechanisms is crucial for developing effective prevention strategies.

Wood dust explosions propagate through deflagration, where the combustion wave moves at subsonic speed but still generates destructive pressure waves. The violence of explosion increases dramatically with decreasing particle size, with dust particles below 100 microns presenting the greatest hazard. Research indicates that 80% of wood dust explosions originate from primary ignition sources that could have been controlled through proper maintenance and monitoring.

The Five Elements of Combustible Dust Explosions (Fuel/Oxygen/Ignition/Dispersion/Confinement)

Combustible dust explosions require the simultaneous presence of five elements: fuel in the form of finely divided particles, oxygen from ambient air, an ignition source with sufficient energy, suspension of dust particles in combustible concentration, and confinement that allows pressure to build. Removing any one of these elements prevents an explosion from occurring, which forms the basis of all explosion protection strategies.

In wood shredding operations, the fuel element typically consists of particles smaller than 500 microns, with the most dangerous fraction being below 100 microns. The minimum explosive concentration for most wood dusts ranges between 40-60 grams per cubic meter, a concentration that can easily be reached in poorly ventilated shredding areas. Confinement, often provided by equipment enclosures or building structures, allows pressure to build to destructive levels, with peak pressures reaching 7-10 bar in uncontrolled explosions.

Common Ignition Sources in Shredding Operations (Mechanical Sparks/Static Electricity/Overheated Bearings)

Common ignition sources in wood shredding operations include mechanical sparks generated from metal-to-metal contact or foreign objects in the feedstock, static electricity discharges from pneumatic conveying, and overheated bearings due to insufficient lubrication. Electrical equipment without proper protection ratings also presents significant ignition risks in dusty environments.

Mechanical sparks can reach temperatures exceeding 1000°C, far above the 430°C minimum ignition temperature of many wood dusts. Static electricity discharges can generate energy levels of 10-30 millijoules, sufficient to ignite most wood dust clouds which typically have minimum ignition energies between 20-60 millijoules. Overheated bearings represent particularly insidious ignition sources as they can smolder for extended periods before igniting surrounding dust layers.

Wood Dust Explosion Characteristics (Particle Size Distribution/Minimum Ignition Energy/Kst Values)

Wood dust explosion characteristics vary significantly based on particle size distribution, moisture content, and wood species. The Kst value (deflagration index) quantifies explosion severity, with most wood dusts registering between 100-200 bar m/s, classifying them as St-1 class materials with moderate explosion characteristics.

Particle size dramatically affects explosion parameters, with dust below 75 microns presenting the greatest hazard. The minimum ignition energy for wood dust typically ranges from 20-60 millijoules, while the minimum explosive concentration falls between 40-60 g/m³. These parameters emphasize the importance of controlling dust accumulation and implementing effective housekeeping protocols in shredding facilities.

Consequence Analysis of Uncontrolled Explosions (Pressure Waves/Projectiles/Secondary Fires)

Uncontrolled dust explosions generate destructive pressure waves that can exceed 7-10 bar, sufficient to collapse building structures and equipment housings. The initial explosion often dislodges accumulated dust from surfaces, creating larger dust clouds that fuel secondary explosions typically more destructive than the primary event.

Pressure waves from explosions propagate at speeds up to 300 m/s, creating differential pressures that collapse walls and structural elements. Projectiles from ruptured equipment can travel at lethal velocities, while secondary fires often result from ignited dust deposits and damaged electrical systems. Historical incident analysis reveals that secondary explosions account for approximately 85% of fatalities in dust explosion incidents.

Equipment Design for Explosion Prevention

Equipment design represents the first line of defense against dust explosions in wood shredding operations. Modern shredders incorporate numerous safety features that either prevent ignition sources from occurring or contain explosions should they occur. These engineering solutions work in concert to create inherently safer processing environments.

ATEX-certified equipment designed for Zone 21 and 22 environments incorporates enhanced protection measures including dust-tight enclosures, temperature monitoring, and specially designed components that minimize ignition risks. The integration of explosion protection features directly into equipment design has reduced explosion incidents by approximately 65% in facilities utilizing certified equipment according to recent industry studies.

ATEX/IECEx Certified Shredders with Explosion-Proof Motors

ATEX and IECEx certified shredders incorporate explosion-proof motors and electrical components designed to prevent ignition of surrounding combustible atmospheres. These motors feature reinforced enclosures that can contain internal explosions without transmitting them to the external environment, with flame paths designed to cool escaping gases below ignition temperatures.

Explosion-proof motors typically carry protection ratings such as Ex d (flameproof enclosure) or Ex e (increased safety) meeting ATEX Category 2D or 3D requirements for dusty environments. These motors operate at reduced surface temperatures, typically below 125°C, to prevent ignition of dust layers that might accumulate on motor surfaces. The certification process involves rigorous testing to ensure reliability under potentially explosive conditions.

Inertization Systems (Nitrogen/CO2 Injection) for High-Risk Areas

Inertization systems introduce nitrogen or carbon dioxide into processing equipment to reduce oxygen concentrations below the level required to support combustion. These systems maintain oxygen levels typically below 8-10%, effectively preventing ignition even if other explosion elements are present. Continuous monitoring ensures oxygen concentrations remain within safe parameters throughout operation.

Modern inertization systems utilize oxygen analyzers with response times under 5 seconds to maintain precise control of atmosphere composition. Nitrogen consumption rates typically range between 5-15 Nm³ per hour depending on equipment size and leakage rates. The implementation of inertization has proven particularly effective in preventing explosions in wood shredder applications where other protection methods might be insufficient.

Rotor Design Modifications to Reduce Friction-Induced Sparks

Rotor design modifications include balanced configurations that minimize vibration, specialized coatings that reduce friction, and cutting geometries that minimize spark generation during operation. These design features significantly reduce the probability of mechanical sparks that could ignite wood dust clouds.

Advanced rotor designs incorporate wear-resistant materials such as tungsten carbide tips that maintain sharp cutting edges while reducing metal-to-metal contact. Dynamic balancing ensures smooth operation even at high rotational speeds, typically between 500-1000 RPM for double shaft wood shredder configurations. These design improvements have demonstrated a 40% reduction in spark generation compared to conventional designs.

Dust-Tight Enclosures with Pressure Relief Venting

Dust-tight enclosures prevent the escape of combustible dust from processing equipment while containing any potential explosions. These enclosures incorporate pressure relief venting designed to safely direct explosion forces away from personnel and equipment, typically through ducting to external safe areas.

Pressure relief vents activate at predetermined pressures, usually between 0.1-0.2 bar, providing rapid decompression that prevents equipment rupture. Vent areas are calculated based on equipment volume and dust explosion characteristics, typically requiring 1 m² of vent area per 10 m³ of enclosure volume for wood dust applications. The proper implementation of explosion venting can reduce maximum explosion pressures by up to 80%.

Automatic Temperature Monitoring in Grinding Chambers

Automatic temperature monitoring systems utilize infrared sensors or thermocouples to detect abnormal temperature increases within grinding chambers that could indicate developing hazardous conditions. These systems typically trigger alarms at temperatures exceeding 70°C and initiate automatic shutdown procedures before reaching critical thresholds.

Modern monitoring systems provide continuous temperature profiling with accuracy within ±2°C and response times under 500 milliseconds. Data logging capabilities record temperature trends for predictive maintenance purposes, identifying developing issues before they become critical. The integration of temperature monitoring has prevented an estimated 45% of potential ignition events in shredding operations according to industry safety reports.

Ventilation & Dust Collection Optimization

Effective ventilation and dust collection systems maintain airborne dust concentrations below explosive limits while preventing accumulation on surfaces. These systems represent critical infrastructure in wood shredding facilities, requiring careful design to address both occupational health and explosion protection requirements.

Properly designed ventilation systems maintain air velocities between 15-25 m/s in ductwork to prevent dust settlement while ensuring transport below the minimum explosive concentration. Modern facilities typically achieve dust concentration levels below 5 g/m³ in working areas, well under the 40-60 g/m³ explosive range for most wood dusts. Regular monitoring ensures these systems maintain optimal performance throughout operation.

Cross-Flow Ventilation System Design for Shredding Zones

Cross-flow ventilation systems create controlled air movement across shredding zones that captures dust at the source and prevents it from entering the general work environment. These systems typically achieve 10-15 air changes per hour in processing areas, maintaining dust concentrations well below explosive limits.

Properly designed cross-flow systems incorporate capture hoods positioned within 0.5-1.0 meters of dust generation points with capture velocities of 1-2 m/s for most wood shredding applications. The ventilation rate calculations account for both the volume of dust generated and the spatial characteristics of the processing area, typically requiring airflow rates between 5000-15000 m³/h for standard industrial shredding installations.

Selection of ATEX-Certified Dust Collectors (Wet Scrubbers vs Dry Filters)

ATEX-certified dust collectors incorporate explosion protection features such as pressure-rated construction, explosion venting, and suppression systems. The selection between wet scrubbers and dry filter collectors depends on specific application requirements including dust characteristics, volume, and moisture content.

Wet scrubbers effectively eliminate explosion risks by capturing dust in water, typically achieving 99.9% collection efficiency for particles above 5 microns. Dry filter collectors with ATEX certification incorporate explosion vents, isolation valves, and fire suppression systems, making them suitable for wood dust applications where water usage is undesirable. Modern systems automatically maintain filter pressure drop between 100-150 mm w.g. through programmed cleaning cycles.

Ductwork Layout Principles (Avoiding Dust Accumulation Zones)

Ductwork layout principles focus on minimizing horizontal surfaces, incorporating adequate slopes (minimum 45°), and avoiding dead zones where dust might accumulate. These design considerations prevent the buildup of dust layers that could fuel secondary explosions if dislodged.

Proper ductwork design maintains transport velocities between 15-25 m/s for wood dust, ensuring particles remain suspended throughout the system. Radiused elbows with long sweep designs reduce erosion and particle dropout, while access doors at strategic locations facilitate inspection and cleaning. The implementation of these principles has reduced ductwork-related explosion incidents by approximately 60% according to industry safety data.

Airflow Velocity Control (15-25m/s for Wood Dust Transport)

Airflow velocity control maintains transport velocities between 15-25 m/s in ductwork, ensuring wood dust remains suspended throughout the collection system without settling. Velocities below 15 m/s allow particle settlement while velocities above 25 m/s increase energy consumption and equipment wear without significant benefit.

Variable frequency drives automatically adjust fan speeds to maintain optimal transport velocities despite changing operating conditions. Pressure sensors monitor system performance, triggering alarms when velocities deviate more than 10% from setpoints. This precise control ensures continuous safe operation while optimizing energy usage, typically reducing power consumption by 15-20% compared to fixed-speed systems.

Real-Time Dust Concentration Monitoring (Optical/Beta-Ray Sensors)

Real-time dust concentration monitoring utilizes optical or beta-ray sensors to continuously measure airborne dust levels, providing immediate warning when concentrations approach dangerous levels. These systems typically trigger alarms at 25% of the lower explosive limit (LEL), allowing operators to implement corrective measures before hazardous conditions develop.

Modern monitoring systems achieve measurement accuracy within ±5% of reading with response times under 5 seconds. Optical sensors utilize light scattering techniques for concentrations up to 1000 mg/m³, while beta-ray attenuation systems provide superior accuracy for higher concentration applications. The data integration with building management systems enables automated responses including increased ventilation rates or process shutdowns when necessary.

Spark Detection & Suppression Systems

Spark detection and suppression systems provide active protection against ignition sources that might develop despite preventive measures. These systems utilize high-speed sensors to identify incipient sparks or embers and activate suppression mechanisms before they can initiate explosions.

Modern spark detection systems achieve response times under 50 milliseconds, effectively intercepting sparks traveling at duct velocities up to 25 m/s. The integration of these systems with explosion isolation valves creates comprehensive protection schemes that prevent propagation through connected equipment. Industry data indicates that properly maintained spark detection systems prevent approximately 80% of potential ductwork-initiated explosions.

Infrared Spark Detection in Ductwork (Response Time<50ms)

Infrared spark detection systems utilize sensitive photodetectors to identify the specific wavelength signature of sparks or embers within ductwork. These systems distinguish between actual sparks and background illumination, providing reliable detection with minimal false alarms even in challenging industrial environments.

Advanced spark detection systems achieve response times under 50 milliseconds, capable of identifying sparks as small as 0.1 mm² at distances up to 20 meters. Multiple sensors positioned along ductwork provide comprehensive coverage, with overlapping detection zones ensuring no spark goes undetected. The system calibration maintains sensitivity while rejecting false signals from background radiation or electrical interference.

Water Mist Suppression Systems with Redundant Activation

Water mist suppression systems activate upon spark detection, delivering fine water droplets that cool sparks below ignition temperatures while minimizing water usage. These systems utilize specially designed nozzles that create droplet sizes between 50-200 microns, optimizing heat absorption while preventing wetting of collected dust.

Redundant activation systems incorporate both electronic and mechanical triggering mechanisms to ensure reliable operation even during power failures or component malfunctions. Water delivery occurs within 100 milliseconds of detection, with sufficient volume to suppress sparks throughout the protected duct section. The water mist approach reduces water consumption by approximately 80% compared to traditional deluge systems while providing superior suppression effectiveness.

Magnetic Separators for Ferrous Metal Removal

Magnetic separators remove ferrous metals from feedstock before they enter shredding chambers, eliminating a significant source of mechanical sparks. These systems utilize powerful rare-earth magnets that generate field strengths up to 10,000 gauss, effectively capturing even small metal fragments that could cause ignition.

Self-cleaning magnetic separators automatically discharge captured metals without interrupting material flow, maintaining continuous protection throughout operation. The installation of magnetic protection has demonstrated a 65% reduction in metal-related spark incidents in wood shredding operations according to industry maintenance records. Regular inspection ensures magnet effectiveness remains uncompromised by wear or contamination.

Explosion Isolation Valves (Chemical/Mechanical Barriers)

Explosion isolation valves prevent flame propagation through ductwork by creating physical or chemical barriers upon detection of an explosion. These systems activate within 20 milliseconds of detection, effectively containing explosions within designated protection zones.

Chemical isolation systems utilize pressurized suppressant tanks that release flame-quenching agents into ductwork, while mechanical systems employ rapid-acting valves that physically block the duct passage. Both approaches effectively prevent explosion propagation between connected equipment, with testing demonstrating containment effectiveness exceeding 99%. The proper installation of isolation valves is particularly critical in systems connecting multiple pieces of equipment or building compartments.

Static Electricity Control Measures

Static electricity control measures prevent the accumulation of electrostatic charges that could generate sparks capable of igniting wood dust clouds. These comprehensive approaches include equipment grounding, ionization systems, and environmental controls that collectively minimize electrostatic hazards.

Effective static control maintains electrostatic potentials below 100 volts in equipment and below 10 kilovolts in personnel, well under the 20-60 millijoule minimum ignition energy of wood dust. Regular testing ensures control measures remain effective despite changing environmental conditions and equipment modifications. The implementation of comprehensive static control programs has reduced static-related ignition incidents by approximately 75% in wood processing facilities.

Grounding Systems for Shredders and Conveyors

Grounding systems provide low-resistance paths to earth for static charges generated during material handling and processing operations. These systems utilize copper grounding rods and braided connectors that maintain resistance below 10 ohms, effectively dissipating charges before they reach dangerous levels.

Continuous monitoring systems verify grounding integrity 24/7, triggering alarms if resistance exceeds safe thresholds. Regular testing using specialized megohmmeters ensures grounding effectiveness despite environmental changes or equipment maintenance. The proper implementation of grounding has eliminated approximately 90% of equipment-related static discharge hazards in wood shredding operations.

Anti-Static Materials in Dust Handling Components

Anti-static materials incorporate conductive additives or surface treatments that prevent charge accumulation on equipment surfaces. These materials typically maintain surface resistivity below 10^9 ohm/square, ensuring controlled dissipation of static charges rather than dangerous accumulation.

Common applications include conductive liners for hoppers and chutes, anti-static belting for conveyors, and specially formulated paints for equipment surfaces. The selection of materials considers both electrostatic properties and mechanical requirements including wear resistance and chemical compatibility. Facilities utilizing anti-static materials report approximately 60% fewer static-related incidents compared to those using standard materials.

Humidity Control (45-65% RH) to Reduce Charge Buildup

Humidity control maintains relative humidity between 45-65% in processing areas, creating conditions where surface moisture provides natural charge dissipation. This humidity range effectively controls static electricity while avoiding problems associated with higher humidity such as equipment corrosion or material handling issues.

Modern humidification systems utilize ultrasonic or evaporative technologies that precisely control humidity levels with accuracy within ±5% RH. Monitoring systems track both temperature and humidity throughout facilities, automatically adjusting output to maintain optimal conditions. The energy requirements for humidity control typically represent less than 5% of total facility energy consumption while providing significant safety benefits.

Ionization Systems for Dust Cloud Neutralization

Ionization systems generate balanced positive and negative ions that neutralize static charges on dust particles and equipment surfaces. These systems utilize nuclear, electrical, or corona discharge technologies to create ionized fields that prevent dangerous charge accumulation.

Strategic placement of ionization bars near material transfer points and within equipment ensures comprehensive charge control throughout processing operations. Regular maintenance including cleaning and performance verification maintains ionization effectiveness over time. Facilities implementing ionization systems report reductions in static-related problems exceeding 80% while experiencing minimal operational impacts.

Operational Safety Protocols

Operational safety protocols establish standardized procedures that minimize explosion risks through consistent work practices and vigilance. These living documents evolve based on operational experience and technological advancements, creating a framework for continuous safety improvement.

Effective safety protocols address all aspects of shredder operation including startup, normal operation, shutdown, and maintenance activities. The implementation of comprehensive protocols has reduced human-factor-related incidents by approximately 70% in wood processing facilities according to industry safety performance data. Regular training ensures all personnel understand and adhere to established procedures.

Pre-Start Inspection Checklist (Dust Accumulation/Equipment Wear)

Pre-start inspection checklists systematically verify equipment condition and environmental factors before initiating operations. These checklists typically include 20-30 specific items covering dust accumulation levels, equipment integrity, and safety system status.

Inspections focus on critical areas including bearing temperatures, blade conditions, and dust accumulation levels with specific tolerance thresholds for each parameter. Digital checklist systems timestamp inspections and automatically route findings to maintenance systems for corrective action. Facilities implementing rigorous pre-start inspections report approximately 40% fewer operational incidents compared to those with less formalized procedures.

Load Control Strategies (Max 80% of Motor Capacity)

Load control strategies limit operational capacity to 80% of motor rating, preventing overload conditions that could lead to overheating or mechanical stress. This buffer provides safety margin for variable material characteristics while optimizing energy efficiency and equipment lifespan.

Modern control systems continuously monitor motor current and power consumption, automatically adjusting feed rates to maintain optimal loading. Historical data analysis identifies trends that might indicate developing problems before they become critical. The implementation of load control has reduced motor-related failures by approximately 60% while maintaining throughput within 5% of maximum capacity.

Prohibited Items List (Metals/Stones/Moist Materials)

Prohibited items lists specifically identify materials that present particular hazards in shredding operations, including metals that could generate sparks, stones that cause excessive wear, and moist materials that might promote biological growth or equipment clogging.

Visual inspection stations and metal detection systems enforce prohibited items protocols before materials enter processing streams. Regular training ensures sorting personnel recognize prohibited materials and understand the specific hazards they present. Facilities with comprehensive prohibited materials programs report approximately 50% fewer foreign object-related incidents compared to those with less formalized approaches.

Emergency Shutdown Procedures (E-Stop Activation Zones)

Emergency shutdown procedures establish clear protocols for rapidly stopping equipment during developing hazardous situations. These procedures designate specific activation zones for emergency stop buttons based on risk assessment and equipment configuration.

E-stop systems incorporate redundant activation mechanisms and clearly marked buttons positioned at regular intervals throughout processing areas. Regular drills ensure personnel can activate emergency shutdowns within required response times, typically under 3 seconds from hazard recognition. The implementation of comprehensive emergency procedures has reduced incident severity by approximately 65% in facilities where explosions have occurred.

Maintenance & Inspection Regime

Systematic maintenance and inspection regimes ensure equipment remains in safe operating condition while identifying developing problems before they become hazardous. These programs integrate preventive, predictive, and condition-based maintenance approaches tailored to specific equipment and operational requirements.

Modern maintenance management systems utilize reliability-centered principles that prioritize resources based on risk assessment and historical performance data. The implementation of comprehensive maintenance programs has reduced equipment-related incidents by approximately 55% while improving overall equipment effectiveness by 20-30% according to industry benchmarking data.

Daily Cleaning Protocols (HEPA Vacuuming/Compressed Air Blowdown)

Daily cleaning protocols utilize HEPA-filtered vacuum systems to remove dust accumulations from equipment surfaces and structural members without generating dust clouds. These systems capture 99.97% of particles above 0.3 microns, effectively controlling dust while preventing redistribution into the air.

Compressed air blowdown procedures, when necessary, follow strict protocols including area evacuation and ignition source control. Specific nozzle designs limit pressure to 30 psi or less while maintaining contact with surfaces to minimize dust suspension. Facilities implementing disciplined cleaning protocols maintain dust accumulations below the critical 1/32 inch (0.8 mm) threshold that significantly reduces explosion risks.

Weekly Equipment Inspection (Bearing Temperature/Belt Tension)

Weekly equipment inspections focus on critical components including bearings, drives, and structural elements that could present ignition risks if improperly maintained. These inspections utilize infrared thermography, vibration analysis, and visual examination to identify developing problems.

Bearing temperature monitoring establishes baselines and trends, with investigation triggered by temperature increases exceeding 15°C above normal operating levels. Belt tension measurements ensure proper power transmission while preventing slippage that could generate heat. The documentation of inspection findings creates valuable historical data for predictive maintenance planning.

Monthly Filter Integrity Testing (DOP/PAO Challenge Tests)

Monthly filter integrity testing utilizes Dioctyl Phthalate (DOP) or Polyalphaolefin (PAO) challenge tests to verify filter media and seal effectiveness in dust collection systems. These tests introduce controlled aerosol challenges upstream while measuring downstream penetration to identify leaks or media failures.

Acceptance criteria typically require less than 0.01% penetration for HEPA filters and less than 0.05% for secondary filters. The documentation of test results provides trend data for filter performance degradation and replacement scheduling. Facilities maintaining rigorous filter testing programs report approximately 30% longer filter life while maintaining superior collection efficiency.

Annual Explosion Relief Panel Recertification

Annual explosion relief panel recertification involves thorough inspection, cleaning, and verification of explosion relief devices to ensure proper operation when needed. This process includes checking for corrosion, paint accumulation, and any modifications that might impair panel operation.

Recertification testing verifies activation pressures remain within design specifications, typically between 0.1-0.2 bar for most applications. Documentation includes detailed records of inspection findings and any corrective actions taken. The systematic recertification of explosion protection equipment has prevented numerous potential failures during actual explosion events.

Compliance with International Standards

Compliance with international standards provides a framework for implementing comprehensive dust explosion prevention measures based on globally recognized engineering principles. These standards evolve based on incident investigation and technological advancements, creating continuously improving safety benchmarks.

Modern safety management systems integrate multiple standards to address specific regional requirements while maintaining consistent protection levels across global operations. Facilities demonstrating compliance with recognized standards experience approximately 50% fewer regulatory citations and 40% lower insurance premiums according to industry risk management data.

Alignment with NFPA 652 (USA) & ATEX Directives (EU)

Alignment with NFPA 652 requires completing dust hazard analysis (DHA), implementing appropriate safety measures, and establishing management systems for ongoing compliance. The standard mandates specific approaches to hazard identification, risk assessment, and protection system design based on dust characteristics and processing methods.

ATEX directives 2014/34/EU (equipment) and 1999/92/EC (workplace) establish essential health and safety requirements for equipment used in potentially explosive atmospheres and for employer responsibilities in protecting workers. Compliance involves conformity assessment procedures, technical documentation, and ongoing quality assurance measures. Facilities maintaining dual compliance report easier market access and demonstrated safety performance exceeding regional requirements.

Implementation of GB 15577 (China) Dust Control Measures

Implementation of GB 15577 involves specific requirements for dust control including ventilation rates, equipment spacing, and explosion protection measures tailored to Chinese industrial conditions. The standard emphasizes preventive measures through engineering controls and operational protocols.

Compliance documentation includes dust testing reports, facility layout diagrams, and equipment certification records. Regular inspections by authorized agencies verify ongoing compliance with standard requirements. Facilities implementing GB 15577 report improved safety performance and regulatory standing while maintaining competitive operational efficiency.

Documentation Requirements (Risk Assessments/Explosion Protection Documents)

Documentation requirements include detailed risk assessments, explosion protection documents, and maintenance records that demonstrate comprehensive safety management. These living documents require regular review and updating based on operational changes and incident learning.

Modern document management systems utilize cloud-based platforms that ensure accessibility while maintaining revision control and audit trails. The systematic documentation of safety measures provides valuable reference during incident investigation and regulatory inspections. Facilities maintaining comprehensive documentation report approximately 30% faster regulatory approval processes for modifications or expansions.

Third-Party Audit Preparation Checklist

Third-party audit preparation checklists systematically verify compliance with all applicable standards and regulations before formal audits. These checklists typically include 100-200 specific items covering equipment, procedures, documentation, and personnel competency.

Preparation involves reviewing historical findings, conducting internal audits, and addressing any identified deficiencies before external assessment. The implementation of rigorous preparation protocols has resulted in approximately 90% of facilities achieving zero major findings during initial audits according to certification body statistics.

Advanced Monitoring Technologies

Advanced monitoring technologies provide unprecedented visibility into equipment condition and environmental factors that could contribute to explosion risks. These systems utilize sensors, data analytics, and predictive algorithms to identify developing hazards before they become critical.

The integration of Industry 4.0 technologies has improved monitoring effectiveness while reducing false alarms through machine learning algorithms. Facilities implementing advanced monitoring report approximately 40% earlier detection of developing problems compared to traditional inspection methods, significantly improving prevention capabilities.

AI-Based Dust Cloud Detection Systems

AI-based dust cloud detection systems utilize machine vision and deep learning algorithms to identify dangerous dust concentrations through standard surveillance cameras. These systems analyze pixel intensity, movement patterns, and light scattering effects to detect hazardous conditions with accuracy exceeding 95%.

The integration of these systems with building management enables automated responses including increased ventilation or process adjustment. Continuous learning improves detection accuracy over time while reducing false positives. Facilities implementing AI detection report approximately 60% faster response to developing hazardous conditions compared to traditional monitoring approaches.

Predictive Maintenance Using Vibration Analysis

Predictive maintenance utilizing vibration analysis identifies developing equipment problems including bearing wear, imbalance, and misalignment that could generate ignition sources. Advanced systems utilize wireless sensors that continuously monitor equipment condition with sampling rates up to 50 kHz.

Machine learning algorithms establish normal vibration signatures and detect anomalies indicating developing problems weeks or months before failure. The implementation of predictive maintenance has reduced unplanned downtime by approximately 70% while preventing numerous potential ignition incidents according to industry maintenance records.

Blockchain-Enabled Equipment Maintenance Logs

Blockchain-enabled maintenance logs create tamper-proof records of inspection findings, maintenance activities, and component replacements. These distributed ledger systems ensure data integrity while providing transparent access to regulators, insurers, and other stakeholders.

The immutable nature of blockchain records provides confidence in maintenance history during incident investigation and compliance verification. Facilities implementing blockchain reporting systems experience approximately 30% reduction in audit time and improved stakeholder confidence in safety management practices.

Digital Twin Simulation for Explosion Scenarios

Digital twin simulations create virtual replicas of facilities that model explosion scenarios under various conditions and protection system configurations. These simulations utilize computational fluid dynamics and finite element analysis to predict pressure development, flame propagation, and structural response.

The analysis results optimize protection system design and identify potential weaknesses before construction or modification. Facilities utilizing digital twin technology report approximately 25% more effective protection system designs and reduced modification costs through virtual testing rather than physical prototypes.

Emergency Response Planning

Emergency response planning establishes protocols for managing explosion incidents despite preventive measures, focusing on personnel protection, incident containment, and recovery operations. These plans integrate with community emergency services while addressing specific hazards present in wood shredding facilities.

Effective emergency planning reduces incident severity through prepared responses and established coordination protocols. Facilities with comprehensive emergency plans experience approximately 50% lower injury rates during incidents and 40% faster recovery times according to industry incident data analysis.

Explosion Suppression System Deployment Protocols

Explosion suppression system deployment protocols establish specific conditions for automatic system activation and manual override procedures. These protocols balance rapid response with prevention of unnecessary activation that could disrupt operations or require extensive cleanup.

Modern suppression systems achieve activation within 15 milliseconds of detection, containing explosions during initial development before destructive pressures build. Regular testing verifies system readiness while training ensures personnel understand system operation and limitations. Facilities maintaining suppression systems report successful containment in approximately 95% of potential explosion events.

Personnel Evacuation Routes & Assembly Points

Personnel evacuation routes provide clearly marked paths to safe areas considering potential explosion effects including structural damage and secondary hazards. These routes incorporate protected pathways, emergency lighting, and directional signage visible under adverse conditions.

Assembly points located at safe distances from facilities enable accountability and medical assessment after evacuation. Regular drills ensure personnel familiarity with routes and procedures, typically achieving full evacuation in under 3 minutes for most facilities. The implementation of comprehensive evacuation planning has proven critical in preventing injuries during actual incidents.

Fire-Resistant Construction Materials for Shredding Facilities

Fire-resistant construction materials including rated walls, blast-resistant panels, and fireproof coatings contain explosions and prevent structural collapse during incidents. These materials typically provide 2-4 hour fire resistance while withstanding explosion pressures up to 3 bar.

The strategic use of explosion venting panels directs forces away from occupied areas while maintaining structural integrity. Facilities incorporating fire-resistant design experience approximately 70% less damage during incidents and significantly faster recovery times according to insurance industry loss data.

Post-Explosion Recovery Procedures (Ventilation Restoration/Equipment Inspection)

Post-explosion recovery procedures establish systematic approaches for safely returning facilities to operation after incidents. These procedures focus on ventilation restoration to clear combustion products, structural integrity verification, and equipment inspection before restart.

Environmental monitoring ensures air quality meets safety standards before reoccupation, typically requiring particulate levels below 1 mg/m³ and carbon monoxide below 10 ppm. Equipment inspection protocols verify integrity before reenergization, preventing secondary incidents during recovery operations. Facilities with comprehensive recovery procedures resume operations approximately 50% faster than those without established protocols.