Soft Material Shredding Solutions

Soft Material Shredding Solutions refer to specialized shredding systems designed to handle flexible and lightweight materials such as plastics, rubber, textiles, foam, and soft packaging waste. These materials require a precise shredding process to ensure uniform particle size while preventing clogging or excessive wear on machinery.

Shredding soft materials plays a crucial role in recycling and waste management. It facilitates easier material handling, improves efficiency in downstream processes, and enhances the quality of recycled products. Many industries, including manufacturing, packaging, and textile production, rely on these solutions to manage waste and optimize resource utilization.

Unlike hard material shredding, which focuses on breaking down metals or dense materials, soft material shredding requires lower torque but precise cutting technology. Advanced shredding solutions ensure that materials are processed efficiently without excessive energy consumption or machine wear.

Investing in the right shredding technology improves sustainability efforts, reduces landfill waste, and supports the circular economy by converting soft materials into reusable or repurposed resources.

What is Soft Material Shredding Solutions?

Soft Material Shredding Solutions are designed to break down non-rigid materials into smaller, uniform pieces for recycling, waste reduction, and further processing. These solutions are commonly used in plastic recycling, textile waste management, and foam reprocessing industries.

The shredding process ensures that soft materials are reduced in size without excessive fiber entanglement or clogging. Specially designed cutting blades and optimized shredding speeds help maintain efficiency while producing high-quality shredded output.

Soft material shredders vary in configuration, including single-shaft, dual-shaft, and fine grinders. Each type serves different purposes depending on the material type and end-use requirements, such as pelletizing, compounding, or remanufacturing.

Why is Efficient Soft Material Shredding Important?

Efficiency in Soft Material Shredding directly impacts operational productivity, recycling effectiveness, and waste management costs. A well-optimized shredding system ensures minimal material loss while producing high-quality, reusable shredded output.

Poorly designed shredders can cause issues such as material tangling, excessive dust generation, and uneven particle sizes, leading to inefficiencies in downstream processing. Proper shredding solutions prevent these problems by employing advanced cutting mechanisms and controlled feeding systems.

Furthermore, efficient shredding contributes to environmental sustainability by reducing waste sent to landfills, supporting recycling programs, and repurposing soft materials into valuable secondary raw materials. This not only benefits industries but also aligns with global sustainability initiatives.

How Do Shredders Enhance Soft Material Recycling?

Soft Material Shredders play a crucial role in the recycling process by converting bulk waste into manageable and uniform pieces suitable for reuse. The shredded material can be further processed into pellets, fibers, or powders, depending on the application.

By reducing material size efficiently, shredders enhance sorting and separation processes, making it easier to extract valuable materials and eliminate contaminants. This step is essential in achieving high-purity recycled outputs for manufacturing new products.

Advanced shredding solutions also integrate dust control systems, energy-efficient motors, and intelligent automation to optimize performance while minimizing environmental impact. These improvements help industries maximize resource efficiency and reduce production costs.

Types of Shredders Used in Soft Material Processing

There are various types of Soft Material Shredders designed to handle different materials and processing requirements. The most common types include:

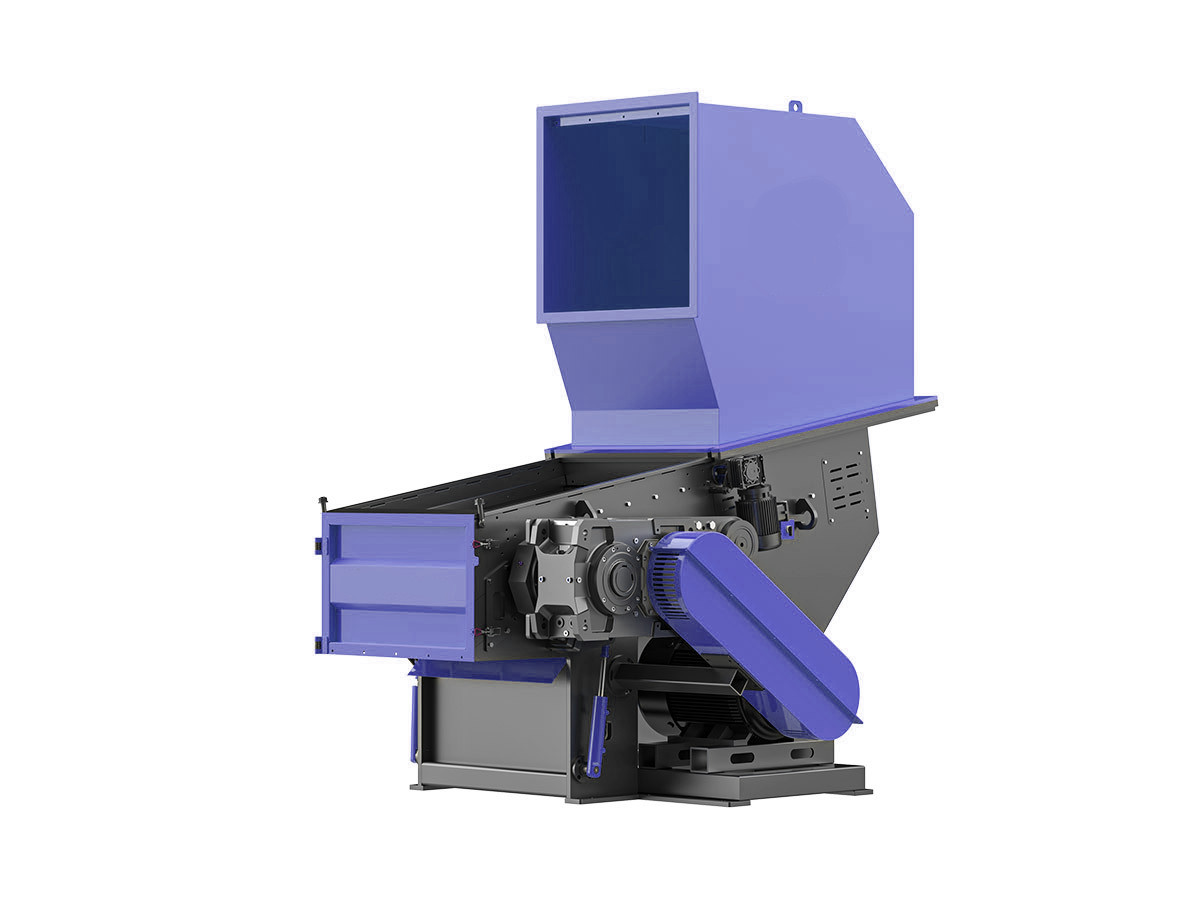

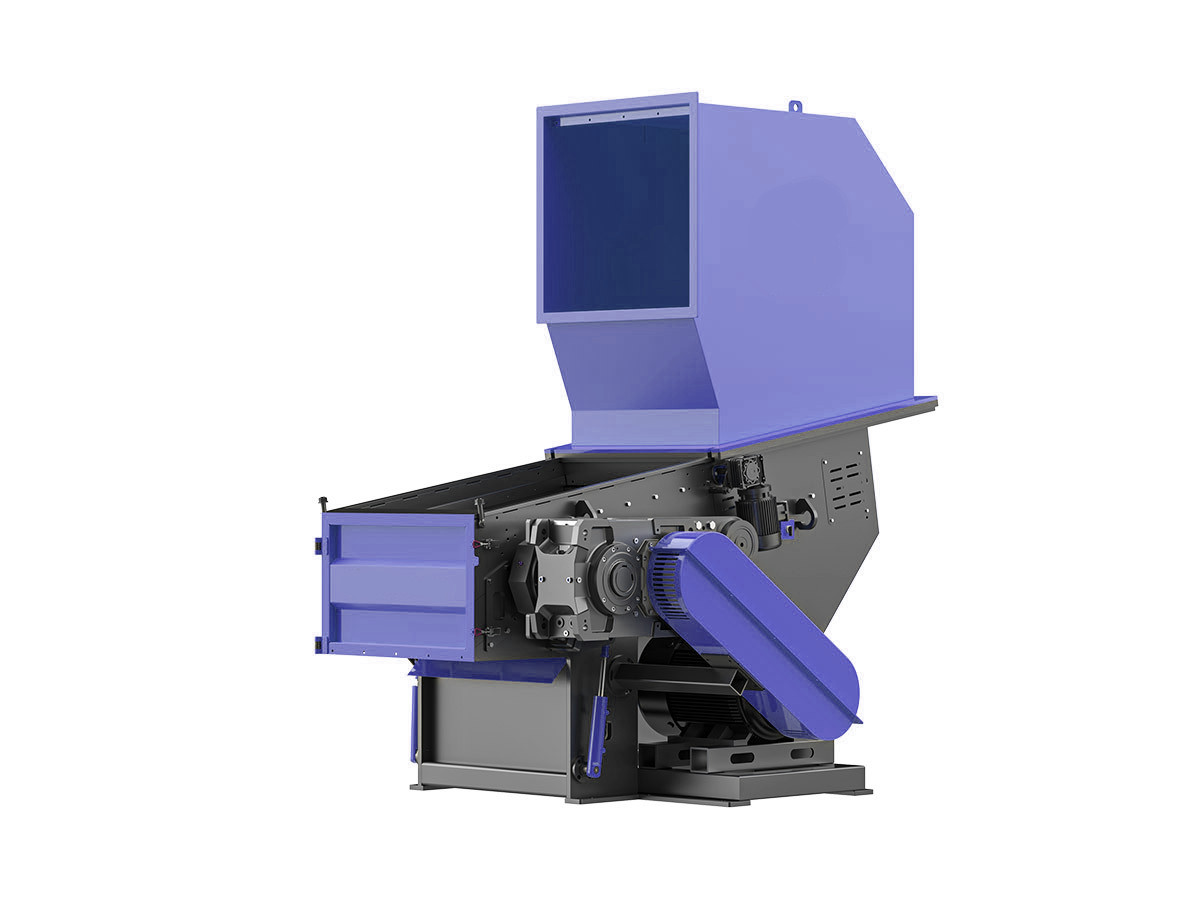

Single-Shaft Shredders: Best suited for processing soft plastics, textiles, and light foam materials. These machines offer precise cutting and controlled particle size.

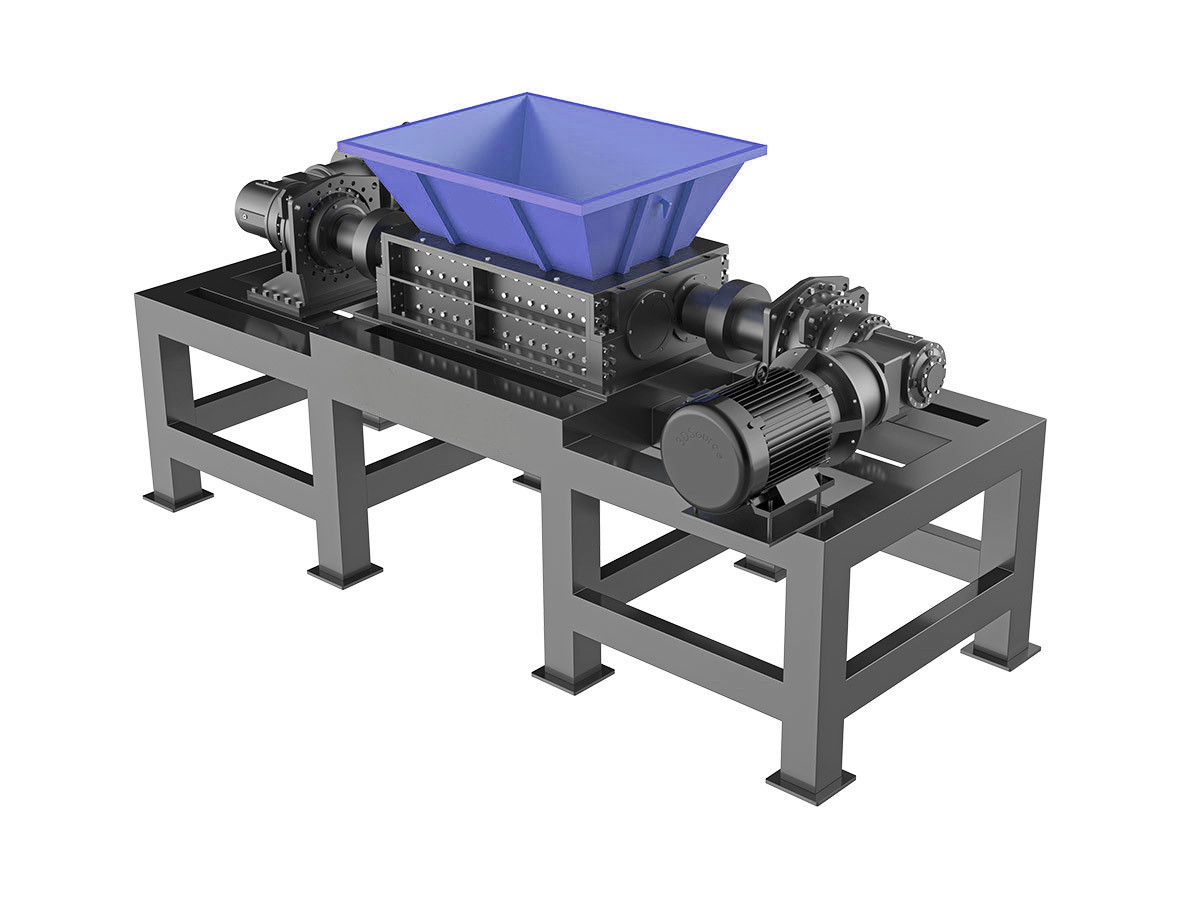

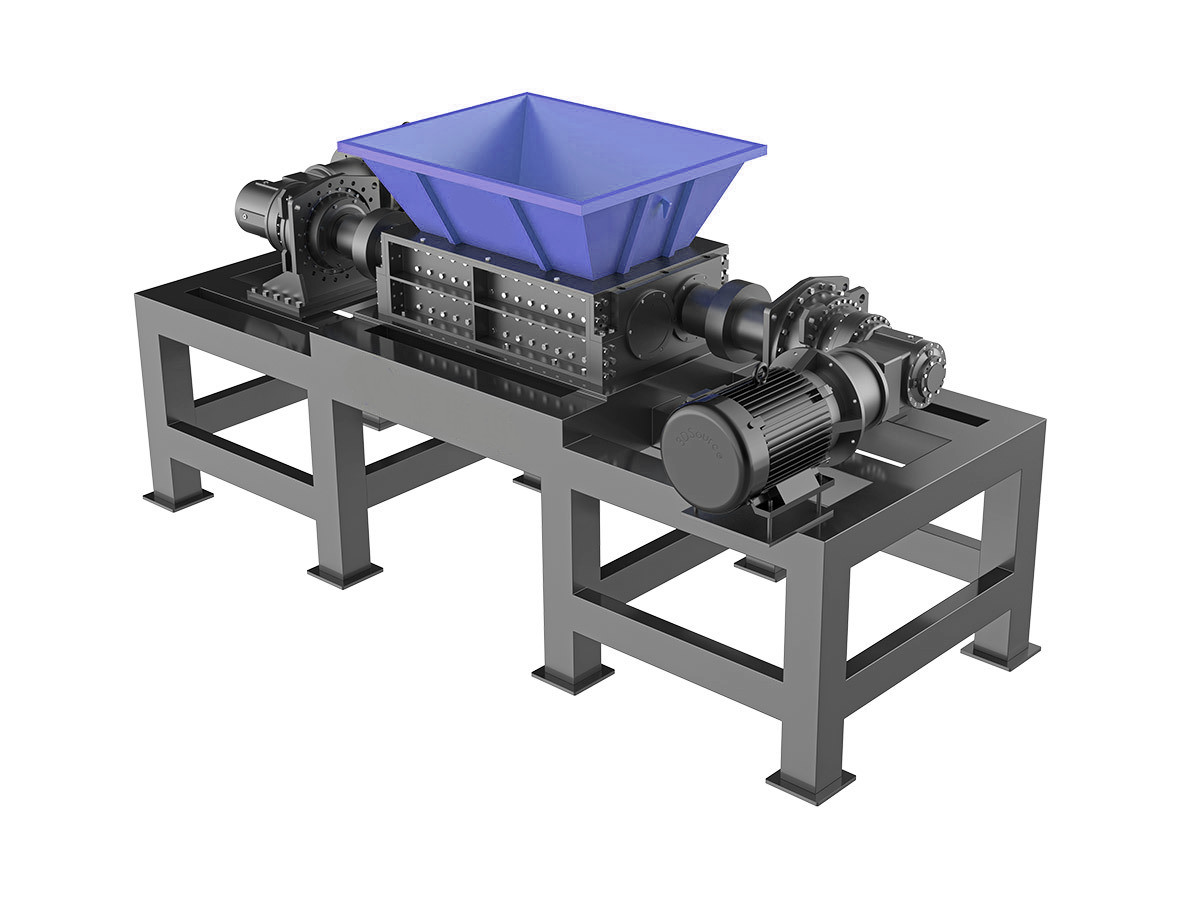

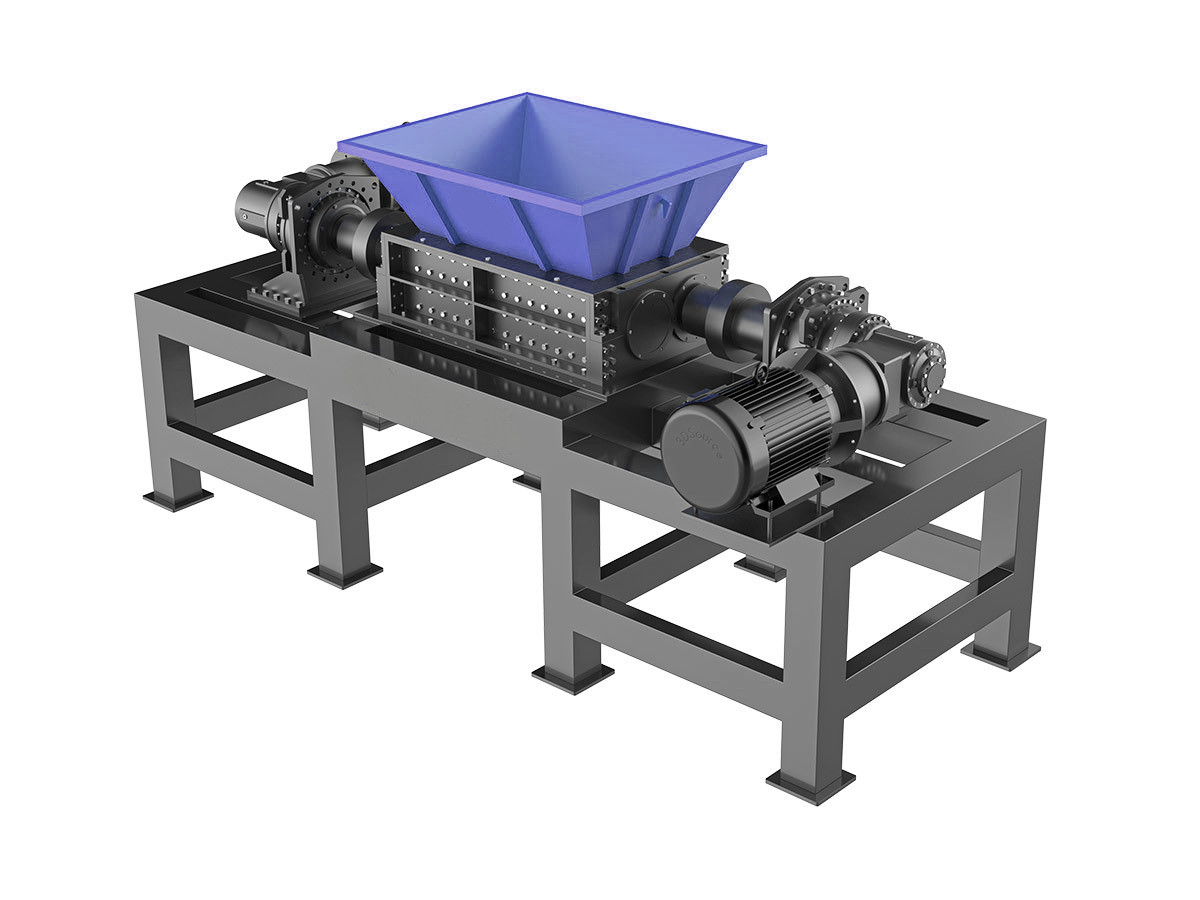

Dual-Shaft Shredders: Used for tougher soft materials such as thick rubber sheets or dense foam. They provide better torque and cutting force for handling complex materials.

Granulators: These fine grinders break down shredded soft materials into small, consistent granules, which are often used for compounding and reprocessing.

Choosing the right type of shredder depends on material composition, desired output size, and end-use applications.

Key Factors in Choosing the Right Shredders for Soft Materials

Selecting the right Soft Material Shredder requires careful consideration of several factors to ensure optimal efficiency and cost-effectiveness.

Material Type: Understanding the composition and flexibility of the material being shredded helps in selecting the right cutter design and shredder model.

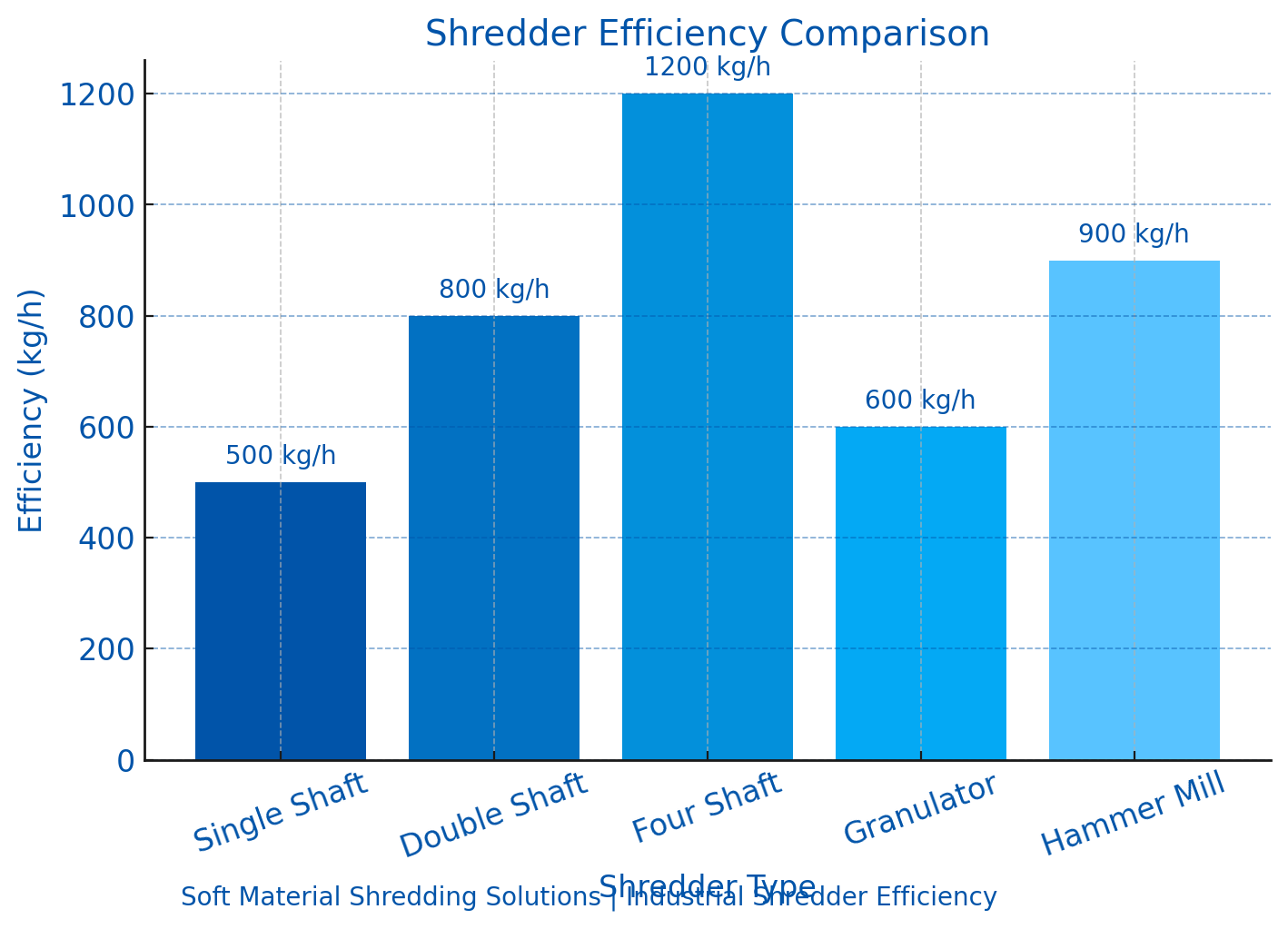

Shredding Capacity: Different shredders offer varying throughput capacities. High-volume applications require industrial-grade shredders with robust cutting mechanisms.

Energy Efficiency: Modern shredders incorporate energy-saving features, such as variable speed drives and optimized cutting angles, to reduce power consumption.

Maintenance and Durability: Machines with easy-to-replace blades, self-cleaning functions, and automatic safety features help reduce downtime and extend machine life.

FAQ

Q: What industries benefit from Soft Material Shredding Solutions?

A: Industries such as plastic recycling, textile manufacturing, packaging waste management, and foam processing benefit from soft material shredders.

Q: Can a single shredder handle multiple types of soft materials?

A: Some high-performance shredders are designed for multi-material processing, but it is essential to choose a shredder optimized for specific material types to achieve the best results.

Q: How can I improve the lifespan of my soft material shredder?

A: Regular maintenance, including blade sharpening, lubrication, and proper material feeding techniques, can extend the lifespan and efficiency of the shredder.

Q: What is the ideal output size for recycled soft materials?

A: The required output size depends on the intended application. For example, textile shredding may require larger strips, while plastic granulation demands fine particles for remanufacturing.

Main Components of Solid Waste Shredder

Shredding Solutions

Soft Material Shredding Solutions

Efficiently handle and process soft materials with our specialized soft material shredding solutions. Designed for materials like rubber, textiles, foam, and soft plastics, our shredders offer precise size reduction while ensuring optimal throughput and minimal downtime. Ideal for industries requiring soft material processing for recycling, waste management, and material recovery, our shredding machines are built for durability, energy efficiency, and high performance.

Learn more >>

Hard Material Shredding Solutions

Tackle tough materials with our advanced hard material shredding solutions. Engineered to process metal, concrete, wood, stone, and dense plastics, our shredders provide powerful performance for efficient size reduction and recycling. Designed for industries handling heavy-duty waste, our shredders ensure durability, precision, and high throughput, helping businesses optimize waste management and material recovery.

Learn more >>

High Toughness Material Shredding Solutions

Efficiently shred and process high toughness materials with our specialized shredding solutions. Designed for materials such as thick rubber, hard plastics, reinforced composites, and industrial metal alloys, our machines provide powerful cutting performance and exceptional durability. Built to handle the toughest materials, our shredders ensure optimal size reduction for recycling, waste management, and material recovery.

Learn more >>

Composite Material Shredding Solutions

Efficiently process and recycle composite materials with our specialized shredding solutions. Designed for fiber-reinforced plastics, carbon composites, and other complex materials, our shredders offer precision cutting and exceptional durability to handle tough and intricate substances. Ideal for industries such as automotive, aerospace, and construction, our machines ensure effective size reduction for reuse or disposal.

Learn more >>