Agricultural waste management is a critical global challenge, with billions of tons of biomass produced annually. Traditional disposal methods are increasingly unsustainable, leading to environmental pollution and lost economic opportunities. The advent of industrial wood shredders represents a transformative shift, turning problematic waste into valuable resources. These powerful machines, distinct from simple chippers, employ shear, tear, and crush mechanisms to systematically reduce a wide variety of agricultural woody biomass into uniform, manageable fragments. This process is foundational to creating a circular economy within the agricultural sector, promoting sustainability and adding value to what was once considered waste.

The Current State and Challenges of Agricultural Waste Management

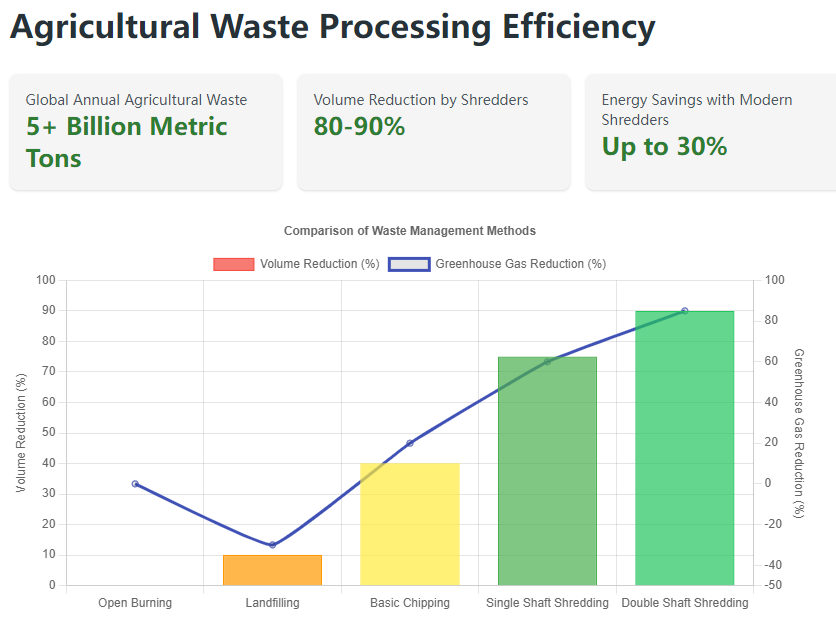

Agricultural operations generate a staggering volume of waste, estimated to be over 5 billion metric tons globally each year. This waste encompasses a diverse range of materials, from crop residues like straw and stalks to woody biomass from orchard trimmings and forestry operations. The primary challenge lies in the bulky and heterogeneous nature of this waste, which makes transportation, storage, and processing economically and logistically difficult. Traditional methods have failed to address these issues effectively, often creating new problems in the process.

Furthermore, evolving environmental regulations worldwide are imposing stricter controls on waste disposal practices. Policies are increasingly penalizing harmful activities like open burning and mandating more sustainable waste management solutions. This regulatory pressure is forcing farmers and agribusinesses to seek innovative technologies that can not only manage waste responsibly but also create economic benefits, moving beyond mere compliance to value creation.

Diverse Sources and Characteristics of Agricultural Waste

The composition of agricultural waste varies significantly depending on the type of farming. Crop residues, such as rice straw, wheat stubble, and corn stalks, are characterized by their high volume and low density, making them cumbersome to handle. A single hectare of farmland can yield several tons of such residue after harvest. Conversely, woody waste from orchards, vineyards, and forestry operations, including pruning branches and fallen trees, presents a different challenge due to its higher density and irregular shapes, often requiring robust equipment like a double shaft wood shredder for effective processing.

Each type of waste possesses unique properties that influence its management. High-cellulose woody biomass is ideal for shredding and subsequent use in bioenergy or composting, while softer crop residues may be suited for different applications. Understanding this diversity is the first step in selecting the appropriate shredding technology and designing an efficient waste-to-resource pipeline, ensuring that the specific characteristics of the waste stream are matched with the correct processing solution.

Environmental and Economic Costs of Traditional Treatment Methods

For decades, the default method for disposing of agricultural waste, particularly straw and stubble, has been open-field burning. This practice releases enormous quantities of greenhouse gases, including carbon dioxide and methane, along with particulate matter that severely impacts air quality and public health. Studies have linked seasonal burning to a significant deterioration in air quality across major agricultural regions, contributing to respiratory illnesses.

Landfilling organic waste is another common but flawed practice. As this waste decomposes anaerobically in landfills, it generates methane, a potent greenhouse gas with a global warming potential many times greater than CO2. Economically, both burning and landfilling represent a total loss of valuable biomass resources. They incur costs for the farmer through labor and potential fines, while also wasting the potential energy and nutrients locked within the biomass, effectively discarding potential revenue streams.

Application of Wood Shredders in Agricultural Waste Volume Reduction

Industrial wood shredders serve as the critical first step in modern agricultural waste management by dramatically reducing the volume of biomass. A high-capacity shredder can process several tons of woody waste per hour, reducing its volume by up to 80-90%. This size reduction transforms piles of unwieldy branches and stalks into a homogeneous, bulk-density material that is exponentially easier to handle, transport, and store. The efficiency gains in logistics alone can justify the investment in shredding technology for many large-scale farming operations.

The economic implications of this volume reduction are substantial. By shredding waste on-site, farms can drastically cut transportation costs, as more material can be loaded onto each truck. This also reduces the number of trips required, lowering fuel consumption and associated emissions. The shredded material then becomes the feedstock for a variety of value-added applications, turning a cost center into a potential profit center and establishing a new revenue model for agricultural businesses.

Evaluating the Efficiency and Effectiveness of Shredding Technology

The performance of shredders can vary significantly based on their design. For instance, a single shaft wood shredder is excellent for pre-cutting large logs and dense wood blocks, while a double shaft machine offers high torque and is ideal for tearing apart mixed woody waste with potential contaminants. The choice of machine directly impacts throughput, energy consumption, and the final particle size distribution of the output material, which must be matched to its intended use.

The final粒度 (particle size) of the shredded material is a crucial factor determining its downstream application. For composting and use as mulch, a coarse shred of 50-100 mm is often sufficient to accelerate decomposition and facilitate spreading. In contrast, producing biomass fuel pellets requires a much finer grind, typically under 10 mm, to ensure proper densification and combustion efficiency. Modern shredders are equipped with interchangeable screen grates to control output size, providing the flexibility needed for various applications.

Advantages of Shredded Material as Organic Fertilizer or Mulch

When applied to fields, shredded woody biomass acts as an excellent organic mulch. This layer helps retain soil moisture by reducing evaporation, suppresses weed growth by blocking sunlight, and slowly decomposes to enrich the soil with organic matter and nutrients. This mimics natural forest floor processes, improving soil structure, water infiltration, and overall soil health without the need for synthetic fertilizers or herbicides, promoting a more organic and sustainable farming approach.

From a nutrient cycling perspective, shredding and returning biomass to the soil completes a natural loop. The shredded material decomposes faster than unprocessed waste, making nutrients more readily available for the next crop cycle. This practice can reduce dependency on chemical fertilizers, lower input costs, and enhance long-term soil fertility and carbon sequestration. It represents a shift from a linear "take-make-dispose" model to a circular, regenerative agricultural system.

Innovative Practices in Agricultural Waste Resource Utilization via Shredders

Beyond simple volume reduction, wood shredders are the gateway to advanced resource recovery from agricultural waste. The consistent, sized material produced by these machines is the essential raw material for a suite of innovative bio-based industries. By enabling the efficient conversion of waste into standardized feedstock, shredders unlock economic value that was previously inaccessible, driving the development of new markets and sustainable business models centered on circular economy principles.

This transformation is fueling the growth of a bio-economy where farms are not just food producers but also suppliers of renewable energy and materials. Shredders sit at the heart of this transformation, providing the mechanical processing necessary to integrate disparate streams of agricultural waste into organized industrial supply chains. This creates new revenue opportunities for farmers and contributes to national and global goals for renewable energy and reduced carbon emissions.

Technical Process and Key Points of Biomass Energy Production

The journey to bioenergy begins with shredding. The uniformly sized feedstock is often further processed in a pellet mill or briquette press to create high-density solid fuels. These pellets are a renewable alternative to coal and are used in specialized boilers for heating or power generation. Alternatively, shredded biomass can be fed into anaerobic digesters where microorganisms break it down to produce biogas, a mixture of methane and CO2 that can be used for heat, electricity, or upgraded to vehicle fuel.

For advanced biofuel production, such as cellulosic ethanol or gasification for syngas, the shredding process is even more critical. A consistent and small particle size is required to maximize the surface area for enzymatic or thermal reactions, ensuring high conversion efficiency and yield. The quality of the initial shredding operation directly impacts the economics of the entire bioenergy plant, making the selection of a robust and reliable wood shredder a fundamental strategic decision.

Innovative Directions and Market Prospects for Biomass Material Manufacturing

The applications for shredded agricultural biomass extend far beyond energy. It is increasingly used as a raw material for manufacturing a range of bio-based products. For example, shredded woody material can be bonded with natural resins under heat and pressure to create particleboard, fiberboard, or oriented strand board (OSB), providing a sustainable alternative to wood from forests. This not only reduces deforestation pressure but also utilizes a waste stream effectively.

Innovative companies are also developing new composite materials using shredded agricultural fibers mixed with bioplastics to create durable and biodegradable products for construction, automotive interiors, and packaging. The market for such green materials is growing rapidly, driven by consumer demand for sustainable products and corporate sustainability initiatives. This creates a compelling economic driver for the adoption of shredding technology on a large scale, as it provides the foundational processing step for these advanced material streams.

Future Trends: How Wood Shredders Drive Change in Waste Management

The future of agricultural waste management is inextricably linked to the continued evolution of shredding technology. We are moving towards smarter, more connected, and more efficient machines that integrate seamlessly into the broader ecosystem of the circular economy. The next generation of shredders will not only be more powerful but also more intelligent, capable of optimizing their operation based on the input material and desired output, reducing energy use and wear while maximizing throughput and product quality.

This technological progression will be supported by increasingly sophisticated material handling and sorting systems, creating fully integrated waste-to-resource facilities. In this future, agricultural waste will be viewed not as a disposal problem but as a valuable commodity, and shredders will be recognized as the essential engines of this conversion process, driving both environmental and economic benefits across the agricultural sector.

Technology Innovation for Enhanced Shredder Performance and Efficiency

Technological advancements are focused on increasing the efficiency and durability of shredders while reducing their operational costs. Innovations include the development of advanced cutting geometries and wear-resistant materials for knives and screens, such as tungsten carbide tips, which significantly extend maintenance intervals. Furthermore, intelligent drive systems with variable frequency drives (VFDs) allow the motor power to be matched precisely to the load, resulting in energy savings of up to 30% compared to traditional fixed-speed systems.

Automation and Industry 4.0 principles are being integrated into shredder design. Modern machines can be equipped with sensors that monitor key parameters like torque, vibration, and temperature. This data is processed by programmable logic controllers (PLCs) to optimize performance and predict maintenance needs, preventing unexpected downtime. Remote monitoring capabilities allow operators to manage and troubleshoot equipment from anywhere in the world, enhancing operational reliability and reducing service costs.

Policy Support and Market Mechanisms for Industry Development

The adoption of advanced waste management technologies is heavily influenced by government policy and market incentives. Many governments offer capital cost subsidies, tax credits, or favorable tariffs for energy produced from biomass, which directly improves the financial return on investment for shredding and subsequent bioenergy systems. These policies are designed to internalize the environmental benefits of waste recycling and renewable energy, making these projects more competitive with traditional disposal methods.

The emergence of carbon trading markets and green financing provides further economic impetus. Farms and waste processing companies can generate carbon credits by avoiding methane emissions from decomposition and displacing fossil fuels with bioenergy. These credits can be sold, creating an additional revenue stream. Furthermore, financial institutions are increasingly offering loans with preferential terms for projects that demonstrate clear environmental benefits, lowering the barrier to acquiring advanced technology like industrial shredders and supporting the transition to a greener economy.