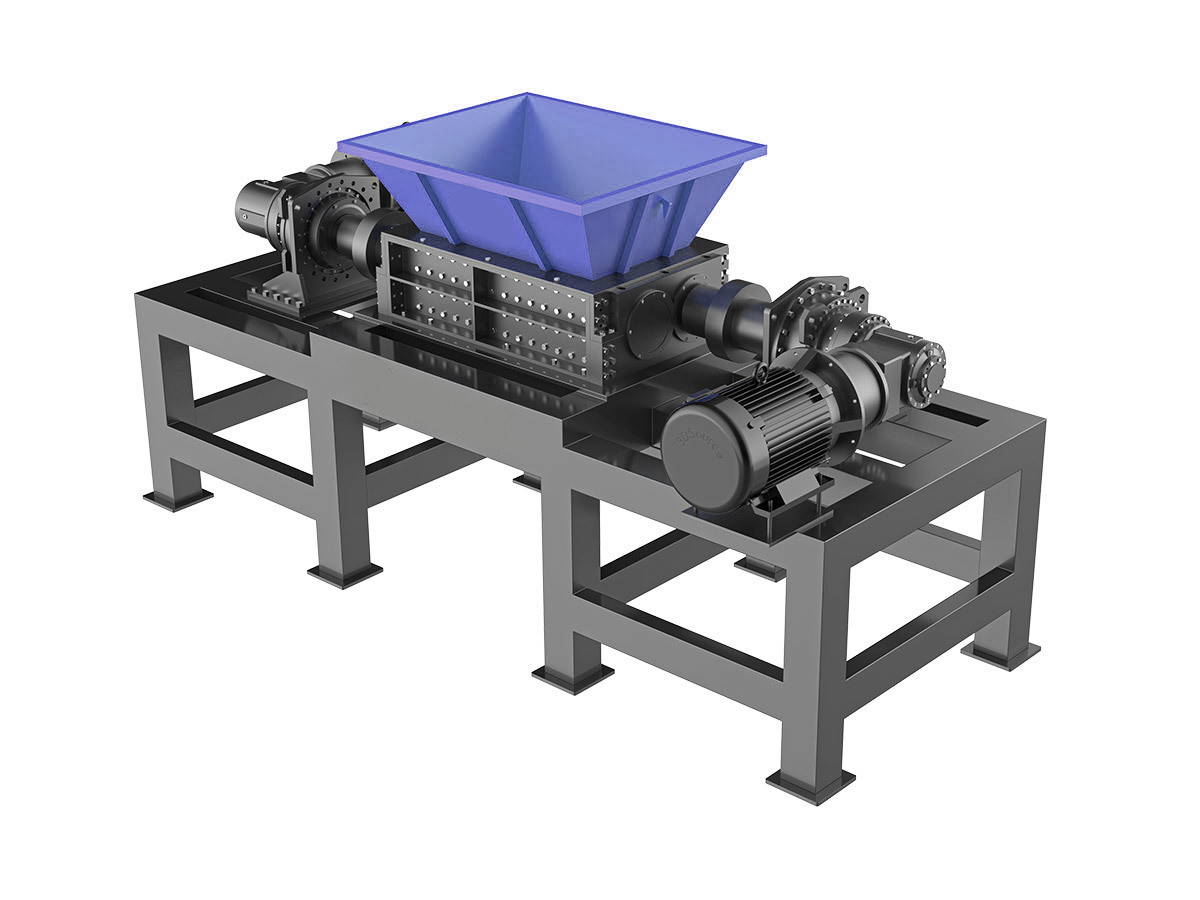

Double Shaft Waste Plastic Shredder

A double shaft plastic shredder is a powerful industrial machine designed to efficiently break down large volumes of plastic waste. Unlike single shaft shredders, this type of shredder operates with two counter-rotating shafts equipped with sharp blades that tear through plastic materials with ease. This dual-shaft design allows for higher torque and greater cutting efficiency, making it ideal for handling tough plastic waste such as drums, pipes, containers, and thick sheets.

Double shaft plastic shredders are widely used in industries such as recycling, manufacturing, and waste management. Their ability to process a variety of plastics, including rigid and flexible materials, makes them essential in reducing plastic waste and promoting sustainability. By breaking plastic into smaller pieces, these shredders facilitate further processing, such as granulation, melting, or chemical recycling.

Designed for durability and high performance, double shaft plastic shredders offer a reliable solution for businesses looking to manage plastic waste effectively. With their high-torque, slow-speed operation, they ensure consistent output while minimizing energy consumption, making them a cost-effective investment for industrial recycling operations.

Key Advantages of Using a Double Shaft Waste Plastic Shredder

One of the primary advantages of a double shaft plastic shredder is its ability to process bulky and high-strength plastic materials. Unlike traditional shredders, which may struggle with thick or reinforced plastics, the twin shafts work together to grip, tear, and cut through materials efficiently. This makes them particularly useful for recycling large plastic components such as crates, IBC tanks, and automotive parts.

Another significant benefit is the reduced risk of material jamming. The dual-shaft mechanism allows the shredder to handle irregularly shaped or oversized materials more effectively. The self-cleaning function of the interlocking blades prevents clogs, ensuring smooth operation and reducing the need for manual intervention. This enhances productivity and minimizes downtime in industrial settings.

Additionally, double shaft plastic shredders are designed for long-term reliability. Their heavy-duty construction ensures they can withstand continuous use, even in demanding environments. Many models come with replaceable blades and easy maintenance access, allowing businesses to keep their shredding operations running efficiently with minimal maintenance costs.

How a Double Shaft Waste Plastic Shredder Works

The shredding process in a double shaft plastic shredder is driven by two parallel rotating shafts, each fitted with cutting discs. When plastic waste is fed into the machine, the counter-rotating blades grip and pull the material into the cutting chamber, where it is gradually shredded into smaller fragments. The interlocking blades create a shearing and tearing motion, which efficiently reduces the size of the plastic.

The low-speed, high-torque operation of the shredder ensures controlled and energy-efficient processing. Unlike high-speed shredders that rely on impact forces, double shaft shredders work through mechanical shearing, which generates less heat and prevents plastic from melting during the process. This is particularly beneficial for materials that require careful handling to maintain their recyclability.

Most modern double shaft plastic shredders come with advanced control systems that allow operators to adjust speed, monitor blade wear, and optimize performance. Some models also include automated overload protection, reversing functions to prevent jamming, and customizable screen sizes to achieve the desired output size. These features enhance both safety and operational efficiency, making double shaft shredders a valuable asset in plastic recycling and waste management industries.