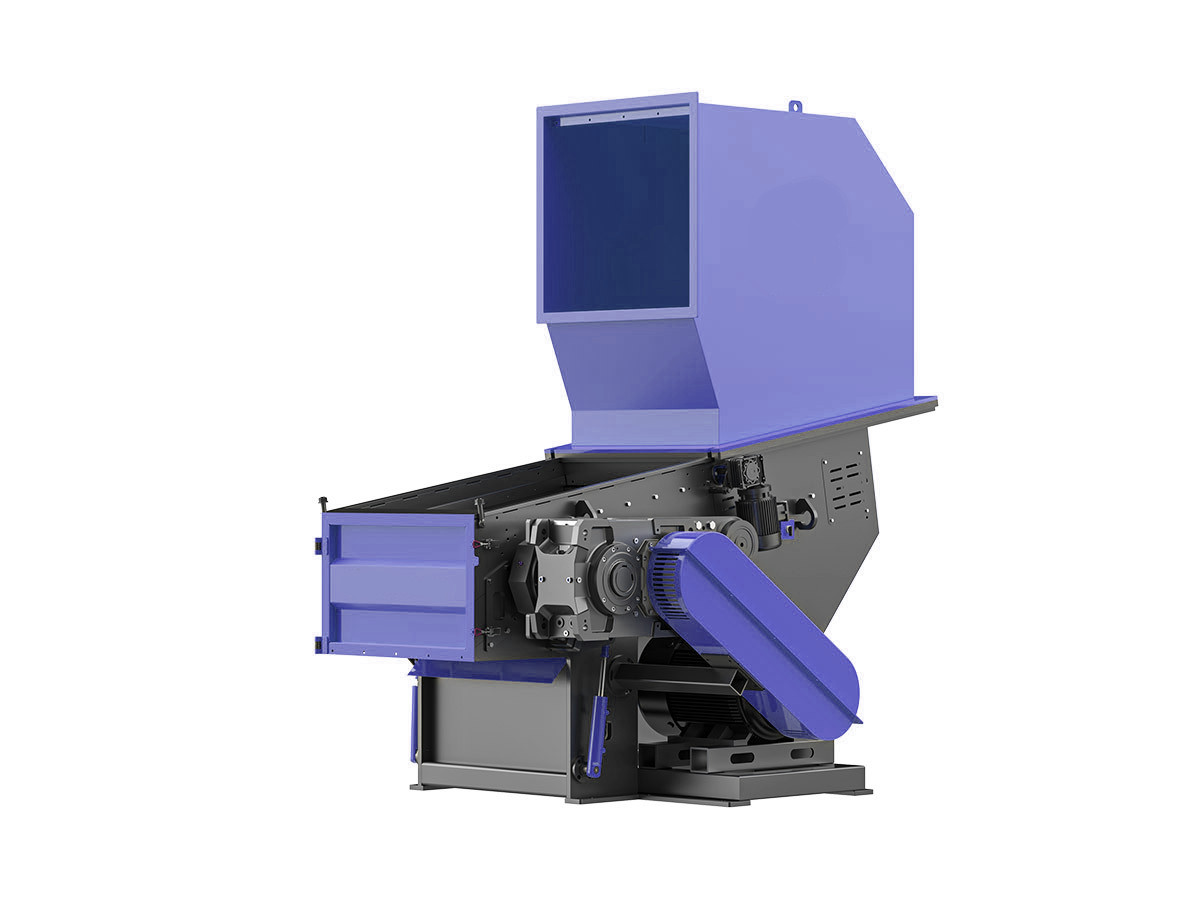

Single Shaft Waste Plastic Shredder

A single shaft plastic shredder is a powerful industrial machine designed to break down plastic waste into smaller, more manageable pieces. Unlike multi-shaft shredders, this type of shredder operates with a single rotating shaft equipped with sharp, high-torque blades that efficiently cut through various plastic materials. Whether used for recycling, waste management, or material processing, single shaft plastic shredders play a vital role in reducing plastic waste and promoting sustainability.

These shredders are widely used in industries that generate significant amounts of plastic waste, such as packaging, manufacturing, and plastic product disposal. The ability to process a variety of plastic types—including PET, HDPE, PVC, and polypropylene—makes them a versatile choice for businesses looking to optimize their recycling efforts. The uniform size of the shredded plastic ensures that it can be easily handled for further processing, such as granulation or re-melting.

Single shaft plastic shredders are designed for efficiency, providing precise cutting and high output rates while maintaining energy efficiency. Their simple yet robust construction makes them reliable for continuous operation, ensuring long-term performance in industrial settings where plastic waste management is essential.

Benefits of Using a Single Shaft Waste Plastic Shredder

One of the primary advantages of a single shaft plastic shredder is its ability to produce consistent, uniform-sized plastic particles. The controlled shredding process ensures that plastic waste is reduced to a manageable size, making it easier to transport, store, and recycle. The uniformity of the shredded material enhances its usability for secondary processing, such as pelletizing or extrusion, contributing to a more sustainable circular economy.

Another key benefit of this shredder type is its efficiency in handling different plastic materials. Whether dealing with soft plastics like film and bags or harder plastics such as pipes and containers, the single shaft shredder is engineered to accommodate various materials without compromising performance. Many models come with customizable blade configurations to adapt to specific shredding requirements, allowing businesses to optimize processing for their unique plastic waste streams.

Additionally, single shaft plastic shredders are designed with operational safety and ease of maintenance in mind. Many models include advanced features such as hydraulic rams that assist in feeding material into the cutting chamber, overload protection systems to prevent damage, and easy-access maintenance points for blade replacement and servicing. These features help improve overall productivity while minimizing downtime in industrial operations.

How a Single Shaft Waste Plastic Shredder Works

The operation of a single shaft plastic shredder revolves around a high-torque, slow-speed rotor equipped with precision-engineered blades. When plastic waste is fed into the shredder, the rotating shaft systematically pulls the material into the cutting chamber, where it is progressively shredded into smaller pieces. The controlled cutting process ensures minimal heat generation, reducing the risk of plastic melting or degradation.

Many single shaft plastic shredders feature a hydraulic pusher system that helps press the plastic material against the rotor, ensuring efficient and continuous shredding. This system prevents material blockages and enhances the throughput rate, making the shredding process smooth and efficient. The shredded plastic is then discharged through a perforated screen, which determines the final size of the shredded pieces based on the application requirements.

Modern single shaft plastic shredders are equipped with intelligent control systems that monitor the shredding process in real-time. These systems can adjust rotor speed, detect overload conditions, and automatically shut down the machine if necessary to prevent damage. This level of automation enhances both safety and efficiency, allowing operators to maintain optimal performance with minimal manual intervention.