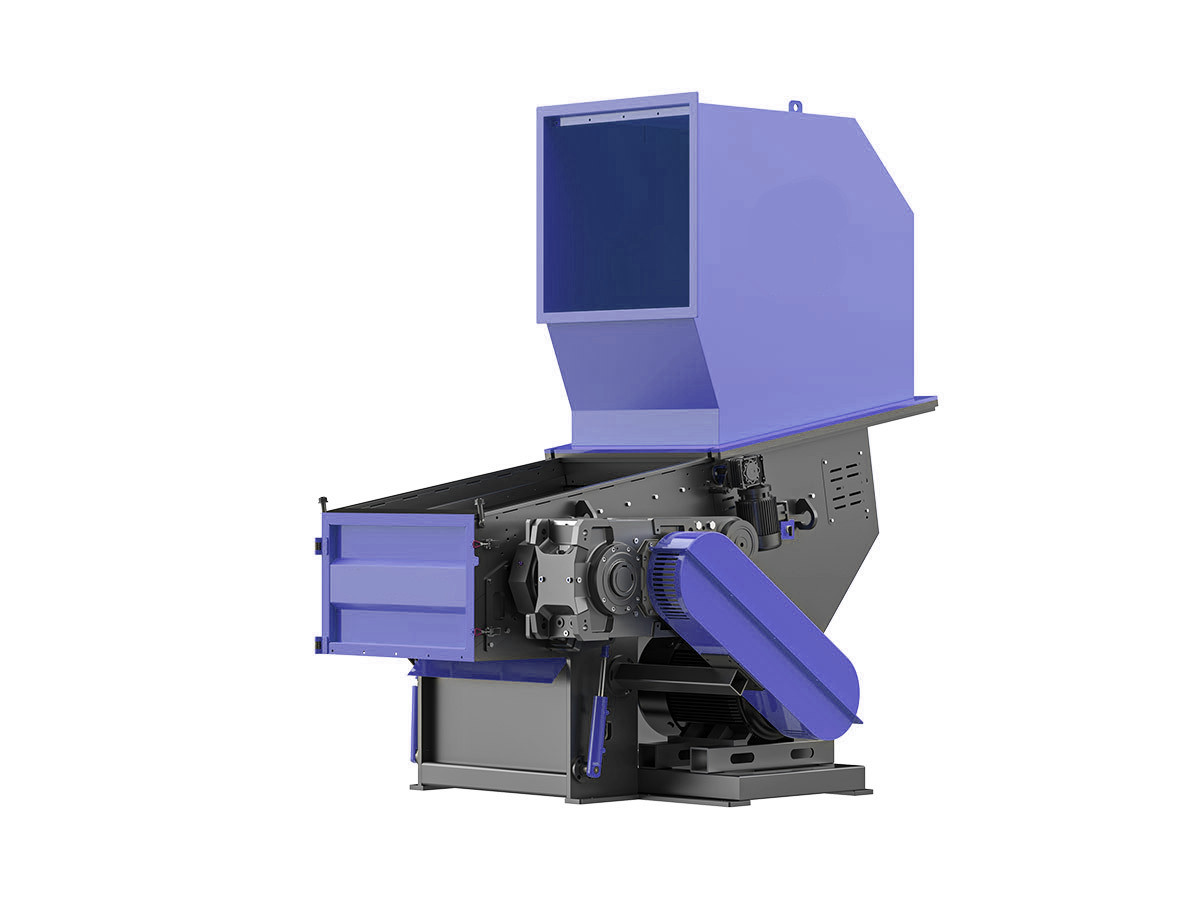

Waste Plastic Film Shredder

A plastic film shredder is a highly specialized industrial machine designed to process thin, flexible plastic materials such as packaging film, agricultural films, plastic bags, and shrink wraps. Unlike standard plastic shredders, which are optimized for rigid plastics, plastic film shredders feature precision cutting mechanisms that prevent tangling and ensure efficient size reduction.

Industries such as waste management, recycling, and manufacturing rely on plastic film shredders to manage excess plastic waste and improve material recovery rates. Because plastic films are lightweight and prone to clogging traditional shredders, specialized shredding systems are required to handle them effectively. These machines are designed to cut and tear films into small, uniform pieces that can be easily recycled or repurposed.

With their advanced cutting technology and robust construction, plastic film shredders provide a reliable solution for businesses looking to optimize plastic waste processing. They help reduce environmental pollution by ensuring that discarded plastic films can be effectively broken down and transformed into reusable materials.

Advantages of Waste Plastic Film Shredders

One of the key advantages of a plastic film shredder is its ability to handle thin and flexible materials without causing machine jams. Traditional shredders often struggle with plastic films because they tend to wrap around the cutting shafts. Plastic film shredders, however, are equipped with specially designed blades and anti-wrapping mechanisms that ensure smooth and uninterrupted shredding.

Another major benefit is the machine’s efficiency in reducing bulk plastic film waste. Due to its lightweight nature, plastic film takes up significant storage space. By shredding it into smaller, compact pieces, businesses can significantly reduce the volume of waste, making storage, transportation, and recycling more cost-effective and manageable.

Additionally, plastic film shredders improve recycling outcomes by producing uniformly sized output. The consistent particle size ensures that the shredded plastic film can be easily processed in downstream recycling applications, such as pelletizing or extrusion. This makes it easier to reintroduce the material into manufacturing processes, promoting sustainability and resource conservation.

How a Waste Plastic Film Shredder Works

The operation of a plastic film shredder involves a systematic cutting process that ensures efficiency and precision. The plastic film waste is fed into the shredder through a controlled feeding system, preventing material from bunching up or overloading the machine. Once inside, high-torque rotating blades grip and tear the film into smaller pieces.

Many plastic film shredders utilize a dual or multi-stage shredding system. In the initial stage, the plastic film is roughly torn into smaller strips. These strips then pass through additional cutting blades, which further reduce them into uniform, manageable pieces. This step-by-step process ensures complete size reduction while minimizing the risk of machine blockages.

Modern plastic film shredders come equipped with intelligent control features, such as automatic feed regulation, overload protection, and adjustable output sizes. These advanced features enhance operational efficiency, reduce energy consumption, and extend the lifespan of the machine. With their specialized design and innovative technology, plastic film shredders offer an essential solution for industries seeking to improve plastic waste management and recycling.