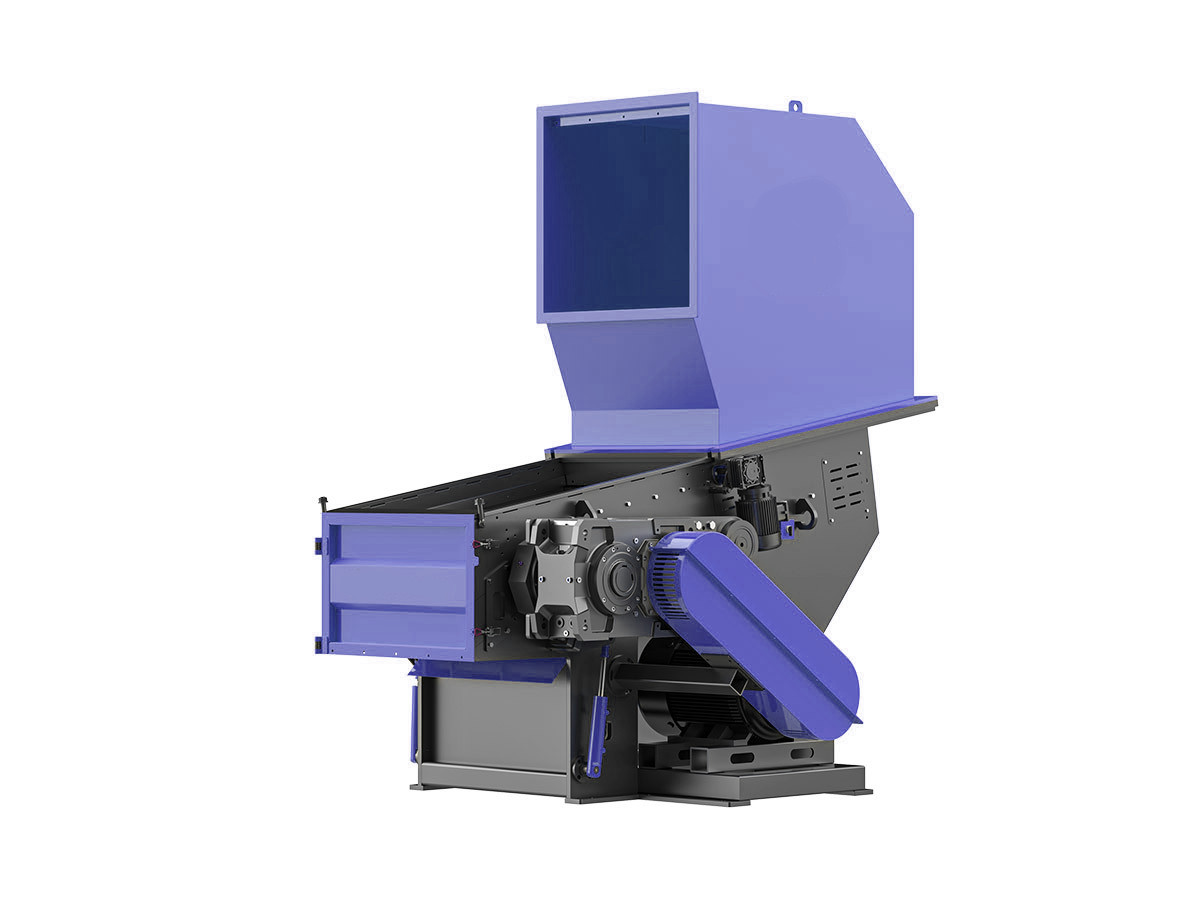

Single Shaft Waste Tire Shredder

A single shaft tire shredder is an advanced industrial machine designed for efficiently processing used and waste tires into smaller, manageable pieces. Unlike multi-shaft shredders, which use multiple cutting mechanisms, a single shaft tire shredder operates with one high-torque rotating shaft equipped with sharp, wear-resistant blades. This design ensures controlled shredding, making it ideal for handling various types of tires, including car tires, truck tires, and even off-road vehicle tires.

The demand for efficient tire recycling has increased due to environmental concerns and the need to repurpose waste rubber into valuable materials. Single shaft tire shredders are widely used in industries such as recycling plants, rubber processing facilities, and waste management operations. These machines help reduce the size of tires, making them suitable for further processing into rubber granules, crumb rubber, or alternative fuels.

With their durable construction, high efficiency, and precision cutting capabilities, single shaft tire shredders provide an effective solution for businesses looking to improve tire recycling processes while minimizing environmental impact.

Key Advantages of a Single Shaft Waste Tire Shredder

One of the primary benefits of a single shaft tire shredder is its ability to provide consistent and controlled shredding. The carefully engineered cutting system ensures that tires are broken down into uniform pieces, reducing the need for additional processing while optimizing recycling efficiency.

Another key advantage is the shredder’s ability to handle various tire types and sizes. Whether processing passenger vehicle tires, large truck tires, or industrial rubber components, a single shaft tire shredder delivers reliable performance without excessive wear on the cutting blades.

Additionally, single shaft tire shredders are designed for durability and low maintenance. The high-torque motor, reinforced cutting chamber, and advanced hydraulic feeding system ensure smooth operation with minimal downtime. Many models also include intelligent features such as automatic overload protection, adjustable shredding speeds, and easy-access maintenance points, making them ideal for long-term industrial use.

How a Single Shaft Waste Tire Shredder Works

The shredding process in a single shaft tire shredder involves a slow-speed, high-torque rotating shaft fitted with sharp blades. When waste tires are fed into the machine, the shaft pulls the material into the cutting chamber, where the blades progressively break it down into smaller pieces.

Many single shaft tire shredders incorporate a hydraulic pusher system that applies consistent pressure to the material, ensuring even feeding and preventing blockages. This controlled shredding process helps produce uniform output while minimizing energy consumption and reducing wear on the machine.

Modern single shaft tire shredders also come equipped with advanced control systems that allow operators to customize shredding settings based on material type and desired output size. Features such as automatic reverse operation for jam prevention, load-sensing technology, and variable speed control enhance efficiency and safety. With their innovative design and superior shredding capabilities, single shaft tire shredders offer an eco-friendly and cost-effective solution for tire recycling and waste rubber processing.