The effective management of plastic waste is a critical challenge in modern recycling operations, and the choice of shredding technology sits at the heart of this process. Single-shaft and dual-shaft shredders represent two dominant mechanical approaches, each with distinct advantages and limitations. This article provides a systematic comparison of their efficiency in plastic waste processing, analyzing mechanical structure, crushing effects, and economic performance to offer a comprehensive technical reference for businesses making critical equipment selection decisions.

Selecting the right shredder is not merely about throughput; it's about matching the machine's capabilities to the specific type of plastic waste, desired output size, and overall operational economics. The wrong choice can lead to increased energy consumption, premature wear, and an inferior product that is harder to sell. Understanding the fundamental differences between these two technologies is therefore essential for optimizing any plastic recycling operation.

Comparison of Mechanical Structure and Working Principles

The core efficiency of any shredder is dictated by its fundamental mechanical design and the principles it employs to reduce material size. Single-shaft and dual-shaft shredders approach this task in fundamentally different ways, leading to variations in their application, performance, and maintenance needs. These structural differences define their respective niches in the recycling ecosystem.

Where one machine relies on precision shearing, the other utilizes tearing and pulling forces. This divergence in first principles affects everything from the types of materials they can handle most effectively to the way they are fed and how their components wear out over time. A deep understanding of these mechanics is the first step toward intelligent equipment selection.

Single-Shaft Shredder: Single Rotating Rotor + Static Blades (Shear-Type Crushing)

A single-shaft shredder operates on a relatively straightforward principle. It features a powerful, single rotating rotor equipped with multiple hook-shaped cutting blades. As the rotor turns, these blades draw material towards a set of stationary counter-blades mounted on the housing. The plastic is sheared and torn into smaller pieces in the precise gap between the rotating and stationary blades.

This scissor-like shearing action is highly effective for achieving a controlled, uniform output size. The geometry of the cutting chamber and the hooks on the rotor also provide a self-feeding action, pulling material inward. However, this design can be susceptible to jamming if fed too quickly or with overly flexible materials that wrap around the rotor.

Dual-Shaft Shredder: Dual Counter-Rotating Shafts (Tearing and Squeezing Mechanism)

In contrast, a dual-shaft shredder employs two parallel shafts that rotate at low speed and high torque in opposite directions. Each shaft is fitted with intermeshing disc-shaped cutters. The material is grabbed, torn, and crushed between these cutters, with the opposing rotation of the shafts creating a powerful pulling and chewing action.

This mechanism is less about precise shearing and more about brute-force size reduction through ripping and compression. The slow-speed, high-torque operation makes it exceptionally good at handling large, bulky, and heterogeneous items without jamming, as the cutters can effectively grab and process materials of varying shapes and sizes.

Feed Method Differences (Force-Feeding vs. Gravity Feeding)

The feeding mechanism is a critical differentiator. Single-shaft shredders often rely on a hopper with a hydraulic ram or a conveyor system that pushes material into the cutting chamber. This forced feeding is necessary to ensure a consistent flow of material into the shearing zone and to prevent bridging—where material arches over the opening and fails to drop in.

Dual-shaft shredders, with their aggressive grabbing action, often function effectively with simple gravity feeding from a large hopper. The intermeshing cutters pull the material down into the cutting chamber autonomously, reducing the need for complex and energy-intensive hydraulic ram systems, which simplifies the overall feeding infrastructure.

Blade Wear Pattern Comparison (More Concentrated Wear on Single-Shaft Stationary Blades)

Wear patterns differ significantly. In a single-shaft system, the stationary counter-blades experience concentrated, localized wear at the points of contact with the rotating hooks. These blades may need to be rotated or replaced more frequently to maintain a sharp cutting edge and a consistent output size. The rotating hooks themselves also wear, but often more evenly.

In a dual-shaft shredder, wear is distributed across the many cutting discs on both shafts. While the total number of cutting edges is higher, the individual wear per edge can be lower for certain materials. However, because the cutters on both shafts are active and intermeshing, the alignment and maintenance of both sets are critical, and wear can lead to a loss of cutting clearance and efficiency.

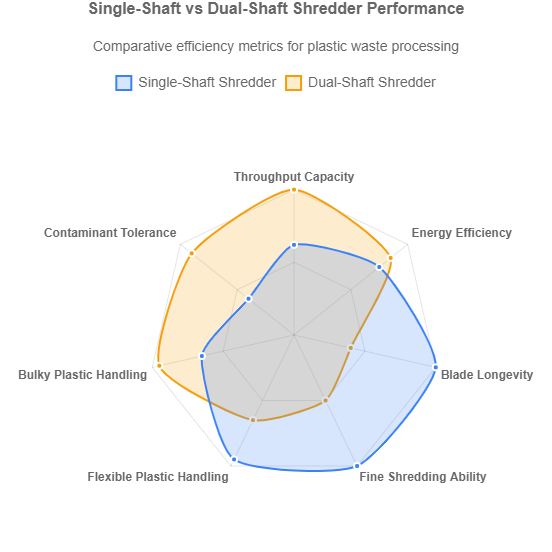

Throughput Capacity and Particle Size Control

The intended use of the shredded plastic flake directly influences the required particle size and the necessary processing capacity. Single-shaft and dual-shaft shredders excel in different areas of this spectrum, making them suitable for different stages in a recycling line or for different end-market requirements.

Throughput, measured in tons per hour, is a function of the machine's design, power, and the material's characteristics. Similarly, the ability to control the final particle size distribution is a key factor in determining the market value and handling properties of the recycled material.

Single-Shaft Equipment: Fine Shredding (Output Size<50mm)

Single-shaft shredders are masters of fine shredding. They are typically configured to produce a controlled, homogeneous output, often with a top size of less than 50mm. This makes them ideal for applications where a consistent, smaller flake is required, such as for direct injection into an extruder for pelletizing or for producing a high-quality regrind material. The shearing action provides good control over the final particle size distribution.

This capability for producing a uniform product is a significant advantage in markets where consistency is valued, as it can command a higher price per ton compared to a more irregularly shaped coarse shred.

Dual-Shaft Equipment: Coarse Shredding Capacity (Output Size 50-200mm)

Dual-shaft shredders are the workhorses of primary or coarse shredding. They are designed to break down large, voluminous items—like entire plastic pallets, drums, or large bundles of film—into manageable chunks typically ranging from 50mm to 200mm. Their high throughput and robust construction allow them to handle large input sizes that would stall or damage a single-shaft machine.

This coarse output is often the first step in a multi-stage size reduction process, where the material is later fed into a finer single-shaft shredder or a granulator to achieve the final desired size.

Plastic Film Processing Efficiency Differences (Single-Shaft Anti-Wrapping Advantage)

Flexible plastic films and bags present a unique challenge due to their tendency to wrap around rotating components. Single-shaft shredders, particularly those designed as plastic film shredders, often incorporate specialized hook-shaped rotor blades and bed knives that are designed to slice through film without allowing it to wrap. The shearing action cuts the film into strips or flakes effectively.

While dual-shaft shredders can process film, the tearing action can sometimes lead to tangling around the shafts if the machine is not specifically configured for such light, flexible materials. For dedicated film recycling lines, single-shaft machines are often the preferred choice for their superior anti-wrapping characteristics.

Hard Plastic (e.g., PVC Pipes) Shredding Capacity Comparison

For hard and brittle plastics like PVC pipes or thick ABS components, both shredder types can be effective, but their performance differs. A dual-shaft shredder uses its high torque to crush and break these materials effectively, making short work of large-diameter pipes. The slow speed reduces the risk of generating excessive dust.

A single-shaft shredder will shear through hard plastics, often producing a cleaner cut with less dust. The choice may come down to the desired output characteristics; dual-shaft for coarse, irregular fragments, or single-shaft for more uniformly sized pieces.

Energy Consumption and Economic Analysis

The decision between shredder types extends beyond technical capability into the realm of economics. The total cost of ownership encompasses not only the initial purchase price but also ongoing operational expenses, primarily energy consumption and maintenance costs. These factors collectively determine the long-term viability and profitability of the recycling operation.

A machine with a lower purchase price but higher energy and maintenance costs may ultimately be more expensive than a higher-priced, more efficient alternative. A thorough economic analysis is therefore crucial for making a sound investment.

Single-Shaft Equipment: Low-Power Design (Suitable for Small-Batch Processing)

Single-shaft shredders are often designed for precision and control rather than pure mass throughput. Consequently, they frequently operate with lower installed power motors compared to dual-shaft machines of a similar physical size. This makes them more energy-efficient for applications that require fine shredding of smaller volumes or for facilities with limited power availability.

Their economic advantage lies in lower energy bills for specific tasks and their ability to produce a high-value, ready-to-use output in a single step, saving on downstream processing costs.

Dual-Shaft Equipment: High-Throughput Energy Ratio (Power Consumption<60 kWh/t)

Dual-shaft shredders are built for volume. Their low-speed, high-torque operation is remarkably energy-efficient when measured in terms of power consumption per ton of material processed. For many common plastics, efficient dual-shaft systems can achieve a specific energy consumption of less than 60 kWh per ton of material shredded.

This high throughput at a relatively low energy cost per ton makes them the economically superior choice for primary size reduction in large-scale recycling facilities where the goal is to process massive volumes of material quickly and efficiently.

Maintenance Cost Structure Differences (Higher Blade Replacement Frequency for Dual-Shaft)

Maintenance costs follow different patterns. A single-shaft shredder's maintenance often focuses on the periodic replacement or rotation of the stationary bed knives and the sharpening of the rotor hooks. The wear is predictable and localized.

A dual-shaft shredder has a larger number of cutting discs, and while individual discs

may wear slower, the cost of replacing a full set of cutters on two shafts can be significantly higher. Furthermore, maintaining the precise alignment between the two shafts is

critical and can require more skilled labor, impacting maintenance labor costs.

Total Cost of Ownership (TCO) Comparison Model

The most accurate way to compare economics is through a Total Cost of Ownership (TCO) model. This model factors in the initial capital expenditure (CAPEX), installation costs, energy consumption over the machine's lifespan, routine maintenance costs (like blade replacement), unscheduled downtime costs, and expected resale value.

For a high-volume operation processing mixed, bulky plastics, a dual-shaft shredder's higher throughput and lower energy cost per ton will likely yield a better TCO. For a specialized operation requiring a fine, consistent output from a specific plastic stream, a single-shaft shredder may prove more economical in the long run.

Plastic Material Adaptability Research

Not all plastics behave the same way when subjected to mechanical stress. Their polymer type, thickness, flexibility, and former life as a product all influence how they should be shredded. The adaptability of a shredder to various plastic types is a key determinant of its versatility and value in a diverse waste stream.

Some machines are generalists, capable of handling a wide array of materials moderately well. Others are specialists, excelling with specific material types but performing poorly with others. Matching the machine's strengths to the primary material stream is essential.

Single-Shaft Equipment: Advantage with Flexible Materials (PE/PP Film)

As previously mentioned, single-shaft shredders with their shear-cutting action are particularly well-suited for processing flexible materials. Polyethylene (PE) and Polypropylene (PP) films, bags, and sheets are effectively sliced into flakes without excessive wrapping, especially in machines designed with anti-winding features. This makes them the industry standard for film recycling operations.

Dual-Shaft Equipment: Efficiency with Bulky Materials (PET Bottles/ABS Parts)

Dual-shaft shredders excel at processing rigid, bulky items. Whole bales of PET bottles, large ABS computer housings, polycarbonate sheets, and large plastic totes are no match for the grabbing and crushing action of the intermeshing cutters. They can reduce these voluminous items to a conveyable size quickly and reliably, making them ideal for the initial breakdown step in a recycling line.

Mixed Plastic Processing Capability Comparison (With Metal/Fabric Impurities)

Real-world plastic waste is often contaminated with non-plastic materials like metals, labels, and fabrics. Dual-shaft shredders are generally more robust when dealing with such mixed and contaminated loads. Their slow-speed, high-torque operation is less likely to be damaged by an occasional piece of tramp metal passing through the system.

Single-shaft shredders are more sensitive to contaminants. Metal pieces can severely damage the precision shear gaps between the rotor and stationary blades, leading to costly repairs and downtime. Effective pre-sorting is more critical for single-shaft operations.

Thermoplastic vs. Thermoset Plastic Processing Differences

This is a critical distinction. Thermoplastics (like PET, PE, PP) can be remelted and reshaped, making them the primary target for mechanical recycling. Both shredder types can process them effectively.

Thermoset plastics (like polyurethane foam, epoxy resins, or vulcanized rubber) do not melt. When shredded, they break down into a powder or crumb. Dual-shaft shredders are often better suited for this task, as their crushing and tearing action is effective at breaking the cross-linked polymer chains into a fine powder, whereas single-shaft shredders may struggle or produce an inconsistent output.

Analysis of Typical Application Scenarios

The theoretical strengths and weaknesses of each shredder type become concrete when applied to specific real-world recycling scenarios. Different applications prioritize different outcomes—whether it's precise size control, maximum throughput, or the ability to handle a specific contaminated stream.

Examining these scenarios provides a practical framework for understanding which technology is the right tool for the job, moving from abstract specifications to tangible operational benefits.

Single-Shaft Equipment: RDF Fuel Preparation Pre-Treatment (Particle Size Control)

In the production of Refuse-Derived Fuel (RDF), a consistent particle size is crucial for efficient combustion in cement kilns or specialized power plants. A single-shaft RDF shredder is often employed in the final shredding stage to ensure the output material meets the strict size specifications (often below 50mm). Its ability to produce a homogeneous flake is a key advantage in this application.

Dual-Shaft Equipment: Electronic Waste (WEEE) Dismantling Line Integration

E-waste shredding lines frequently use powerful dual-shaft shredders as the primary crusher. These machines are capable of processing entire computer cases, printers, and other electronic equipment, liberating the internal components for subsequent separation of metals, plastics, and circuit boards. Their robustness is essential for handling the heterogeneous and often hard nature of electronic waste.

Packaging Material Recycling Line (Multi-Layer Composite Film Processing)

Recycling multi-layer flexible packaging (e.g., chip bags, food pouches) is challenging. These materials are designed to be tough and barrier-resistant. Single-shaft shredders are typically used to break these films down into flakes. The challenge is overcoming the potential for wrapping, which requires specialized rotor and knife designs to ensure clean cutting and continuous operation.

Special Requirements for Marine Plastic Waste Processing

Marine plastic waste, or "ghost gear," often consists of heavily degraded fishing nets and ropes made from HDPE or Nylon. These materials are tough, abrasive, and usually contaminated with sand and salt. Dual-shaft shredders are often chosen for this demanding task due to their ability to grip and pull these tangled masses into the cutting zone and their robustness in handling abrasive contaminants that would rapidly wear a fine-cutting single-shaft system.

Actual Production Data Comparison

Beyond theoretical comparisons, real-world operational data provides the most compelling evidence for the performance differences between single-shaft and dual-shaft shredders. This data, collected from active recycling facilities, offers insights into practical throughput, maintenance intervals, reliability, and the market's reception of the different output materials.

These metrics are invaluable for building realistic financial models and setting accurate expectations for operational performance, downtime, and product quality.

Measured Data from a Recycling Plant (5t/h vs. 8t/h Throughput)

In a direct comparison at a facility processing mixed rigid plastics, a mid-sized single-shaft shredder might achieve a stable throughput of 5 metric tons per hour, producing a 20mm output. A comparably powered dual-shaft shredder processing the same feed material might achieve a throughput of 8 metric tons per hour, but with a coarser 100mm output. This highlights the dual-shaft's advantage in raw volume reduction versus the single-shaft's advantage in achieving a finer product in a single pass.

Blade Replacement Cycle Comparison (Single-Shaft 2000h vs. Dual-Shaft 800h)

Maintenance data reveals a significant difference in wear parts life. The stationary knives on a single-shaft shredder may require rotation or replacement every 2000 operational hours when processing clean PP/PE. In contrast, the cutting discs on a dual-shaft shredder processing a mixed and potentially abrasive stream might need inspection and possible replacement more frequently, for example, every 800 hours, to maintain optimal performance and output size.

Failure Rate Statistics (Higher Bearing Failure Rate for Dual-Shaft)

Reliability statistics often show different patterns. The high-torque, slow-speed operation of dual-shaft shredders places significant stress on the bearings supporting the two shafts. If not meticulously maintained, these bearings can be a point of failure. Single-shaft shredders, while not immune to bearing issues, may experience fewer such failures but might see more issues related to the hydraulic system of the feed ram or wear on the rotor drive components.

Finished Product Market Acceptance Survey (Impact of Particle Uniformity)

The market value of the shredded plastic flake is heavily influenced by its consistency. A survey of plastic recyclers and buyers often shows a preference for the uniform, clean-cut flakes produced by a well-maintained single-shaft shredder, as they are easier to wash, dry, and feed into an extruder. The more irregularly shaped pieces from a dual-shaft shredder, while perfectly adequate for many applications, may be priced slightly lower due to the need for further processing or concerns about bulk density and handling.

Technology Trends and Selection Recommendations

The landscape of shredding technology is not static. Innovations in design, control systems, and materials are continuously enhancing the capabilities of both single-shaft and dual-shaft machines. Understanding these trends helps in making a future-proof investment decision.

The optimal choice is not always a strict either/or. The evolving trend is toward integrated systems that leverage the strengths of both technologies in a coordinated process to achieve the best overall efficiency and product quality.

Modular Design Breakthroughs (Integration of Single and Dual-Shaft Functions)

Some manufacturers are developing hybrid or modular systems. For instance, a machine may feature a dual-shaft primary stage followed by an integrated single-shaft secondary stage within a single housing. This allows for coarse volume reduction and fine shredding in one continuous process, saving space and simplifying material handling between stages.

Intelligent Control Systems (Load-Adaptive Adjustment)

Modern shredders are increasingly equipped with smart PLC control systems. These systems monitor motor amperage and hydraulic pressure in real-time. They can automatically reverse the rotor(s) to clear a jam, adjust the feed rate to maintain optimal load, and provide operators with data on throughput and maintenance schedules, maximizing uptime and efficiency.

Special Coating Blade Applications (Improving Wear Resistance)

The application of advanced wear-resistant coatings, such as tungsten carbide or specialized ceramic layers, onto the cutting blades is becoming more common. These coatings can extend the operational life of both single-shaft hooks and dual-shaft cutters by a factor of two or three, especially when processing abrasive materials like fiber-reinforced plastics or contaminated streams, significantly reducing long-term maintenance costs.

Hybrid Crushing Process Innovation (Linked Coarse and Fine Crushing)

The most efficient large-scale recycling plants often employ a two-stage process that leverages the strengths of both shredder types. A primary dual-shaft shredder is used for initial coarse reduction of large, bulky items. Its output is then conveyed to a secondary single-shaft shredder or granulator for final sizing. This hybrid approach maximizes overall system throughput and energy efficiency while delivering a high-quality, consistent end product.