Discarded fishing nets represent a significant environmental challenge, with an estimated 640,000 tons of gear abandoned in oceans annually, contributing to marine pollution and ecosystem damage. Utilizing waste plastic shredders transforms these nets into valuable recycled materials, supporting circular economy principles. This process involves specialized shredding technology that breaks down tough polymer structures into uniform fragments, enabling efficient reprocessing. The shredded material can be converted into products like textile fibers or construction materials, increasing its market value by up to 40% compared to untreated waste. This article examines the technological applications, process optimizations, and economic benefits of shredder-based recycling, providing insights into sustainable waste management practices.

Advanced shredding systems address the unique properties of fishing nets, which are typically made from nylon or polyethylene polymers. These materials exhibit high tensile strength and flexibility, requiring robust shredding mechanisms to achieve consistent particle sizes. Studies indicate that proper shredding can reduce the volume of fishing net waste by over 70%, facilitating easier transportation and processing. The integration of shredders into recycling workflows enhances material purity, which is crucial for high-value applications. This approach aligns with global sustainability goals, such as the United Nations' targets for marine conservation, while offering economic incentives through resource recovery.

Background and Challenges of Discarded Fishing Net Recycling

The accumulation of discarded fishing nets in marine environments poses severe ecological threats, including entanglement of marine life and microplastic generation. These nets are primarily composed of synthetic polymers like nylon-6 or high-density polyethylene, which degrade slowly and persist for centuries in aquatic systems. Recycling these materials is complex due to their entangled nature and frequent contamination with salt, sand, and organic matter. The global fishing industry generates approximately 10% of marine plastic pollution, with nets being a major component. Addressing this issue requires innovative recycling solutions that can handle the material's durability and irregular shapes.

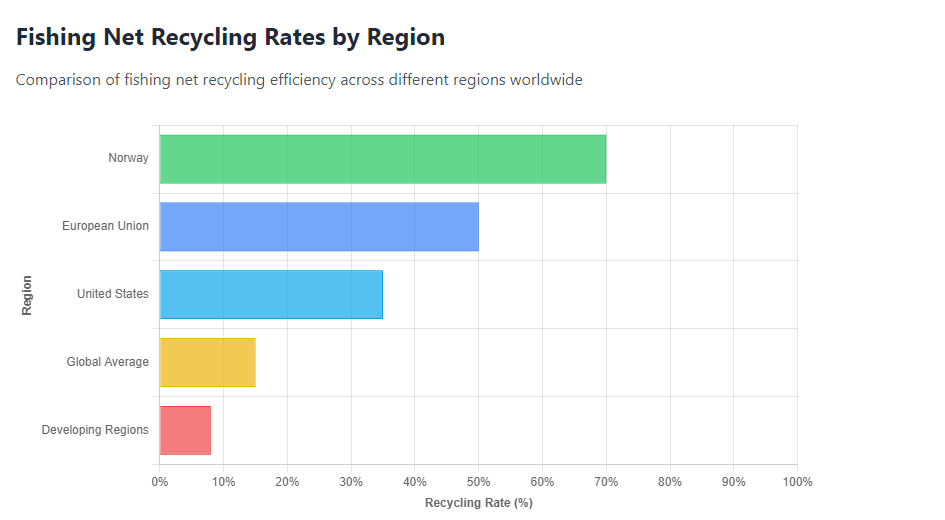

Economic and logistical barriers further complicate fishing net recycling, as collection and transportation from coastal areas incur significant costs. Many regions lack dedicated infrastructure for net recovery, leading to low recycling rates below 15% in some areas. Regulatory frameworks, such as the European Union's Single-Use Plastics Directive, are driving change by mandating extended producer responsibility. Market demand for recycled ocean plastics is growing, with companies seeking sustainable materials for consumer products. However, achieving scalable recycling requires overcoming technical challenges related to material consistency and processing efficiency.

Material Properties and Environmental Impact of Fishing Nets

Fishing nets are engineered for strength and durability, using polymers like nylon that have high abrasion resistance and tensile strength up to 80 MPa. These properties make them resistant to natural degradation, leading to persistent pollution in marine ecosystems. When nets break down, they release microplastics that can enter the food chain, affecting marine organisms and potentially human health. Research shows that a single abandoned net can degrade into millions of microplastic particles over several decades, contributing to the estimated 14 million tons of plastic entering oceans annually.

The environmental impact extends beyond marine life, as ghost fishing continues to catch and kill species long after nets are discarded. This phenomenon accounts for approximately 10% of all marine litter, according to the Food and Agriculture Organization. Recycling these materials through shredding prevents further environmental damage while recovering valuable resources. The transformation of waste nets into new products reduces the need for virgin plastic production, which typically consumes non-renewable petroleum resources and generates higher carbon emissions.

Tangling and Clogging Issues in Recycling Processes

The fibrous and entangled nature of fishing nets presents significant challenges in recycling operations, often causing machinery jams and reduced throughput. Traditional recycling equipment struggles with these materials, leading to frequent downtime and maintenance requirements. Shredders specifically designed for tough plastics can mitigate these issues through specialized cutting mechanisms that prevent material wrapping around components. Industrial experience shows that proper shredder selection can reduce clogging incidents by over 60%, maintaining consistent processing rates.

Clogging not only affects efficiency but also increases energy consumption, as motors must work harder to overcome resistance. This can elevate operational costs by 15-20% in poorly optimized systems. Implementing anti-jamming features, such as reversible rotors and automated clearing cycles, helps maintain continuous operation. The use of hopper anti-bridging systems prevents material accumulation at the feed point, ensuring smooth material flow into the shredding chamber.

Economic and Logistics Barriers in Net Recycling

Economic viability remains a primary concern in fishing net recycling, with collection and transportation accounting for up to 50% of total processing costs. Nets are often dispersed across large geographic areas, requiring coordinated retrieval efforts from fishing communities and cleanup initiatives. The low density of nets makes transportation inefficient, as they occupy significant volume relative to their weight. Recycling facilities must be strategically located near source points to minimize logistics expenses, which can be prohibitive for small-scale operations.

Market fluctuations for recycled materials also impact profitability, with prices for nylon regrind varying by 30% or more annually. Government subsidies and extended producer responsibility schemes can improve economics, as seen in countries like Norway where fishing gear recycling rates exceed 70%. Partnerships between manufacturers, recyclers, and NGOs help create stable supply chains and offset initial investment costs. Developing standardized collection systems and incentivizing participation through deposit schemes could further enhance the economic attractiveness of net recycling.

Regulatory Frameworks and Sustainability Goals

International regulations are increasingly targeting fishing gear pollution, with measures like the MARPOL Annex V prohibiting the discharge of plastics at sea. The European Union's Circular Economy Action Plan sets specific targets for plastic recycling, including fishing gear, with a goal of 50% recycling rates by 2025. These regulatory pressures drive innovation in recycling technologies and create markets for recycled materials. Compliance often requires documentation of recycling processes and environmental impact assessments, adding administrative layers to operations.

Sustainability certifications, such as the Ocean Bound Plastic certification, provide market differentiation for products made from recycled nets. Companies utilizing these materials can leverage environmental claims to attract conscious consumers, potentially commanding premium prices. The alignment with United Nations Sustainable Development Goals, particularly Goal 14 for marine conservation, enhances the social license for recycling initiatives. International cooperation through platforms like the Global Ghost Gear Initiative facilitates knowledge sharing and standardizes best practices across regions.

Overview of Shredder Technology for Fishing Net Processing

Industrial shredders designed for plastic waste employ sophisticated mechanisms to process challenging materials like fishing nets. These machines utilize shear, tear, and impact forces to reduce nets into consistent fragments, typically ranging from 10-50 mm in size. The shredding process increases the surface area of the material, facilitating subsequent washing, separation, and reprocessing stages. Modern shredders incorporate durable components capable of withstanding the abrasive nature of synthetic fibers, ensuring long-term reliability. Throughput capacities vary from 100 to 5,000 kg per hour, depending on the shredder size and configuration.

Shredder selection for fishing nets considers factors such as motor power, cutting chamber design, and automation features. Machines with 30-200 kW motors provide sufficient torque to handle entangled materials without stalling. The integration of granulator blades made from tungsten carbide or similar hard materials extends operational life between sharpening cycles. Automated control systems monitor parameters like temperature and load, adjusting operations to prevent overloads. These technological advancements enable efficient processing of fishing nets while minimizing energy consumption and maintenance requirements.

Shredder Types and Models Suitable for Fishing Nets

Different shredder configurations offer varying advantages for fishing net processing, with single-shaft, double-shaft, and four-shaft models being most common. Single-shaft shredders provide high torque for dense materials, making them suitable for initial size reduction of heavily entangled nets. Double-shaft shredders employ counter-rotating cutters that shear materials efficiently, producing more uniform output fragments. Four-shaft systems offer additional cutting surfaces for finer shredding, ideal for applications requiring small particle sizes. The double shaft plastic shredder is particularly effective for fishing nets, as its interlocking blades prevent fiber wrapping.

Selection depends on the specific application requirements, including desired output size, capacity needs, and downstream processing methods. Throughput rates for fishing nets typically range from 200-1,000 kg/h for standard industrial models, with specialized high-capacity units reaching 3,000 kg/h. Machine specifications should match the material characteristics, considering factors like polymer type, contamination level, and moisture content. Pilot testing with actual net samples helps verify performance before full-scale implementation, ensuring the selected shredder meets processing objectives.

Blade Design and Material Durability

Shredder blades for fishing nets require exceptional hardness and wear resistance to withstand the abrasive nature of synthetic fibers. Tungsten carbide tipped blades maintain sharpness 3-5 times longer than standard steel blades when processing nylon materials. The blade geometry is optimized for cutting rather than tearing, with specific clearance angles that prevent material wrapping. Hardness ratings typically exceed 60 HRC to resist the abrasive effects of sand and salt contaminants commonly found in recovered nets.

Regular blade maintenance is essential for consistent performance, with sharpening intervals ranging from 200-800 operating hours depending on material volume and contamination. Some advanced systems feature self-sharpening mechanisms that extend service life. The use of wear-resistant liners in the cutting chamber protects structural components from abrasion, reducing long-term maintenance costs. Proper blade selection and maintenance contribute significantly to overall operational efficiency and product quality.

Processing Capacity and Throughput Optimization

Shredder capacity for fishing nets is influenced by multiple factors, including motor power, cutting chamber dimensions, and feed mechanism design. Machines with 75-150 kW motors typically handle 300-800 kg/h of net material, while larger 200+ kW units can process over 1,500 kg/h. Throughput optimization involves balancing feed rate with power consumption to achieve maximum efficiency. Variable frequency drives allow operators to adjust rotor speed based on material characteristics, preventing overload while maintaining target processing rates.

Automated feeding systems ensure consistent material presentation to the cutting chamber, maximizing utilization of available power. The integration of hydraulic ram technology in some models provides controlled compression of entangled nets, facilitating smoother feeding. Performance monitoring through sensors tracks parameters like current draw and temperature, enabling real-time adjustments. Regular maintenance of cutting elements and drive systems maintains optimal capacity throughout the equipment lifecycle.

Automation and Safety Control Systems

Modern shredders incorporate comprehensive automation features that enhance operational safety and efficiency. Programmable logic controllers (PLCs) manage functions like start-up sequencing, overload protection, and emergency stopping. These systems monitor critical parameters including motor temperature, bearing condition, and blade sharpness, triggering maintenance alerts when thresholds are exceeded. Safety interlocks prevent access to moving parts during operation, while emergency stop buttons provide immediate shutdown capability.

Remote monitoring capabilities allow operators to track performance metrics from control rooms or mobile devices, reducing exposure to noise and dust. The implementation of control panel PLC HMI interfaces provides intuitive operation with real-time data visualization. Automated lubrication systems ensure proper maintenance of moving components, extending service intervals. These features collectively reduce human error while maintaining safe working environments in demanding recycling facilities.

Fishing Net Shredding and Value Enhancement Process

The transformation of discarded fishing nets into valuable recycled materials follows a multi-stage process beginning with collection and culminating in manufacturing new products. Initial sorting separates nets by polymer type and removes non-plastic components like metal weights or floats. Shredding reduces the material to manageable fragments, typically between 10-30 mm, creating uniform feedstock for subsequent processing. Washing stages remove contaminants including salt, sand, and organic matter using water and detergent solutions. The clean fragments undergo further separation to isolate target polymers before being melted and reformed into pellets for manufacturing.

Process optimization focuses on maximizing material yield and quality while minimizing energy and resource consumption. Studies show that optimized shredding can improve polymer recovery rates by 25% compared to manual processing methods. The integration of air conveying system technology transports shredded material between processing stages without manual handling. Quality control measures include spectroscopic analysis to verify polymer composition and filtration to remove residual contaminants. This systematic approach ensures the production of high-quality recycled material suitable for demanding applications.

Collection and Pre-treatment Methods for Fishing Nets

Effective collection systems for discarded fishing nets involve partnerships with fishing communities, port authorities, and environmental organizations. Incentive programs, such as deposit schemes or collection bonuses, encourage proper disposal rather than abandonment at sea. Collected nets undergo manual sorting to separate different polymer types and remove large contaminants. Pre-treatment may include cutting oversized nets into manageable sections using manual tools or preliminary shredding equipment. This stage is crucial for ensuring consistent feeding into primary shredders and preventing processing bottlenecks.

Storage conditions affect material quality, with covered, dry areas preventing further degradation and contamination. Some facilities implement washing before shredding to remove salt and sand, though this increases handling requirements. The development of standardized collection protocols helps maintain material consistency, which is important for downstream processing. International initiatives like the Fishing for Energy program in the United States demonstrate successful large-scale collection models, recovering over 3,000 tons of gear since 2008.

Shredding Parameters and Optimization Techniques

Optimal shredding parameters for fishing nets depend on factors including polymer type, net thickness, and desired output size. Rotor speeds typically range from 30-60 RPM for single-shaft shredders, while double-shaft models may operate at 15-40 RPM. Screen sizes between 10-50 mm control the maximum particle dimension, with smaller openings producing finer material for specialized applications. Throughput rates must balance with power consumption, with efficient systems processing 500 kg/h while consuming approximately 80-120 kWh.

Optimization involves adjusting parameters based on real-time performance data, such as motor current and output particle distribution. The use of screen mesh with appropriate aperture sizes ensures consistent output quality. Regular maintenance of cutting elements maintains shredding efficiency, with dull blades increasing energy consumption by up to 20%. Process monitoring systems track key performance indicators, enabling continuous improvement through data analysis. These techniques collectively enhance the economic and environmental performance of shredding operations.

Fragment Washing and Contaminant Removal

Washing shredded net fragments removes adherent contaminants that affect material quality and subsequent processing. Typical washing systems employ heated water (50-70°C) with biodegradable detergents to dissolve organic residues and salt. Agitation mechanisms, such as rotating drums or paddle mixers, enhance cleaning efficiency by increasing contact between fragments and cleaning solutions. Multiple rinse stages ensure thorough contaminant removal, with water filtration and recycling systems minimizing consumption. The cleaned fragments undergo centrifugal drying to reduce moisture content below 2% before further processing.

Contaminant removal efficiency exceeds 95% in well-designed systems, producing material suitable for high-value applications. The integration of magnetic separator technology captures ferrous metals that may remain after initial sorting. Sink-float separation tanks isolate different polymer types based on density differences, improving material purity. Water treatment systems remove suspended solids and chemicals before discharge or reuse, ensuring environmental compliance. These processes collectively transform contaminated net fragments into clean, consistent recycled feedstock.

Material Sorting and Quality Verification

Advanced sorting technologies separate shredded net fragments by polymer type and color, maximizing material value. Near-infrared spectroscopy identifies different polymers based on their molecular signatures, with pneumatic systems diverting fragments into appropriate collection streams. Color sorting optics separate light and dark materials, enabling production of consistent-colored recycled products. These automated systems achieve sorting accuracy exceeding 98%, significantly reducing manual labor requirements.

Quality verification includes testing for mechanical properties, melt flow index, and contamination levels. The recycled material must meet specifications for intended applications, with tensile strength typically 80-90% of virgin material. Certification to standards like ISO 14021 for recycled content provides market confidence in material claims. The implementation of eddy current separator technology removes non-ferrous metals that may affect processing or final product quality. These measures ensure the production of high-value recycled materials competitive with virgin alternatives.

Value Enhancement Strategies and Economic Benefit Analysis

Transforming shredded fishing nets into higher-value products requires strategic approaches that leverage material properties and market opportunities. The recycled material can be engineered for specific applications through compounding with additives that enhance characteristics like UV resistance or flexibility. Product development focuses on sectors with strong sustainability preferences, such as automotive components or sporting goods, where recycled content provides marketing advantages. Economic analysis must consider the complete value chain, from collection costs to potential revenue streams, with successful operations achieving profitability within 2-3 years.

The market for recycled ocean plastics is growing at 15-20% annually, driven by consumer demand and corporate sustainability commitments. Products made from recycled nets can command price premiums of 10-30% compared to conventional recycled materials. The integration of high-toughness material shredding solutions enables production of consistent quality material suitable for demanding applications. Life cycle assessment studies demonstrate that recycling fishing nets reduces carbon emissions by 40-60% compared to virgin plastic production. These factors collectively enhance the economic attractiveness of fishing net recycling initiatives.

Recycled Material Markets and Application Development

Recycled fishing net material finds applications across multiple industries, with textile fibers representing the highest value opportunity. The apparel industry utilizes recycled nylon from fishing nets in products like swimwear and activewear, with brands like Adidas and Patagonia incorporating this material. Injection molding applications include automotive parts, furniture components, and consumer goods, where the material's durability provides performance advantages. The construction sector uses recycled net material in products like fencing, decking, and pipes, benefiting from the weather resistance of marine-grade polymers.

Market development requires close collaboration between recyclers and manufacturers to ensure material specifications meet application requirements. Technical certifications, such as UL environmental claims validation, facilitate market acceptance. The global market for recycled ocean plastics exceeded $400 million in 2022 and is projected to reach $700 million by 2027. Product innovation continues to expand application possibilities, with recent developments including 3D printing filaments and composite materials. These diverse markets provide stability against sector-specific demand fluctuations.

Cost Reduction and Revenue Generation Calculations

Economic analysis of fishing net recycling must account for all cost components, including collection, transportation, processing, and administration. Collection costs typically range from $0.10-0.50 per kilogram, depending on logistics complexity and geographic factors. Processing costs, including shredding, washing, and pelletizing, add approximately $0.30-0.80 per kilogram. Revenue from recycled material varies by polymer type and quality, with clean nylon fragments commanding $1.50-2.50 per kilogram compared to $0.80-1.20 for mixed polyolefins.

The business case improves with scale, as fixed costs are distributed across larger volumes. Facilities processing 1,000+ tons annually typically achieve operational breakeven, with profitability increasing at higher volumes. The implementation of single shaft plastic shredder technology can reduce processing costs by 15-20% through higher energy efficiency and lower maintenance requirements. Government grants and environmental credits can provide additional revenue streams, improving overall economics. These financial considerations determine the viability of recycling operations and guide investment decisions.

Environmental Benefits and Carbon Footprint Reduction

Recycling fishing nets through shredding processes delivers significant environmental advantages beyond waste reduction. Life cycle assessment studies indicate that producing recycled nylon from fishing nets generates 60% fewer greenhouse gas emissions compared to virgin nylon production. The process conserves non-renewable resources, with each ton of recycled material displacing approximately 1.5 tons of petroleum feedstock. Marine ecosystem benefits include reduced entanglement risk for wildlife and decreased microplastic generation, supporting biodiversity conservation.

Carbon credit mechanisms can monetize these environmental benefits, with verified emissions reductions generating additional revenue. The avoidance of landfill disposal prevents methane generation and reduces land use impacts. The use of oil-free cutting system technology in shredders minimizes potential contamination from lubricants, further enhancing environmental performance. These collective benefits contribute to corporate sustainability goals and align with international climate commitments, creating value beyond direct financial returns.

Operation Maintenance and Performance Optimization

Maintaining shredders for fishing net processing requires systematic approaches that address the unique challenges of these materials. Regular inspection schedules identify wear components before failure, preventing unplanned downtime that can cost $500-2,000 per hour in lost production. Performance optimization focuses on maximizing throughput while minimizing energy consumption and maintenance requirements. Operational data collected through monitoring systems enables predictive maintenance strategies, with advanced analytics identifying patterns that precede equipment issues. These practices extend equipment lifespan beyond 10,000 operating hours while maintaining consistent output quality.

Operator training ensures proper equipment use and early problem identification, reducing the frequency and severity of maintenance events. The implementation of lubrication system automation maintains optimal bearing and gear conditions without manual intervention. Maintenance records track component lifecycles, enabling proactive replacement before failures occur. These comprehensive maintenance approaches minimize total cost of ownership while ensuring reliable operation in demanding recycling environments.

Daily Operation and Safety Protocols

Standard operating procedures for shredders processing fishing nets include pre-operation inspections, startup sequences, and shutdown protocols. Daily checks verify proper functioning of safety systems, including emergency stops and guarding integrity. Operators monitor parameters like motor current, temperature, and vibration levels during operation, responding to any anomalies immediately. Lockout-tagout procedures ensure energy isolation during maintenance, preventing accidental startup. These protocols reduce accident rates by over 80% compared to informal operating approaches.

Safety training covers specific hazards associated with fishing net processing, including entanglement risks and sharp edges on shredded material. Personal protective equipment requirements typically include cut-resistant gloves, safety glasses, and hearing protection. The integration of overheat protection sensor technology automatically shuts down equipment if temperatures exceed safe limits. Regular safety audits identify potential improvements, creating continuously safer working environments. These measures protect personnel while maintaining operational efficiency.

Blade Wear Monitoring and Replacement Scheduling

Blade condition directly impacts shredding efficiency, with worn blades increasing energy consumption and reducing output quality. Regular inspection intervals of 100-200 operating hours identify wear patterns before they affect performance. Measurement techniques include thickness gauges to track material loss and visual examination for chips or cracks. Replacement thresholds typically correspond to 10-15% reduction from original dimensions, though this varies based on blade material and application.

Replacement scheduling considers production requirements, with strategic timing during planned maintenance windows minimizing disruption. The use of fixed bed knives with reversible design extends service life by enabling multiple sharpening cycles. Inventory management ensures spare blades are available when needed, reducing downtime waiting for replacements. These practices maintain cutting efficiency while controlling maintenance costs, contributing to overall operational reliability.

Cleaning and Anti-Tangling Techniques

Preventing material accumulation in shredders requires regular cleaning protocols that address potential build-up points. Daily cleaning removes residual fragments from the cutting chamber, feed hopper, and discharge areas. Specialized tools facilitate access to internal components without disassembly, reducing cleaning time by 30-40%. Anti-tangling strategies include the application of food-grade release agents to cutting surfaces, preventing adhesive buildup from melted polymers.

Periodic deep cleaning involves complete disassembly for thorough inspection and removal of accumulated material. The implementation of dust suppression system technology controls airborne particles during cleaning operations, improving working conditions. Cleaning frequency depends on material volume and contamination level, with high-throughput facilities requiring more frequent attention. These techniques prevent performance degradation and extend equipment lifespan while maintaining product quality.

Future Prospects and Innovation Directions

The future of fishing net recycling will be shaped by technological advancements that enhance efficiency, reduce costs, and expand application possibilities. Emerging trends include the integration of artificial intelligence for real-time process optimization and predictive maintenance. Material science innovations are developing specialized additives that improve the properties of recycled polymers, expanding their suitability for high-performance applications. The circular economy model is driving increased collaboration across the value chain, with manufacturers designing products for easier recycling. These developments will further improve the economic and environmental performance of fishing net recycling.

Global initiatives are creating supportive policy frameworks and funding mechanisms for recycling infrastructure development. The United Nations Environment Programme's Global Partnership on Marine Litter has set targets to significantly reduce fishing gear loss by 2025. The implementation of tungsten carbide cutters with advanced coatings is extending blade life in abrasive applications. Consumer awareness campaigns are increasing demand for products made from recycled ocean plastics, creating market pull for recycled materials. These interconnected trends will accelerate the transition to more sustainable management of fishing net waste.

Technological Advancements and Automation Integration

Shredder technology continues evolving with innovations that address specific challenges of fishing net processing. Smart sensors monitor blade sharpness in real-time, triggering automatic adjustments to maintain cutting efficiency. Robotics are being integrated for material handling tasks, reducing labor requirements and improving safety. Machine learning algorithms analyze operational data to optimize parameters like rotor speed and feed rate, increasing throughput by 15-20% while reducing energy consumption. These advancements are making recycling processes more efficient and cost-effective.

Digital twin technology creates virtual models of shredding systems, enabling simulation-based optimization without disrupting actual operations. The development of solid waste double shaft shredder designs with enhanced sealing prevents material escape and reduces noise emissions. Remote operation capabilities allow expert supervision from centralized locations, improving resource utilization. These technological innovations collectively enhance the performance and accessibility of fishing net recycling solutions.

Circular Economy and Closed-Loop System Development

The transition to circular models for fishing gear involves designing products for recyclability and establishing collection systems that return end-of-life nets to manufacturers. Extended producer responsibility schemes are being implemented in various regions, requiring gear manufacturers to manage the disposal of their products. Chemical recycling technologies are emerging as complements to mechanical shredding, capable of breaking down polymers to molecular level for true closed-loop recycling. These approaches minimize waste and maximize resource efficiency throughout the product lifecycle.

Industry collaborations are developing standardized material specifications that facilitate the use of recycled content in new fishing gear. The creation of composite material shredding solutions addresses the challenge of mixed-material products increasingly used in modern fishing equipment. Digital product passports that track material composition and recycling history are being piloted to improve traceability. These systemic innovations support the creation of truly circular systems for fishing gear management.

Global Initiatives and Collaborative Networks

International cooperation is essential for addressing the transboundary nature of marine plastic pollution from fishing gear. The Global Ghost Gear Initiative brings together stakeholders from across the fishing industry, government, and conservation sectors to develop solutions. Regional agreements like the OSPAR Convention coordinate action among neighboring countries to prevent and retrieve abandoned gear. These collaborative efforts share best practices, standardize methodologies, and pool resources for larger impact.

Research partnerships between academic institutions and industry are advancing recycling technologies through shared knowledge and funding. The development of double shaft wood shredder technology has provided insights applicable to plastic shredding through material science cross-pollination. Certification programs create market incentives for sustainable practices, with standards evolving to include specific requirements for fishing gear recycling. These networks amplify individual efforts and accelerate progress toward common environmental goals.