V-belts serve as critical power transmission components in waste plastic shredders, transferring rotational energy from motors to cutting mechanisms with an efficiency rating of 95-98% when properly maintained. These rubber-and-fiber composites withstand substantial tensile forces while maintaining grip on pulley systems, yet they represent one of the most common failure points in shredding operations. Industry data indicates that V-belt failures account for approximately 23% of unplanned downtime in plastic recycling facilities, with associated costs reaching $5,000-$15,000 per incident when considering lost production and repair expenses. This comprehensive tutorial examines the complete lifecycle of V-belt management, from preventive maintenance strategies to replacement procedures and performance optimization, providing operators with practical knowledge to enhance equipment reliability.

Understanding V-belt dynamics requires knowledge of mechanical engineering principles, as these components must balance flexibility for installation with rigidity for power transmission. Modern V-belts for industrial shredders typically incorporate synthetic rubber compounds reinforced with polyester or aramid cords, designed to withstand operating temperatures up to 140°F (60°C) and momentary overloads up to 150% of rated capacity. The trapezoidal cross-section creates wedging action in pulley grooves, generating friction that enables power transfer without slippage under normal conditions. Proper maintenance extends V-belt service life from the typical 6-12 months to 18-24 months, significantly reducing operational costs and improving shredder availability for plastic processing applications.

Overview and Impact Analysis of V-Belt Problems

V-belt failures in waste plastic shredders manifest through various symptoms that progressively worsen if left unaddressed, beginning with subtle performance degradation and culminating in complete operational failure. Initial indicators include audible squealing during startup or under heavy load, visible vibration in the drive system, and noticeable speed reduction in cutting rotors despite maintained motor RPM. These symptoms typically emerge when belts lose approximately 15-20% of their original tension, reducing power transmission efficiency and generating excess heat through friction. The operational impacts extend beyond immediate performance issues, as slipping belts generate temperatures exceeding 300°F (149°C) at pulley interfaces, accelerating degradation of both belts and pulley surfaces through thermal damage.

The economic consequences of V-belt failures extend far beyond replacement part costs, encompassing production losses, secondary component damage, and potential safety incidents. Studies of plastic recycling operations indicate that a single V-belt failure can interrupt processing of 5-15 tons of plastic material per hour of downtime, with average resolution times of 4-8 hours for complete replacement and realignment. Secondary damage frequently includes worn pulley grooves that require machining or replacement, motor bearing overload from uneven tension, and in extreme cases, drive shaft distortion from unbalanced forces. The integration of V-belts with other critical systems like the hardened steel shaft means that failures can propagate through connected components, multiplying repair costs and extending downtime significantly.

V-Belt Functions and Role in Shredder Operations

V-belts in waste plastic shredders perform multiple essential functions beyond basic power transmission, including shock absorption during material engagement, overload protection through controlled slippage, and vibration damping between motor and reduction systems. The elastic nature of V-belts accommodates momentary torque spikes when shredders encounter dense plastic materials or contaminants, preventing direct shock transfer to motor windings and gearbox components. This protective function becomes particularly important in applications involving variable material density, such as when processing mixed plastic streams with inconsistent hardness characteristics. Properly specified V-belts can absorb up to 30% of impact energy during heavy loading events, significantly reducing stress on mechanical components.

The power transmission efficiency of V-belts depends critically on proper tension maintenance, with industry standards recommending deflection of approximately 1/64 inch per inch of span between pulleys. In typical shredder configurations with 40-60 horsepower motors, V-belts transmit torque values ranging from 1,200-2,500 lb-ft while maintaining rotational speeds of 1,000-1,800 RPM at the cutter assembly. The wedging action within pulley grooves creates mechanical advantage through increased surface contact, enabling compact drive designs that would require significantly wider flat belts for equivalent power capacity. This efficient power transfer directly influences shredding consistency and throughput rates in plastic recycling operations.

Common Symptoms of Slipping and Breaking

V-belt slipping manifests through distinct operational indicators that trained operators can identify during routine equipment checks, including audible cues, visual observations, and performance metrics. High-pitched squealing or chirping sounds during startup typically indicate insufficient tension, while smoke or burning rubber odors suggest advanced slippage generating excessive heat. Visible clues include black dust accumulation around pulley guards from belt material abrasion, glazing on belt surfaces from friction heat, and rhythmic vibration in the drive guard during operation. Performance degradation appears as reduced throughput rates despite maintained feed rates, increased amperage draw on motor displays without corresponding output improvement, and inconsistent particle size in processed plastic materials.

Complete belt failure presents more obvious symptoms including loud snapping sounds, immediate cessation of cutter rotation despite operating motor, and visible belt fragments within the drive compartment. Progressive failure patterns often show accelerated wear on specific belt sections rather than even distribution, indicating misalignment issues or pulley groove damage. Operators monitoring the control panel PLC HMI may notice torque fluctuation patterns before visible symptoms emerge, providing early warning of developing V-belt issues. Documenting these precursor symptoms enables predictive maintenance scheduling before catastrophic failures occur, minimizing operational disruption.

Impact on Shredding Efficiency and Equipment Longevity

V-belt performance directly influences multiple aspects of shredder operation, with slipping belts reducing energy transfer efficiency by 15-40% depending on severity, substantially increasing electricity consumption per ton of processed material. This efficiency loss manifests as heat generation rather than productive work, raising operational temperatures throughout the drive system and accelerating degradation of bearings, seals, and electrical components. The inconsistent power delivery from slipping belts creates variable torque application to cutting rotors, producing uneven particle sizes that complicate downstream sorting and washing processes in plastic recycling streams. Throughput reductions of 20-35% commonly occur before complete failure, significantly impacting production economics.

Equipment longevity suffers substantially from persistent V-belt issues, with misaligned or slipping belts generating sideload forces on motor and reducer bearings that can reduce their service life by 50-70%. The heat generated by slipping belts elevates operating temperatures throughout the drive system, degrading lubricants in associated gearboxes and increasing wear rates on components like the fixed bed knives due to inconsistent cutting speeds. Pulley groove wear accelerates under slipping conditions, with hardened steel pulleys developing polished, widened grooves that cannot properly grip replacement belts, necessitating costly pulley replacement. These cumulative effects demonstrate how proper V-belt maintenance preserves overall equipment integrity beyond immediate drive system components.

Safety Risks and Potential Cost Implications

V-belt failures present multiple safety hazards in industrial shredding environments, including sudden projectile fragments traveling at high velocity, exposure to rotating components during failure events, and potential electrical hazards from motor overload situations. Statistical analysis of industrial accidents indicates that drive system failures account for approximately 12% of reported incidents in recycling facilities, with V-belt issues representing the most common specific failure mode within this category. The kinetic energy stored in rotating shredder systems can propel broken belt fragments at speeds exceeding 150 feet per second, capable of penetrating standard machine guards and creating significant strike hazards for personnel within 20-30 feet of the equipment.

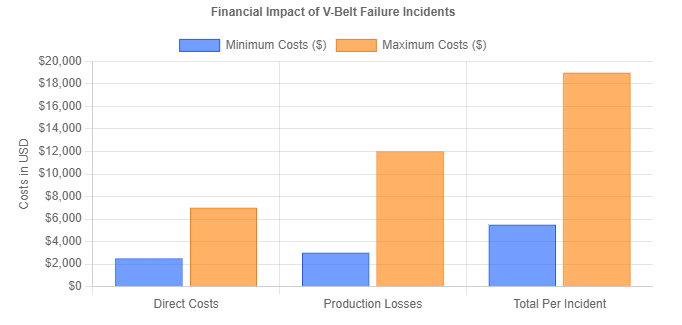

The financial implications of V-belt failures extend beyond direct replacement costs, encompassing production losses, secondary damage repairs, and potential regulatory penalties

for safety incidents. A comprehensive cost analysis for mid-sized plastic recycling facilities indicates that a single V-belt failure event typically generates $2,500-$7,000 in

direct costs including parts and labor, plus $3,000-$12,000 in lost production revenue during downtime. Facilities operating without proper dust collection system integration may experience additional complications from plastic dust

accumulation in pulley grooves, accelerating wear and increasing failure frequency. These cumulative costs highlight the economic importance of proactive V-belt maintenance

programs in shredding operations.

Cause Analysis and Diagnostic Methods

Systematic diagnosis of V-belt issues requires understanding of multiple potential failure mechanisms, including mechanical wear patterns, installation errors, environmental factors, and operational practices. Mechanical causes typically account for 65-70% of premature failures, with improper tension representing the most common specific issue at approximately 30% of documented cases. Diagnostic procedures should progress from simple visual inspections to precise measurements using specialized tools, beginning with shutdown observations of belt condition and pulley alignment before advancing to operational tests with appropriate safety protocols. This structured approach efficiently identifies root causes rather than addressing superficial symptoms, enabling effective corrective actions that prevent recurrence.

Advanced diagnostic techniques incorporate infrared thermography to identify overheating sections of drive systems, vibration analysis to detect abnormal oscillation patterns indicating misalignment, and laser alignment tools to verify pulley positioning within thousandths of an inch accuracy. These methods complement traditional approaches like straightedge alignment checks and tension measurement using deflection gauges or sonic tension meters. Documentation throughout the diagnostic process creates valuable historical data for trend analysis, helping identify recurring issues that may indicate underlying equipment problems. This systematic approach to V-belt diagnosis supports continuous improvement in maintenance practices and equipment reliability.

Mechanical Causes Including Wear and Insufficient Tension

Mechanical deterioration represents the predominant category of V-belt failures, with tension-related issues constituting the most frequent specific problem across industrial applications. Insufficient tension allows belts to slip within pulley grooves during load application, generating friction heat that degrades rubber compounds and accelerates wear on both belt surfaces and pulley grooves. Conversely, excessive tension creates bearing overload in both motor and driven equipment, with studies indicating that 15% overtension reduces bearing life by approximately 25% while 30% overtension cuts bearing life in half. Proper tension balancing requires understanding of specific installation requirements, with most industrial V-belts requiring initial tension approximately 50% higher than operational tension to account for seating and run-in periods.

Progressive wear patterns provide diagnostic clues about underlying issues, with uniform wear across all belt sides suggesting normal aging while localized wear indicates specific problems. Glazing appearance on belt sides typically results from chronic slippage, while cracks perpendicular to the belt length emerge from flex fatigue caused by small pulley diameters or excessive tension. Severe wear on one side of the belt suggests pulley misalignment, while matched wear patterns on both sides indicate worn pulley grooves that no longer provide proper wedging action. These visual indicators help maintenance personnel identify appropriate corrective actions beyond simple belt replacement, addressing root causes to prevent rapid recurrence of failures.

Operational Errors Including Overloading and Improper Use

Operational practices significantly influence V-belt service life, with abrupt loading patterns and continuous operation beyond rated capacity representing common contributors to premature failures. Waste plastic shredders frequently experience variable loading as different plastic types and forms enter the cutting chamber, with dense items like plastic drums or thick polyethylene sheets creating sudden torque spikes that stress V-belt assemblies. Operators attempting to process materials exceeding equipment design capacity compound these issues, driving sustained operation at 110-130% of rated power where V-belts experience accelerated wear from increased friction and heat generation. These practices reduce typical V-belt service life from the expected 12-18 months to as little as 3-6 months in severe cases.

Improper operational techniques include frequent jam clearing through motor reversal without allowing complete shutdown, creating shock loading that separates belt plies and damages reinforcement cords. Extended operation at reduced speeds below design parameters prevents proper airflow around belts and pulleys, allowing heat accumulation that degrades rubber compounds. Inadequate clearing of the hopper anti-bridging system can lead to inconsistent feed rates that cause cyclic loading patterns, generating fatigue stress in V-belts. These operational issues often stem from insufficient training or production pressure overriding equipment limitations, highlighting the importance of comprehensive operator education and clear equipment capability guidelines.

Diagnostic Tools and Inspection Procedures

Systematic V-belt inspection utilizes specialized tools that provide quantitative data beyond visual assessment, beginning with tension measurement devices that determine whether belts operate within recommended ranges. Deflection gauges measure the force required to produce standard deflection between pulleys, while sonic tension meters use vibration frequency analysis to calculate tension values without physical contact. Laser alignment tools project reference beams across pulley faces to identify parallel misalignment or angular offset, detecting deviations as small as 0.001 inches per inch of pulley width. Infrared thermometers identify overheating sections of drive systems, with temperature differences exceeding 30°F (17°C) between similar components indicating problems requiring investigation.

Inspection procedures should follow established sequences beginning with complete equipment shutdown and lockout/tagout implementation for personnel safety. Visual examination documents belt condition including cracks, glazing, uneven wear, and material transfer between belts and pulleys. Pulley groove inspection verifies proper profile maintenance without edge rounding or sidewall wear that reduces gripping capability. Straightedge checks across pulley faces identify parallel misalignment, while angular alignment requires specialized tools for precise measurement. Operational tests with proper guarding in place monitor vibration patterns and audible signatures that indicate developing issues before complete failure occurs. These systematic procedures ensure comprehensive assessment of drive system condition.

Preventive Measures and Routine Maintenance

Effective V-belt maintenance programs incorporate scheduled inspections, precise adjustment procedures, and condition monitoring that collectively reduce failure rates by 70-80% compared to reactive replacement approaches. Industry studies demonstrate that preventive maintenance programs typically require 15-25% of the time expenditure of emergency repairs while costing approximately 30-40% less in direct expenses and eliminating production losses from unplanned downtime. Maintenance intervals should reflect operational intensity, with high-volume plastic shredding facilities conducting formal inspections every 200-400 operating hours while lower utilization operations may extend intervals to 500-800 hours. These scheduled activities complement daily visual checks that operators perform during normal equipment monitoring.

Preventive maintenance extends beyond belt adjustment to encompass entire drive system care, including pulley condition assessment, bearing lubrication, and guard integrity verification. Proper maintenance of associated systems like the lubrication system ensures that motor and reducer bearings function correctly, preventing external forces that could influence V-belt alignment and tension. Maintenance documentation creates historical records that help identify wear patterns and optimal replacement intervals specific to each application, enabling continuous improvement of maintenance schedules. These comprehensive approaches transform V-belt management from unpredictable failure response to planned component replacement within overall equipment maintenance strategies.

Tension Calibration and Regular Inspection Intervals

Proper tension calibration represents the most critical aspect of V-belt maintenance, balancing sufficient grip to prevent slippage against excessive force that accelerates bearing wear. Initial tensioning of new belts requires approximately 50% higher tension than operational specifications to account for seating and initial stretch during the run-in period of 24-48 operating hours. Tension should be rechecked after the first 50-100 operating hours and adjusted to standard operational values, then monitored at regular intervals based on service conditions. Industrial standards recommend tension verification every 400-800 operating hours for single-shift operations, with more frequent checks in high-vibration environments or applications with significant temperature variations.

Tension measurement methods vary in sophistication from simple deflection tests using calibrated spring scales to electronic sonic tension analyzers that calculate tension based on vibration frequency. The deflection method applies measured force at the midpoint between pulleys and observes displacement, comparing results to manufacturer specifications for the specific belt type and span length. Sonic tension meters offer non-contact measurement that improves safety and accessibility, particularly on guarded drives where physical access is limited. Proper tension values typically allow approximately 1/64 inch of deflection per inch of span length between pulley centers when applying force equivalent to the belt's weight per inch of span. These precise measurement techniques ensure optimal V-belt performance throughout service life.

Cleaning and Contamination Management

Contaminant exclusion significantly extends V-belt service life by preventing abrasive particles from becoming embedded between belts and pulleys, where they accelerate wear through mechanical action and chemical degradation. Plastic shredding operations generate substantial dust and fragment particles that accumulate on drive components, with polyvinyl chloride and polyethylene particulates presenting particular challenges due to their semi-abrasive characteristics and potential for static adhesion. Regular cleaning using compressed air at pressures below 30 PSI removes loose debris without driving particles deeper into belt structures, while specialized belt cleaning solutions dissolve oil and grease without damaging rubber compounds. These cleaning procedures should precede tension checks and adjustments to ensure accurate measurements and prevent contaminant introduction during maintenance activities.

Contamination management extends to environmental controls around shredder equipment, including proper maintenance of the oil-free cutting system to minimize lubricant mist that could deposit on drive components. Belt guard integrity verification ensures that enclosures properly exclude dust while allowing adequate airflow for heat dissipation. Strategic placement of external ventilation or local exhaust systems captures airborne particles before they settle on drive systems. In severely contaminated environments, specially coated V-belts with anti-static properties or oil-resistant compounds provide enhanced performance where standard belts would experience rapid degradation. These comprehensive contamination control measures preserve both V-belt integrity and overall drive system reliability.

Load Control and Operational Specifications

Proper load management represents a fundamental aspect of V-belt preservation, with controlled ramp-up periods during startup and consistent feeding practices during operation significantly extending service life. Industrial shredders benefit from soft-start systems that gradually apply power over 3-5 second intervals rather than instantaneous full-power engagement, reducing initial shock loads that can cause belt slippage and internal damage. Operational guidelines should establish clear capacity limits based on motor amperage draw rather than visual assessment of material volume, with automatic feed rate adjustment or operator alerts when approaching 85-90% of rated capacity. These practices prevent sustained operation in overload conditions that generate excessive heat and accelerate V-belt degradation.

Load monitoring incorporates multiple data sources including motor current sensors, vibration analysis systems, and thermal imaging of drive components during operation. The integration of these monitoring systems with the double shaft plastic shredder control platform enables real-time performance tracking and historical trend analysis for predictive maintenance planning. Operational parameters should clearly define acceptable material types and sizes, with specific prohibitions against processing materials exceeding established hardness or density thresholds that generate excessive shock loads. These comprehensive load management strategies balance production requirements with equipment preservation, optimizing both output and component longevity through controlled operation within design specifications.

Replacement Preparation and Tool Checklist

Comprehensive preparation before V-belt replacement ensures efficient, safe procedures that minimize downtime while producing optimal results. Preparation begins with accurate belt identification using existing part numbers, dimensional measurements, or manufacturer specifications to secure correct replacement components before beginning disassembly. The tool checklist should include both standard maintenance items and specialized equipment specific to drive system work, with verification that all tools remain in good condition and appropriate for the required tasks. Safety equipment requirements extend beyond standard personal protective equipment to include specific items like pulley holding fixtures that prevent accidental rotation during disassembly and alignment tools that verify proper reassembly. These preparatory steps typically require 20-30% of the total replacement time but substantially reduce the active replacement duration and improve outcome quality.

Replacement planning should address potential complications discovered during disassembly, with contingency resources including additional personnel for difficult access situations, alternative tooling for stubborn fasteners, and supplementary components like pulley inserts or bearing kits if inspection reveals secondary issues. Documentation review provides critical specifications including torque values for fasteners, tension requirements for the specific belt type, and alignment tolerances for the drive system. Communication protocols establish clear procedures for equipment isolation, work team coordination, and production scheduling around the maintenance window. These comprehensive preparation measures transform belt replacement from emergency response to planned maintenance activity with predictable duration and outcome.

Tools Including Wrenches, Tension Gauges, and Cleaning Supplies

The tool complement for V-belt replacement spans basic hand tools, specialized measurement devices, and cleaning equipment that collectively enable precise, efficient work. Standard wrenches and sockets in both metric and imperial sizes accommodate various fastener types found on motor mounts, pulley hubs, and guard assemblies, with torque wrenches ensuring proper fastener tension during reassembly. Specialty tools include pulley holding fixtures that prevent rotation during belt removal, pry bars of appropriate length and curvature for controlled component separation, and bearing pullers for situations requiring pulley replacement. These mechanical tools complement measurement devices including straightedges, alignment lasers, feeler gauges, and tension analysis equipment that verify proper system configuration after replacement.

Cleaning supplies represent a critical component of the tool checklist, encompassing safety solvents for degreasing, lint-free wiping cloths, wire brushes for pulley groove cleaning, and compressed air sources for debris removal. The replacement process for components like the screen mesh often generates additional plastic particles that require containment and removal during V-belt service. Supplementary items include marking pens for alignment reference, anti-seize compound for fastener threads, and appropriate lubricants for bearing points and adjustment mechanisms. This comprehensive tool collection addresses all aspects of the replacement process from disassembly through final verification, ensuring professional results that extend beyond simple belt exchange to comprehensive drive system maintenance.

New V-Belt Selection and Specification Matching

Proper V-belt selection requires matching multiple parameters beyond basic length and profile dimensions, including tensile cord material, rubber compound specifications, and performance characteristics aligned with application requirements. Standard V-belts utilize polyester tensile members for general applications, while high-performance variants incorporate aramid fibers for improved strength and stretch resistance in high-horsepower shredding applications. Rubber compounds vary in heat resistance, oil compatibility, and static conductivity, with specific formulations recommended for environments with temperature extremes, lubricant mist, or explosive dust potentials. These material considerations complement dimensional specifications including top width, depth, and angle measurements that ensure proper fit in existing pulley grooves.

Specification verification should reference original equipment manufacturer documentation, existing belt markings, or precise measurement of worn components using V-belt gauges that account for stretch and wear patterns. Matched set designations ensure consistent length across multiple-belt drives where slight variations cause uneven load sharing and premature failure. Performance ratings including horsepower capacity, minimum pulley diameter, and maximum speed limitations must align with operational requirements to prevent underwpecification that leads to rapid failure. These selection criteria ensure replacement belts provide equivalent or improved performance compared to original components, maintaining system reliability through the replacement lifecycle.

Step-by-Step Replacement Tutorial and Techniques

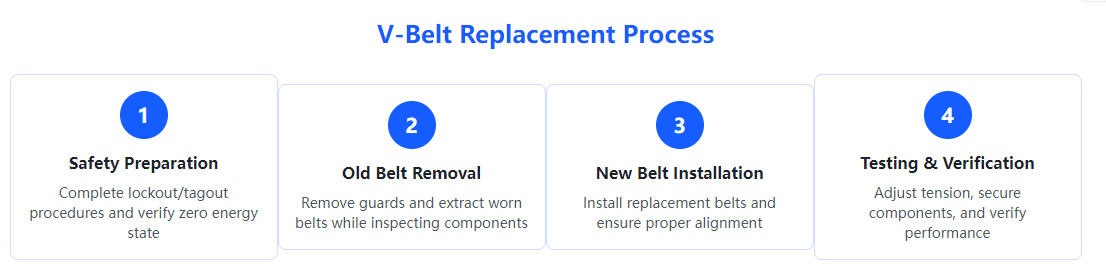

Systematic V-belt replacement follows a logical sequence that progresses from safety preparation through final verification, with each phase building upon the previous to ensure comprehensive, correct completion. The process begins with complete equipment isolation including electrical lockout, mechanical securing of all energy sources, and verification of zero energy state before any disassembly activities. Subsequent phases include careful documentation of existing configurations, controlled disassembly preserving components for reuse, thorough cleaning and inspection of all drive elements, precise installation of new belts, systematic tensioning and alignment procedures, and comprehensive testing before returning to service. This methodical approach typically requires 2-4 hours for standard single-belt shredder drives but prevents costly errors and ensures optimal post-replacement performance.

Replacement techniques emphasize preservation of existing components where possible, careful handling of new belts to prevent damage, and verification at multiple stages rather than single final inspection. Specific methods include proper loosening sequences for motor base bolts to prevent binding, use of mechanical advantage rather than excessive force during pulley separation, and strategic application of food-grade lubricants on pulley grooves to ease installation without compromising future grip. The integration of these techniques with proper tool usage creates an efficient replacement process that minimizes physical effort while maximizing result quality. These procedures apply universally across shredder types including the single shaft plastic shredder configurations, with minor adaptations for specific drive arrangements.

Step One: Safety Preparation and Old Belt Removal

Safety initiation represents the most critical phase of V-belt replacement, beginning with complete equipment shutdown through established lockout/tagout procedures that isolate all energy sources including electrical, hydraulic, and pneumatic systems. Verification of zero energy state requires physical testing of controls rather than assumption of disconnection, with particular attention to potential energy stored in tensioned systems or rotational inertia in flywheel components. Personal protective equipment must include cut-resistant gloves for handling belt materials, safety glasses with side shields for eye protection during disassembly, and appropriate footwear with slip-resistant soles for stability around equipment. These safety measures establish the foundation for secure work throughout the replacement process.

Old belt removal proceeds systematically once safety verification completes, beginning with guard removal using proper fastening techniques that preserve threads and avoid cross-threading during reassembly. Motor base adjustment bolts loosen in sequence to maintain alignment reference points, with documentation of original positions using measurement or marking techniques. Belt extraction utilizes the created slack without forcing components, with careful inspection during removal to identify pre-existing conditions that may have contributed to failure. The old belt should be retained for comparative measurement with replacement components and potential failure analysis if unusual wear patterns suggest underlying issues. This controlled removal process preserves components and provides diagnostic information for improved future performance.

Step Three: New Belt Installation and Alignment

New belt installation begins with verification of compatibility through comparative measurement with the removed belt, checking length within manufacturing tolerances of ±0.5% and profile matching to pulley grooves. Installation techniques avoid tools that could damage belt cords or cover materials, instead using rotational manipulation of pulleys while guiding belts into position. For difficult access situations, temporary lubrication with soapy water or specialized belt dressing eases installation without compromising long-term grip, though these substances must completely evaporate before operation. Multiple-belt drives require simultaneous installation of all belts rather than sequential placement to ensure equal initial tension and prevent variation in seating position.

Alignment verification follows belt installation using straightedges, laser tools, or precision strings stretched across pulley faces to identify parallel and angular misalignment. Parallel misalignment appears as offset pulley planes when viewed from above, while angular misalignment shows non-parallel shaft axes when measured across pulley faces. Correction techniques include shimming motor bases, adjusting slide rail positions, or in extreme cases machining mounting surfaces to achieve specified tolerances typically within 0.001 inches per inch of pulley width. These precise alignment procedures ensure even belt wear across the entire contact surface, preventing the edge wear that rapidly degrades performance in misaligned systems.

Step Four: Tension Adjustment and Securing

Initial tension setting applies approximately 50% greater force than operational specifications to account for seating and initial stretch during the run-in period, using measured deflection or sonic analysis to achieve target values. Tension adjustment mechanisms vary from simple bolt-operated sliding bases to sophisticated hydraulic or spring-loaded tensioners that maintain consistent force automatically. The adjustment process increments tension gradually while checking multiple points around the drive system to ensure even application, with particular attention to alignment maintenance during final tightening sequences. Fastener torque values follow manufacturer specifications to prevent under-tightening that allows movement during operation or over-tightening that distorts components and creates internal stresses.

Final securing includes verification of all fasteners in the drive system beyond the immediate adjustment mechanism, including motor mounts, pulley set screws, and guard attachments. Anti-seize compound application on adjustment threads preserves future mobility while thread-locking compounds on critical fasteners prevent vibration-induced loosening. Tension documentation records initial values for comparison during subsequent maintenance, establishing baseline measurements for the new installation. These comprehensive securing procedures ensure the drive system remains stable through operational cycles, maintaining proper tension and alignment through the initial run-in period and beyond.

Testing Verification and Performance Optimization

Post-replacement testing progresses through systematic phases that verify installation quality before operational loading, beginning with manual rotation checks and advancing to controlled operation under increasing loads. Initial verification confirms free rotation without binding or interference through complete revolutions of the drive system, listening for unusual sounds and observing smooth movement through all positions. Empty operation at normal operating speed for 15-30 minutes establishes baseline performance including temperature stabilization, vibration patterns, and alignment maintenance under rotational forces. These no-load tests identify installation issues before application of operational stresses that could damage new components or associated systems.

Performance optimization utilizes data collected during testing to fine-tune operational parameters, potentially including slight tension adjustments after the initial run-in period, alignment refinements based on observed vibration patterns, or operational protocol modifications to extend service life. Documentation throughout testing creates reference data for future maintenance activities and establishes performance benchmarks for comparison during routine inspections. Optimization extends beyond the immediate drive system to include evaluation of connected components like the high-toughness material shredding solutions that may benefit from adjusted operation parameters. This comprehensive approach ensures the replacement not only restores original function but potentially improves overall system performance through updated components and refined configuration.

Testing Procedures and Key Performance Indicators

Structured testing protocols employ specific metrics to quantitatively evaluate installation quality, beginning with vibration analysis using handheld meters or permanently installed sensors that measure displacement in mils or velocity in inches per second. Industry standards typically specify maximum vibration levels of 0.1-0.2 inches per second for properly aligned and balanced drives, with measurements taken in horizontal, vertical, and axial orientations at both motor and driven equipment bearings. Thermal imaging or contact thermometers monitor temperature differentials across drive components, with normal operation showing minimal variation while misalignment or overtension creates localized hot spots exceeding ambient temperature by 30°F (17°C) or more.

Performance indicators extend to electrical measurements including motor current draw during operation, with stable amperage within 10% of nameplate rating indicating proper loading while fluctuations suggest slipping or binding. Audible analysis identifies unusual frequencies that may indicate specific issues, with technicians using stethoscopes or ultrasonic detectors to isolate sound sources beyond human hearing range. Visual inspection during operation verifies proper belt tracking without wandering tendencies and stable tension without visible flutter under load. These multidimensional performance indicators provide comprehensive assessment of drive system condition following replacement, identifying any required adjustments before returning to full production operation.

Long-Term Monitoring and Data Recording

Continuous performance monitoring establishes baseline patterns for new V-belt installations, enabling detection of developing issues through deviation from established norms rather than absolute measurement thresholds. Vibration trend analysis tracks gradual changes in amplitude and frequency that indicate wear progression, with established programs typically recording data at 200-400 hour intervals to create meaningful historical records. Thermal imaging archives provide comparative reference for heat patterns, with consistent documentation under similar operating conditions enabling identification of subtle changes that precede visible symptoms. These monitoring practices transform maintenance from scheduled interval replacement to condition-based intervention, optimizing component life while preventing unexpected failures.

Data recording systems range from manual logbook entries to automated condition monitoring platforms that integrate with overall equipment management systems. Essential data points include operational hours, environmental conditions, load profiles, and any maintenance activities performed between regular inspections. The integration of this information with production records correlates drive system performance with processing rates and material types, identifying operational patterns that accelerate wear. These comprehensive records support continuous improvement in maintenance practices, component selection, and operational protocols, creating increasingly reliable drive system performance through iterative refinement based on historical performance data.

Future Technologies and Innovation Trends

V-belt technology continues evolving through material science advancements, design innovations, and integration with digital monitoring systems that collectively enhance reliability and operational intelligence. Next-generation elastomer compounds incorporating nanotechnology additives demonstrate 40-60% improvement in heat resistance and 30-50% longer flex life compared to conventional materials, significantly extending service intervals in demanding applications. Reinforcement materials are transitioning from traditional polyester and aramid fibers to carbon nanotube-infused filaments that provide equivalent strength with reduced weight and improved heat dissipation. These material advancements complement structural innovations including variable profile designs that optimize stress distribution and hybrid constructions that combine multiple belt types within single units for specific application requirements.

Digital integration represents the most transformative trend in drive system management, with sensor-embedded belts monitoring tension, temperature, and wear in real-time while communicating with equipment control systems. These smart drive components enable true condition-based maintenance through continuous performance assessment rather than periodic manual inspection, with wireless data transmission eliminating physical access requirements for monitoring. Self-tensioning systems utilizing shape-memory alloys or hydraulic compensation maintain optimal tension through thermal expansion and contraction cycles, eliminating manual adjustment requirements. These innovations collectively advance V-belt technology from passive mechanical components to active system elements that contribute to overall equipment intelligence and reliability.

Material Innovations and Durability Enhancements

Advanced polymer science developments focus on addressing traditional failure mechanisms through molecular-level engineering, with heat resistance improvements representing a primary research area. New ethylene-propylene-diene-monomer (EPDM) compounds maintain elasticity at temperatures up to 300°F (149°C) compared to 140°F (60°C) for standard materials, significantly reducing thermal degradation in high-slip situations. Abrasion resistance enhancements through ceramic nanoparticle additives increase surface hardness without compromising flexibility, extending service life in contaminated environments common to recycling operations. These material improvements collectively increase typical service life from 12-18 months to 24-36 months in equivalent operating conditions, substantially reducing maintenance frequency and associated costs.

Structural durability enhancements include optimized cord placement that reduces stress concentrations at belt edges, integrated wear indicators that visually signal approaching replacement intervals, and specialized cover treatments that resist chemical degradation from industrial cleaners or process materials. The development of composite material shredding solutions has driven parallel innovations in drive components capable of handling the variable loads generated by advanced material processing. These comprehensive durability improvements address both mechanical and environmental failure mechanisms, creating V-belts capable of reliable performance in increasingly demanding industrial applications while reducing total cost of ownership through extended service intervals.

Predictive Maintenance Technologies

Predictive maintenance systems for V-belts utilize multiple monitoring technologies that detect developing issues before they progress to failure, with vibration analysis representing the most established methodology. Advanced systems employ triaxial accelerometers that capture vibration data in three dimensions, with algorithms identifying specific frequency patterns associated with misalignment, imbalance, bearing wear, and belt defects. Thermal monitoring complements vibration analysis through infrared sensors that track temperature gradients across drive systems, with abnormal patterns indicating insufficient tension, lubrication issues, or impending bearing failure. These monitoring technologies integrate with equipment control systems to provide early warning of developing issues, enabling planned intervention during scheduled downtime rather than emergency response to failures.

Implementation ranges from portable data collection systems used during routine inspections to permanently installed continuous monitoring networks that provide real-time equipment health assessment. The economic justification for these systems derives from dramatically reduced unplanned downtime, with studies showing 70-80% reduction in emergency repairs through effective predictive maintenance programs. The integration of these technologies with overall equipment management platforms enables maintenance scheduling optimization, spare parts inventory reduction, and repair duration minimization through advance problem identification. These comprehensive predictive approaches transform V-belt management from reactive replacement to proactive component life optimization within overall equipment reliability strategies.