Selecting the right non-stick waste plastic shredder is essential for efficiently recycling plastic bottles that have labels and adhesives. These materials often cause operational issues, such as clogging and reduced efficiency, which can impact recycling outcomes. This guide explains the critical aspects of choosing a shredder, including technological features, performance metrics, and economic considerations. It aims to help users make informed decisions based on scientific principles and industry data, ensuring optimal performance in various recycling environments.

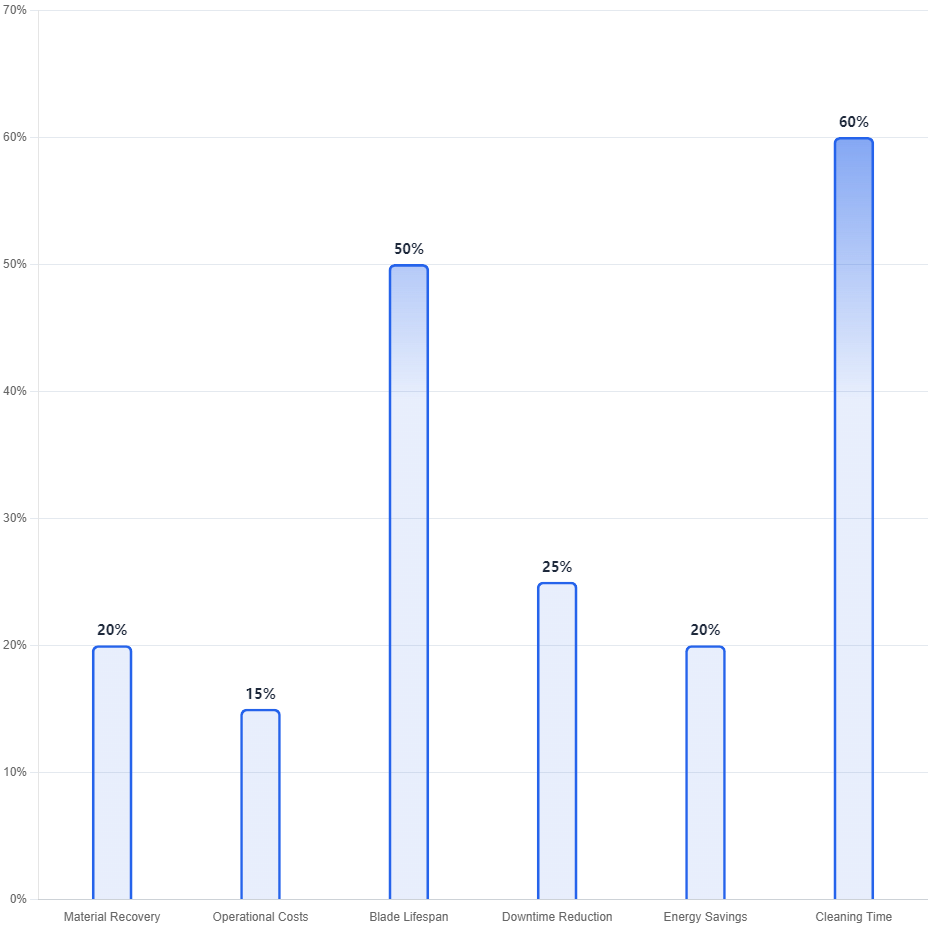

Understanding the specific requirements for processing adhesive-covered plastics can lead to significant improvements in recycling rates. For instance, studies indicate that proper shredder selection can enhance material recovery by up to 20% while reducing energy consumption. This article delves into practical steps and innovations that support sustainable waste management practices.

Challenges and Needs Analysis for Processing Plastic Bottles with Labels

Processing plastic bottles with labels and adhesives presents unique difficulties in recycling operations. Labels often contain glue and synthetic materials that adhere to shredder components, leading to frequent downtime and maintenance. A thorough needs analysis involves evaluating material composition, throughput requirements, and regulatory standards to ensure the shredder can handle these challenges effectively.

Industry reports show that adhesive residues can increase operational costs by approximately 15% due to cleaning and repair needs. Assessing factors such as bottle types and label materials helps in identifying the right shredder specifications. This analysis ensures that the equipment aligns with both economic and environmental goals.

Impact of Labels and Adhesives on Shredding Processes

Labels and adhesives affect shredding by causing material buildup on cutting surfaces. This buildup reduces cutting efficiency and can lead to uneven particle sizes. Research indicates that shredders processing labeled bottles may experience up to 30% more wear on blades compared to those handling clean plastics.

Adhesives can melt during shredding, creating sticky residues that attract other particles. This phenomenon often results in blockages and requires additional energy to overcome. Understanding these effects is crucial for selecting shredders with enhanced anti-stick properties.

Common Issues Like Clogging and Residue Accumulation

Clogging is a frequent problem when shredding plastic bottles with labels, as adhesives bind shredded fragments together. Data from recycling facilities show that clogging incidents can reduce throughput by 25% if not addressed. Residue accumulation also compromises the quality of output material, affecting its value in recycling markets.

Energy consumption tends to rise with residue buildup, as motors work harder to maintain performance. Regular monitoring and tailored shredder designs can mitigate these issues, ensuring consistent operation and output quality.

Throughput Requirements and Processing Capacity Matching

Matching shredder capacity to throughput needs is vital for efficient operations. For example, a facility processing 1,000 kg of plastic bottles per hour may require a shredder with a minimum capacity of 1,200 kg/h to account for adhesive-related slowdowns. Calculating based on material density and adhesive content prevents bottlenecks.

Underestimating capacity can lead to frequent overloads and increased maintenance cycles. Industry standards recommend a buffer of 10-20% above expected throughput to handle variations in material input, ensuring reliable performance.

Environmental Regulations and Safety Standards Considerations

Compliance with environmental regulations, such as EPA guidelines, is necessary when selecting shredders. These rules often mandate limits on emissions and noise levels, which can influence shredder design. For instance, shredders must typically operate below 85 dB to meet workplace safety standards.

Adhesive components may release volatile organic compounds during shredding, requiring integrated dust and fume management systems. Ensuring adherence to these standards not only avoids legal penalties but also promotes worker safety and environmental protection.

Key Features of Non-Stick Shredders

Non-stick shredders incorporate advanced technologies to prevent adhesion and improve efficiency. Features like specialized coatings and automated cleaning systems are designed to handle sticky materials without compromising performance. These innovations are backed by material science research, offering durability and reduced maintenance needs.

For example, shredders with non-stick surfaces can achieve up to 40% longer operational intervals between cleanings. This section explores the core characteristics that make these machines suitable for challenging recycling tasks, emphasizing their role in enhancing productivity.

Non-Stick Coatings and Surface Treatment Technologies

Non-stick coatings, such as PTFE or ceramic layers, create a smooth surface that resists adhesive buildup. These treatments reduce friction and prevent materials from sticking to shredder components. Tests show that coated shredders maintain efficiency even after processing thousands of bottles with labels.

Surface treatments often involve heat-resistant applications that withstand temperatures up to 200°C. This durability ensures consistent performance in high-stress environments, contributing to lower operational costs and extended equipment life.

Blade Materials and Shear Mechanism Optimization

Blades made from hardened steel or carbide alloys offer superior resistance to wear from adhesives. Optimized shear mechanisms, such as angled cuts, minimize contact with sticky residues. Data indicates that such blades can last up to 50% longer than standard versions in adhesive-heavy applications.

The shear design also influences particle uniformity, with studies showing that optimized mechanisms reduce fine particle generation by 15%. This results in higher-quality output and better downstream processing efficiency. For instance, the granulator blades in modern shredders are engineered to handle tough materials without frequent replacements.

Automatic Cleaning and Anti-Clogging Systems

Automatic cleaning systems use brushes or air jets to remove residues during operation, preventing clogging. These systems can reduce manual cleaning time by over 60%, according to industry surveys. Anti-clogging features often include sensors that detect buildup and trigger cleaning cycles.

Integrated systems may also incorporate self-lubricating components to further minimize adhesion. This automation supports continuous operation, which is critical for high-volume recycling facilities. The air conveying system is an example of technology that helps transport shredded materials without blockages.

Power Systems and Energy Efficiency Metrics

Modern shredders employ efficient power systems, such as variable frequency drives, that adjust energy use based on load. Energy-efficient models can save up to 20% on electricity compared to conventional designs. These systems are essential for reducing the carbon footprint of recycling operations.

Power ratings typically range from 10 to 100 kW, depending on processing needs. Selecting the right power configuration ensures that the shredder handles adhesive-laden materials without excessive energy consumption. The hardened steel shaft in these systems provides the necessary strength to sustain high-torque operations.

Selection Criteria and Key Parameter Evaluation

Choosing a non-stick shredder requires evaluating technical parameters and supplier credibility. Key factors include particle size consistency, processing speed, and compatibility with existing systems. This evaluation helps users identify machines that meet specific operational demands while adhering to budget constraints.

For instance, shredders that achieve uniform particle sizes of 10-20 mm are preferred for bottle recycling, as they facilitate later separation stages. This section outlines the criteria that influence decision-making, supported by empirical data and industry benchmarks.

Particle Size and Output Consistency Requirements

Consistent particle size is crucial for efficient sorting and recycling. Shredders that produce uniform fragments reduce contamination in downstream processes. Research shows that variations greater than 5 mm can decrease material value by 10-15%.

Output consistency depends on blade sharpness and chamber design. Regular calibration ensures that shredders maintain specified size ranges, enhancing overall recycling efficiency. The screen mesh plays a key role in controlling particle size distribution.

Processing Speed and Capacity Calculations

Processing speed, measured in kilograms per hour, directly impacts throughput. Capacity calculations should account for adhesive content, which can slow down shredding rates by up to 15%. Selecting a shredder with adjustable speeds allows flexibility in handling different materials.

High-capacity models often feature reinforced structures to sustain performance under heavy loads. Accurate capacity planning prevents overloading and extends equipment lifespan. For example, a double shaft plastic shredder is designed for high-volume processing with minimal downtime.

Equipment Dimensions and Installation Space Constraints

Shredder dimensions must fit within available space, considering safety clearances and accessory placement. Standard models may require 10-50 square meters, depending on capacity. Space constraints can influence the choice between vertical and horizontal designs.

Installation also involves utility connections, such as power and ventilation systems. Proper planning ensures that the shredder integrates seamlessly into existing workflows. The compact design of a single shaft plastic shredder makes it suitable for facilities with limited space.

Supplier Credentials and After-Sales Service Evaluation

Supplier reputation and service support are critical for long-term reliability. Certifications like ISO 9001 indicate quality management standards. After-sales services, including spare parts availability and technical support, reduce downtime risks.

User reviews and industry referrals provide insights into supplier performance. Establishing a partnership with reputable suppliers ensures ongoing operational success. It is advisable to verify if suppliers offer components like the fixed bed knives for easy replacements.

Performance Testing and Optimization Recommendations

Conducting performance tests verifies a shredder's ability to handle adhesive-rich materials. Key metrics include adhesion resistance, energy usage, and noise levels. Optimization involves adjusting operational parameters and implementing preventive measures to maximize efficiency.

Tests in controlled environments show that optimized shredders can achieve adhesion-free operation for over 500 hours. This section details testing protocols and improvement strategies based on scientific analysis.

Testing Procedures and Key Metric Monitoring

Standardized testing procedures involve running the shredder with labeled bottles and monitoring parameters like temperature and output quality. Metrics such as adhesion frequency and power draw are recorded to assess performance. Studies indicate that regular testing can identify issues before they cause significant downtime.

Monitoring systems often use sensors to track real-time data, enabling prompt adjustments. This proactive approach maintains shredder efficiency and reduces operational costs. For broader applications, insights from solid waste shredder testing can be adapted to plastic shredding scenarios.

Adhesion Resistance and Residue Inspection Methods

Adhesion resistance is evaluated by examining shredder surfaces for residue after extended use. Inspection methods include visual checks and weight measurements of accumulated material. Data from these inspections help in refining non-stick features.

Residue levels below 2% of processed weight are considered acceptable in most recycling standards. Achieving this requires continuous improvement in material and design choices. The use of advanced tungsten carbide cutters in some models demonstrates how material innovations enhance resistance.

Energy Consumption and Noise Level Assessments

Energy consumption is measured in kWh per ton of processed material, with efficient models using under 30 kWh/ton. Noise assessments ensure compliance with safety regulations, typically aiming for levels below 80 dB. These evaluations contribute to sustainable and worker-friendly operations.

Reducing energy and noise outputs often involves upgrading motor systems and adding soundproofing enclosures. Such enhancements support environmental goals and operational efficiency. Similar principles apply to metal shredder designs, which prioritize energy efficiency in heavy-duty applications.

Maintenance and Lifespan Extension Strategies

Regular maintenance is essential for preventing failures and extending shredder lifespan. Strategies include scheduled cleaning, part replacements, and operator training. These practices address the wear caused by adhesives, ensuring consistent performance over time.

Data show that well-maintained shredders can operate for over 10,000 hours before major overhauls. This section covers maintenance techniques that optimize durability and reliability.

Daily Cleaning and Anti-Stick Maintenance Steps

Daily cleaning involves removing residues from blades and chambers using appropriate tools. Anti-stick maintenance may include applying release agents to reduce adhesion. Consistent cleaning prevents buildup that can lead to mechanical failures.

Maintenance logs track cleaning frequency and outcomes, helping to identify patterns and improve schedules. This disciplined approach reduces repair costs by up to 25%. Incorporating features from wood shredder maintenance protocols can offer additional insights for adhesive-heavy environments.

Blade Wear Inspection and Replacement Intervals

Blade wear is assessed through thickness measurements and visual inspections for chips or dullness. Replacement intervals vary based on usage, but typically range from 500 to 1,000 operating hours. Worn blades increase energy use and reduce output quality.

Using durable blade materials extends replacement cycles, lowering long-term costs. Regular inspections ensure timely replacements, maintaining shredder efficiency. The oil-free cutting system in some models reduces the need for frequent lubrication and blade changes.

Lubrication and Power System Maintenance

Lubrication of moving parts reduces friction and wear, especially in adhesive-prone environments. Power system maintenance includes checking electrical connections and motor performance. Proper lubrication can extend component life by 20% or more.

Scheduled maintenance prevents unexpected breakdowns and supports smooth operation. Documenting maintenance activities aids in forecasting future needs. For complex systems, referring to the lubrication system used in tire shredders can provide best practices for high-stress applications.

Cost Analysis and Investment Decisions

Cost analysis for non-stick shredders involves evaluating purchase prices, operational expenses, and potential returns. Investment decisions should balance performance with budget limitations, considering factors like energy savings and recycling revenue.

For example, shredders with higher initial costs may offer faster payback periods through reduced maintenance and improved efficiency. This section provides a framework for economic assessment, using industry data to guide choices.

Initial Purchase and Installation Costs

Initial costs include the shredder price, transportation, and installation fees. These can range from $20,000 to $100,000, depending on capacity and features. Installation may require additional investments in infrastructure, such as reinforced flooring.

Budgeting for these expenses ensures that projects remain financially viable. Comparing multiple quotes helps in securing cost-effective solutions. The plastic film shredder category, for instance, offers models with varying price points to suit different budgets.

Operational Energy and Maintenance Expenses

Operational costs cover electricity, lubrication, and routine maintenance. Energy expenses can account for 30-40% of total operating costs in shredding operations. Efficient models mitigate these costs through advanced power management.

Maintenance expenses include part replacements and labor, which should be factored into long-term budgets. Predictive maintenance strategies reduce unexpected costs and downtime. Learning from the overheat protection sensor in paper shredders can help in designing cost-effective monitoring systems for plastic shredders.

Efficiency Improvements and Recycling Value Gains

Efficiency improvements from non-stick shredders increase recycling output and material quality. This can boost revenue by 10-20% through higher-value recycled products. Gains also include reduced waste disposal costs.

Quantifying these benefits helps justify investments in advanced shredder technologies. Continuous monitoring ensures that efficiency targets are met. The integration of smart features, as seen in some e-waste shredder models, can further enhance value gains through automated optimization.

Future Trends and Technological Innovations

The future of non-stick shredders is shaped by advancements in smart technologies and sustainable materials. Trends include AI integration, eco-friendly coatings, and circular economy applications. These innovations aim to enhance performance while minimizing environmental impact.

For instance, AI-powered shredders can optimize operations in real-time, reducing adhesion issues by 25%. This section explores emerging developments that will influence shredder design and usage.

Smart Technologies and IoT Applications

Smart shredders use IoT sensors to monitor conditions like temperature and adhesion levels. Data analytics enable predictive maintenance and automatic adjustments. These technologies improve reliability and reduce human intervention.

IoT integration also facilitates remote monitoring, allowing operators to manage shredders from any location. This connectivity supports efficient and responsive recycling processes. The evolution of control panel PLC HMI systems is a key enabler of these smart features.

New Anti-Stick Materials and Coating Developments

Research into new materials, such as graphene-based coatings, offers superior anti-stick properties. These coatings are more durable and environmentally friendly than traditional options. Testing shows they can double the time between cleanings.

Developments in biodegradable release agents further support sustainability goals. Adopting these materials reduces the ecological footprint of shredding operations. Innovations in wear-resistant liners for metal shredders are being adapted for plastic applications to enhance durability.

Sustainability and Environmental Compliance Advancements

Sustainability trends drive the adoption of shredders that lower energy use and emissions. Compliance with evolving regulations, such as the EU's Circular Economy Package, requires continuous innovation. Shredders that exceed standards often qualify for green certifications.

Advances in material recovery technologies enhance the recyclability of adhesive-covered plastics. These efforts contribute to global sustainability targets and resource conservation. The push for greener solutions is evident in the development of RDF shredder systems that prioritize energy recovery and waste reduction.