This article provides a scientific approach to evaluating tire types when choosing a waste tire shredder, ensuring the equipment aligns with operational demands. It covers tire classifications, key selection criteria, technical specifications, and common pitfalls to facilitate informed decision-making. Understanding these elements is crucial for optimizing recycling efficiency and maximizing return on investment in waste management operations.

Basic Classification and Characteristics of Tire Types

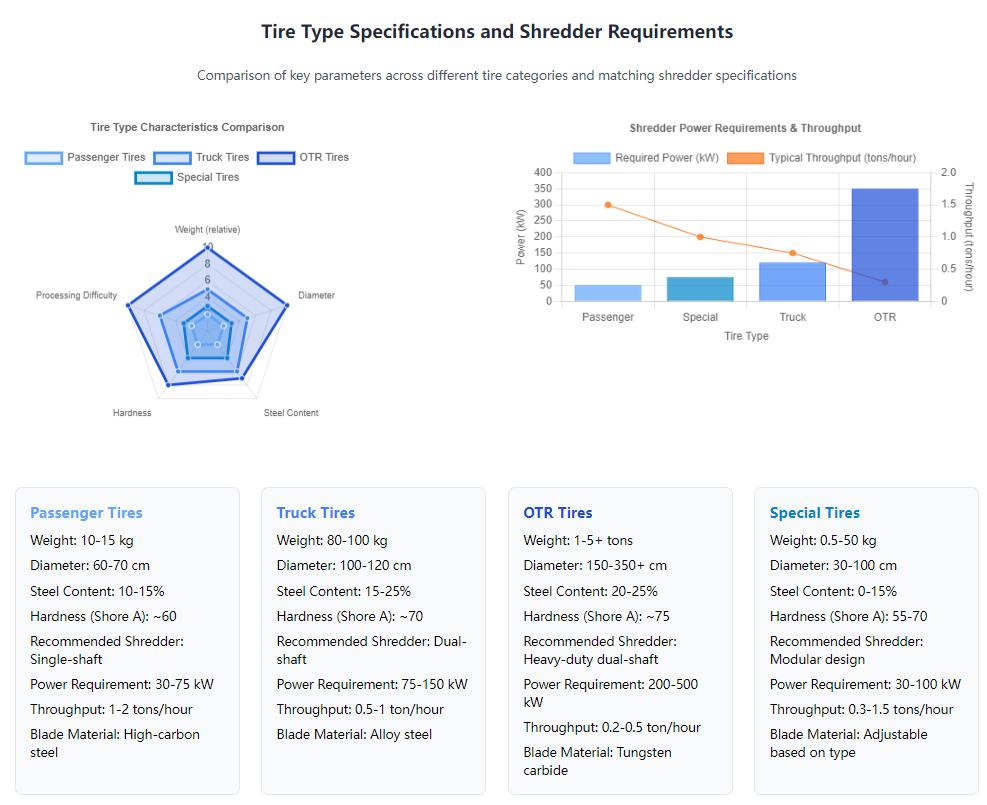

Tire types vary significantly in size, structure, and material composition, which directly influences shredder selection. Passenger tires are generally lightweight and made of softer rubber, while truck tires incorporate steel reinforcements for heavy loads. Off-the-road (OTR) tires represent the largest category, with diameters exceeding three meters and high durability. Specialized tires, such as those for bicycles or aircraft, require unique handling due to their niche applications. Recognizing these differences is the first step in matching a shredder to the specific tire stream.

The composition of tires includes rubber compounds, fabric layers, and steel belts, each affecting shredding mechanics. For instance, passenger tires typically weigh between 10 to 15 kilograms and have minimal steel content, whereas truck tires can exceed 100 kilograms with substantial steel belts. OTR tires may weigh several tons, demanding robust equipment. This diversity necessitates a tailored approach to shredder design, focusing on factors like input size and material hardness.

Typical Parameters of Passenger Tires and Shredder Requirements

Passenger tires are characterized by their relatively soft rubber and small dimensions, with an average diameter of 60 to 70 centimeters. They contain limited steel belts, making them easier to process compared to heavier tires. Shredders for these tires must prioritize high-speed operation and sharp blades to efficiently handle the material without excessive energy consumption. A machine with a throughput of 1 to 2 tons per hour is often sufficient for small-scale recycling facilities.

The shredder should feature blades made of standard high-carbon steel, which balances cost and durability for soft rubber. Automated feeding systems can enhance efficiency, but the primary focus is on maintaining consistent output sizes of 50 to 100 millimeters for downstream recycling. Properly configured, such shredders can process passenger tires with minimal maintenance intervals, typically requiring blade sharpening after every 500 hours of operation.

Challenges of Truck Tires: Steel Content and Shredder Power

Truck tires pose significant challenges due to their high steel content, which can account for up to 25% of the tire's weight. These tires are designed for heavy loads, featuring multiple steel belts that increase their hardness and resistance to shredding. Shredders must deliver high torque and power, often requiring motors rated at 75 to 150 kW to handle the material effectively. The presence of steel mandates integrated magnetic separators to extract metal fragments during processing.

A double-shaft shredder is commonly recommended for truck tires, as its interlocking blades provide superior tearing force against steel reinforcements. These machines typically operate at slower speeds to generate higher torque, reducing the risk of jamming. Regular maintenance is critical, with blade inspections needed every 200 hours to address wear from abrasive steel components.

Handling Solutions for OTR Tires' Giant Sizes

OTR tires, used in mining and construction, can have diameters over 3.5 meters and weigh up to 5 tons. Their massive size and thick rubber composition demand shredders with large feed openings, often exceeding 1.5 meters in width. Industrial-grade shredders with hydraulic rams are essential to force these tires into the cutting chamber safely. Power requirements are substantial, with motors ranging from 200 to 500 kW to achieve necessary throughput.

The shredding process for OTR tires often involves primary and secondary stages to reduce the material to manageable chunks. Primary shredders break the tire into large pieces, while secondary units further refine the output to sizes below 100 millimeters. This two-step approach minimizes stress on the equipment and ensures efficient material recovery. Facilities handling OTR tires must also consider dust extraction systems to manage particulate emissions during shredding.

Personalized Selection Suggestions for Special Tires

Special tires, such as those for bicycles or aircraft, exhibit unique properties like varied rubber compounds or specialized reinforcements. Bicycle tires are small and lack steel, but may have fabric layers that require precise cutting. Aircraft tires, though rare in recycling streams, feature high-strength materials that demand shredders with adjustable speed settings. Flexibility in output size control is key, as these tires often feed into niche recycling markets.

Shredders for special tires should offer customizable blade configurations and modular designs to adapt to irregular shapes. For example, a single-shaft shredder with variable rotor speeds can handle diverse materials without overloading. Output sizes may need to be as fine as 10 millimeters for applications like rubber crumb production. Operators should prioritize machines with easy maintenance access to accommodate frequent adjustments for varying tire types.

Core Impact of Tire Types on Shredder Selection

Tire type fundamentally dictates shredder specifications, including power, size, and auxiliary systems. Harder tires necessitate higher power ratings and reinforced components to withstand abrasive materials. The physical dimensions of tires influence feed opening design, while internal reinforcements like steel or fiber require integrated separation mechanisms. Quantifying processing needs based on tire mix ensures the shredder meets capacity demands without underutilization or overload.

For instance, a facility processing mixed tires must account for the average hardness and size distribution to select an appropriately rated shredder. Hardness scales, such as the Shore A scale, indicate that passenger tires score around 60, while truck tires exceed 70, directly correlating to power needs. Similarly, daily volume estimates prevent oversizing; a shredder handling 10 tons per day of passenger tires may suffice with a 50 kW motor, but truck tires could require 100 kW for the same throughput.

Matching Hardness Differences to Shredder Cutting Mechanisms

Tire hardness, measured on scales like Shore A, varies from 55 for soft passenger tires to 75 for heavy-duty OTR tires. Softer tires are efficiently processed by high-speed shear shredders that slice through material quickly. In contrast, hard tires demand low-speed, high-torque machines that apply crushing force to break down resistant structures. This distinction ensures energy efficiency and reduces wear on cutting components.

Shredders designed for hard tires often incorporate hydraulic systems that adjust pressure based on material resistance. For example, a machine processing truck tires might operate at 20 RPM to maximize torque, while one for passenger tires runs at 40 RPM for faster output. This adaptability prolongs blade life and maintains consistent particle size, which is crucial for recycling applications where uniformity affects material value.

Adaptation Principles for Feed Opening Size and Tire Diameter

The diameter of tires directly determines the required feed opening size of a shredder. Passenger tires, with diameters under 70 centimeters, can be processed by shredders with openings of 80 centimeters. Larger tires, such as OTR varieties, need openings exceeding 1.5 meters to prevent blockages and ensure smooth feeding. An undersized opening leads to frequent jams, increasing downtime and maintenance costs.

Modern shredders address this through adjustable feed mechanisms or hydraulic rams that compress tires during entry. For mixed tire streams, a wider opening accommodates size variations without compromising efficiency. Data shows that optimizing feed opening size can increase throughput by up to 30% by reducing handling time. This consideration is especially important in high-volume facilities where continuous operation is critical.

Separation Function Needs for Reinforcement Materials

Tires with steel belts require shredders equipped with magnetic separators to extract metal during or after shredding. This separation is vital for producing clean rubber feedstock and preventing damage to downstream equipment. Fiber-reinforced tires, common in some industrial applications, need air classification or screening systems to isolate non-rubber components. Integrating these functions into the shredder design streamlines the recycling process.

For example, a magnetic separator can remove over 95% of steel fragments from shredded truck tires, enhancing the purity of the output material. Systems without separation capabilities risk contaminating the rubber product, reducing its market value. Facilities should evaluate the reinforcement content of their tire supply to determine the necessary separation technology, ensuring compliance with recycling standards.

Throughput Calculation Based on Tire Type and Quantity

Calculating shredder throughput involves analyzing the types and quantities of tires processed daily. Passenger tires, with an average weight of 12 kilograms, allow higher piece counts per hour compared to heavier tires. A shredder rated for 5 tons per hour might process 400 passenger tires but only 50 truck tires in the same period. This disparity highlights the need for volume-based capacity planning.

Operators can use formulas incorporating tire weight and desired hourly output to select shredder size. For instance, if a facility handles 100 truck tires daily (each weighing 80 kilograms), the required throughput is 8 tons per day, necessitating a shredder with at least 1 ton per hour capacity. Factoring in operational hours and maintenance schedules ensures the machine meets demand without excessive idle time, optimizing investment returns.

Key Selection Factors: From Tire Types to Shredder Parameters

Selecting a shredder based on tire types involves evaluating parameters like power, blade material, and automation levels. Power requirements scale with tire hardness, while blade durability depends on reinforcement content. Automation features improve efficiency in mixed-tire environments, and cost-benefit analysis balances initial investment with long-term operational expenses. These factors collectively determine the shredder's suitability for specific applications.

Power consumption data indicates that shredding passenger tires requires approximately 30 kWh per ton, whereas truck tires need 50 kWh per ton due to their steel content. Blade materials range from standard steel for soft tires to tungsten carbide for abrasive materials. Automated systems, such as programmable logic controllers (PLCs), can reduce labor costs by up to 20% in large facilities. Weighing these elements against tire type ensures optimal machine performance.

Power Calculation Models for Different Tire Types

Power needs for shredders correlate strongly with tire hardness and volume. A basic model estimates power as P = k * H * V, where P is power in kW, k is a material constant (e.g., 0.5 for passenger tires, 0.8 for truck tires), H is hardness, and V is hourly volume in tons. For example, shredding 2 tons per hour of truck tires with a hardness of 70 requires approximately 112 kW. This model helps avoid underpowered machines that struggle with hard materials.

Advanced shredders incorporate variable frequency drives (VFDs) to adjust power output based on real-time load detection. This technology optimizes energy use, reducing consumption by 15% compared to fixed-speed motors. Facilities should consult manufacturer data to refine calculations, as factors like blade sharpness and feed consistency also influence power demands. Accurate power matching prevents operational bottlenecks and extends equipment life.

Blade Material Selection Guide: From Standard Steel to Alloy

Blade material choice is critical for handling different tire compositions. Standard high-carbon steel blades suffice for passenger tires, offering a balance of cost and performance. For tires with steel reinforcements, alloy blades with chromium or tungsten coatings provide enhanced wear resistance. Data shows that alloy blades can last up to three times longer than standard blades when processing abrasive materials like truck tires.

The selection process should consider the proportion of steel in the tire stream. If steel content exceeds 15%, tungsten carbide cutters are recommended due to their exceptional hardness. Regular blade inspections are necessary; for high-steel tires, replacements may be needed every 300 hours, whereas passenger tires allow intervals of 800 hours. Investing in durable blades reduces downtime and maintenance costs over the shredder's lifespan.

Application of Automation Systems in Mixed Tire Processing

Automation enhances efficiency in facilities handling diverse tire types by streamlining feeding, shredding, and sorting processes. Automated conveyors and sensors regulate material flow, preventing overloads and ensuring consistent feed rates. PLC systems can adjust shredder settings based on tire size and hardness detected at the intake, optimizing performance for each tire category. This reduces manual intervention and minimizes errors.

In mixed-tire operations, automation can improve throughput by up to 25% by maintaining optimal operating conditions. For instance, a system might slow the rotor speed when a truck tire is detected to increase torque, then accelerate for passenger tires. Integration with separation units, such as bead wire separators, further automates the recycling line. While initial costs are higher, the long-term savings in labor and increased productivity justify the investment.

Cost Analysis: Return on Investment Based on Tire Type

Cost-effectiveness in shredder selection depends on aligning machine capabilities with the tire types processed. A shredder for passenger tires may cost $50,000 with low operating expenses, whereas one for OTR tires can exceed $200,000 due to heavy-duty components. Return on investment (ROI) calculations should include factors like energy consumption, maintenance frequency, and output value. For example, processing truck tires yields higher-value steel scrap, offsetting higher shredder costs.

ROI models show that a shredder handling mixed tires can break even within two years if optimized for the dominant tire type. Data indicates that facilities processing over 10,000 tons annually benefit from high-end shredders with automation, while smaller operations may prefer modular options. Lifecycle cost analysis, including disposal savings from recycled materials, provides a comprehensive view. Choosing a shredder that matches tire types ensures maximum financial returns.

Precise Matching of Shredder Technical Parameters to Tire Types

Technical specifications of shredders, such as shaft configuration and output size adjustability, must align with tire characteristics to ensure efficient processing. Single-shaft shredders suit simpler materials, while dual-shaft models excel with reinforced tires. Output size control affects downstream recycling applications, and safety features mitigate risks associated with hard tires. Energy efficiency standards also play a role in sustainable operations.

For instance, a dual-shaft shredder provides greater tearing force for truck tires compared to a single-shaft unit, reducing processing time by 20%. Output sizes can be tuned from 50 millimeters for coarse chips to 10 millimeters for fine powder, depending on end-use requirements. Safety systems like overload protection prevent damage when encountering unexpected hard objects. Compliance with energy standards, such as ISO 50001, minimizes environmental impact while cutting costs.

Advantages of Dual-Shaft Systems in Processing Steel-Belted Tires

Dual-shaft shredders feature two counter-rotating shafts with interlocking blades that generate high shear and tear forces. This design is ideal for steel-belted tires, as it effectively dismantles the reinforced structure without excessive energy use. The slow rotational speed, typically 10 to 30 RPM, allows for high torque application, crucial for breaking through steel layers. Tests show that dual-shaft models can process truck tires 30% faster than single-shaft alternatives.

These shredders often include reinforced shafts and durable bearings to withstand the stress of steel components. The cutting action produces uniform chunks that facilitate downstream separation. For facilities focused on truck or OTR tires, investing in a dual-shaft system ensures reliable performance and reduces the frequency of blade replacements. This configuration is a industry standard for heavy-duty tire recycling.

Impact of Output Size Adjustment on Downstream Recycling

Adjustable output sizes in shredders allow operators to tailor material for specific recycling pathways. Coarse output (50-100 mm) is suitable for tire-derived fuel (TDF), while finer sizes (10-20 mm) are used in rubber crumb production for surfaces like playgrounds. The ability to modify output without changing hardware enhances flexibility and market adaptability. Consistent size control also improves the quality of recycled products.

Shredders with screen-based size control can achieve variances within 5% of the target size, ensuring uniformity. For example, a facility producing TDF might set the shredder to 75 mm, whereas one making rubber mulch targets 15 mm. This precision reduces reprocessing needs and increases material value. Operators should select shredders with easy screen replacement systems to switch between sizes quickly, maximizing operational efficiency.

Role of Safety Features like Overload Protection in High-Pressure Scenarios

Safety mechanisms are essential when shredding hard tires, which can cause sudden load spikes. Overload protection systems automatically halt the shredder if torque exceeds safe limits, preventing motor burnout or blade damage. Hydraulic systems may reverse the shafts briefly to clear jams, resuming operation once the obstruction is resolved. These features reduce downtime and protect expensive components.

In high-volume operations, safety systems can prevent accidents that lead to hours of inactivity. For instance, an overload sensor might activate when an OTR tire with hidden metal objects enters the chamber. Advanced shredders include PLC-based controls that log incidents for analysis, helping operators identify recurring issues. Prioritizing safety not only protects equipment but also ensures worker well-being in demanding environments.

Energy Efficiency Ratings and Green Handling of Tire Types

Energy-efficient shredders reduce operational costs and environmental impact, especially when processing high-resistance tires. Motors with high efficiency ratings (e.g., IE3 or IE4) consume less electricity while maintaining performance. For example, an IE4 motor can save up to 5% energy compared to standard models during tire shredding. This is significant in continuous operations where energy accounts for 40% of total costs.

Green handling also involves dust suppression and noise reduction systems to meet environmental regulations. Shredders equipped with dust collection systems capture over 90% of particulate matter, improving air quality. Choosing energy-star certified equipment may qualify facilities for incentives, enhancing sustainability credentials. Aligning shredder selection with eco-friendly practices supports long-term viability in the recycling industry.

Practical Application Scenarios and Case Studies

Real-world examples illustrate how tire type influences shredder selection and operational outcomes. Urban recycling centers often handle mixed tire streams, requiring versatile equipment, while specialized plants optimize for single types. Analyzing both successes and failures provides valuable insights for potential buyers. Data-driven case studies highlight the importance of matching shredders to specific tire profiles.

For instance, a recycling facility in Europe increased throughput by 40% after switching to a shredder designed for its dominant tire type—passenger tires. Conversely, a North American plant faced frequent breakdowns by using a general-purpose shredder for OTR tires. These cases underscore the need for thorough tire analysis before investment. Learning from others' experiences helps avoid common mistakes and achieve better financial results.

Shredder Configuration Case for Mixed Tire Processing Scenarios

Mixed tire streams, common in municipal recycling programs, contain a variety of passenger, truck, and occasional specialty tires. A modular shredder system with primary and secondary units handles this diversity effectively. The primary shredder reduces whole tires to large chunks, while the secondary unit refines the material to consistent sizes. This approach accommodates varying hardness and sizes without compromising efficiency.

In one case, a facility in Asia implemented a double-shaft primary shredder followed by a granulator for mixed tires, achieving 98% material recovery. The system included automated sorting to direct different tires to optimal processing paths. Throughput reached 8 tons per hour, with minimal manual intervention. This configuration demonstrates how tailored solutions maximize productivity in complex environments.

Dedicated Machine Selection for Single-Type Tire Plants

Facilities processing a single tire type, such as OTR tires from mining operations, benefit from shredders optimized for that specific material. These plants often use high-power, slow-speed shredders with large feed openings to handle the immense size and hardness. Dedicated systems simplify maintenance and operation, as parameters remain constant. This specialization leads to higher uptime and lower per-ton processing costs.

A case study from Australia showed that an OTR tire recycling plant achieved 99% availability by using a custom shredder with 400 kW power and a 2-meter feed opening. The output was sized for TDF production, generating significant revenue. The shredder's design included reinforced components to withstand abrasive wear, extending service intervals. Such examples highlight the advantages of purpose-built equipment in niche applications.

Common Error Case: Failures Due to Ignoring Tire Type

Ignoring tire type during shredder selection leads to operational failures, such as frequent jams, excessive wear, or inadequate throughput. A documented case involved a facility that purchased a shredder rated for passenger tires but used it for truck tires. The machine's motor overheated within weeks, and blades required replacement after 100 hours, far below the expected 500-hour lifespan. This error resulted in unplanned downtime and increased maintenance expenses.

The root cause was a lack of pre-purchase analysis on tire composition, particularly the steel content. Corrective action involved retrofitting a more powerful shredder with magnetic separation, but at a higher cost than initial proper selection. This case emphasizes the importance of consulting technical specifications and conducting material tests before investment. Avoiding such pitfalls requires diligence in assessing the tire stream's characteristics.

Best Practice: Data-Driven Selection for Maximum Return

Successful shredder investments rely on data-driven decisions that consider tire type metrics like hardness, size distribution, and volume. Facilities that conduct detailed audits of their tire supply can select shredders with precision, optimizing performance and ROI. For example, a company in the U.S. used tire weight and steel content data to choose a shredder that increased annual capacity by 25% while reducing energy use by 15%.

Key practices include partnering with manufacturers for trials and using software to model shredder performance under different scenarios. Data collection on output quality and maintenance intervals fine-tunes operations over time. This approach ensures the shredder remains aligned with evolving tire streams, supporting long-term profitability. Emulating these strategies leads to sustainable recycling operations.

Common Errors and Avoidance Strategies

Selecting a tire shredder involves pitfalls that can be avoided with careful planning. Underestimating tire diversity leads to mismatched equipment, while over-investing in unnecessary features inflates costs. Neglecting maintenance needs tied to tire type results in premature failures, and overlooking future expansion limits scalability. Awareness of these errors enables proactive mitigation.

For instance, assuming a one-size-fits-all shredder works for all tires is a frequent mistake, as tire hardness and size vary widely. Similarly, focusing solely on initial price without considering operating expenses for specific tire types reduces long-term value. Maintenance schedules should account for abrasive materials like steel, which accelerate wear. Planning for growth ensures the shredder can handle increased volumes or new tire types.

Error 1: Drawbacks of Using a Universal Shredder for All Tire Types

Universal shredders marketed for multiple materials often lack the specialization needed for efficient tire processing. They may struggle with steel-belted tires due to insufficient torque or damage soft tires with overly aggressive cutting. This mismatch causes low throughput, high energy consumption, and frequent breakdowns. Data indicates that dedicated tire shredders outperform universal models by 30% in efficiency when handling mixed streams.

To avoid this error, buyers should prioritize shredders designed specifically for tires, with features like tire-specific blades and reinforced structures. Customization options allow adjustments for different tire categories within a single machine. Investing in tailored equipment upfront prevents costly retrofits and ensures reliable operation across the tire spectrum.

Error 2: Impact of Ignoring Tire Type on Replacement Cycles

Tire type directly affects wear rates on shredder components, particularly blades and bearings. Hard tires with steel accelerate wear, necessitating more frequent replacements than soft tires. Ignoring this correlation leads to unexpected downtime and increased spare parts costs. For example, blades processing truck tires may need replacement every 200 hours, whereas passenger tires allow 800-hour intervals.

Strategic avoidance involves creating maintenance plans based on tire type analysis. Stocking备用 blades rated for abrasive materials and scheduling inspections after processing hard tires prevent surprises. Using wear-resistant materials, such as tungsten carbide, extends intervals. Proactive management ensures continuous operation and reduces lifetime costs.

Error 3: Failing to Assess Downstream Use Requirements for Shredder Output

Shredder output size and purity must align with downstream applications, such as rubber crumb production or TDF. Selecting a shredder without considering end-use can render the output unsuitable, requiring reprocessing or reducing its market value. For instance, TDF requires chunks of 50-100 mm, while finer sizes are needed for molded products. Overlooking this leads to inefficiencies.

Avoidance strategies include consulting with recycling partners early in the selection process to define output specifications. Shredders with adjustable screens or granulators offer flexibility to meet varying demands. Conducting trials with sample tires confirms output suitability before full-scale deployment. Aligning shredder capabilities with end-products maximizes revenue from recycled materials.

Error 4: Overlooking Regulations and Environmental Standards

Different tire types may subject facilities to specific regulations regarding noise, emissions, or waste handling. For example, shredding OTR tires often generates more dust, requiring advanced containment systems. Ignoring these standards risks fines or operational shutdowns. Compliance involves selecting shredders with certifications like CE or EPA ratings for environmental safety.

To avoid non-compliance, buyers should review local laws related to tire recycling and choose shredders with