Transforming end-of-life tires into safe, high-performance infill for synthetic sports fields is a complex process that combines mechanical engineering, material science, and stringent environmental oversight. This guide details the entire journey, from whole tire to finished product, outlining the critical equipment needed, the international standards that must be met, and the environmental compliance measures that ensure sustainability. The process not only diverts waste from landfills but creates a valuable resource that provides cushioning and resilience for athletes worldwide.

The production chain begins with coarse shredding to liberate the rubber, steel, and fiber components, followed by a series of separation and refinement stages. Each step must be carefully controlled to achieve the precise granulate size and purity required by international sports bodies. Furthermore, the operation must manage dust, noise, and water usage to minimize its environmental footprint. Understanding this full spectrum—from the power of a tire shredder to the nuances of chemical testing—is essential for producing a competitive and compliant product.

Technical Principles of Producing Sports Infill from Waste Tires

The core challenge in recycling tires for infill lies in breaking down the vulcanized rubber's robust cross-linked structure without degrading its desirable elastic properties. This requires a combination of mechanical force and, in some advanced processes, cryogenic or chemical assistance. The goal is to liberate the pure rubber from the reinforcing steel belts and textile fibers embedded within the tire's matrix, then size it into uniform, clean granules.

Once separated, the rubber granules often undergo surface activation to improve their hydrophilicity, preventing them from repelling water and ensuring they behave consistently in wet playing conditions. The entire process is a balance between applying enough energy to break the tire apart and being gentle enough to preserve the rubber's inherent bounce and durability, which are the very reasons it is chosen for sports surfaces.

Shear-Extrusion Crushing Principle of Twin-Shaft Shredders

The primary size reduction of whole tires is most efficiently accomplished by a double shaft shredder. This machine operates on the principle of shear-extrusion. Two parallel rotors, fitted with intermeshing cutting discs, rotate at low speeds but generate immense torque. As whole tires are fed into the cutting chamber, the rotors grab and pull them in. The tires are then sheared between the counter-rotating discs and torn apart against the machine's interior bed knives.

This action is more like a powerful, controlled tearing than a high-impact smash, which helps prevent the generation of excessive heat that can degrade the rubber. The slow, methodical process allows for the production of a relatively uniform output chip, typically 2 to 4 inches in size, which is ideal for the next stages of processing. The high torque ensures that even steel belt radials are processed consistently without stalling the machine.

Application of Glass Transition in Cryogenic Grinding Technology

For applications requiring very fine rubber powder, cryogenic grinding is employed. This technology leverages a fundamental property of materials called the glass transition temperature. When rubber is cooled below this critical point (approximately -80°C for tire rubber using liquid nitrogen), it loses its elastic, flexible nature and becomes brittle and glass-like.

In this brittle state, the rubber can be easily fractured by mechanical impact. The pre-shredded chips are conveyed into a hammer mill or impact mill where they are shattered into fine particles. This method allows for precise size control and produces granules with a large surface area and minimal heat history, which is beneficial for certain chemical modification processes later on. However, the high cost of liquid nitrogen makes it less common for standard sports infill production.

Relationship Model Between Magnetic Strength and Metal Separation Rate

After primary shredding, the liberated steel wire must be removed with high efficiency. This is achieved using powerful overband magnets or magnetic drums. The separation rate is directly proportional to the magnetic field strength, measured in Gauss. A standard magnet might generate a field of 6,000 Gauss, which is sufficient for most applications. However, for maximum recovery of fine steel wires, high-intensity magnets exceeding 8,000 Gauss are used.

The relationship is not perfectly linear due to factors like material depth on the conveyor belt and the size of the steel pieces. A mathematical model used in industry predicts that increasing the magnetic strength by 20% can improve the separation efficiency of fine wires by up to 15%, ensuring that the final rubber product has a metal content of less than 0.1%, a key requirement for most international infill standards.

Improvement of Rubber Granule Hydrophilicity with Surface Activators

Virgin tire rubber is naturally hydrophobic, meaning it repels water. This can be problematic on a sports field, leading to puddling, inconsistent bounce, and granules that stick to players' skin and clothing. To solve this, the rubber granules are often treated with a surface activator or chemical coupling agent.

These agents, often applied in a rotating drum mixer, create a microscopic hydrophilic layer on the surface of each granule. This allows a thin film of water to coat the granule, improving overall field drainage and player comfort. Importantly, this treatment only affects the surface chemistry; the bulk properties of the rubber—its elasticity, durability, and shock absorption—remain completely intact, preserving the playing characteristics.

Core Production Equipment Selection Matrix

Selecting the right combination of equipment is paramount for building an efficient and profitable tire recycling plant for infill production. The selection is not about choosing the best individual machine, but about choosing the best system where each unit complements the others in terms of capacity, output size, and material handling. The matrix involves decisions at every stage: primary size reduction, metal separation, fiber removal, and final sizing.

The choice between different technologies at each stage involves trade-offs between capital cost, operational cost, maintenance complexity, and final product quality. For example, a higher initial investment in a more efficient magnetic separator will yield a cleaner product and reduce wear on downstream equipment. The optimal matrix is unique to each producer's specific feedstock, target market, and local regulatory environment.

Secondary Crushing Solutions for Particles Larger than 20mm

The output from a primary shredder can contain a fraction of particles larger than the desired 20mm maximum for many infill applications. These oversize pieces require secondary reduction. This is typically done using a granulator or a high-speed hammer mill. A granulator uses a rotor with knives that work against stationary bed knives to slice the material, with the final size determined by a screen.

An alternative is a

slow-speed shear shredder for more precise sizing. The choice depends on the volume of oversize material and the desired shape of the final granule. Granulators produce a more

cubic particle, while hammer mills can produce a more irregular shape. The secondary crusher must be matched to the throughput of the primary line to avoid becoming a bottleneck in

the entire production process.

Balancing Point Between Magnetic Strength and Equipment Energy Consumption

While stronger magnets improve metal recovery, they also consume significantly more energy. Electromagnets, which can be tuned to different strengths, require a continuous supply of electricity to maintain their magnetic field. A 8,000 Gauss electromagnet might consume 15-20% more power than a standard 6,000 Gauss model. The decision is an economic calculation: does the value of the additional recovered steel and the improved product purity justify the higher ongoing electricity cost?

For most dedicated infill producers, the answer is yes. The cost of electricity for the magnet is small compared to the risk of having a batch of product rejected for exceeding metal content limits. Furthermore, removing more metal upstream protects downstream equipment like granulators from abrasive wear, reducing their maintenance costs and extending their lifespan, which offsets the higher energy spend.

Impact of Fiber Content on the Rebound Resilience of Infill

Textile fiber from the tire's inner liner, if not removed effectively, becomes a contaminant in the rubber infill. Even small amounts of fiber can negatively impact the performance of the sports field. Fiber tends to mat together when wet, creating a impermeable layer that compromises the field's drainage system. More critically, it affects the shock absorption and rebound resilience of the surface.

Laboratory tests show that a fiber content exceeding 0.5% by weight can reduce the force reduction (shock absorption) of a field by up to 3%. This is a significant deviation that would fail the strict performance criteria for FIFA Quality or FIFA Quality Pro fields. Therefore, investing in efficient fiber removal technology, such as air classifiers or specific vibration screens, is not optional but a core requirement for producing performance-grade infill.

Synergistic Design of Dust Collection and Particle Recovery Systems

Shredding and granulating tires generates a significant amount of dust and fine rubber particles. A well-designed dust collection system is crucial for both environmental compliance and product recovery. The system must capture airborne particles at key transfer points, such as the discharge of shredders, granulators, and screens.

This captured material, often a very fine rubber powder, is not waste. It can be sold as a valuable commodity for use in asphalt modification or as a filler in various rubber products. The dust collection system is therefore designed not just as pollution control but as a product recovery circuit. Cyclones and baghouse filters work in stages to first capture coarse recoverable material and then the finest dust, maximizing overall product yield from the raw tires.

International Standards Comparison for Sports Field Infill

The global market for rubber infill is governed by a complex landscape of international standards and regulations. These standards ensure that products from different manufacturers provide a consistent and safe playing experience for athletes. The major standards come from organizations like FIFA for soccer, World Rugby, and national standard bodies, which set limits on everything from heavy metal content to mechanical performance.

Navigating these standards is critical for any producer. The requirements can vary significantly; for example, a limit for a certain chemical in Europe may be ten times stricter than in another region. Producers aiming for the global market must design their process and quality control labs to meet the most stringent requirements, ensuring their product is acceptable everywhere. This often involves rigorous third-party testing and certification.

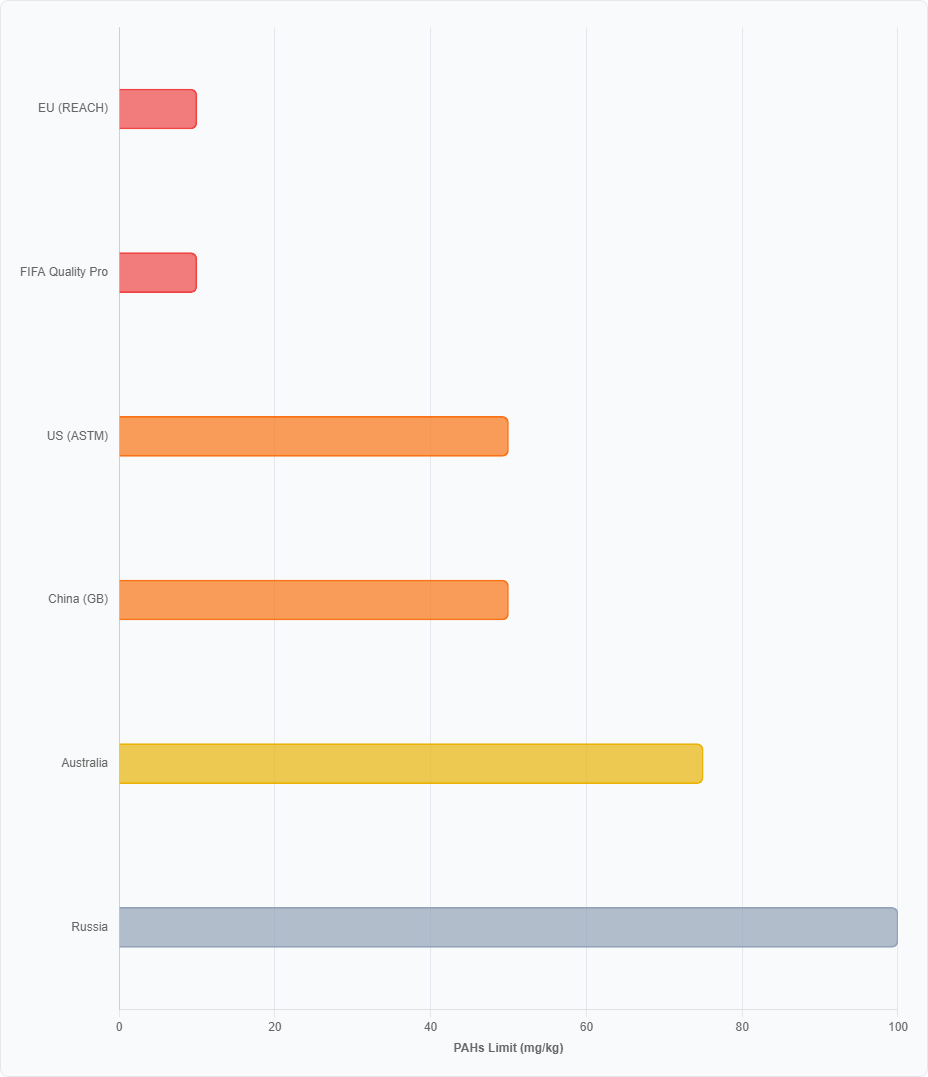

Global Limit Comparison for Polycyclic Aromatic Hydrocarbons (PAHs)

PAHs are a group of chemicals that can be present in carbon black used in tire manufacturing. Some PAHs are considered carcinogenic. Therefore, their presence in infill is strictly regulated. The most famous regulation is the European REACH directive, which sets a very low limit of 10 mg/kg for the sum of 8 specific PAHs. This is the de facto global benchmark for high-quality infill.

Other regions may have older or less stringent limits, sometimes as high as 100 mg/kg. However, the market trend is unequivocally moving towards the stricter REACH standard. Producers using advanced pyrolysis or chemical washing processes can reduce PAH content to levels below 5 mg/kg, future-proofing their product and accessing the most valuable markets in Europe and for international FIFA projects.

Test Condition Differences for Zinc Migration (Acidic vs. Neutral Simulant)

Zinc oxide is a key activator in the tire vulcanization process, and consequently, zinc is present in recycled rubber. Standards assess the potential for zinc to leach out into the environment using migration tests. However, the test conditions vary. Some standards use an acidic simulant (dilute hydrochloric acid) to represent worst-case scenarios like acid rain, while others use a neutral water simulant.

The choice of simulant dramatically affects the result. Zinc migration rates can be an order of magnitude higher in an acidic solution. A product might pass a test with a neutral simulant but fail with an acidic one. Therefore, understanding the specific testing protocols of your target market is essential. Producers may need to implement additional washing or leaching steps in their process if they aim for markets that enforce the acidic test condition.

Colorfastness Grade After UV Aging (Grade 8 vs Grade 5)

The aesthetic appearance of the infill, particularly its color stability under prolonged sunlight exposure, is tested through UV aging chambers. The resulting colorfastness is rated on a scale, often from 1 to 8, where 8 represents perfect stability and 1 represents severe fading. FIFA requires a high grade of 7-8 after 3000 hours of accelerated UV aging, ensuring the field maintains a consistent, professional appearance for years.

Lower-grade infill products may only achieve a rating of 4 or 5 after testing, indicating significant fading and graying. This is often due to the degradation of the rubber's polymer chains and the loss of carbon black from the surface. Achieving a high grade requires high-quality raw material (passenger car tires are best) and a gentle grinding process that does not overhear the rubber, which can make it more susceptible to UV degradation.

Water Flow Rate Parameters for Drainage Performance Testing

The drainage capability of a synthetic turf system is a critical performance and safety factor. It is tested by measuring how quickly water passes through a sample of the turf, including the infill. Standards define specific water flow rates for this test. For instance, a test might specify applying water at a constant rate of 50 liters per minute to a standardized sample and measuring the time for it to drain or the height of water retained.

A faster drainage time indicates a better-performing system. The infill plays a key role in this; improperly sized or contaminated infill can clog the pores between the turf fibers. Producers must ensure their granulate is free of fine dust and has a particle size distribution that promotes water flow rather than inhibiting it. This is a key functional test that links directly back to the efficiency of the production and cleaning process.

Environmental Compliance Control Points

Operating a tire recycling facility is subject to a wide range of environmental regulations designed to protect air, water, and soil quality. Proactive management of these compliance points is not just a legal obligation but also a social responsibility and a factor in maintaining a license to operate. The major control points involve the containment and treatment of airborne dust, the management of noise pollution for nearby communities, and the handling of process water and residual wastes.

A comprehensive environmental management system involves engineering controls, such as enclosed conveying systems and negative pressure buildings, continuous monitoring with sensors, and detailed record-keeping. Regular audits ensure that the facility meets all permit conditions. Investing in best-available technology for pollution control, while costly upfront, prevents fines, shutdowns, and reputational damage in the long run.

Design Specifications for Negative Pressure in Crushing Workshops

The primary shredding and granulation areas are the biggest sources of dust. A key engineering control is to design the entire crushing workshop as a negative pressure environment. This means that the air pressure inside the building is kept slightly lower than the atmospheric pressure outside. This is achieved by using powerful exhaust fans that pull air out of the building through dust filtration units.

The negative pressure ensures that when doors are opened, air rushes *into* the building rather than dust-laden air escaping out. All potential dust emission points are thus contained. The air exhausted from the building must pass through high-efficiency dust extraction systems, like baghouse filters, which capture 99.9% of particulate matter before the cleaned air is released into the atmosphere. This design is a fundamental requirement for modern, environmentally compliant facilities.

Noise Level Limits Measured by the 1-Meter Method

Industrial shredders are powerful and inherently noisy machines. Environmental permits strictly limit the noise that can emanate from a facility's property line. To control this, noise is measured at the source. The "1-meter method" involves taking sound level readings exactly one meter from the surface of a machine, in multiple directions.

A primary double shaft shredder might generate 110 dB(A) at 1 meter. To reduce this, enclosures fitted with acoustic damping panels are built around the equipment. These enclosures can reduce transmitted noise by 20-30 dB(A). Additionally, buildings are constructed with sound-insulating materials. The goal is to ensure that by the time the sound reaches the property boundary, it is below the legal limit, which is often 55-65 dB(A) during daytime hours, protecting the surrounding community from noise pollution.

Anti-seepage Grade Requirements for Leachate Collection Ponds

Stormwater runoff that comes into contact with tire stockpiles or processing areas can become contaminated and is classified as leachate. Regulations mandate that this water must be collected and treated before release or reuse. Collection ponds and storage tanks used for this purpose must be constructed to a specific anti-seepage grade, meaning they are impermeable to prevent contaminants from leaking into the underlying soil and groundwater.

This is typically achieved by lining the pond with a high-density polyethylene (HDPE) geomembrane, which is highly resistant to chemicals and punctures. The thickness and installation standards for this liner are specified in the facility's environmental permit. The collected leachate is then tested and treated, often in a closed-loop system where it is used for dust suppression on the site, minimizing freshwater consumption and ensuring zero discharge of wastewater.

Building Market Recycling Channels for Metal Waste

The steel wire recovered from tires is a high-quality scrap product. Establishing reliable recycling channels for this metal is a key part of the operation's economic and environmental model. This involves building relationships with local scrap metal dealers or directly with steel mills. The steel is often baled for efficient transportation.

This is not waste disposal but a genuine recycling loop. The tire-derived steel is melted down in electric arc furnaces and used to produce new steel products. Documenting this downstream recycling chain is increasingly important for sustainability reporting and certifications like ISO 14001. It demonstrates a circular economy approach, ensuring that every component of the end-of-life tire is converted into a valuable raw material for new industries.

Process Configuration for Typical Application Scenarios

The ideal production process for rubber infill is not universal; it is tailored to the specific requirements of the end-use application. The performance, safety, and cost criteria for a school playground are very different from those of a professional soccer stadium certified by FIFA. The process configuration, from the choice of equipment to the level of chemical purification, must be designed to meet these specific targets efficiently.

Factors such as budget, local climate, intended usage intensity, and the required certification level all influence the design. A producer may have several different product lines or a flexible system that can be adjusted to produce different grades of infill from the same core machinery, allowing them to serve multiple market segments effectively.

Daily Throughput Calculation for a 5-a-Side Football Field

Sizing a recycling plant often starts with a specific application. For example, a 5-a-side football field typically requires 15-20 tons of rubber infill. If a contractor has a project to install 10 such fields per month, they need a steady supply of 150-200 tons of infill. A recycling plant supplying this demand would need a daily processing capacity of approximately 7-10 tons of output infill, assuming 20 working days per month.

Factoring in process efficiency, material loss during separation, and a 10% waste factor, the plant would need to process roughly 12-15 tons of whole tires per day. This calculation directly informs the size of the primary shredder, the capacity of the separation equipment, and the required storage space. A single-shaft shredder with a 75-100 kW motor might be sufficient for this scale of operation, providing a clear link between end-market application and equipment selection.

Particle Size Distribution Requirements for FIFA Quality Pro Certification

The highest certification for soccer fields, FIFA Quality Pro, has strict guidelines for infill size and distribution. The granulate must be between 1-4 mm in diameter. Furthermore, the size distribution must be controlled: no more than 10% of the particles can be below 1mm, and no more than 3% can be above 4mm. This ensures optimal performance, providing the right balance of cushioning, stability, and rotational resistance for the ball and player movement.

Meeting this specification requires precise control over the entire grinding and screening process. Multiple stages of screening with precisely sized meshes are used to classify the granulate. The oversize material is recirculated for further grinding, and the fines are removed and diverted to other markets. This rigorous sizing is a key differentiator for premium infill products and is a non-negotiable requirement for supplying fields for professional leagues and international tournaments.

Low-Temperature Impact Testing Scheme for Ice Hockey Fields

In colder climates, synthetic fields for sports like ice hockey or multi-use recreational areas must perform in sub-zero temperatures. The rubber infill must not become brittle and lose its shock-absorbing properties. Standards for these applications include a low-temperature impact test, where a weighted missile is dropped onto a sample of the turf system that has been conditioned in a freezer at, for example, -25°C.

The force reduction and vertical deformation are measured and must remain within a specified range. This ensures the surface provides adequate protection for athletes even in freezing conditions. Producers targeting these markets may need to select their feedstock more carefully (certain rubber compounds perform better in the cold) and avoid processes that could make the rubber more susceptible to embrittlement.

Microbial Inhibition Coating Technology for Tropical Regions

In hot and humid tropical climates, microbial growth (mold, mildew, bacteria) on synthetic turf can become a problem, leading to unpleasant odors and potential health concerns. To combat this, specialized infill products incorporate microbial inhibition technology. This involves coating the rubber granules with a non-toxic, inorganic additive, such as silver ions or zinc-based compounds, that prevents microorganisms from proliferating.

These coatings are engineered to be long-lasting and not wash away, providing protection for the lifespan of the infill. This is a value-added feature that is essential for acceptance in markets in Southeast Asia, South America, and the southern United States. It represents an additional step in the production process but is critical for both performance and hygiene in these specific environmental conditions.

Key Quality Control Checkpoints

Maintaining consistent product quality is essential for customer satisfaction and compliance with international standards. A robust Quality Control (QC) system implements checkpoints at multiple stages of the production process: at the incoming raw material stage, during processing (in-process control), on the finished product, and through periodic environmental audits. This multi-layered approach catches deviations early, preventing the production of large quantities of non-conforming product.

Modern QC labs are equipped with sophisticated instruments for chemical and physical analysis. The data collected is not only used for release testing but is also fed back to production teams to help them optimize process parameters. This closed-loop system of measurement, analysis, and adjustment is what separates a premium supplier from a commodity producer.

Rapid Screening Application of XRF Spectrometers for Incoming Materials

Handheld X-Ray Fluorescence (XRF) spectrometers are a vital tool for rapid incoming inspection of truckloads of tires. This device can analyze the elemental composition of a material in seconds without damaging it. By pointing the gun at a tire, operators can screen for undesirable elements that might indicate contamination.

For instance, an abnormally high reading for chlorine could indicate the presence of PVC or other chlorinated compounds, which are not suitable for infill production and can produce harmful dioxins if processed. Similarly, elevated levels of heavy metals like cadmium or lead would be immediate cause for rejection. This rapid screening at the gate prevents contaminated feedstock from entering the production stream and compromising an entire batch of product.

Online Integration Scheme for Laser Particle Size Analyzers

To ensure the final product consistently meets the strict size distribution specifications, modern plants integrate laser particle size analyzers directly into the production line. A small sample of the granulate is automatically diverted from the main conveyor on a periodic basis and fed into the analyzer. The instrument uses the principle of laser diffraction to measure the size of thousands of particles in a few seconds, generating a complete distribution curve.

This data is fed directly to the Plant's PLC control system. If the analysis shows a trend towards particles becoming too large or too fine, the system can automatically adjust the speed of the granulator or the screening units to correct the deviation in real-time. This level of automation ensures unparalleled consistency and reduces reliance on manual sampling and offline lab analysis.

Parameter Settings for Dynamic Compression Testing Machines

The shock absorption properties of the infill are tested using a dynamic compression test. A weighted hammer is dropped from a specified height onto a sample of the infill, and the force of the impact is measured. The key parameter is Force Reduction, which is the percentage by which the infill reduces the impact force compared to a solid concrete surface. For FIFA Quality Pro, this must be between 60-70%.

Calibrating the testing machine correctly is critical. Parameters like the drop height, hammer weight, and data acquisition rate must be set exactly as prescribed by the standard (e.g., EN 14808). Even minor deviations can lead to inaccurate results. QC labs perform this test on every production batch to certify that the product provides the required level of athlete protection.

VOC Collection Specifications for Micro-Environmental Chamber Testing

Volatile Organic Compound (VOC) emissions from infill are a major area of regulatory focus. Testing is conducted by placing a sample of the infill in a sealed micro-environmental chamber, which is maintained at a specific temperature and humidity (e.g., 60°C, 5% relative humidity). Air is passed through the chamber at a controlled rate, and the outgoing air is collected on special adsorption tubes.

These tubes are then analyzed in a laboratory using gas chromatography-mass spectrometry (GC-MS) to identify and quantify the VOCs present. The entire chamber operation and sampling process follows strict protocols to ensure the results are accurate, reproducible, and comparable across different labs and suppliers. Products must demonstrate VOC emissions below the thresholds set by standards like ISO 16000-9 to be deemed safe for indoor or enclosed sports facilities.

Future Technology Development Trends

The tire recycling industry is continuously evolving, driven by advances in technology and increasing demands for sustainability and traceability. The next generation of processes will likely be smarter, more efficient, and more integrated with digital technologies. These trends point towards a future where tire recycling is a fully optimized, data-driven operation that produces consistently high-quality materials for a circular economy.

Key areas of development include novel biological and chemical processes for breaking down rubber, artificial intelligence for purifying material streams, and blockchain technology for providing irrefutable proof of compliance and sustainability to end customers. Adopting these technologies early will provide a significant competitive advantage in the marketplace.

Research Progress in Enzymatic Treatment of Aged Rubber

One of the most promising areas of research is the use of specially engineered enzymes to break down the sulfur cross-links in vulcanized rubber—a process called devulcanization. Traditional devulcanization uses heat and chemicals, which can damage the rubber polymer chains. Enzymatic devulcanization offers a "cold," highly specific alternative.

Researchers are identifying and optimizing enzymes that can target and break the carbon-sulfur and sulfur-sulfur bonds that form the cross-links, without damaging the main polymer backbone. This would allow the rubber to be truly "re-vulcanized" into new products, moving beyond simple downcycling into infill and towards a genuine circular loop for tire rubber. While still largely in the lab phase, progress in bioengineering could make this a commercial reality within the next decade.

Application of Vision Systems in Fiber Separation

Traditional methods for separating fiber from rubber rely on differences in size, density, or aerodynamics. However, these methods are not perfect. Advanced sorting systems are now incorporating high-resolution vision systems and artificial intelligence. These systems use high-speed cameras to scan the stream of granulate on a conveyor belt.

An AI algorithm, trained on thousands of images, can identify and differentiate between rubber granules and foreign materials like fiber or leftover metal fragments in milliseconds. Upon detection, a precise jet of compressed air is triggered to eject the contaminant from the stream. This technology can achieve purification levels beyond 99.9%, significantly boosting product quality and enabling the recycling of more challenging feedstock.

Development of Real-Time Process Parameter Optimization Algorithms

The future of plant operation lies in full automation and optimization through machine learning. Sophisticated algorithms can analyze real-time data from all parts of the process: motor load on the shredder, power consumption, particle size distribution from online analyzers, and product quality data from the lab. The algorithm learns the complex relationships between these variables.

Once trained, the system can autonomously adjust process parameters—like feed rate, rotor speed, and screen sizes—in real-time to maximize throughput, minimize energy consumption, and ensure the final product consistently meets its quality specifications, all without human intervention. This moves operation from reactive control to predictive and prescriptive optimization, squeezing the maximum efficiency and profitability from the production line.

Construction of Interconnected Global Standards Databases

As the global market for recycled products grows, navigating the patchwork of international standards becomes increasingly complex. A emerging trend is the development of interconnected, digital databases that compile all relevant standards, regulations, and testing requirements for materials like rubber infill in different countries.

A producer could query this database to instantly generate a compliance checklist for exporting to a new market. Furthermore, with the integration of blockchain technology, the results of quality control tests and certifications could be immutably recorded and instantly shared with customers and regulators anywhere in the world. This digital infrastructure will greatly reduce trade barriers for recycled products and build trust through transparent, verifiable data.