Selecting the right tire shredder is a critical decision that goes beyond just the initial purchase price. It involves a delicate balancing act between processing capacity and the total cost of ownership over the entire lifespan of the machine. A shredder that is too small will become a bottleneck, while an oversized machine leads to unnecessary capital expenditure and higher operational costs. The key is to find the optimal point where the machine's throughput efficiently meets your production goals while minimizing long-term expenses related to energy, maintenance, and wear parts. This art of balance ensures a profitable and sustainable tire recycling operation, turning end-of-life tires into valuable crumb rubber, steel, and fiber.

Modern industrial shredders, like a double shaft tire shredder, are engineered to handle the tough and abrasive nature of tires. They utilize powerful shear and tearing forces to reduce whole tires into smaller, uniform chips. The selection process must consider the specific type of tires being processed, the desired output size for downstream markets, and the integration of separation technologies. For instance, a facility aiming to produce fine crumb rubber for athletic fields will require a different setup than one producing tire-derived fuel (TDF). Understanding these core needs is the first step in mastering the selection process.

Understanding the Core Needs of Tire Processing

Before investing in a shredding system, a comprehensive analysis of the raw material and the final product is essential. Not all tires are created equal; their size, construction, and composition vary significantly. A passenger car tire is far easier to process than a massive off-the-road (OTR) mining tire, which may require specialized heavy-duty equipment. The volume of tires to be processed hourly, daily, or annually directly dictates the size and power of the machinery needed. Furthermore, the presence of steel belts and textile fibers within tires adds another layer of complexity, requiring robust shredders capable of handling these mixed materials without excessive wear.

The output requirements are equally crucial. The desired chip size influences the entire equipment configuration, potentially requiring a multi-stage process involving primary and secondary shredding. A primary shredder might break whole tires into 2-inch chips, while a secondary granulator or mill reduces them further to a half-inch or smaller. Each stage must be perfectly synchronized to achieve a seamless and efficient production flow, maximizing output and minimizing energy consumption per ton of material processed.

Correlation Between Tire Type and Shredding Difficulty

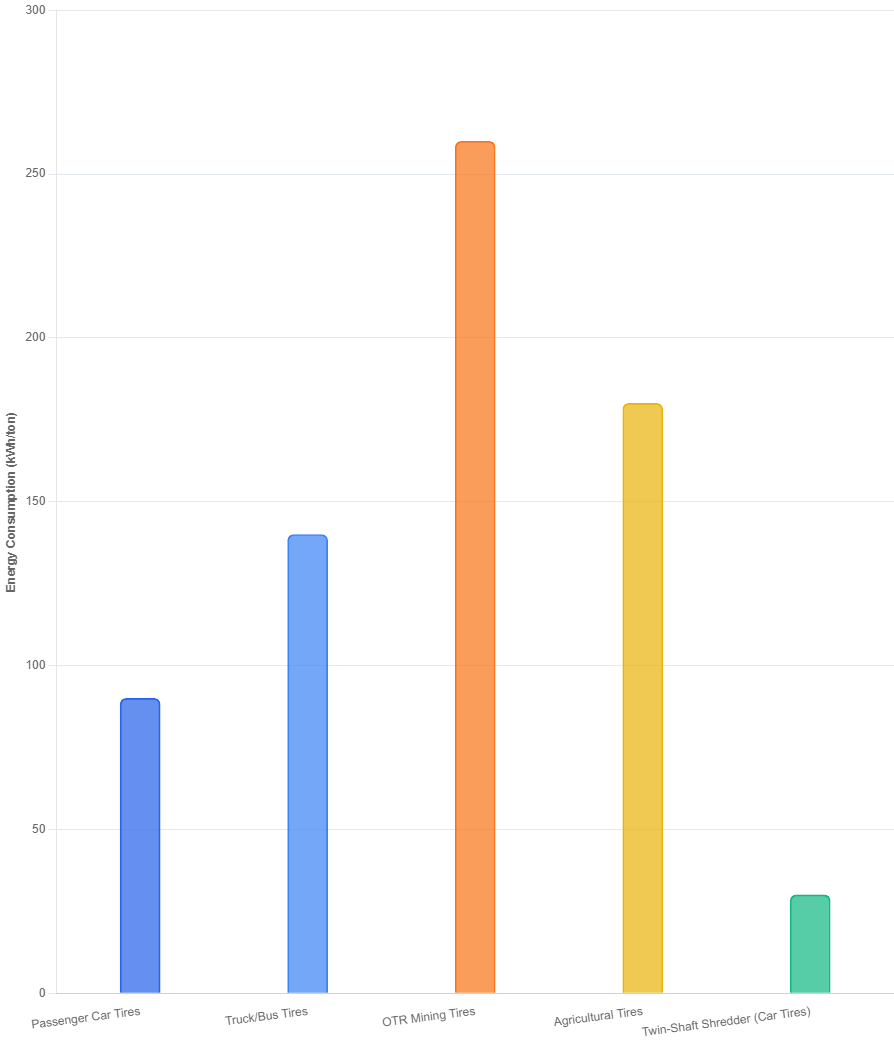

The physical properties of different tire types directly impact shredder selection. Passenger car tires, which make up the majority of waste streams, are relatively uniform and easier to shred. In contrast, truck and bus tires contain thicker rubber and more steel, demanding shredders with higher torque and more durable cutting elements. The most challenging are OTR and agricultural tires; their immense size, often over 2 meters in diameter, and extreme toughness require massive, powerful primary shredders with hydraulic rams to force the material into the cutting zone.

Shredding difficulty is measured by the energy required to cut through the rubber and steel. For example, a standard car tire might require a specific energy input of 80-100 kWh per ton, while an OTR tire can demand over 250 kWh per ton. This difference means a shredder designed for a mixed stream must be overpowered for the smaller tires to ensure it can handle the toughest ones, highlighting the need for careful feedstock analysis.

Mathematical Model for Throughput (TPH) and Equipment Sizing

Determining the required throughput in tons per hour (TPH) is a mathematical foundation for equipment selection. This calculation starts with the total annual volume of tires to be processed. For instance, a facility planning to process 10,000 tons per year with 7,000 operational hours needs an average throughput of approximately 1.4 TPH. However, this average must be adjusted for peak loading and operational efficiency. Industry standards suggest using an overall equipment effectiveness (OEE) factor of 70-80% for shredding operations, meaning the machine's maximum capacity should be around 1.8-2.0 TPH to reliably achieve the 1.4 TPH target.

This TPH target then dictates the power and size of the tire shredder. A rough industry guideline is that processing car tires into 2-inch chips requires about 40-50 horsepower per ton per hour. Therefore, a 2 TPH system would typically need a 100 HP motor. This model ensures the selected machine has sufficient power to handle the load without constant overloading, which extends component life and reduces downtime.

Influence of Output Size on Downstream Recycling Processes

The final size of the shredded material is not arbitrary; it is dictated by its intended market or subsequent processing steps. Larger chips, around 2 to 6 inches, are ideal for Tire-Derived Fuel (TDF) used in cement kilns or power plants, as they flow easily and burn efficiently. Medium-sized chips, approximately 1 to 2 inches, are often used as playground mulch or in civil engineering applications. For the highest value application—crumb rubber used in new products or athletic surfaces—a much finer granulate of less than 1/4 inch is required.

Each output size necessitates different equipment. Achieving TDF chips may only require a single-pass through a primary shredder. Producing crumb rubber, however, requires a multi-stage system: a primary shredder, a secondary granulator, and sometimes even a fine mill. Each stage adds capital and operational cost, so the choice of output size is a significant economic decision that affects the entire recycling plant's design and profitability.

Equipment Compatibility Requirements for Mixed Material Handling

Tires are a composite material of rubber, high-tensile steel bead wire, and textile fabric. A shredder must not only cut the rubber but also manage the metal and fiber without jamming or suffering accelerated wear. This requires compatible material handling systems integrated with the shredder. Immediately after the primary shredding stage, a powerful magnetic separator is used to extract the steel wire, which can be sold as scrap.

The remaining material, now rubber and fiber, may proceed to a secondary shredder where the fiber is liberated from the rubber. Air classifiers or oscillating screens are then used to separate the lightweight fiber from the heavier rubber granules. Equipment compatibility is key; the conveyors, separators, and shredders must be matched in capacity and designed to handle the abrasive nature of the material to ensure a continuous, clog-free operation from start to finish.

Main Types of Shredding Equipment and Their Capacity Characteristics

The heart of any tire recycling plant is the shredding equipment itself. There are several main types, each with distinct mechanisms and performance profiles suited for different stages of the size reduction process. The most common configurations are single-shaft, double-shaft, and four-shaft shredders, each employing a different method to tear apart the tires. The choice between them depends on the required input size, output size, and the need for subsequent material separation.

Beyond the shredder type, the overall system design plays a crucial role in defining capacity. A primary shredder works in tandem with a secondary granulator to achieve fine output. Furthermore, plants must decide between continuous-feed systems, which offer higher throughput for large volumes, and batch systems, which might be more suitable for smaller or more varied feedstock. Modern designs often incorporate modularity, allowing facilities to start with a basic setup and expand capacity by adding modules as their business grows.

Shearing Efficiency of Twin-Shaft Shredders

Twin-shaft shredders are the workhorses of primary tire reduction. They feature two parallel rotors equipped with cutting discs that intermesh and rotate at low speeds but with high torque. This action creates a powerful shearing and tearing force that rips tires apart into manageable chips. Their key advantage is their ability to process whole tires of various sizes with minimal pre-processing, and their slow-speed, high-torque operation is inherently robust and reliable, reducing the risk of jamming and minimizing wear.

The efficiency of a twin-shaft shredder is measured by its ability to produce a consistent output size with low energy consumption per ton. Modern designs feature optimized rotor geometry and cutting knife placement to maximize the shear angle, reducing the force required per cut. This directly translates to lower energy costs. For example, an efficient twin-shaft model can process passenger car tires at a rate of 10-15 tons per hour with a specific energy consumption of around 25-35 kWh per ton, making them highly effective for the initial size reduction stage.

Particle Size Control in Granulators

Following primary shredding, secondary size reduction is often handled by granulators or hammer mills. Granulators use a high-speed rotor equipped with knives that work against stationary bed knives to slice the pre-shredded chips into smaller, more uniform particles. The output size is precisely controlled by a screen grate encircling the rotor; material remains in the cutting chamber until it is small enough to pass through the screen's holes. This allows for excellent control over the final product size, which is critical for high-value applications.

The capacity of a granulator is directly linked to the screen size and the horsepower of the motor. A smaller screen size (e.g., 10mm) will naturally have a lower throughput than a larger screen (e.g., 30mm) on the same machine because it takes more cuts and more time to reduce the material to a finer size. For instance, a 200 HP granulator might achieve 2.5 TPH with a 20mm screen but only 1.8 TPH with a 10mm screen. This trade-off between fineness and capacity must be carefully considered during system design.

Capacity Limiting Factors of Cryogenic Grinding Technology

Cryogenic grinding is a specialized alternative to mechanical shredding for producing very fine rubber powder. In this process, pre-shredded tire chips are cooled to extremely low temperatures (below -80°C) using liquid nitrogen, making the rubber brittle. The brittle material is then fed into a hammer mill or impact mill where it fractures into tiny particles. While this method excels at producing high-quality, fine powder with minimal heat degradation, it has significant capacity constraints and high operational costs.

The primary limiting factor is the immense cost and logistics of liquid nitrogen, which can account for over 50% of the operational expenses. The process is also more complex, requiring insulated feed systems and precise temperature control. Consequently, cryogenic grinding is generally not used for high-volume bulk reduction but is reserved for niche applications where the superior quality of the powder justifies the substantially higher cost per ton processed, often for use in high-value rubber compounds.

Impact of Automated Feeding Systems on Continuous Production

An often-overlooked aspect of shredder capacity is the efficiency of the feeding system. Manual feeding with forklifts is inconsistent and can lead to shredder starvation or overload, reducing overall efficiency. An automated feed system, such as a conveyor belt with a metering device or a hydraulic ram, ensures a consistent and optimal flow of material into the shredder's hopper. This allows the shredder to operate at its designed capacity continuously, maximizing throughput and protecting the machine from the damage caused by uneven loading.

For a hydraulic ram feeder, the system forcefully pushes whole tires or large fragments into the cutting rotors. This constant pressure ensures the rotors are always engaged with material, preventing the "no-load" condition that wastes energy and causes unnecessary wear on the cutting elements. In high-capacity plants, automated feeding is not a luxury but a necessity for achieving the designed ton-per-hour rates and ensuring the long-term mechanical health of the shredding equipment.

Total Lifecycle Cost Components

The purchase price of a tire shredder is just the beginning of its financial story. The total lifecycle cost (TLC) provides a more accurate picture of the investment, encompassing all expenses from acquisition to disposal. This includes the initial capital expenditure (CAPEX), ongoing operational expenditures (OPEX) like energy and labor, maintenance and repair costs, and finally, the machine's residual value. A cheaper machine with high energy consumption and frequent breakdowns can ultimately be far more expensive than a higher-priced, efficient, and reliable model.

Key factors influencing TLC include the wear rate of cutting knives and other replaceable parts, which require periodic shutdowns for replacement. Energy consumption is another major contributor, as shredders are powerful machines that can run for thousands of hours per year. Furthermore, the complexity of maintenance and the resulting machine availability directly impact revenue; unplanned downtime means lost production. A sophisticated analysis weighs all these factors over an expected equipment lifespan of 7-10 years to determine the true cost of ownership.

Cost-Benefit Analysis of Knife Materials (HSS vs. Carbide)

The choice of cutting knife material is a critical trade-off between initial cost and longevity. High-Speed Steel (HSS) knives are a common and less expensive option upfront. They are tough and can be sharpened multiple times, but they wear down relatively quickly when processing abrasive materials like tires filled with grit and steel wire. A set of HSS knives might need to be replaced or re-sharpened after processing every 500-1,000 tons of material, leading to frequent downtime and labor costs.

Tungsten Carbide Tipped (TCT) knives represent a significant advancement. While they can cost 3-5 times more than HSS knives initially, their wear resistance is vastly superior. A set of TCT knives can process 5,000 to 10,000 tons of tires before requiring service. This extends service intervals by a factor of ten, drastically reducing downtime, labor costs for changes, and the number of spare parts needed in inventory. For high-volume operations, the return on investment for TCT knives is usually very positive, making them the preferred choice despite the higher initial price.

Monitoring Methods for Motor Power and Actual Energy Consumption

Energy is one of the largest operational costs for a shredding plant. A large primary shredder can have a motor rated at 500 kW or more. Therefore, monitoring and optimizing energy use is paramount for controlling lifecycle costs. Modern shredders are equipped with PLCs (Programmable Logic Controllers) that monitor the motor's amperage draw in real-time. This amperage is directly proportional to the power (kW) being consumed and the torque being generated by the shredder.

By analyzing this data, operators can identify optimal feeding patterns that keep the motor loaded within its most efficient operating range (typically around 80-95% of full load). Running the motor too lightly is inefficient, while consistent overloading trips breakers and causes damage. Furthermore, tracking kWh per ton of processed material provides a key performance indicator (KPI) for the entire operation, allowing managers to pinpoint inefficiencies and compare performance against industry benchmarks, which can range from 25 to over 100 kWh/ton depending on the process.

Impact of Standardized Wear Parts on Maintenance Costs

Maintenance downtime is a major cost driver. A key strategy to minimize this is the use of standardized, easily replaceable wear parts. This includes not only knives but also screen grates, bearing units, and hydraulic components. Standardization means that parts are readily available from multiple suppliers, reducing procurement lead times and cost. It also simplifies the inventory a facility must hold on-site, lowering carrying costs.

For example, a shredder designed with a bolted-in knife cartridge system allows mechanics to replace a full set of knives in a matter of hours instead of days. The old cartridge is unbolted and a pre-assembled, pre-balanced new one is installed. This minimizes machine downtime and requires less specialized tooling and labor skill compared to traditional methods where each individual knife is painstakingly removed and replaced. This design philosophy directly translates to higher overall equipment effectiveness (OEE) and lower lifetime maintenance expenses.

Role of Smart Monitoring Systems in Improving OEE

Overall Equipment Effectiveness (OEE) is a metric that measures how effectively a manufacturing operation is utilized. It is a combination of availability, performance, and quality. Smart monitoring systems are now integral to maximizing OEE for industrial shredders. These systems use a network of sensors to track vibration, temperature, torque, and power consumption, feeding this data to a central PLC control panel.

The system can provide early warnings of potential problems, such as a bearing that is beginning to fail (indicated by rising vibration levels) or a knife that is becoming dull (indicated by a gradual increase in energy consumption for the same throughput). This enables predictive maintenance, where repairs are scheduled during planned downtime instead of resulting in catastrophic unplanned failures. By preventing major breakdowns and optimizing performance, smart monitoring can boost OEE from a typical 70% to over 85%, significantly impacting the profitability and lifecycle cost of the shredding asset.

Strategies for Optimizing the Balance Between Capacity and Cost

Achieving the perfect equilibrium between high throughput and low operational cost requires a strategic approach to system design and operation. It is not just about selecting individual machines but about optimizing how they work together as a complete system. Strategies include implementing intelligent controls that dynamically adjust machine parameters based on the load, incorporating effective pre-processing steps to reduce the burden on the main shredder, and designing flexible systems that can adapt to varying feed materials and market demands.

The goal is to create a smooth, efficient material flow that minimizes energy peaks, reduces wear on components, and maximizes the value of the output products. This often involves a holistic view of the entire recycling line, from the moment tires are unloaded to the final packaging of rubber crumb, steel, and fiber. By analyzing each step for potential improvements, operators can squeeze out inefficiencies and create a highly competitive operation with an optimal cost-per-ton.

Energy Optimization Effect of Variable Frequency Drive (VFD) Technology

A Variable Frequency Drive (VFD) is a crucial component for optimizing energy consumption in shredder motors. A VFD controls the speed and torque of an AC electric motor by varying the frequency and voltage of its power supply. During the shredding process, the load on the motor is not constant; it spikes when a tough section of steel wire is encountered and drops when cutting through softer rubber. Without a VFD, the motor runs at a constant speed, wasting energy during low-load moments.

A VFD allows the motor to slow down slightly when the load is light, reducing energy draw. When a high-torque demand is sensed, the VFD provides the necessary power to overcome it without stalling. This results in significant energy savings, typically in the range of 15-25%, and also provides a soft start function that reduces mechanical stress on the drive train. The investment in VFD technology often has a payback period of less than two years through electricity savings alone.

Reducing Shredding Load via Magnetic and Air Separation Pre-processing

One of the most effective ways to lower the cost and wear on a shredder is to remove non-shreddable materials before they even enter the machine. While tires themselves are shreddable, they often contain dirt, rocks, and other contaminants that accelerate wear. More importantly, the steel bead and belt wire are extremely abrasive. Implementing a powerful overband magnet on the feed conveyor can remove loose metal objects before they enter the shredder.

After the primary shredding stage, the steel wire is liberated but mixed with the rubber chips. Immediately passing this output stream under another magnetic separator removes up to 99% of the steel. This means the secondary shredding or granulation stage processes almost pure rubber, drastically reducing wear on its knives and screens. This pre-removal of abrasive material can extend the life of secondary size reduction components by 200% or more, representing a huge saving on maintenance and parts replacement costs over the life of the equipment.

Synergistic Advantages of Integrated Shredding and Sorting Equipment

The highest efficiency is achieved when shredding and sorting equipment are designed as an integrated system rather than a collection of separate machines. In an integrated design, conveyors are perfectly matched in speed and capacity, transfer points are optimized to prevent material jamming or spillage, and sorting units are placed immediately after the shredding stage where they are most effective. The control system is unified, allowing the entire line to be monitored and adjusted from a single interface.

This synergy ensures that a bottleneck in one area does not limit the entire line. For example, if the magnetic separator becomes full, the control system can momentarily pause the shredder feed conveyor to allow the separator to clear, preventing a backup that could jam the shredder discharge. This level of coordination maximizes the throughput of the entire system, reduces manpower requirements, and ensures consistent product quality, all of which contribute to a lower cost per ton of processed material and a faster return on investment.

Ability of Flexible Production Modes to Respond to Demand Fluctuations

Market demand for recycled tire products can fluctuate. A cost-effective operation must have the flexibility to adapt its production mode without sacrificing efficiency. This can be achieved through system design. For example, a plant can be designed with bypass conveyors that allow material to be routed to different paths. In high demand for TDF, the primary shredded chips can be sent directly to storage, bypassing the secondary granulation stage entirely, saving energy and wear on the finer grinding equipment.

This flexibility can also be built into the shredders themselves. Some modern shredders offer quick-change screen systems or adjustable cutting gaps, allowing operators to switch between producing a coarse and a medium output size within minutes. This ability to pivot production based on real-time market demands ensures that the operation can always produce the highest-value product possible, maximizing revenue and protecting against the risk of idle equipment and inventory buildup.

Cost-Benefit Case Studies in Typical Application Scenarios

Real-world examples best illustrate the principles of balancing capacity and lifecycle cost. The optimal equipment configuration varies dramatically based on the scale of the operation, its location, and its target markets. A small local recycling station has vastly different needs and financial constraints than a large regional tire processing facility. Analyzing these scenarios helps to ground the theoretical concepts in practical economic reality.

Factors such as local labor costs, electricity rates, and transportation expenses for feedstock and finished products all play a significant role in the calculation. A mobile shredding solution might have a higher cost per ton processed but can be economically superior for a distributed waste stream by eliminating transportation costs for whole tires. These case studies demonstrate that there is no one-size-fits-all solution and that a customized approach is essential for financial success.

Modular Equipment Combination Scheme for Small and Medium Enterprises

A small to medium enterprise (SME) aiming to process 50 tons of tires per day faces a typical capital constraint. A modular approach offers a perfect solution. The operation might start with a core module: a mid-sized single-shaft shredder with a 150 kW motor and an integrated magnetic separator, capable of producing 2-3 TPH of clean rubber chips. This initial setup allows the business to generate revenue from TDF and scrap steel while keeping the initial investment manageable.

As the business grows, a secondary module can be added: a granulator with a 100 kW motor and various screens to produce finer rubber crumb for higher-value markets. The modules are designed to work together from the outset, so integration is seamless. This phased investment strategy spreads the capital expenditure over time, aligns costs with revenue growth, and allows the business to adapt its product line based on market experience, significantly reducing financial risk compared to building a large, expensive plant from day one.

Fully Automated Turnkey Solution for a Large-Scale Factory

A large-scale factory processing 5万吨 (50,000 tons) per year requires a completely different approach. Here, the emphasis is on maximizing throughput and minimizing labor costs through full automation. The solution would be a turnkey system featuring a high-capacity primary double shaft shredder (e.g., 1000+ kW), automated feed conveyors with metal detection, and a series of secondary granulators. The entire material handling between stages would be via enclosed conveyors and air systems to control dust.

The sorting process would be comprehensive, including multiple stages of magnetic separation, air classification to remove fiber, and even optical sorting to ensure product purity. A central PLC would control the entire process, monitoring energy consumption, predicting maintenance needs, and providing production data in real-time. While the capital investment is substantial (often in the multi-million dollar range), the incredibly low cost per ton achieved through economies of scale, automation, and high uptime makes it a profitable venture, provided a consistent feedstock supply and product offtake agreement are in place.

Application of Mobile Shredding Stations in Landfills

For landfills or large collection points where tires are scattered over a wide area, transporting them to a central processing plant is logistically complex and expensive. A mobile shredding station presents an excellent cost-benefit case. This unit typically integrates a diesel-powered primary shredder, a magnetic separator, and a generator all mounted on a semi-trailer. It can be moved from site to site, processing tires directly where they are stockpiled.

The key financial benefit is the drastic reduction in transportation costs. Instead of hauling whole tires, which are mostly air, the mobile station reduces them to dense chips, reducing the number of truckloads needed to transport the processed material by up to 75%. This saves on fuel, labor, and trucking fees. The higher operational cost of the mobile unit (due to diesel power and higher wear from varied conditions) is more than offset by the savings in logistics, making it the most economical solution for decentralized tire piles.

Cost Considerations for Anti-freeze Design in Cold Regions

Operating tire shredding equipment in cold climates introduces unique challenges that impact lifecycle cost. Tires become stiffer and more difficult to shred at low temperatures, increasing the energy requirement and mechanical stress on the machine. Furthermore, hydraulic systems can suffer if the fluid becomes too viscous, and water used in dust suppression can freeze, damaging pipes and pumps.

Equipment for these regions requires specific design features, such as insulated and heated enclosures for the hydraulic power unit, synthetic hydraulic fluids with a low pour point, and trace heating on water lines. The shredder housing itself may need extra insulation to retain the minimal heat generated by the process. These anti-freeze measures add 5-10% to the initial equipment cost. However, this investment is essential to avoid massive operational losses from winter downtime, frozen equipment damage, and the significantly higher energy consumption of trying to process frozen tires without these supportive systems.

Influence of Future Technology Trends on Selection Decisions

Investing in a tire shredder is a long-term commitment, so it is prudent to consider how emerging technologies might impact the industry during the machine's operational life. Trends in automation, material science, and energy efficiency are rapidly transforming industrial processes. A shredder selected today should, where possible, be "future-proofed" to accommodate these advancements, either through adaptable design or by choosing suppliers who are leaders in innovation.

Technologies like artificial intelligence for process optimization, the Internet of Things (IoT) for predictive maintenance, and new wear-resistant materials for cutting components are already moving from concept to reality. Furthermore, the global push towards carbon neutrality is driving the development of energy recovery systems that can capture and reuse the heat generated by the shredding process. Understanding these trends allows an investor to make a selection that will remain efficient and competitive for years to come.

Application of Machine Learning Algorithms in Knife Wear Prediction

Machine learning (ML) is taking predictive maintenance to a new level. Instead of simply alerting operators to a potential problem, ML algorithms can predict the remaining useful life (RUL) of shredder knives with high accuracy. The system is trained on historical data, including power consumption patterns, motor torque curves, acoustic emissions, and vibration spectra recorded throughout the life of previous knife sets. It learns to recognize the subtle signatures that indicate progressive wear.

This allows for incredibly precise maintenance scheduling. The system can forecast, for example, that a specific set of knives will need replacement in 147 hours of operation. This enables the plant manager to order the exact parts needed and schedule the maintenance during a planned weekend shutdown, maximizing production uptime and eliminating the cost and safety risks associated with unexpected knife failures. This technology transforms maintenance from a reactive cost center into a predictable, planned operation.

Optimization of Equipment Commissioning via Digital Twin Technology

A digital twin is a virtual, dynamic model of a physical shredding system. Before any metal is cut or concrete poured for a new plant, engineers can build and test the entire process in a simulation environment. The digital twin can model material flow, energy consumption, potential bottlenecks, and even wear patterns on components under different operating scenarios. This allows for the optimization of the system layout and equipment selection before any capital is spent.

During commissioning, the digital twin remains connected to the physical machine via sensors. Operators can test new parameters (e.g., rotor speed, feed rate) in the simulation first to predict the outcome before implementing them on the actual equipment. This drastically reduces the time and risk associated with commissioning, ensures the system reaches its peak performance faster, and prevents costly misconfigurations that could lead to damage or suboptimal operation.

Enhancement of Knife Performance through Nano-coating Technology

The ongoing quest for greater wear resistance has led to the development of advanced nano-coatings for shredder knives. These coatings, such as diamond-like carbon (DLC) or advanced ceramic composites, are applied in layers only a few micrometers thick at the nanoscale. They significantly increase the surface hardness of the knife, reducing friction and providing a barrier against abrasion and adhesion.

A nano-coated knife can exhibit up to a 300% increase in service life compared to an uncoated equivalent. While the coating process adds to the knife's initial cost, the extension in lifespan and the reduction in changeover downtime provide a substantial return on investment. This technology is particularly beneficial for the final fine-grinding stages where wear is most acute due to the increased surface area of the material being processed. As this technology matures and becomes more cost-effective, it will become a standard feature for high-performance shredding operations.

Application of Heat Recovery Systems in the Shredding Process

Shredding is an energy-intensive process that converts electrical energy into mechanical energy and, ultimately, into heat through friction. A significant amount of this heat is wasted, dissipating into the machine structure and the surrounding air. Heat recovery systems capture this wasted thermal energy and repurpose it, contributing to the plant's carbon neutrality goals and reducing operating costs.

For instance, a closed-loop water cooling system can be installed to circulate water through channels in the shredder's bearing housings and gearbox. The heated water is then passed through a heat exchanger to warm the facility's offices or to pre-heat water used in other processes, such as cleaning or steam production. In large facilities, this recovered heat can offset a meaningful portion of the building's heating requirements, turning a waste product into a valuable resource and improving the overall energy efficiency of the recycling operation.