At the heart of every industrial shredder lies its cutting system, and the knives are the components that directly interact with and process the waste material. The design, engineering, and material selection of these knives are paramount to the shredder's overall performance, efficiency, and operating costs. This guide delves into the science behind shredder knives, explaining how their geometry and composition directly influence critical factors like wear resistance, energy consumption, maintenance frequency, and the total cost of processing each ton of material.

The Core Function of Shredder Knives and The Challenges They Face

Shredder knives are subjected to one of the most punishing environments in industrial machinery. They are the primary agents of size reduction, tasked with fracturing a vast and unpredictable array of materials. Their performance dictates the productivity of the entire machine, making them a focal point for operational optimization and cost management.

Shear, Tear, and Impact: The Multiple Roles of Knives in Material Size Reduction

Knives perform a complex combination of actions. Initially, they must impact and penetrate the feed material. Hook-shaped knives are designed to grab and tear tough, flexible items. Once engaged, the opposing motion of the shafts and the sharp edges of the knives apply a powerful shearing force to cut the material. The specific design of the knife determines the proportion of tearing versus clean shearing that occurs during processing.

Extreme Working Loads: Abrasive Wear, Impact Loading, and Corrosive Environments

Knives face a relentless assault. Abrasive wear is caused by hard minerals, sand, and glass within the waste stream, slowly grinding away the cutting edge. Impact loading occurs when the knives strike non-shreddables like metal chunks or when processing very hard materials, potentially causing chipping or catastrophic failure. Furthermore, a corrosive environment from wet or chemically-laden waste can accelerate the degradation of the knife surface.

Primary Failure Modes of Knives: Wear, Chipping, Fracture, and Corrosion

The end of a knife's service life can manifest in several ways. Normal abrasive wear gradually dulls the edge, increasing the cutting force required. Chipping occurs on the cutting edge due to high-impact shocks. A complete fracture of the knife body is a severe failure often caused by an uncrushable object or material fatigue. Corrosion can pit and weaken the surface, exacerbating other wear mechanisms.

Key Performance Indicators: Service Life, Tonnage Processed, and Maintenance Intervals

Knife performance is measured objectively. Service life is often tracked in operating hours or by the total tonnage of material processed before sharpening or replacement is needed. The interval between maintenance events is a direct function of knife durability. Extending these intervals is a primary goal of knife optimization, as it directly reduces downtime and labor costs.

The Geometry of Knife Design: How Shape and Angles Affect Shredding Efficiency

The physical design of a knife is a precise science that balances cutting efficiency, strength, and longevity. Even a knife made from the best material will perform poorly if its geometry is wrong for the application. The shape determines how force is applied to the material, influencing power demand and the quality of the output.

Classification of Knife Geometries: Hook, Square, Serrated and Their Applications

Different knife shapes are tailored for specific materials. A hook-shaped knife has a pronounced grabby profile, ideal for pulling in and tearing apart flexible materials like plastics, tires, and textiles. A square or straight-edged knife provides a clean, powerful shear cut, better suited for brittle materials like electronic waste or wood. Serrated knives offer a combination, helping to grip and initiate cuts in tough materials.

Optimizing the Rake Angle and Clearance Angle for Specific Materials

The rake angle is the angle at which the knife edge meets the material. A positive rake angle (a sharper, more aggressive angle) cuts with less force but may be weaker and more prone to chipping. A negative or neutral rake angle is stronger and better for impact but requires more power. The clearance angle prevents the back of the knife from rubbing against the material, reducing friction and heat generation. Finding the right balance is key to efficiency.

Single-Sided vs. Double-Sided Designs: Trading Maintenance Ease for Material Use

Single-sided knives have one cutting edge. When it becomes dull, the knife must be replaced or re-sharpened. Double-sided knives are reversible; once one edge is worn, the knife can be flipped to use a fresh, identical edge. This doubles the service life between changes and can reduce spare parts inventory, but the initial cost and complexity of the knife holder may be higher.

Knife Mounting and Fixation Systems: The Importance of Modularity and Stability

A knife is only as good as its mount. Knives must be held securely to prevent movement during operation, which causes premature wear and can be dangerous. Modern systems often use hydraulic clamping systems that allow for quick and secure knife changes without traditional bolts, significantly reducing downtime during maintenance. A stable mount ensures consistent cutting performance and protects the shredder shafts from damage.

The Science of Knife Materials: From Standard Tool Steel to Specialized Alloys

The base material of a knife is its first and most important line of defense against wear and failure. Metallurgical advancements have led to a range of alloys and treatments, each offering a unique balance of hardness (resistance to wear) and toughness (resistance to chipping and breaking). Selecting the right material is a cost-benefit analysis tailored to the waste stream.

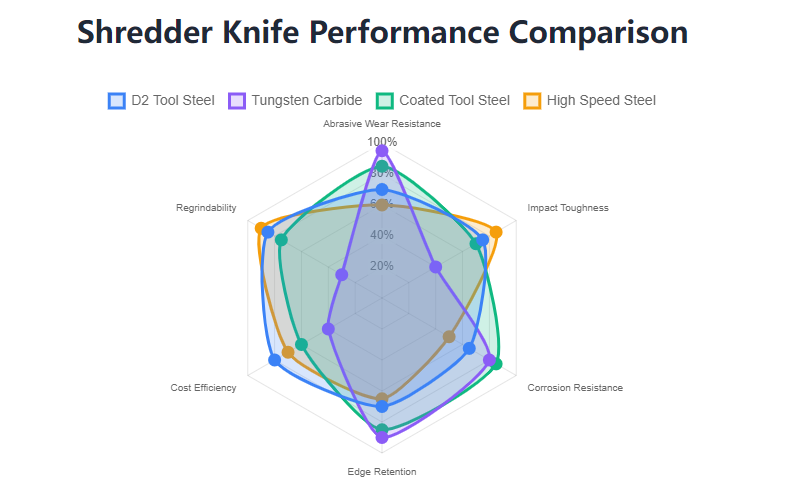

High-Carbon High-Chromium Tool Steels (D2, A8): The Balanced Choice

Tool steels like D2 and A8 are the industry workhorses. They offer an excellent balance of hardness (often up to 60-62 HRC after heat treatment) and good toughness at a reasonable cost. D2 steel has high chromium content, giving it good corrosion resistance, making it a versatile choice for many mixed waste applications. It is widely used in paper shredders and standard industrial shredders.

Tungsten Carbide Reinforced Knives: The Ultimate Wear Solution for High-Abrasion

For highly abrasive materials like fiberglass, electronic waste (PCBs), or mineral-filled plastics, standard tool steels may wear too quickly. Tungsten carbide, an extremely hard ceramic-metal composite, is used. It is often applied as a welded overlay on the cutting edges or as full tips brazed onto the knife body. Carbide-enhanced knives can last up to 10 times longer than tool steel in abrasive applications, justifying their higher initial cost.

Optimizing Material Properties Through Heat Treatment and Cryogenic Treatment

Heat treatment is a controlled process of heating and cooling steel to alter its microscopic structure and enhance its mechanical properties. Quenching and tempering are used to achieve the desired combination of hardness and toughness. Cryogenic treatment, which involves cooling the steel to extremely low temperatures, helps convert residual austenite into martensite and precipitates fine carbides, further enhancing wear resistance and dimensional stability.

Surface Enhancement Techniques: Nitriding and PVD/CVD Coatings

Beyond bulk material properties, the knife's surface can be enhanced. Nitriding diffuses nitrogen into the surface, creating a extremely hard, wear-resistant layer with good lubricity. Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) coatings apply thin, ultra-hard layers of materials like titanium nitride (TiN) or diamond-like carbon (DLC). These coatings drastically reduce friction and adhesion ( preventing material from sticking to the knife) and boost surface hardness, extending life significantly.

Knife Wear Mechanisms and Predictive Life Modeling

Understanding precisely how and why knives wear out allows for the development of strategies to combat it. Moving from reactive replacement to predictive maintenance requires models that can forecast knife life based on operational data, minimizing surprise failures and optimizing change-out schedules.

Analyzing the Mechanism of Abrasive Wear and Strategies for Mitigation

Abrasive wear is a gradual process where hard particles in the waste stream microscopically scratch and cut the knife material, slowly blunting the edge. Mitigation strategies include selecting a harder base material or coating, optimizing the knife geometry to reduce sliding contact, and employing surface treatments that lower the coefficient of friction.

Impact Fatigue and Ductile Fracture: Addressing the Challenge of Non-Shreddables

When a knife strikes a hard, unbreakable object, the impact can cause immediate damage (chipping) or create micro-cracks that grow with repeated impacts (fatigue), eventually leading to fracture. Choosing a tougher, more ductile steel grade can absorb more impact energy without failing. Furthermore, modern shredders are equipped with control systems that detect sudden load spikes and automatically reverse to spit out the offending object, protecting the knives.

Empirical Life Prediction Models Based on Operating Hours and Material Tonnage

The simplest predictive model is based on historical data. By recording the number of operating hours or tons processed before a specific level of wear is observed, operators can establish a baseline life expectancy. For example, a set of knives processing mixed plastics might be scheduled for inspection every 250 operating hours based on past experience.

Implementing Condition Monitoring for More Accurate Life Prediction

Advanced operations use condition monitoring for precision. This can involve periodically using laser micrometers to measure the actual thickness of knives to track wear. More integrated systems analyze the shredder's power consumption; as knives dull, the motor draws more current to achieve the same size reduction. Tracking this trend allows operators to predict exactly when the knives will be too dull to operate efficiently.

Optimizing Maintenance Strategies to Minimize Downtime and Operational Costs

A proactive and well-organized maintenance strategy transforms knife management from a source of costly downtime into a scheduled, efficient operation. The goal is to maximize the productive life of each knife set while minimizing the time and labor required to maintain them.

Establishing a Preventive Maintenance (PM) Schedule: Inspection and Replacement Cycles

A preventive maintenance plan is essential. This involves creating a strict schedule based on time or tonnage for visually inspecting knives, checking for wear, damage, and tightness of mounting. The schedule should dictate not only when to inspect but also when to rotate, sharpen, or replace knives based on predefined wear limits, preventing failures before they occur.

Best Practices for Knife Reconditioning and Regrinding

Professional regrinding can restore a worn knife to like-new condition at a fraction of the cost of replacement. Best practices include using the correct grinding wheel and coolant to avoid overheating, which can ruin the knife's heat treatment. It is also crucial to maintain the original geometry and angles. Most knives can be reground a limited number of times before they must be discarded, as each grind reduces their overall dimensions.

Knife Inventory Management: Determining Safety Stock and Preparing Change-Out Kits

To avoid extended downtime waiting for replacement parts, a strategic inventory of spare knives must be maintained. The "safety stock" level should be based on the lead time from the supplier and the predicted failure rate. Furthermore, preparing complete "change-out kits" that include not only the knives but also all new bolts, seals, and shims needed for the job can cut maintenance time in half.

Implementing Standard Operating Procedures (SOPs) to Prevent Human Damage

Many knife damages are preventable through proper operation. SOPs must strictly prohibit starting the shredder without first ensuring the cutting chamber is clear. They should mandate controlled, even feeding to avoid overloading and define procedures for handling jams. Training operators on these SOPs is a low-cost way to significantly extend knife life.

The Impact of Knife Selection on Comprehensive Operational Costs

The choice of knives reverberates throughout the entire operation, influencing far more than just the maintenance budget. The right knife selection directly affects energy bills, system throughput, product quality, and ultimately, the profitability of the recycling or waste processing operation.

The Link Between Sharpness and Energy Consumption: How Dull Blades Overload Motors

A sharp knife cuts efficiently with minimal resistance. As a knife dulls, it requires more force to tear through material rather than shear it cleanly. This increased resistance forces the drive motors to work harder, drawing more electrical current. Studies have shown that operating with dull knives can increase energy consumption by 15% to 30%, making regular sharpening an energy-saving measure.

How Output Consistency Affects Downstream Sorting Efficiency and Product Value

Knives in poor condition produce an inconsistent output. Dull knives may create un-shredded "flippers" or large chunks that can damage or jam downstream equipment like screens and air separators. For operations selling recovered materials, a clean, well-defined cut is essential to achieving high purity and, therefore, a higher market price. A four-shaft plastic shredder with sharp knives is critical for producing high-quality plastic flakes.

Calculating the Cost-Per-Ton for Different Knife Options

The true cost of knives is not their purchase price, but their cost per ton of material processed. This is calculated by adding the amortized cost of the knives (purchase price divided by lifetime tonnage), the cost of energy consumed during their life, and the labor cost for changing them. This metric allows for a direct comparison between a cheaper knife that wears quickly and an expensive, long-lasting knife.

ROI Analysis: Justifying the Investment in Premium Knives or Coatings

An Return on Investment (ROI) analysis based on the cost-per-ton model can clearly demonstrate the value of upgrading to a superior knife. For example, if a set of titanium nitride-coated knives costs twice as much as uncoated knives but lasts three times longer and reduces energy consumption by 10%, the payback period and long-term savings can be precisely calculated, often making the premium investment highly justified.