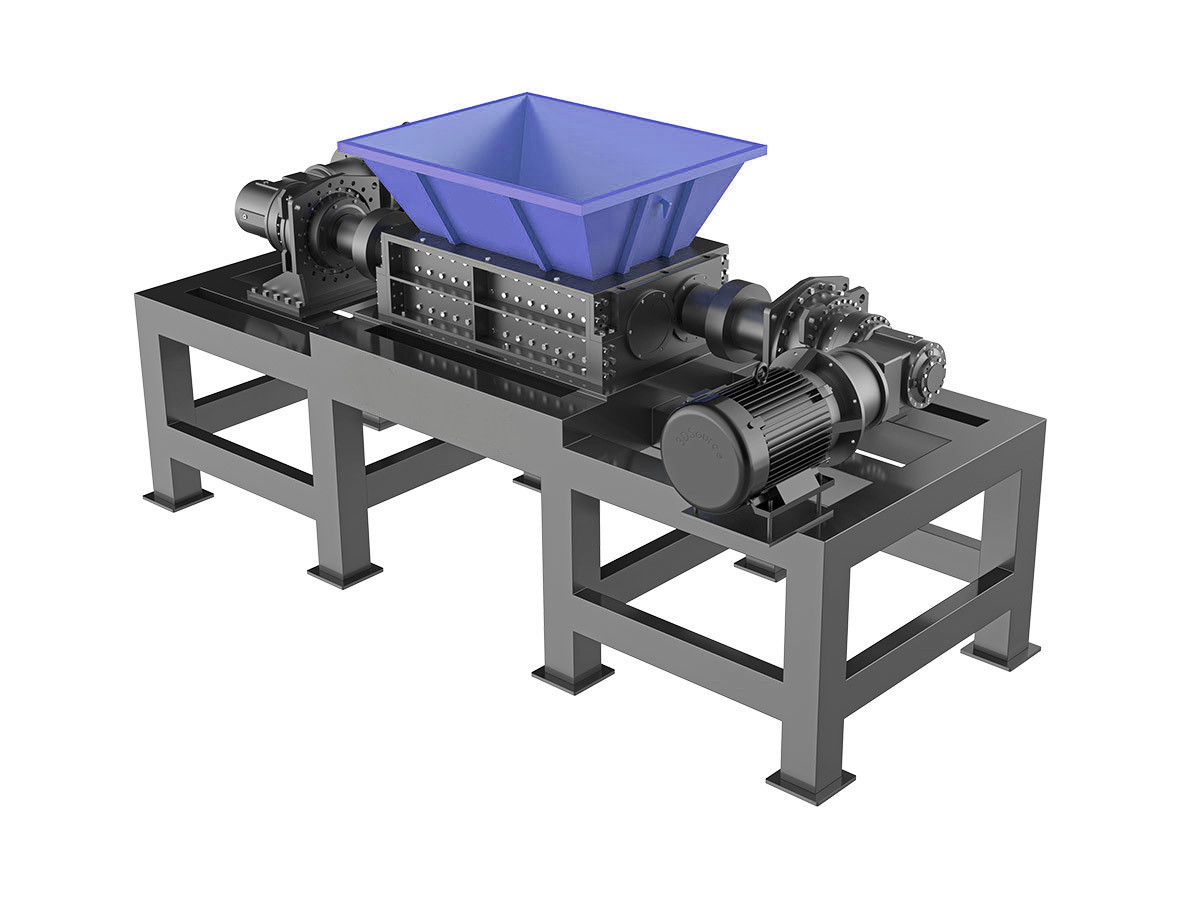

Double Shaft Waste Paper Shredder

A double shaft paper shredder is a powerful industrial machine designed for high-capacity shredding of paper waste. Unlike single shaft shredders, which rely on a single cutting mechanism, double shaft shredders use two counter-rotating shafts equipped with sharp, high-torque blades. This dual-shaft design allows for greater efficiency, higher throughput, and improved shredding performance, making it ideal for handling bulk paper materials, including documents, newspapers, books, and packaging waste.

Double shaft paper shredders are widely used in industries such as document destruction, recycling, and waste management. Their ability to process large volumes of paper quickly makes them essential for businesses looking to securely dispose of confidential information while optimizing paper waste reduction. The shredded material can then be recycled or repurposed for further use.

With their heavy-duty construction and energy-efficient operation, double shaft paper shredders offer a reliable solution for businesses and organizations that require consistent and high-performance shredding capabilities. Their ability to handle tough paper materials with minimal maintenance makes them a preferred choice in industrial environments.

Key Advantages of Using a Double Shaft Waste Paper Shredder

One of the primary benefits of a double shaft paper shredder is its ability to handle large volumes of paper waste efficiently. The dual-shaft mechanism allows the machine to grip and pull in bulky materials, reducing them into smaller fragments without frequent operator intervention. This makes it an excellent choice for continuous shredding operations.

Another major advantage is the shredder’s ability to process not only standard paper but also thick or bound materials, such as books, catalogs, and cardboard. The high-torque, slow-speed operation ensures that even dense paper products are shredded effectively without excessive wear on the cutting blades, extending the lifespan of the machine.

Additionally, double shaft paper shredders are designed with low maintenance requirements. Their durable blades and self-cleaning cutting mechanism help prevent jamming and clogging, reducing downtime and increasing overall efficiency. Many models also feature advanced control systems that allow for easy monitoring and adjustment of shredding performance.

How a Double Shaft Paper Waste Shredder Works

The shredding process in a double shaft paper shredder is based on two synchronized, counter-rotating shafts fitted with cutting discs. When paper waste is fed into the machine, the rotating blades grip, tear, and shear the material into smaller pieces. The dual-shaft system ensures that even large stacks of paper are processed smoothly and evenly.

Unlike high-speed shredders that rely on impact cutting, double shaft shredders operate at low speeds with high torque. This method produces less noise and dust, making it an environmentally friendly option for industrial applications. The slow-speed operation also reduces the risk of overheating, ensuring a consistent and reliable shredding process.

Many modern double shaft paper shredders come with intelligent control features such as automatic overload detection, adjustable speed settings, and reverse operation to prevent jams. These features enhance the machine’s overall performance while improving safety and ease of use. With their robust design and advanced functionality, double shaft paper shredders provide an efficient and cost-effective solution for large-scale paper waste management and document destruction.