Industrial shredders are powerful machines designed to reduce the size and volume of various materials, playing a critical role in recycling and waste management. Selecting the right shredder technology is vital for operational efficiency and cost-effectiveness. This guide provides a detailed comparison between two prevalent industrial shredder types: the dual-shaft and the four-shaft shredder. We will explore their fundamental operating principles, performance metrics, ideal applications, and total cost of ownership to equip you with a clear framework for making an informed decision for your specific mixed waste processing needs.

Fundamentals of Industrial Solid Waste Shredding: Dual-Shaft vs. Four-Shaft Design Principles

Understanding the core design philosophy behind each shredder type is the first step toward selection. The fundamental mechanism of how a shredder processes material dictates its capabilities, strengths, and limitations. This knowledge forms the essential groundwork for evaluating their performance on specific waste streams.

How a Dual-Shaft Shredder Works and Its Structural Features

A dual-shaft shredder operates using two parallel, counter-rotating shafts. Each shaft is fitted with cutting discs or knives that intermesh with those on the opposite shaft. As material is fed into the hopper, a hydraulic ram pushes it down onto the rotating shafts. The cutting knives grab, shear, and tear the material apart in a primary, coarse-size reduction process. This design excels at handling large, voluminous, and tough materials by applying high torque and ripping forces.

The Two-Stage Concept and Refining Action of a Four-Shaft Shredder

A four-shaft shredder incorporates two pairs of counter-rotating shafts, often arranged in a top and bottom configuration. The top two shafts function as a primary shredding unit, similar to a dual-shaft machine, performing the initial break-down of large items. The pre-shredded material then falls onto the secondary set of shafts underneath, which further refine and grind it into a smaller, more homogeneous particle size. This secondary stage is what differentiates the four-shaft shredder, providing a milling action.

Core Mechanical Differences: The Application of Shear, Tear, and Grinding Forces

The primary force in a dual-shaft shredder is high-torque tearing and shear. It is designed to rip through materials. A four-shaft system also utilizes these forces in its primary stage but adds a significant component of grinding and crushing in its secondary stage. The percentage of grinding force is markedly higher in a four-shaft machine, which is why it produces a more consistent output particle size.

Key Distinctions in Drive Systems and Power Configuration

Dual-shaft shredders typically use two powerful motors, each driving one shaft, often synchronized through a gearbox or coupling. Four-shaft shredders may use four independent motors—one for each shaft—or a combination of larger motors with complex drive trains. Independent drives for the secondary shafts offer greater control over the refining process but can increase the complexity of the power and control system.

In-Depth Performance Comparison: Throughput, Energy Consumption, and Output Size

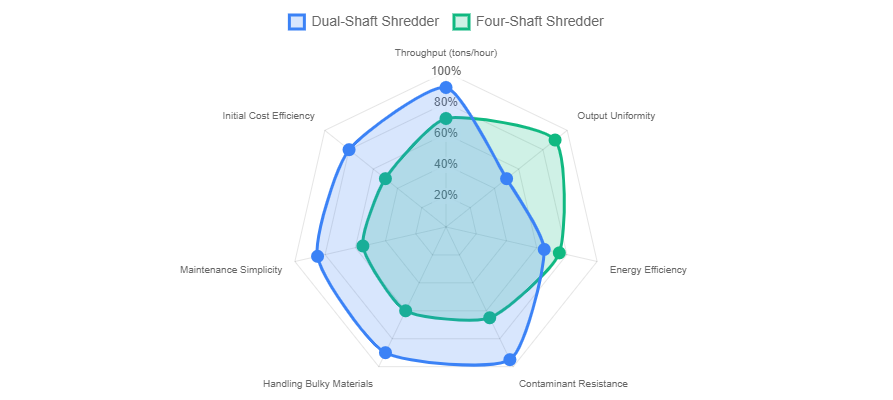

Evaluating shredders based on quantifiable metrics allows for an objective comparison of their operational capabilities. Key performance indicators provide a clear picture of what each machine can achieve under specific conditions, directly impacting the bottom line of a waste processing operation.

Throughput Capacity Comparison

For processing mixed industrial waste, a robust dual-shaft shredder can achieve throughput rates ranging from 5 to 50 tons per hour, depending on its size and the material composition. A four-shaft shredder might have a slightly lower raw throughput for the same input material because its secondary stage requires more time to achieve the finer grind. However, its output is often more readily processable by downstream equipment, effectively increasing the system's overall efficiency.

Specific Energy Consumption Analysis: Calculating Cost Per Ton Processed

Energy consumption is a major operational cost. Dual-shaft shredders consume significant power, often between 100 to 500 kWh, to generate the high torque needed for initial size reduction. Four-shaft shredders, while also energy-intensive, may distribute this consumption across the primary and secondary stages. The energy required per ton of processed material is highly dependent on the target output size; achieving a very fine size with a four-shaft machine will consume more energy than a dual-shaft machine producing coarse shreds.

Control and Uniformity of Final Output Particle Size

This is a key differentiator. The output from a dual-shaft shredder is typically a strip-like or ragged chunk material, with a wide range of particle sizes. A four-shaft shredder, equipped with a sizing screen or grate after its secondary stage, can produce a highly uniform granulate, often with over 90% of the particles falling within a specific size range (e.g.,<50mm). This homogeneity is critical for producing Refuse-Derived Fuel (RDF) or for efficient material separation in downstream processes like eddy current separation.

Processing Stability When Facing Fluctuating Material Composition

Dual-shaft shredders are generally more robust against sudden changes in feed material, such as an unexpected metal contaminant. Their high-inertia, high-torque design can often withstand such shocks. The finer tolerances and additional stages of a four-shaft shredder can make it more sensitive to significant feed variations, potentially requiring more frequent maintenance if the input is highly inconsistent.

Application Scenarios and Adaptability for Mixed Industrial Waste

The nature of the waste stream is the most critical factor in determining the appropriate shredder technology. Each machine has a set of material types it handles most effectively, and understanding these niches ensures optimal system performance and longevity.

Dual-Shaft Shredder Advantageous Scenarios: Bulky Waste, Tangled Materials, and High-Contaminant Waste

The dual-shaft shredder is the workhorse for primary reduction. It is exceptionally suited for bulky items like pallets, white goods, and large plastic lumps. Its tearing action is ideal for materials that tend to wrap, such as carpets, tires, and rolled metals. It can also handle waste streams with a high probability of containing non-shreddables, thanks to its robust construction and often reversible shafts that can clear jams.

Four-Shaft Shredder Advantageous Scenarios: RDF/SRF Production, Precision Recycling, and Homogenization

The four-shaft shredder shines in applications requiring a defined, uniform output. It is the preferred technology for producing high-quality RDF and SRF, where consistent particle size ensures optimal combustion. In advanced recycling plants, its homogeneous output is essential for maximizing the efficiency of downstream air separation systems and optical sorters, leading to higher purity of recovered materials like plastics and metals.

Synergistic Processing Solutions for Complex Mixed Waste

Many modern facilities employ a combined approach. A primary dual-shaft shredder is used for initial coarse reduction of incoming mixed waste. This material is then screened and separated. The remaining fractions destined for RDF production or further refining are then fed into a secondary four-shaft shredder to achieve the final precise particle size. This two-stage system leverages the strengths of each technology.

Tackling Challenging Materials: Textiles, Elastic Plastics, and Lightweight Films

Elastic materials like films and textiles can be problematic. They can wrap around shafts in a single-stage shredder. While dual-shaft designs with hook-shaped knives are better at grabbing and pulling these materials in, a four-shaft system can often process them more effectively after they have been pre-shredded, as the secondary stage helps break them down further. Specialized knife designs, like granulator blades, are often used in these applications.

Lifecycle Analysis of Operational and Maintenance Costs (TCO)

The purchase price is only a fraction of the total investment in an industrial shredder. A comprehensive analysis of all costs over the machine's operational life provides a true picture of its financial impact and helps in making a sound long-term investment decision.

Comparison of Initial Investment Cost (CAPEX) and Installation Complexity

Generally, a four-shaft shredder represents a higher initial capital investment due to its more complex design, additional drive systems, and larger number of components. Installation may also be more involved, potentially requiring more substantial foundations and more complex electrical connections. A dual-shaft shredder, while still a significant investment, is often a more straightforward machine to purchase and install.

Wear Parts Comparison: Wear Rate and Replacement Cost for Blades and Screens

Wear parts are a recurring cost. A four-shaft shredder has more knives and typically includes a sizing screen, which is also a wear item. However, because the secondary stage often processes pre-broken material, the wear on its knives might be different—perhaps less abrasive but more frequent. The knives on a primary dual-shaft shredder face the full, unprepared load, leading to potential higher impact wear. The total cost of ownership for wear parts depends on the specific material processed.

Man-Hour Requirements for Daily Maintenance and Planned Downtime

The relative mechanical simplicity of a dual-shaft shredder can translate into easier daily inspections and maintenance routines. A four-shaft system, with its additional bearings, drives, and a screen changing mechanism, may require more meticulous maintenance and potentially longer planned downtime for services like screen replacement or rotor inspection. Modern shredders with centralized lubrication systems help reduce routine maintenance time for both types.

Modeling the Proportion of Energy and Labor Costs in Total Cost of Ownership (TCO)

Building a TCO model involves projecting all costs over, for example, a 5-year period. Energy consumption often becomes the largest single OPEX component, especially with high electricity prices. Labor for operation and maintenance is another key factor. A model might reveal that a more expensive but energy-efficient four-shaft system could have a lower TCO in a high-throughput RDF plant, whereas a dual-shaft machine might be more cost-effective for a scrap yard doing primary volume reduction.

Selecting the Optimal Solution for Your Business: A Decision Framework

Choosing between a dual-shaft and four-shaft shredder is a strategic decision. A systematic approach that aligns your operational goals with the technical characteristics of each machine will lead to the most successful outcome.

Step 1: Define Your Feedstock Characteristics and Final Product Goals

Begin with a detailed waste audit. Document the composition, size, moisture content, and presence of contaminants in your incoming waste stream. Simultaneously, define the specifications for your desired output product. Is it a coarse 300mm shred for landfilling, a 50mm homogenous chip for composting, or a 30mm granulate for RDF? This clarity is the most critical input for the selection process.

Step 2: Evaluate Your Existing or Planned Process Flow and Downstream Equipment

The shredder is rarely a standalone unit. It must integrate seamlessly with upstream equipment like feed conveyors and downstream systems like magnetic separators, balers, or sorting lines. The output size and consistency from the shredder must be compatible with the requirements of these adjacent systems to ensure overall plant efficiency.

Step 3: Quantify Key Performance Requirements: Capacity, Particle Size, Budget, and Space

Create a list of non-negotiable requirements. These are your hard constraints, such as a minimum throughput of 20 tons per hour, a maximum particle size of 80mm, a fixed capital budget, or a limited footprint for the equipment. Also, list flexible criteria where there is room for compromise, which helps in evaluating different vendor proposals.

Step 4: Make the Decision Based on Total Cost of Ownership (TCO), Not Just Purchase Price

Use the TCO model developed earlier. Engage with potential suppliers to get realistic data on expected energy consumption, wear part life, and recommended maintenance schedules. A machine with a slightly higher purchase price but significantly lower energy and maintenance costs will be the more economical choice over its lifespan.

Step 5: Key Points for Supplier Evaluation and Technology Comparison

When engaging with manufacturers, ask for case studies and references from installations with similar waste streams. Request a performance guarantee for throughput and power consumption on your specific material. Scrutinize the quality and accessibility of wear parts like rotary cutters and the availability of service support.

Future Trends and Technological Evolution: Smart Shredding and System Integration

The industrial shredding landscape is continuously evolving with advancements in digitalization and automation. Investing in technology that is future-ready can provide a significant competitive advantage and protect your investment in the long run.

Application of IoT and Predictive Maintenance in Shredders

Modern shredders are increasingly equipped with sensors that monitor key parameters like bearing temperature, vibration, hydraulic pressure, and motor current. This data is fed into a PLC-based control system that can analyze trends and predict component failures before they occur, enabling predictive maintenance and avoiding unplanned downtime.

Adaptive Control and Energy Optimization Systems

Intelligent control systems can now automatically adjust the shredder's operation based on the real-time load. For example, the system can modulate the feed rate or reverse the shafts to clear a potential jam without operator intervention. This not only protects the machine but also optimizes energy use, reducing power consumption during periods of lighter load.

Deep Integration with Robotic Sorting and Artificial Intelligence (AI)

The shredder is becoming a data source within a smart recycling plant. Information about the feed rate and load can be shared with downstream AI-powered robotic sorting systems, allowing them to anticipate the volume and type of material arriving, thus optimizing their sorting patterns and efficiency for a higher overall recovery rate.

Considerations for Modular Design and Upgradeability

Some manufacturers offer modular designs that allow for future upgrades. For instance, a plant might start with a dual-shaft primary shredder and later add a four-shaft secondary module as their business evolves toward producing refined products. Choosing a platform that offers such flexibility can be a wise long-term strategy.