Refuse-Derived Fuel (RDF) shredders are critical in waste management, transforming municipal solid waste into a valuable fuel source. These powerful machines, often equipped with a twin-shaft shear system, face significant operational challenges during winter. Selecting the correct antifreeze is not merely a recommendation but a necessity to prevent costly downtime and damage. The right fluid ensures that the entire hydraulic system, from pumps to valves, continues to function smoothly even when temperatures plummet far below freezing, safeguarding the immense investment these industrial shredders represent.

The science behind antifreeze is centered on lowering the freezing point of the liquid circulating within the shredder's cooling and hydraulic systems. Pure water freezes at 0°C (32°F), but a mixture with glycols can remain liquid at temperatures as low as -50°C (-58°F) or even lower. This prevents the formation of ice crystals that can block flow, cause pressure build-up, and lead to catastrophic component failure. For an RDF shredder, which may operate in northern climates, this protection is integral to year-round productivity and preventing damage to its pre-shredder and main cutting assemblies.

RDF Shredder Hydraulic System Winter Operation Risk Analysis

The hydraulic system is the lifeblood of an industrial shredder, providing the immense power needed to shear through tough materials. In cold weather, hydraulic oil undergoes a dramatic transformation. Its viscosity, or resistance to flow, increases significantly. A fluid that flows like water at 40°C can become as thick as molasses at -20°C. This increased viscosity forces the hydraulic pump to work much harder to move the fluid, leading to a sharp spike in energy consumption and straining the electric motor, potentially tripping overload protectors.

Beyond thickened oil, the physical contraction of metal components and the formation of microscopic ice crystals pose severe risks. Ice crystals can form in any water present within the hydraulic fluid, even in small amounts from condensation. These crystals are abrasive and can score precision surfaces inside pumps and valves. More critically, they can cause valve spools to jam in their housings, rendering the machine inoperable. Simultaneously, metal pipes and fittings contract in the cold, compromising the integrity of seals and O-rings, which leads to pressurized leaks and system failure.

Dynamic Impact Mechanism of Low Temperature on Hydraulic Oil Viscosity

Hydraulic oil viscosity has an inverse relationship with temperature. As temperature drops, the molecular movement within the oil slows down, causing it to thicken. This relationship is not linear but logarithmic, meaning a small drop in temperature can cause a very large increase in viscosity. For example, a common ISO VG 46 hydraulic oil might have a viscosity of 45 centistokes (cSt) at 40°C but can skyrocket to over 2,000 cSt at -20°C. This thick fluid creates immense resistance throughout the system.

This high viscosity creates a cascade of problems. The pump must draw the thick oil from the reservoir, which can lead to cavitation—a phenomenon where voids or bubbles form in the oil due to incomplete filling of the pump chambers. These bubbles collapse violently when they reach high-pressure zones, causing noise, vibration, and erosion of pump components. Furthermore, the thickened oil flows sluggishly through narrow passages and filters, drastically reducing efficiency and increasing pressure drops across the system.

Physical Process of Ice Crystal Formation Causing Hydraulic Valve Blockage

Valve blockage begins with the presence of water. Humidity in the air can condense inside the hydraulic reservoir as temperatures fluctuate, introducing water into the oil. When the ambient temperature falls below the freezing point of water, this suspended water begins to form solid ice crystals. These crystals are hard and can have sharp edges, acting like tiny pieces of abrasive grit circulating within the closed-loop system.

The most critical failure occurs when these ice crystals migrate to the tight tolerances of servo valves and directional control valves. The clearance between a valve's spool and its bore can be as small as a few microns. Even a small accumulation of ice crystals can jam the spool, preventing it from shifting. A jammed valve stops the hydraulic functions it controls, such as the hydraulic ram that pushes waste into the shredder, completely halting the processing line and requiring immediate maintenance to thaw and drain the system.

Typical Case of Seal Failure Induced by Pipeline Contraction

Metals contract when cooled. Steel hydraulic tubing and aluminum manifold blocks have different coefficients of thermal expansion, meaning they shrink at different rates when subjected to the same temperature drop. This differential contraction places immense stress on the threaded connections, flanges, and, most importantly, the elastomeric seals that make these connections fluid-tight.

A common failure point is the seal between a valve block and a pipe connection. An O-ring that provides a perfect seal at 20°C may lose its sealing force as the metal fittings contract away from it at -25°C. This allows high-pressure hydraulic fluid to leak out. A real-world case involved a scrap metal shredder in Canada that experienced multiple leaks from its manifold blocks during the first cold snap of winter, leading to environmental contamination and unplanned downtime until all the seals were replaced with ones rated for lower temperatures.

Current Variation Characteristics of Motor Overload During Low-Temperature Startup

Starting a shredder's hydraulic system with cold, viscous oil is analogous to trying to stir frozen honey with a spoon. The electric motor driving the hydraulic pump must overcome this immense resistance to rotation. This is reflected in the motor's current draw. During a normal startup, inrush current is brief. However, during a cold start, the current remains dangerously high for an extended period as the motor labors to turn the pump against the thickened oil.

Motors are protected by thermal overload relays set to trip at a specific current threshold, usually around 115% of the motor's full-load amperage (FLA). During a cold start, current can easily exceed 200% of FLA. If the overload relay does not trip, the motor can overheat and burn out its windings. If it does trip, it prevents operation until the oil is warmed. Data loggers on shredder motors in Scandinavia have recorded startup currents lasting over 30 seconds at 250% FLA when the oil temperature was below -15°C, highlighting the severe strain placed on the electrical system.

Correlation Between Hydraulic Pump Cavitation and System Vibration

Cavitation in a hydraulic pump is the formation and immediate collapse of vapor bubbles within the oil. In cold conditions, this occurs primarily because the thickened oil cannot flow fast enough to fill the pumping chambers as they open. This creates a void, or vacuum bubble, which then collapses with tremendous force when it is transported to the high-pressure discharge side of the pump.

This collapse generates significant noise—a distinct loud knocking or rumbling sound—and intense vibration that can be felt throughout the machine. The vibration stresses pump bearings, shafts, and couplings. More destructively, the collapsing bubbles erode metal surfaces from the inside out, a process known as cavitation erosion. Over time, this erosion damages pump gears or vanes, leading to a permanent loss of pumping efficiency and, ultimately, catastrophic pump failure that requires a costly replacement.

Core Performance Index System for Antifreeze

Selecting an antifreeze is about much more than just achieving a low freezing point. A high-quality antifreeze for industrial applications must meet a rigorous set of performance criteria to ensure it protects the machine rather than harms it. These criteria form a core performance index system that engineers use to evaluate and compare different products. It encompasses thermal properties, chemical stability, and material compatibility.

The ideal antifreeze must remain stable and effective over long periods, resisting breakdown from heat and oxidation. It must also contain a robust package of inhibitors to protect the various metals in the system—cast iron, steel, copper, brass, aluminum—from corrosion. Furthermore, it must be compatible with the elastomers used in seals and hoses, preventing them from swelling, cracking, or degrading. A failure in any of these areas can lead to reduced equipment life and operational failures.

Quantitative Test Method for Freeze Point Suppression Capability (ASTM D1177)

The primary function of an antifreeze is to suppress the freezing point of the coolant mixture. The standard test method for determining this critical property is ASTM D1177, "Standard Test Method for Freezing Point of Aqueous Engine Coolants." This test provides a reliable and repeatable way to quantify the freeze point, allowing for accurate comparison between different fluids and concentrations.

In this test, a sample of the coolant is placed in a test tube and gradually cooled while being continuously stirred. The temperature is carefully monitored. The freeze point is recorded as the highest temperature at which ice crystals first appear, forming a slush. For example, a 50/50 mix of ethylene glycol and water will typically yield a freeze point of approximately -37°C (-34°F). This data is essential for operators in cold climates to mix their coolant to a concentration that provides adequate protection for the expected minimum ambient temperature.

Non-linear Relationship Between Viscosity Index and Temperature Adaptability

The Viscosity Index (VI) is a dimensionless number that indicates how much a fluid's viscosity changes with temperature. A high VI (e.g., above 150) means the fluid's viscosity changes relatively little between hot and cold temperatures. This property is crucial for a hydraulic fluid or an antifreeze that must operate year-round. It ensures the fluid is not too thick when cold and not too thin when hot.

The relationship between VI and performance is non-linear. A fluid with a VI of 100 will experience a much more dramatic viscosity increase in the cold than a fluid with a VI of 200. For shredders operating in environments with large seasonal temperature swings, such as the temperate zones of North America and Europe, using a high-VI fluid in the hydraulic system is as important as the antifreeze in the cooling system. It ensures easier cold starts and maintains proper lubrication and efficiency when the machine reaches its normal operating temperature.

Separation Efficiency of Anti-Emulsification Performance in Humid Environments

Anti-emulsification is a fluid's ability to separate from water. In a humid environment, water can condense into the fluid reservoir, and a fluid with poor anti-emulsification properties will form a stable emulsion—a milky mixture that does not separate. This is highly undesirable as water in the system promotes corrosion, reduces lubricity, and can freeze.

A good antifreeze or hydraulic fluid will have excellent demulsibility. When tested according to standards like ASTM D1401, the fluid and water should separate into two distinct layers within 30 minutes. This allows the water to settle at the bottom of the reservoir, where it can be periodically drained off. This property is vital for the longevity of a overband magnet hydraulic system or a shredder's bead wire separator, which are susceptible to rust from water contamination.

Cost Impact of Oxidation Stability on Maintenance Cycles

Oxidation stability refers to a fluid's resistance to reacting with oxygen. In a hydraulic system, oil is constantly agitated and exposed to air in the reservoir, and it operates at elevated temperatures. Over time, oxidation occurs, leading to the formation of acids and sludge. These oxidation products are corrosive and can clog small passages and filters.

A fluid with high oxidation stability will significantly extend the service life of the oil and the interval between oil changes. For a large shredder with a hydraulic system holding hundreds of gallons of oil, this represents a substantial cost saving in terms of both new oil purchase and disposal costs for the used oil. It also reduces downtime for maintenance. Laboratory tests, such as the Rotating Pressure Vessel Oxidation Test (RPVOT ASTM D2272), can predict a fluid's oxidative life, helping operators make cost-effective decisions.

Electrochemical Test Principle of Metal Corrosion Inhibition Capability

Antifreeze formulations contain a carefully balanced package of corrosion inhibitors to protect the many different metals found in a cooling system: steel, cast iron, aluminum, copper, and solder. The effectiveness of this inhibitor package is rigorously tested using electrochemical methods and standardized immersion tests.

One key test is ASTM D1384, "Standard Test Method for Corrosion Test for Engine Coolants in Glassware." Metal coupons representing the different alloys are weighed, polished, and immersed in the antifreeze solution, which is maintained at a specified elevated temperature for a set number of weeks. Afterwards, the coupons are cleaned and re-weighed. The weight loss per unit area is calculated to determine the corrosion rate in milligrams per square centimeter per week. A superior antifreeze will show minimal weight loss for all metals, proving its ability to form a protective layer on metal surfaces and prevent electrochemical corrosion reactions.

Comparative Analysis of Typical Antifreeze Types

The market offers several common types of antifreeze, each with distinct chemical bases, performance advantages, and drawbacks. The traditional choice has been ethylene glycol, but propylene glycol and glycerol-based options have gained popularity due to their lower toxicity. More recent innovations include permanent (long-life) antifreezes and biodegradable formulations. The choice depends on a balance of factors including required freeze point, toxicity, cost, and environmental regulations.

Understanding the fundamental differences between these types is the first step in making an informed selection. For instance, a facility concerned about potential spills in an environmentally sensitive area would prioritize a propylene glycol or biodegradable product over ethylene glycol. Conversely, an operation in extremely cold climates might prioritize the superior freeze point depression offered by ethylene glycol, provided it is handled with appropriate safety measures.

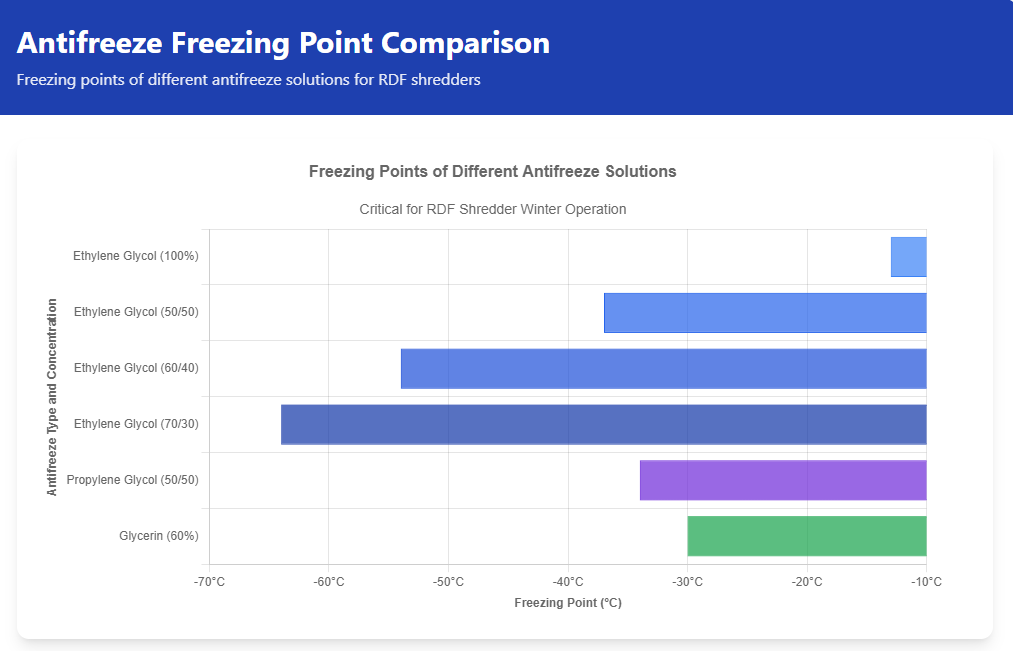

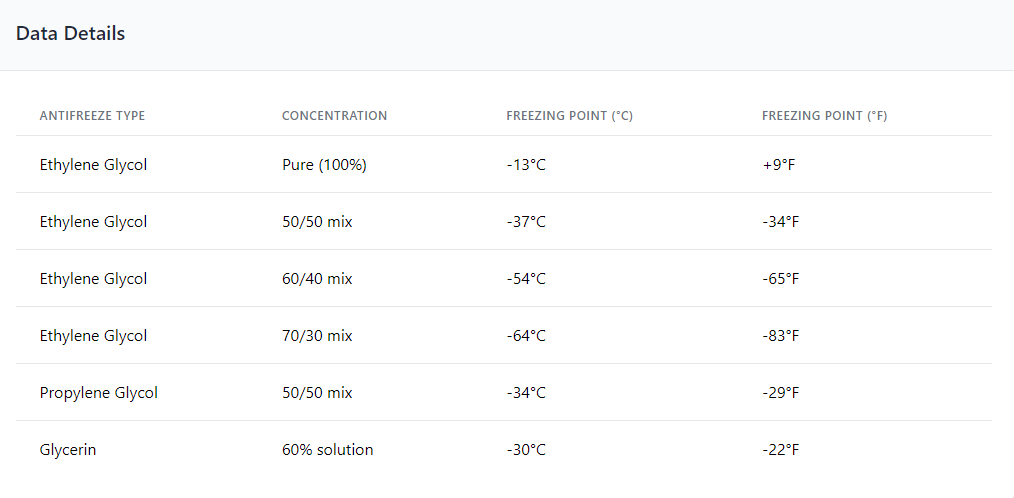

Concentration Ratio Optimization of Ethylene Glycol-Based Antifreeze

Ethylene Glycol (EG) is the most common and effective base for antifreeze. Its freeze point depression capability is excellent; a 60% EG to 40% water mixture provides protection down to approximately -54°C (-65°F). However, more is not always better. Pure ethylene glycol actually freezes at a relatively warm -13°C (+9°F). Its maximum effectiveness is achieved at a specific concentration, after which the freeze point begins to rise again.

Optimizing the concentration is critical for performance and cost. Using too high a concentration wastes expensive glycol, increases viscosity unnecessarily, and reduces the heat transfer efficiency of the coolant. Most manufacturers provide easy-to-read charts showing the freeze protection level for different mixture ratios. For most temperate winter conditions, a 50/50 mix is standard, providing protection to about -37°C. In colder regions like northern Scandinavia or Canada, a 60/40 mix may be required.

Thermal Stability Performance of Propylene Glycol Type Antifreeze

Propylene Glycol (PG) is a less toxic alternative to ethylene glycol. It is often designated as "non-toxic" or "food-grade" and is required in applications where leakage could contact food products or enter waterways. In terms of freeze protection, PG is slightly less efficient than EG; a 50/50 PG/water mix freezes at approximately -34°C (-29°F), a few degrees warmer than an equivalent EG mix.

A key advantage of PG is its superior high-temperature stability, particularly its resistance to thermal degradation and oxidation. This can lead to longer fluid life in systems that run very hot. However, PG-based fluids are generally more expensive and have a higher viscosity when cold compared to EG, which can be a consideration for cold-start performance. Its use is often mandated in municipal waste facilities with strict environmental policies for their solid waste shredder fleet.

Phase Change Temperature Control Characteristics of Glycerin Mixtures

Glycerin (or glycerol) is a natural byproduct of biodiesel production and has been explored as a renewable and biodegradable base for antifreeze. Glycerin-water mixtures provide reasonable freeze protection; a 60% glycerin solution freezes at around -30°C (-22°F). Its primary appeal lies in its very low toxicity and environmental profile.

However, glycerin has significant drawbacks. Its viscosity is extremely high at low temperatures, making it unsuitable for cold weather use in systems with sensitive pumps. It is also more susceptible to microbial growth if not properly inhibited, which can lead to sludge and system blockages. Furthermore, its heat transfer capacity is lower than that of glycols. While an interesting option, glycerin is generally not recommended for high-performance industrial shredding applications without specific modifications and careful system design.

Electrical Insulation Performance Evaluation of Anhydrous Coolants

Anhydrous (waterless) coolants use a base of propylene glycol but are formulated to contain no water. Because they lack water, they do not expand when heated and can operate at higher temperatures without boiling, and they obviously cannot freeze. Their boiling point is typically above 180°C (356°F). A significant secondary benefit is their high electrical resistivity.

This high electrical insulation property can be a major safety feature in industrial shredders, which are packed with powerful electric motors, sensors, and control systems. In the event of a coolant leak onto electrical components, an anhydrous coolant is much less likely to cause a short circuit or ground fault compared to a traditional conductive water-glycol mixture. This can prevent electrical fires and damage to sensitive PLC control panel electronics, though they come at a premium cost.

Microbial Decomposition Rate of Biodegradable Antifreeze

Biodegradable antifreezes are typically based on propylene glycol or glycerin and are designed to break down naturally in the environment through microbial action. The decomposition rate is a key metric of their environmental friendliness. Standardized tests, such as the OECD 301B test, measure the Biochemical Oxygen Demand (BOD) over 28 days to determine the percentage of the fluid that has been broken down by microorganisms.

A high-quality biodegradable antifreeze can achieve over 60% biodegradation within 28 days. This is a critical factor for waste processing plants located near wetlands or waterways, where a spill from an RDF shredder could have significant ecological consequences. While offering peace of mind from an environmental standpoint, these products require careful monitoring as their biodegradable nature can sometimes make them more susceptible to microbial growth within the system itself if stagnant conditions occur.

Equipment Compatibility Verification Process

Introducing a new fluid into a complex machine like a shredder requires thorough compatibility testing. An antifreeze that is chemically incompatible with system materials can cause more damage than plain water. The verification process is a multi-stage evaluation designed to simulate long-term exposure and identify any potential failure modes before the fluid is put into service system-wide.

This process involves testing the fluid's interaction with all wetted materials: metals, polymers, elastomers, and coatings. It's not sufficient to simply check the base chemical (e.g., ethylene glycol); the specific formulation and additive package must be tested, as different inhibitors can have vastly different effects on materials. A fluid approved for one brand of shredder may not be suitable for another due to differences in seal composition or metallurgy.

Accelerated Aging Test for Seal Material Compatibility

Elastomeric seals and hoses are particularly vulnerable to chemical attack. Compatibility testing involves immersing samples of standard seal materials—such as Nitrile (Buna-N), EPDM, Silicone, and Viton—in the heated antifreeze for an extended period, often 500 to 1000 hours at 80-100°C. This accelerated aging simulates years of service.

After immersion, the seals are evaluated for changes in hardness, tensile strength, volume, and elongation. A compatible fluid will cause minimal change. For example, EPDM rubber generally performs well with glycol-based antifreezes, showing a volume swell of less than 5%. Nitrile rubber, however, can experience significant hardening and loss of elasticity when exposed to some modern antifreeze formulations, which would lead to leaks. This testing ensures the seals in a shredder's lubrication system will remain intact.

Interfacial Tension Analysis Between Hydraulic Oil and Antifreeze

In some shredder designs, there is a risk of heat exchanger failure causing the hydraulic oil and engine coolant to mix. Interfacial tension analysis predicts how these two fluids will interact if such a failure occurs. A high interfacial tension means the fluids resist mixing and will tend to separate, making them easier to decant if a leak happens.

A low interfacial tension indicates the fluids will emulsify, creating a stable, sludgy mixture that is difficult to separate and can circulate through both systems, causing poor lubrication, clogged filters, and overheating. Testing for this property helps assess the potential damage and cleanup complexity from a cross-contamination event, informing the decision on whether the chosen antifreeze is suitable for a system with adjacent oil circuits.

Corrosion Resistance Verification of Metal Surface Coatings

Many internal surfaces of cooling systems, such as the inside of an engine block or a heat exchanger, are treated with protective coatings. The antifreeze must not degrade these coatings. Test coupons coated with the same material are immersed in the antifreeze solution and held at an elevated temperature for a specified time.

The coupons are then inspected for blistering, peeling, softening, or other signs of coating failure. A failed coating exposes the underlying metal to corrosive attack, leading to pitting and eventual leakage. This verification is crucial for protecting expensive components like the shredder's engine or the hydraulic oil cooler, ensuring the antifreeze acts as a preservative rather than a destructive agent.

Determination of the Low-Temperature Brittleness Threshold for Rubber Hoses

Rubber hoses must remain flexible and tough at operating temperatures. The brittle point is the temperature at which a rubber material loses its elasticity and becomes glass-like and prone to shattering. This is determined using a test like ASTM D746, where a sample is struck with a pendulum at progressively lower temperatures until it fractures.

For a shredder operating outdoors in winter, the hose's brittle point must be significantly lower than the coldest expected ambient temperature. A hose that becomes brittle at -30°C is a liability in a climate that reaches -40°C, as a simple pressure surge could cause it to crack and burst, resulting in a total loss of coolant and catastrophic overheating. This test ensures all rubber components, from large radiator hoses to small vacuum lines, can withstand the rigors of a cold climate.

Long-Term Soaking Reliability Verification for Electronic Components

While designed to be sealed, electrical connectors, sensors, and solenoid valves can be exposed to fluid leaks or high humidity. Reliability testing involves soaking these components in the antifreeze for extended periods while monitoring their electrical performance. Insulation resistance and dielectric strength are key measurements.

A fluid with good dielectric properties, like an anhydrous coolant, will show little to no degradation in the component's performance. A conductive fluid like a water-glycol mix could cause a drop in insulation resistance, potentially leading to signal interference, component failure, or short circuits. This verification is essential for the reliability of critical sensors monitoring the cooling system temperature or pressure, ensuring the control system receives accurate data.

Environmental Factors Consideration Dimension

The local climate and operating environment are the ultimate determinants in selecting an antifreeze strategy. A solution perfect for a dry, cold continental climate may fail miserably in a humid, salty coastal environment. A comprehensive risk assessment must account for all environmental factors, from the average minimum temperature to airborne contaminants, to design a resilient and reliable winterization plan.

This involves analyzing historical weather data, understanding the specific challenges of the facility's location, and planning for extreme weather events. A holistic approach combines the correct fluid selection with ancillary measures like sheltering equipment, adding insulation, and implementing pre-heating systems to create a robust defense against winter weather.

Fluid Phase Change Control in Polar Climates (-40°C and Below)

Operations in polar or extreme continental climates, such as those in Northern Canada, Alaska, or Siberia, present the ultimate challenge. Temperatures can remain below -40°C (-40°F) for weeks, and standard antifreeze mixtures are pushed to their limits. At these temperatures, fluids approach their pour points, and metals become exceptionally brittle.

The strategy here requires a multi-pronged approach. Antifreeze concentration is pushed to its optimum, often a 70/30 ethylene glycol/water mix, providing protection to about -64°C (-83°F). Equipment is often housed in insulated facilities with heating, and engines and hydraulic systems are equipped with powerful immersion heaters or circulating heater systems that keep the fluids warm around the clock, even when the machine is off. This ensures the shredder can start instantly and operate without stress even in the most severe conditions.

Cyclical Temperature Change Response Strategy in Temperate Monsoon Climates

Temperate monsoon climates, found in regions like Northeast Asia and the Northeastern US, experience large, cyclical temperature swings. Winters can have days that start well below freezing and rise to several degrees above, followed by rapid drops at night. This constant freeze-thaw cycle is particularly harsh on equipment, promoting condensation and accelerating material fatigue.

The antifreeze strategy must provide a wide margin of freeze protection to handle the lowest overnight temperatures. Furthermore, the fluid must have excellent corrosion inhibitors to handle the constant ingress of fresh oxygen and moisture from the air due to temperature-driven breathing of the reservoir. Equipment may also be fitted with automatic drain valves to remove condensate from air tanks and reservoirs daily, preventing water accumulation.

Integrated Dehumidification and Rust Prevention Scheme for High Humidity Environments

In high-humidity environments near oceans or large bodies of water, the primary winter threat is not extreme cold but relentless moisture. This moisture condenses on cold metal surfaces, inside control panels, and into fluid reservoirs, leading to pervasive rust and electrical failures. The antifreeze must have top-tier corrosion inhibitors.

Beyond fluid selection, an integrated approach is necessary. This includes using desiccant breathers on reservoirs to remove moisture from incoming air, installing space heaters or dehumidifiers in electrical enclosures and operator cabs, and applying protective coatings or rust preventative oils to exposed metal surfaces. For a shredder working in such an environment, managing humidity is a constant battle to protect its structural integrity and sensitive eddy current separator electronics.

Multi-Level Protection System Design for Salt Spray Environments

Coastal facilities or those that use salt on roads during winter expose equipment to salt spray, which is highly corrosive. Chloride ions aggressively attack steel, aluminum, and electronic circuits. The antifreeze must contain inhibitors specifically formulated to resist chloride-induced corrosion.

The protection system must extend beyond the coolant. This includes frequent fresh water rinsing of the entire machine to remove salt deposits, the use of sacrificial zinc anodes on exposed metal structures, and the application of wax or epoxy-based corrosion protection compounds to the underside and frame. Electrical components require conformal coatings to protect circuit boards. This multi-level defense is crucial to maintain the lifespan and resale value of expensive shredding equipment operating in ports or coastal recycling centers.

Rapid Response Maintenance Plan for Sudden Cold Waves

Unexpected cold waves can catch facilities unprepared. A rapid response plan is essential to prevent widespread equipment freezing. This plan includes immediate actions: draining cooling systems if inadequate antifreeze is present, adding supplemental portable heaters near critical equipment, circulating fluids manually, and isolating equipment that cannot be protected.

The plan also involves monitoring weather forecasts vigilantly during the winter months and having an emergency kit on hand that includes portable heaters, fluid testers (refractometers), extra drums of antifreeze, and pipe insulation. Training maintenance staff to execute this plan quickly can mean the difference between a minor inconvenience and a multi-day shutdown with frozen and cracked components that require expensive repairs.

Practical Application Scenario Analysis

The theoretical selection of an antifreeze is validated by its performance in real-world applications. Analyzing case studies from different geographic and operational contexts provides invaluable data on what works and what doesn't. This practical evidence helps refine selection strategies and avoid common pitfalls, ensuring that shredders remain operational and profitable throughout the harsh winter months.

Data from these scenarios often reveals that the total cost of ownership is lower with a premium, long-life antifreeze combined with a disciplined maintenance regime, compared to cheaper options that require more frequent changes and pose a higher risk of causing costly downtime and component damage.

Winter Failure Rate Comparison of MRF Projects in Cold Regions

Material Recovery Facilities (MRFs) in cold regions like the Midwest US and Canada have conducted comparative studies on winter failure rates. Facilities that implemented a preventive maintenance program including a full coolant system flush and fill with a premium extended-life antifreeze in the autumn reported a drastic reduction in winter-related downtime.

One case study from a MRF in Michigan showed a 70% decrease in hydraulic system failures and a 90% reduction in engine cooling system issues after switching from a conventional antifreeze changed annually to a long-life organic acid technology (OAT) antifreeze with a 5-year service life. This not only improved reliability but also reduced annual fluid and labor costs associated with coolant changes, proving the economic value of a proactive approach.

Solutions from RDF Processing Plants in High-Latitude Northern Europe

RDF plants in Sweden, Norway, and Finland are experts in operating in extreme cold. Their solutions are often integrated into the building design. Plants are fully enclosed and heated, effectively moving the operational environment indoors. For the shredders themselves, they universally use a high-concentration ethylene glycol mix.

A standard practice is the use of fuel-fired or electric coolant heaters that are automatically activated by a thermostat when the machine is off, maintaining the coolant temperature above 20°C. This guarantees instant starts and immediate full-power operation. Furthermore, they utilize centralized lubricating systems for the twin-shaft shear system that use winter-grade, low-viscosity oils to ensure all bearings and gears are protected from the moment the machine starts turning.

Annual Maintenance Cost Optimization in North American Cold Zones

Large waste management companies in Canada and the northern US states have focused on optimizing annual maintenance costs through fluid analysis. Instead of changing antifreeze on a fixed time schedule, they take regular samples and send them to a laboratory for analysis.

The lab report measures inhibitor levels, contamination, and acidity. This allows the maintenance team to change the fluid only when it is actually depleted, rather than on a conservative calendar basis. This condition-based maintenance has extended coolant service intervals by 50-100% in many cases, significantly reducing annual material and disposal costs. It also provides an early warning system for developing problems, such as a leaking heat exchanger introducing combustion gases into the coolant.

Equipment Retrofitting in Severe Cold Zones of Northern Eurasia

In the extreme cold of Siberia and northern Russia, standard off-the-shelf shredding equipment often requires significant retrofitting to survive. This involves installing extra-powerful block and reservoir heaters, adding insulation jackets to all fluid lines and tanks, and upgrading all seals and hoses to grades certified for extreme low-temperature service.

Another common retrofit is the installation of auxiliary power units (APUs) that can keep the main engine and hydraulic system warm without idling the primary diesel engine, which is inefficient and harmful. These retrofits represent a significant upfront investment but are essential to achieve any reasonable level of equipment availability and lifespan in such a punishing environment, ensuring that the production of refuse-derived fuel can continue year-round.

Innovative Protection Practices in Regions Near the Arctic Circle

The most innovative practices come from operations at the edge of viability, such as in Alaska or northern Scandinavia. Some facilities use geothermal energy to help heat their maintenance bays and fluid storage areas. Others employ passive solar design in their structures to capture minimal winter sunlight.

A key innovation is the use of automated, telemetry-enabled monitoring systems. Sensors track the temperature of each machine's fluids, the status of its block heaters, and the charge of its batteries 24/7. If any parameter falls out of a safe range, the system sends an alert to the maintenance manager's phone, allowing for a response before the equipment is damaged. This connected approach represents the future of winter equipment management in the most remote and cold locations on earth.

Selection Decision Support Tools

Making the optimal antifreeze selection is a complex decision with long-term consequences. Fortunately, several powerful decision-support tools have been developed to guide engineers and maintenance managers. These tools range from simple calculation models to comprehensive analytical frameworks that evaluate financial and environmental impacts, ensuring the choice is data-driven and optimized for the specific application.

Leveraging these tools removes guesswork and provides a clear justification for investment in higher-quality products or more robust winterization strategies. They help balance upfront cost with long-term reliability, safety, and environmental compliance.

Concentration Intelligent Calculation Model Based on Ambient Temperature

The required concentration of glycol in water is directly determined by the lowest expected ambient temperature. Simple digital refractometers are the primary tool for in-the-field measurement of concentration. However, for planning and procurement, intelligent software models are available.

These models, often provided by antifreeze manufacturers as web apps or spreadsheets, allow the user to input their location. The software pulls historical minimum temperature data and calculates the recommended minimum concentration needed to provide a safety margin (e.g., protection to 10°C below the record low). It then outputs the exact ratio of antifreeze to water and the total volume required for the system, minimizing waste and ensuring optimal protection.

Total Cost of Ownership (TCO) Analysis System

TCO analysis is a comprehensive financial model that evaluates all costs associated with an antifreeze over its entire service life. It moves beyond the simple purchase price per gallon to include costs of transportation, labor for flushing and filling, disposal fees for the spent fluid, potential downtime during changes, and the cost of any related failures.

Applying TCO analysis often reveals that a premium long-life antifreeze, while more expensive upfront, has a significantly lower total cost over 5-10 years. It requires fewer changes, reduces labor costs, minimizes disposal volumes, and, most importantly, its superior performance reduces the risk of catastrophic failures that result in massive repair bills and production losses. This makes a compelling financial case for investing in quality.

Environmental Impact Life Cycle Assessment (LCA) Methodology

Life Cycle Assessment is a standardized (e.g., ISO 14040) methodology for evaluating the environmental impact of a product from "cradle to grave." For an antifreeze, this includes the environmental cost of raw material extraction, manufacturing, transportation, use, and final disposal or recycling.

An LCA compares different products, such as ethylene glycol vs. propylene glycol. It might show that while PG is less toxic in use, its manufacturing process has a higher carbon footprint. Or it might demonstrate that the long service life of a product reduces its overall environmental impact by minimizing disposal waste. This tool is essential for companies committed to sustainability and reducing their corporate environmental footprint, guiding them to the most ecologically responsible choice.

Supplier Qualification Certification System (ISO 4925)

ISO 4925 is an international standard that specifies requirements for antifreeze intended for use in the cooling systems of internal combustion engines. While focused on automotive applications, its principles are widely respected and applied in the industrial sector. A supplier whose product is certified to meet ISO 4925 provides a baseline assurance of quality and performance.

This certification signifies that the product has passed rigorous tests for freeze point, boiling point, corrosion protection, foam inhibition, and compatibility with common materials. Procuring antifreeze from ISO-certified suppliers is a fundamental risk mitigation strategy. It ensures that the fluid has a known and verified quality, reducing the risk of introducing a substandard product that could damage expensive shredder engines and hydraulic systems.

Application of Spectroscopic Analysis in On-Site Rapid Detection Technology

Modern maintenance is driven by data. Portable spectroscopic analyzers, such as Fourier-Transform Infrared (FTIR) spectrometers, are now available for on-site fluid analysis. A small sample of used antifreeze can be placed in the device, which quickly identifies the concentration of glycol, the level of key inhibitors, and the presence of contaminants like combustion gases or oil.

This technology provides results in minutes instead of days, allowing for immediate maintenance decisions. For example, a mechanic can test the coolant before the winter season, confirm the concentration is adequate, and check that the inhibitors have not depleted. This empowers a predictive maintenance approach, ensuring the shredder is always protected and maximizing the fluid's service life based on its actual condition rather than a guess.