Selecting the right RDF shredder requires careful consideration of multiple factors to ensure optimal performance and return on investment. This guide provides detailed information about different shredder types, performance metrics, and selection criteria to help you make an informed decision. Understanding these aspects will lead to better operational efficiency and long-term satisfaction with your equipment choice.

Understanding Basic Types of RDF Shredders

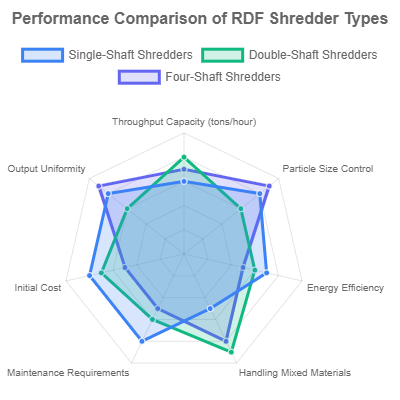

RDF shredders come in various configurations designed for different processing requirements and material characteristics. The fundamental designs include single-shaft, double-shaft, and four-shaft systems, each offering distinct advantages for specific applications. The choice between these configurations significantly impacts processing efficiency, output quality, and operational costs.

Different shredder types employ varying mechanical principles to achieve size reduction. Shear-type shredders use cutting action, while impact shredders utilize hammers or beaters.

The selection depends on material properties such as hardness, toughness, and composition. Understanding these differences helps identify the most appropriate technology for

specific waste streams.

Characteristics and Applications of Single-Shaft RDF Shredders

Single-shaft shredders feature a robust rotating shaft with mounted cutting blades that process material against a stationary bed knife. This design provides high torque output suitable for tough, bulky materials that require significant cutting force. The relatively simple mechanical design offers reliability and ease of maintenance for many applications.

These systems excel in processing materials requiring controlled particle size reduction. The single-shaft configuration typically produces more uniform output sizes compared to other designs. Applications include preliminary size reduction of municipal solid waste and processing of commercial and industrial waste materials.

Powerful Crushing Capability of Double-Shaft RDF Shredders

Double-shaft shredders utilize two counter-rotating shafts with intermeshing cutters that provide powerful shearing and tearing action. This design generates high torque at low rotational speeds, making it ideal for processing tough, fibrous materials that might challenge other shredder types. The twin-shaft system effectively handles materials that could cause jamming in single-shaft units.

The double-shaft configuration offers excellent throughput capacity for continuous operation applications. This design proves particularly effective for processing mixed waste streams containing varying material types and sizes. The tearing action facilitates liberation of different material components for subsequent separation processes.

Efficient Processing and Precision of Four-Shaft RDF Shredders

Four-shaft shredders represent advanced technology offering superior processing capabilities for demanding applications. These systems typically incorporate two primary shredding shafts followed by two secondary sizing shafts. This staged approach enables more controlled size reduction and produces more consistent output material.

The four-shaft design provides enhanced processing flexibility through independent control of primary and secondary shredding stages. This configuration excels in applications requiring precise particle size control and high-quality output material. The technology proves valuable for producing specification-grade RDF meeting strict quality requirements.

Selection Based on Waste Characteristics

Material properties significantly influence shredder selection decisions. Hardness determines the required cutting force and wear resistance of components. Abrasive materials necessitate specialized wear protection on cutting elements and chamber liners. Moisture content affects material flow characteristics and may require special feeding arrangements.

Tough, fibrous materials often perform better in shear-type shredders, while brittle materials may respond better to impact reduction. Composition variability dictates the need for flexible processing capabilities. Comprehensive analysis of waste stream characteristics ensures selection of appropriate shredding technology.

Evaluating RDF Shredder Performance Metrics

Performance assessment requires consideration of multiple interconnected parameters that collectively determine operational effectiveness. Throughput capacity must align with processing requirements while maintaining acceptable energy consumption levels. Output quality specifications influence equipment selection and configuration choices.

Modern shredders incorporate various monitoring systems that track performance parameters in real-time. These systems provide data for operational optimization and preventive maintenance planning. Understanding performance metrics enables informed decisions regarding equipment sizing and operational parameters.

Matching Capacity Requirements with Equipment Size

Throughput requirements determine the necessary equipment size and power rating. Capacity calculations should consider both peak and average processing rates to ensure adequate performance during varying feed conditions. Undersized equipment struggles to meet production targets, while oversized units operate inefficiently at partial load.

Shredder capacity typically ranges from 5-50 tons per hour depending on model size and configuration. Accurate capacity assessment requires consideration of material density, composition, and feed consistency. Professional equipment suppliers can provide detailed capacity calculations based on specific material characteristics.

Impact of Particle Size Control on RDF Quality

Output particle size significantly affects RDF quality and suitability for various applications. Smaller particle sizes generally improve combustion characteristics but increase energy consumption during shredding. Optimal size distribution balances processing costs with product quality requirements.

Particle size control mechanisms include screen sizes, cutter configurations, and operational parameters. Modern shredders can typically produce output sizes ranging from 50-150mm depending on application requirements. Consistent particle size distribution ensures predictable performance in subsequent processing or utilization stages.

Energy Efficiency and Long-Term Operational Costs

Energy consumption represents a significant portion of operational expenses for shredding operations. Efficient designs minimize specific energy consumption measured in kWh per ton processed. Motor efficiency, drive system design, and cutting geometry all influence overall energy performance.

Energy monitoring systems help identify optimization opportunities and track performance over time. Modern high-efficiency motors can reduce energy consumption by 15-20% compared to standard designs. Variable frequency drives allow motor speed adjustment to match processing requirements, further improving energy efficiency.

Cost-Benefit Analysis and Budget Planning

Comprehensive economic assessment considers both initial investment and long-term operational costs. Equipment pricing varies significantly based on size, features, and manufacturing quality. Higher initial investment often translates to lower operating costs through improved efficiency and reduced maintenance requirements.

Lifecycle cost analysis provides the most accurate economic comparison between alternatives. This approach considers purchase price, installation costs, energy consumption, maintenance expenses, and expected equipment lifetime. Return on investment calculations help justify equipment selections based on operational benefits.

Considering RDF Shredder Durability and Maintainability

Equipment longevity depends on robust construction and proper maintenance practices. Durable designs withstand the demanding conditions of waste processing operations while maintaining performance over extended periods. Maintenance considerations significantly impact operational availability and repair costs.

Component accessibility affects maintenance efficiency and downtime duration. Well-designed equipment facilitates routine maintenance tasks and component replacement. Service support availability ensures timely resolution of technical issues and access to genuine replacement parts.

Extension of Equipment Life Through High-Quality Materials

Material selection critically impacts equipment durability and performance. Cutting elements typically utilize hardened steel or tungsten carbide compositions providing extended service life. Structural components require high-strength materials capable of withstanding operational stresses.

Wear protection measures include hardened liners, replaceable wear plates, and specialized surface treatments. These features protect critical components from abrasive wear, extending maintenance intervals and reducing operating costs. Investment in quality materials typically yields long-term benefits through reduced downtime and maintenance expenses.

Replacement Guidelines for Wear Parts

Cutting elements represent the primary wear components in shredding equipment. Replacement frequency depends on material processed, operating hours, and maintenance practices. Regular inspection identifies wear progression and determines optimal replacement timing.

Proper replacement procedures ensure correct installation and alignment of new components. Documentation provides guidance on replacement intervals and procedures. Maintaining adequate inventory of wear parts minimizes downtime when replacements become necessary.

Development and Implementation of Maintenance Plans

Systematic maintenance planning ensures equipment reliability and prevents unexpected failures. Preventive maintenance schedules address routine servicing requirements based on operating hours or material processed. Condition-based maintenance utilizes monitoring data to determine actual maintenance needs.

Maintenance plans should include daily inspections, weekly servicing, and periodic comprehensive maintenance. Documentation of all maintenance activities creates valuable historical data for future planning. Proper maintenance execution preserves equipment value and ensures consistent performance.

After-Sales Service Network and Technical Support

Reliable technical support provides assistance when operational issues arise. Service network coverage determines response times for emergency repairs and routine maintenance. Availability of trained technicians ensures proper equipment servicing and troubleshooting.

Spare parts availability significantly impacts equipment uptime during maintenance activities. Established suppliers maintain adequate parts inventories to support customer needs. Technical support services provide operational guidance and troubleshooting assistance when required.

Exploring Innovative Technologies in RDF Shredders

Technological advancements continue improving shredder performance and operational efficiency. Modern systems incorporate sophisticated control systems that optimize operation based on material characteristics. Automation features reduce labor requirements while improving processing consistency.

Innovative designs address environmental concerns through reduced energy consumption and noise emissions. Advanced monitoring systems provide real-time performance data for operational optimization. Technology integration creates more capable and efficient processing systems.

Enhanced Operational Convenience Through Intelligent Control Systems

Modern control systems automate many operational aspects, reducing operator intervention requirements. Programmable logic controllers manage operational sequences and monitor system parameters. Touchscreen interfaces provide intuitive operation and system status information.

Advanced control systems can automatically adjust operational parameters based on material characteristics. This capability maintains optimal performance despite variations in feed material. Remote monitoring capabilities allow off-site supervision of equipment operation.

Improved RDF Purity Through Automated Sorting Technology

Integrated sorting systems remove contaminants before shredding, improving final product quality. Magnetic separators extract ferrous metals, while eddy current systems remove non-ferrous metals. Optical sorting technology identifies and separates specific material types based on visual characteristics.

These systems typically achieve metal removal efficiencies exceeding 95%, significantly improving RDF quality. Automated sorting reduces manual labor requirements while increasing separation accuracy. The technology enables production of higher-value RDF products meeting strict quality specifications.

Reduced Operating Costs Through Environmental Design

Energy-efficient designs minimize power consumption through optimized motor systems and drive arrangements. Noise reduction measures create better working environments and facilitate compliance with regulatory requirements. Dust control systems maintain air quality and prevent material loss.

Advanced designs incorporate energy recovery systems that capture and reuse energy from the shredding process. These features reduce net energy consumption and operational costs. Environmental considerations increasingly influence equipment design and selection decisions.

Technological Innovation Driving Industry Development

Ongoing research and development continues advancing shredding technology capabilities. New material developments improve wear resistance and component lifetime. Design innovations enhance processing efficiency and reduce operational costs.

Technology integration creates more comprehensive waste processing solutions. These advancements support the evolution toward circular economy models where waste becomes valuable resources. Continuous improvement ensures shredding technology remains relevant to changing market needs.

Conducting Site Visits and Case Analysis

Firsthand observation of equipment operation provides valuable insights beyond technical specifications. Site visits allow potential buyers to observe actual performance under real operating conditions. These visits reveal practical considerations that may not be apparent from documentation alone.

Case studies demonstrate successful equipment applications and provide performance data from actual operations. Analyzing multiple cases identifies patterns and best practices applicable to specific situations. This information helps validate equipment selection decisions.

Importance and Preparation for Site Visits

Proper preparation ensures site visits yield maximum useful information. Defining specific observation objectives focuses attention on relevant aspects of operation. Preparing questions in advance ensures comprehensive information gathering during the visit.

Site selection should consider operations similar to the planned application in terms of scale and material characteristics. Scheduling adequate time allows thorough observation and discussion with operating personnel. Following up with additional questions after the visit clarifies any uncertainties.

Equipment Selection and Configuration in Successful Cases

Successful operations typically result from careful equipment selection matching specific requirements. Configuration details often include customizations addressing particular material characteristics or operational constraints. These adaptations optimize performance for specific applications.

Documentation of successful configurations provides valuable reference for new projects. Understanding the reasoning behind equipment choices helps inform selection decisions. Performance data from successful operations validates equipment capabilities.

Common Problems and Solutions from User Feedback

User experiences reveal practical challenges encountered during equipment operation. Common issues include material handling problems, wear management, and maintenance accessibility. Solutions developed through experience often provide the most effective resolutions.

Understanding potential problems enables proactive measures to prevent similar issues. Equipment modifications or operational adjustments can address identified challenges before they affect performance. This knowledge informs both equipment selection and operational planning.

Influence of Reputation Evaluation on Purchase Decisions

Reputation assessment provides insight into equipment reliability and manufacturer support. User testimonials offer authentic perspectives on equipment performance and service quality. Consistent positive feedback indicates reliable products and good customer support.

Reputation considerations often outweigh minor price differences when making selection decisions. Established manufacturers typically provide better long-term support and parts availability. Comprehensive evaluation includes both technical capabilities and company reputation.

Making Informed Purchase Decisions

Final selection requires synthesis of all gathered information into a comprehensive evaluation. Comparison between alternatives should consider both quantitative performance data and qualitative factors. Decision-making frameworks help organize and weight various selection criteria.

Long-term considerations often prove more important than initial purchase price. Equipment flexibility allows adaptation to changing processing requirements over time. Support services significantly impact operational success throughout the equipment lifecycle.

Comprehensive Comparison Analysis of Brands and Models

Systematic comparison ensures objective evaluation of alternatives against established criteria. Technical specifications provide quantitative data for performance comparison. Feature analysis identifies differences in capabilities and convenience factors.

Cost analysis should consider total ownership costs rather than just purchase price. Performance data from similar applications provides realistic expectations of operational results. Comprehensive comparison reveals the best value proposition among available options.

Technical Support and Upgrade Services in Long-Term Cooperation

Long-term relationships with equipment suppliers provide benefits beyond the initial purchase. Ongoing technical support ensures optimal operation throughout the equipment lifecycle. Upgrade services allow performance enhancement as new technologies become available.

Service agreements formalize support arrangements and ensure response commitments. Regular maintenance services preserve equipment performance and extend operational life. Strong supplier relationships facilitate access to technical expertise when needed.

Interpretation of Key Clauses in Purchase Contracts

Contract terms define rights, responsibilities, and remedies for all parties involved. Performance guarantees should specify measurable parameters and testing methods. Delivery terms outline schedules, responsibilities, and consequences for delays.

Payment terms structure financial arrangements to protect both buyer and seller. Warranty provisions define coverage scope, duration, and claim procedures. Understanding contract details prevents misunderstandings and ensures proper protection.

Risk Assessment and Response in the Decision-Making Process

Risk identification anticipates potential problems that could affect project success. Probability and impact assessment prioritizes risks requiring mitigation measures. Response planning develops strategies to address identified risks effectively.

Contingency planning prepares alternative approaches for dealing with unexpected developments. Risk allocation determines which party bears responsibility for specific risk types. Comprehensive risk management increases project success probability.