Industrial shredders play a critical role in modern recycling operations, transforming bulky materials into manageable fragments for further processing. Among the various types, single-shaft and dual-shaft shredders represent two fundamental designs with distinct capabilities. This guide delves into their differences, focusing on the significant challenges posed by tangled film plastics, such as LDPE packaging and stretch films. Understanding these machines' mechanics is vital for optimizing efficiency, reducing downtime, and making a sound investment in recycling infrastructure. The choice between shredder types directly impacts operational costs and material output quality, making it a decisive factor for businesses handling flexible plastics.

Film plastics are notoriously difficult to process due to their low density, high tensile strength, and tendency to wrap around equipment components. Traditional shredding methods often struggle with these materials, leading to frequent jams and reduced throughput. This article provides a comprehensive comparison, explaining why dual-shaft shredders are specifically engineered to overcome these hurdles. By examining design principles, performance data, and practical applications, readers will gain insights into selecting the right shredder for their needs, ensuring long-term reliability and higher productivity in film plastic recycling.

Understanding the Basic Types of Shredders: Core Design Differences Between Single-Shaft and Dual-Shaft

The fundamental distinction between single-shaft and dual-shaft shredders lies in their rotor configuration and the mechanical forces they employ. Single-shaft shredders utilize a solitary rotating shaft equipped with cutting blades, which work in conjunction with stationary bed knives to slice materials through a shearing action. This design is generally simpler and more compact, often suited for homogeneous, brittle materials that fracture easily under direct pressure. The cutting chamber typically features a hydraulic ram that pushes material against the rotor, ensuring consistent feed and size reduction.

In contrast, dual-shaft shredders incorporate two parallel rotors that rotate at low speeds towards each other. Each rotor is fitted with hooked or staggered cutters that intermesh, creating a tearing and stretching motion rather than pure cutting. This mechanism generates high torque, allowing the machine to grip and pull materials apart with immense force. The difference in force application—shearing versus tearing—is not merely technical but dictates the shredder's ability to handle specific material properties. For instance, dual-shaft systems excel where elasticity and flexibility are present, as the tearing action prevents materials from slipping away or wrapping around components.

Working Principle and Structural Features of Single-Shaft Shredders

Single-shaft shredders operate on a straightforward principle where a central rotor, powered by an electric motor, spins at relatively high speeds. The rotor's blades pass close to fixed counter-knives mounted on the shredder's housing, creating a scissor-like shear point. Materials fed into the hopper are forced against the rotor by a pusher mechanism, often hydraulic, which ensures steady engagement with the cutting elements. This design results in a controlled cutting process, producing uniformly sized fragments that can be further processed based on the installed screen size.

The structure of a single-shaft shredder is characterized by its robust, enclosed cutting chamber, which minimizes noise and contains debris. Typical models feature a drive system with a power range of 15 to 150 kW, depending on the application, and rotor speeds between 40 and 80 revolutions per minute. The simplicity of the single-shaft design translates to easier maintenance and lower initial costs for suitable materials. However, this simplicity becomes a limitation when faced with stretchy or fibrous substances that resist clean shearing and instead cling to the rotor, causing operational issues.

Working Principle and "Tearing" Mechanism of Dual-Shaft Shredders

Dual-shaft shredders function through the synchronized rotation of two shafts, each fitted with cutting discs or hooks that interlock. As materials enter the feed opening, the rotating shafts grab and pull them downward, applying a combination of tension and compression forces. This tearing mechanism effectively rips apart materials by exploiting their weak points, making it highly effective for durable, flexible items. The slow rotational speed, typically 20 to 40 RPM, allows for high torque transmission, often exceeding 10,000 Nm per shaft, which is crucial for processing tough plastics.

The structural integrity of dual-shaft shredders is reinforced by heavy-duty bearings and gearboxes that withstand the intense stresses of tearing actions. The cutting chamber is designed without dead zones, ensuring material flow and reducing the risk of jamming. This design is particularly advantageous for mixed waste streams, as the shredder can handle variations in material composition without significant adjustment. The tearing force not only prevents wrapping but also produces a more flake-like output, which is ideal for subsequent washing and pelletizing stages in recycling lines.

Core Difference Comparison: Shearing Force vs. Tearing Force

Shearing force, as applied in single-shaft shredders, involves two opposing blades sliding past each other to cut materials cleanly. This action requires the material to be brittle enough to fracture under stress, which is why it works well for rigid plastics, wood, or metals. The energy consumption in shearing is generally lower per cut, but continuous operation with unsuitable materials can lead to increased wear and power spikes. For example, shearing a polyethylene film often results in the film deforming and escaping the cut, rather than being severed.

Tearing force, characteristic of dual-shaft shredders, relies on pulling materials apart by applying differential tension. This method is more effective for materials with high elongation properties, as it causes them to break at their tensile limit. The energy input is higher initially, but the efficiency gains in processing challenging materials like films or fibers offset this. Data from industrial applications show that tearing can reduce processing time for film plastics by up to 30% compared to shearing, due to fewer stoppages and more consistent material flow. The mechanical advantage of tearing makes it the preferred method for flexible and composite materials.

Why Design Differences Decisively Affect Material Adaptability

The adaptability of a shredder to various materials is directly influenced by its design philosophy. Single-shaft shredders, with their focus on shearing, are optimal for predictable, uniform materials that break upon impact. Their design assumes that materials will be fed consistently and will not resist the cutting action. However, when confronted with elastic materials, the shear force may simply push them aside or cause them to accumulate, leading to blockages. This limitation is evident in throughput metrics, where single-shaft units processing film plastics can experience up to 50% more downtime than dual-shaft models.

Dual-shaft shredders are engineered for variability and resilience. The intermeshing rotors create a positive feed action that draws materials in aggressively, preventing rebound or wrapping. This design accommodates a wider range of material densities and textures, from soft films to rigid containers, without requiring major adjustments. The ability to handle contaminants, such as labels or dirt in film plastics, further enhances their adaptability. Industry studies indicate that dual-shaft shredders maintain over 90% operational availability in mixed plastic recycling, underscoring their superior design for challenging applications.

The Challenges of Sorting Tangled Film Plastics: Why Traditional Single-Shaft Systems Fall Short

Film plastics, including low-density polyethylene (LDPE) and polypropylene (PP) films, possess unique physical properties that make them difficult to shred. Their low density, often below 1 g/cm³, means they are lightweight and prone to being pushed away by cutting forces rather than engaged. High elongation, sometimes exceeding 500% before breakage, allows these materials to stretch and absorb energy without fracturing. These characteristics are advantageous in packaging but problematic in shredding, as they cause films to act like ropes, twisting around shafts and blades.

Single-shaft shredders, designed for direct cutting, struggle immensely with these properties. The shear action requires materials to be held firmly in place, but films slip through the gaps or wrap around the rotor. This leads to frequent machine stoppages for manual cleaning, reducing overall efficiency. In many cases, the wrapped material can overload the motor or damage the cutting elements, resulting in costly repairs. The inherent limitations of single-shaft systems become apparent when processing film plastics, where their design is fundamentally mismatched with material behavior.

Physical Properties Analysis of Film Plastics: Low Density and High Ductility

Film plastics exhibit a combination of low density and high ductility that defines their processing challenges. Density values range from 0.91 to 0.94 g/cm³ for LDPE, making them buoyant and difficult to compact. Ductility refers to the material's ability to deform under tensile stress; films can stretch to several times their original length before tearing. This elasticity means that when a shear force is applied, the film elongates and moves with the blade, avoiding clean cuts. Instead, it may fold or bundle, creating knots that jam machinery.

The molecular structure of polyethylene contributes to these properties, with long polymer chains that slide past each other when stressed. This allows the material to absorb significant energy without breaking, unlike brittle materials like polystyrene. In shredding terms, this requires a force that exceeds the film's tensile strength, which is where tearing excels. Data show that the tensile strength of LDPE film is around 10-20 MPa, but its elongation at break can be 300-600%, indicating the need for a shredding method that pulls rather than cuts. Understanding these properties is key to selecting equipment that can manage them effectively.

Common Issues with Single-Shaft Shredders When Processing Film: Tangling, Blockages, and Low Efficiency

When single-shaft shredders process film plastics, the most frequent issue is tangling, where films wrap tightly around the rotor shaft. This occurs because the rotating blade acts as a spool, catching and winding the material. Tangling not only halts production but also requires hazardous manual intervention to clear. Blockages in the feed opening are another common problem, as lightweight films may not feed consistently and instead bridge over the hopper. This leads to uneven processing and necessitates constant operator attention, reducing automation potential.

Efficiency metrics highlight these shortcomings; for instance, a single-shaft shredder might achieve only 50-60% of its rated throughput when handling film plastics due to frequent jams. Power consumption can spike by up to 20% during tangling events as the motor struggles against the binding material. In contrast, rigid plastics like PET bottles are processed smoothly, demonstrating the specificity of the issue. The cumulative effect is higher operational costs and lower overall productivity, making single-shaft systems ill-suited for film-dominated waste streams without significant modifications.

Heat Buildup Risks: The Impact of Repeatedly Cutting Ductile Materials

Repeated attempts to cut ductile materials like film plastics generate significant friction heat within the shredder chamber. In single-shaft systems, the shearing action involves continuous blade contact with the material, and if the material does not cut cleanly, the sliding motion produces heat. Temperatures can rise above 80°C, which may soften the plastic further, exacerbating wrapping issues. Prolonged heat exposure also accelerates blade wear, reducing their sharpness and efficiency over time.

Heat buildup poses risks beyond mechanical wear; it can degrade the plastic polymer, affecting the quality of the recycled output. For example, LDPE films may oxidize or melt, leading to agglomerates that are difficult to separate. Cooling systems can mitigate this, but they add complexity and cost. Data from thermal imaging studies show that single-shaft shredders operating on films exhibit hot spots around the rotor, whereas dual-shaft models distribute heat more evenly due to their tearing action. This thermal management difference underscores the importance of matching shredder type to material characteristics.

Uneven Discharge and Subsequent Processing Difficulties

The output from single-shaft shredders processing film plastics is often inconsistent in size and shape. Instead of uniform flakes, long strips or tangled balls may emerge, which complicate downstream operations. These irregular fragments can clog conveyors, reduce the efficiency of washing systems, and cause uneven feeding into extruders. In recycling lines, uniform particle size is crucial for optimal melting and pelletizing; variations can lead to poor-quality pellets with impurities.

Downstream equipment, such as air classifiers or density separators, relies on consistent feed sizes to function properly. Non-uniform shreds from single-shaft machines can cause segregation issues, where light films mix with heavier fragments, reducing purity levels. Industry reports note that post-shredding sorting efficiency drops by 15-25% when feed material is inconsistent. This cascading effect highlights how initial shredding choices impact the entire recycling chain, making discharge quality a critical factor in equipment selection.

The Advantages of Dual-Shaft Shredders: Designed to Conquer Tangled Materials

Dual-shaft shredders are specifically engineered to address the limitations of single-shaft models when handling challenging materials like film plastics. Their design leverages the principles of grabbing, tearing, and pulling to mechanically disassemble materials without allowing them to wrap or rebound. This approach transforms the shredding process from a cutting-based operation to a tearing-dominated one, which aligns perfectly with the properties of flexible plastics. The result is higher throughput, fewer interruptions, and better quality output for recycling applications.

The superiority of dual-shaft systems is evident in their ability to maintain continuous operation even with mixed or contaminated feeds. For instance, they can process film plastics containing labels, dirt, or other debris without significant performance loss. This robustness reduces the need for pre-sorting, saving time and labor costs. Operational data indicate that dual-shaft shredders can achieve throughput rates of 1-3 tons per hour for film plastics, depending on machine size and configuration, with availability rates exceeding 85%. These metrics make them indispensable in modern recycling facilities focused on efficiency and reliability.

How the "Grab-Tear-Pull" Mechanism Solves Tangling Problems

The grab-tear-pull mechanism inherent in dual-shaft shredders begins with the hooked cutters on the rotors seizing the material firmly upon entry. Unlike shearing, which requires the material to be stationary, this action actively draws the film inward, preventing it from escaping. Once gripped, the counter-rotating shafts stretch the material until it ruptures at its weakest point. This process mimics hands pulling apart a flexible object, ensuring that elasticity is exploited rather than resisted.

This mechanism effectively eliminates tangling because the material is constantly under tension and moving downward. There is no opportunity for it to wrap around a single point, as the dual shafts maintain control throughout the cycle. Tests show that dual-shaft shredders can reduce tangling-related stoppages by over 80% compared to single-shaft units. The positive feed action also means that energy is used more efficiently, with power consumption remaining stable even under varying load conditions. This reliability is a key advantage in automated recycling lines where consistency is paramount.

Performance of Dual-Shaft Systems with Mixed Film Plastics Containing Impurities

Dual-shaft shredders demonstrate remarkable tolerance for impurities commonly found in film plastic waste, such as paper labels, adhesives, or sand. The tearing action is less sensitive to contaminant presence than shearing, which can be bluntly impaired by hard inclusions. The high torque generated by the slow-speed rotors allows the shredder to crush or incorporate impurities without damaging the cutters. This capability reduces the need for extensive pre-cleaning, streamlining the recycling process.

In mixed waste streams, dual-shaft machines maintain consistent performance, as evidenced by field studies where they handle post-consumer film with impurity levels up to 5% by weight. The output remains uniform, facilitating better separation in downstream steps like air conveying systems. This adaptability makes dual-shaft shredders ideal for material recovery facilities (MRFs) where waste composition varies daily. The ability to process contaminants without frequent adjustments contributes to higher overall system uptime and lower maintenance costs.

More Controllable Discharge Size: Achieving Uniform Fragments with Screen Configuration

Dual-shaft shredders offer precise control over output size through the use of interchangeable screens or grates placed at the discharge point. The torn fragments are pushed against the screen by the rotors, and only pieces smaller than the screen openings exit the chamber. This ensures a consistent particle size, which is crucial for subsequent processing stages. Screen sizes typically range from 10 mm to 100 mm, allowing customization based on the desired end product.

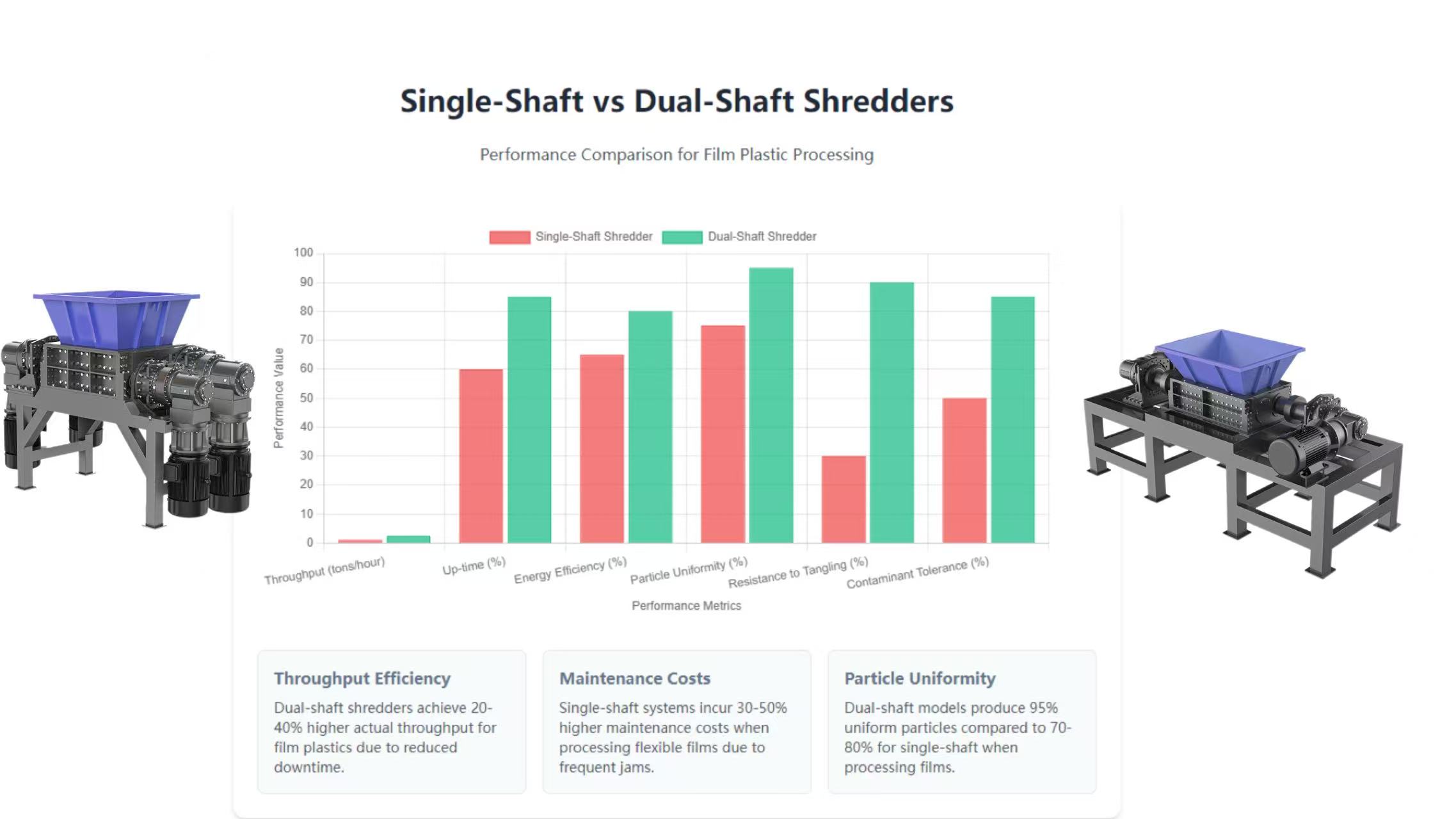

The uniformity of discharge particles enhances the efficiency of sorting and washing equipment. For example, flakes of similar size dry more evenly and melt uniformly in extruders. Data from recycling plants show that dual-shaft shredders with properly sized screens can produce over 95% of particles within a narrow size range, compared to 70-80% for single-shaft models processing films. This consistency improves the quality of recycled pellets, increasing their market value. The screen design also aids in controlling material residence time, preventing over-shredding and optimizing energy use.

Capacity Comparison: Why Dual-Shaft Shredders Achieve Higher Actual Throughput for Films

When evaluating capacity, dual-shaft shredders often outperform single-shaft models in actual operating conditions for film plastics. While theoretical throughput might be similar, the reduction in downtime due to jams and tangling significantly boosts the dual-shaft's effective capacity. For instance, a dual-shaft unit rated at 2 tons per hour can sustain that rate continuously, whereas a single-shaft machine might average only 1 ton per hour after accounting for stoppages.

Real-world data from recycling facilities confirm this disparity; dual-shaft shredders frequently achieve 20-40% higher annual throughput when processing film-rich waste. The continuous feed capability, coupled with lower maintenance requirements, translates to more material processed per operating hour. This efficiency is measurable in terms of reduced labor for clearing jams and lower energy consumption per ton of material. The higher upfront cost of dual-shaft shredders is often offset by these productivity gains, resulting in a better return on investment for high-volume applications.

Key Decision Factors: When Must You Choose a Dual-Shaft Shredder?

Selecting the appropriate shredder involves weighing several factors beyond initial cost. For operations dealing primarily with film plastics, a dual-shaft shredder is often the only viable option due to its material-specific advantages. The decision should be based on a thorough analysis of the waste stream composition, desired output quality, production volume, and long-term business goals. Ignoring these factors can lead to chronic operational issues and higher total cost of ownership.

A clear decision framework helps determine when a dual-shaft system is indispensable. If the material mix includes more than 30% film plastics by volume, or if the waste stream contains significant impurities, a dual-shaft shredder is recommended. Additionally, operations aiming for high automation levels or planning future expansion should prioritize the flexibility of dual-shaft machines. Economic considerations, such as maintenance costs and energy efficiency, further support this choice when processing challenging materials.

Material Type Assessment: Beyond Films, What Other Materials Require Dual-Shaft?

While film plastics are a primary candidate for dual-shaft shredding, other materials also benefit from this technology. Fibrous substances like textiles or carpets share the tendency to tangle, making them unsuitable for single-shaft systems. Bulky items such as large plastic containers, tires, or electronic waste require the high torque and tearing action to break them down efficiently. For example, tire shredding relies on dual-shaft machines to shear steel beads and rubber simultaneously.

In the realm of solid waste, items like mattresses or furniture often contain mixed materials that resist straightforward cutting. Dual-shaft shredders handle these heterogeneous streams effectively, as evidenced by their use in municipal solid waste processing. The ability to process a wide range of materials future-proofs the investment, allowing facilities to adapt to changing waste compositions. This versatility is a key reason why dual-shaft shredders are preferred in diverse recycling applications.

Throughput Requirements and the Need for Automated Feeding

High-volume operations necessitate shredders that can integrate seamlessly with automated feeding systems, such as conveyor belts or robotic arms. Dual-shaft shredders are inherently compatible with automation due to their self-feeding design; the rotating pullers draw material in consistently without requiring external force. This allows for continuous operation with minimal human intervention, maximizing throughput. For film plastics, automated lines can achieve rates exceeding 3 tons per hour, which is challenging for manual-fed single-shaft units.

Throughput demands should be projected over the long term to avoid under-sizing equipment. If daily processing volumes are expected to grow, investing in a dual-shaft shredder with reserve capacity is prudent. The machine's ability to handle peak loads without clogging ensures stable production schedules. Data from automated facilities show that dual-shaft shredders can operate for 20-22 hours daily with proper maintenance, whereas single-shaft models may require frequent pauses. This reliability is critical for meeting contractual obligations and maintaining profitability.

Initial Investment vs. Long-Term Operational Cost (ROI) Considerations

The initial purchase price of a dual-shaft shredder is typically 20-50% higher than that of a comparable single-shaft model, due to its complex construction and heavier components. However, this cost difference must be evaluated against long-term operational expenses. Dual-shaft shredders incur lower maintenance costs because they experience fewer jams and associated wear. Blade life is often extended, as tearing imposes less abrasive stress than repeated shearing on ductile materials.

Return on investment (ROI) calculations should include factors like reduced downtime, labor savings, and higher output quality. For instance, a dual-shaft shredder might pay for itself within 2-3 years through increased productivity and lower repair frequency. Energy consumption per ton of processed material is also favorable, as the efficient tearing action minimizes power waste. Businesses should conduct a lifecycle cost analysis to appreciate the full financial picture, rather than focusing solely on upfront expenditure. The superior ROI of dual-shaft systems makes them a wise choice for serious recycling operations.

Flexibility for Future Business Expansion Considerations

Investing in a dual-shaft shredder provides flexibility to handle a broader range of materials as business needs evolve. If a recycling facility plans to diversify into new waste streams, such as electronics or composites, a dual-shaft machine can adapt without major modifications. This scalability reduces the need for additional capital investments later, protecting against obsolescence. The modular design of many dual-shaft shredders allows for upgrades, such as adding finer screens or enhanced drives.

Market trends indicate growing volumes of flexible packaging and mixed plastics, reinforcing the relevance of dual-shaft technology. By choosing a versatile shredder, businesses position themselves to capitalize on emerging opportunities. The ability to process materials like e-waste or wood waste with the same equipment simplifies operations and reduces space requirements. This forward-thinking approach ensures that the shredder remains a valuable asset for years to come, supporting sustainable growth.

Beyond Single vs. Dual Shaft: Other Key Configurations for Film-Specific Shredders

While the shaft configuration is fundamental, optimizing a shredder for film plastics involves attention to ancillary components and settings. Factors like blade design, screen selection, drive systems, and control technology significantly influence performance. These elements work together to enhance the shredder's ability to handle thin, flexible materials efficiently. Ignoring them can undermine the benefits of even a well-chosen dual-shaft system.

Modern shredders incorporate advanced features that address specific challenges of film processing. For example, specialized hook-shaped blades improve material grabbing, while intelligent controls prevent overloads. Understanding these configurations allows operators to fine-tune the machine for maximum output and longevity. The integration of these components transforms a standard shredder into a high-performance unit tailored for film plastics, ensuring consistent results in demanding recycling environments.

Blade Design and Material: Hook-Shaped Cutters and Special Coatings for Film Optimization

The shape and material of shredder blades are critical for processing film plastics. Hook-shaped cutters, commonly used in dual-shaft shredders, feature a pronounced tip that penetrates and grips the material securely. This design increases the surface area engaged during tearing, reducing the likelihood of slippage. Blades made from high-grade tool steel, such as D2 or H13, offer excellent wear resistance, maintaining sharpness over prolonged use.

Advanced coatings, like tungsten carbide or chromium nitride, further enhance blade durability by reducing friction and preventing adhesion of plastic residues. These coatings can extend blade life by up to 300% compared to uncoated versions, as demonstrated in endurance tests. The optimal blade geometry and material combination ensure efficient tearing with minimal energy input. Regular inspection and rotation of blades maintain cutting performance, making them a key focus in shredder maintenance schedules.

Screen Selection and Size: Impact on Discharge and Material Flow

Screens, or discharge grates, control the final particle size by allowing only sufficiently small fragments to exit the shredding chamber. For film plastics, screen holes are often circular or slotted, with sizes ranging from 15 mm to 50 mm depending on the desired output. Smaller screens produce finer flakes but may reduce throughput due to increased resistance. The screen's thickness and material also affect durability; thicker screens withstand abrasive wear better but require more power to operate.

The screen configuration influences material flow within the chamber. Properly designed screens prevent material from recirculating excessively, which can cause heat buildup. Data show that optimized screens can improve throughput by 10-15% by ensuring smooth discharge. Additionally, screens aid in classifying the output, which is beneficial for downstream processes like washing. Selecting the right screen is a balance between particle size requirements and operational efficiency, and it should be tailored to the specific film plastic being processed.

Power System Configuration: The Benefits of High Torque and Low Speed

Dual-shaft shredders for film plastics typically employ high-torque, low-speed drive systems to generate the necessary tearing force. Electric motors coupled with heavy-duty gearboxes provide torque values exceeding 10,000 Nm, while keeping rotational speeds below 40 RPM. This combination ensures that the shredder can apply sustained force without overheating or stalling. The low speed also reduces wear on moving parts, contributing to longer service intervals.

Hydraulic drive systems are an alternative, offering variable speed control and overload protection. They automatically adjust torque based on material resistance, preventing damage from hard contaminants. Power consumption data indicate that high-torque systems operate more efficiently under load, with energy use proportional to material toughness. The choice between electric and hydraulic drives depends on factors like available power infrastructure and desired flexibility. Both options prioritize torque over speed, which is essential for effective film shredding.

Intelligent Control and Anti-Overload Protection Systems

Modern shredders incorporate programmable logic controllers (PLCs) and human-machine interfaces (HMIs) to monitor and adjust operation in real time. These systems track parameters like motor load, temperature, and vibration, triggering automatic responses to abnormal conditions. For example, if an overload is detected, the shredder may reverse briefly to clear a jam before resuming. This intelligence minimizes manual intervention and reduces the risk of damage.

Anti-overload protection is particularly important for film plastics, where unexpected contaminants can cause sudden stress. Sensors detect current spikes or pressure changes, activating safety protocols. Historical data from controlled shredders show a 50% reduction in unplanned downtime due to jams. Additionally, smart controls optimize energy use by adjusting speed based on feed rate, saving up to 15% on power costs. These features make shredders more reliable and user-friendly, supporting uninterrupted production.

Operation and Maintenance Tips: Ensuring Dual-Shaft Shredders Remain Efficient When Handling Film

Proper operation and maintenance are essential to maximize the performance and lifespan of a dual-shaft shredder dedicated to film plastics. Even the best equipment can underperform if not used correctly. Key practices include controlled feeding, regular inspection of wear parts, and adherence to manufacturer guidelines. These measures prevent common issues like uneven wear, blockages, and premature failure, ensuring consistent output quality.

Maintenance routines should be proactive rather than reactive, scheduling checks based on operating hours or material throughput. For instance, blade inspection every 200 hours of operation helps identify dullness before it affects performance. Lubrication of bearings and gearboxes according to specifications prevents friction-related failures. Training operators on best practices reduces human error, contributing to safer and more efficient operations. A well-maintained shredder not only performs better but also retains its value over time.

Feeding Techniques: Achieving Uniform and Continuous Feed to Prevent Blockages

Consistent feeding is crucial for dual-shaft shredders to maintain optimal tearing action. Operators should avoid dumping large, compacted bales of film plastics directly into the hopper, as this can overwhelm the shredder. Instead, material should be fed evenly using conveyors or manual methods that spread the load. This allows the rotors to grab and process material without sudden surges that cause overloads.

Automated feeding systems with metering devices ensure a steady flow, reducing the risk of bridging or ratholing in the hopper. Data show that controlled feeding can increase throughput by up to 20% by maintaining ideal chamber conditions. Operators should also monitor material for oversized items or contaminants that might bypass pre-sorting. Proper feeding not only prevents blockages but also promotes uniform wear on blades, extending their service life and reducing maintenance frequency.

Daily Maintenance Checklist: Inspecting Blade Wear, Bearing Condition, and Clearing Debris

A daily maintenance routine involves visual inspections and simple checks to catch issues early. Blades should be examined for signs of dulling, chipping, or coating wear, which can reduce grabbing efficiency. Bearings must be checked for unusual noise or heat, indicating potential failure. The shredder chamber and discharge area should be cleared of accumulated debris that might impede material flow.

Recording observations in a log helps track wear patterns and plan replacements proactively. For example, blade life typically ranges from 500 to 1000 operating hours for film plastics, depending on material purity. Using proper lubrication at recommended intervals ensures smooth rotation of shafts. Daily maintenance takes only minutes but prevents major repairs, supporting continuous operation and reducing long-term costs.

Blade Wear Assessment and Rotation Strategies

Blade wear in dual-shaft shredders is not uniform; cutters near the feed opening experience more stress than those downstream. Regular assessment involves measuring blade thickness and edge sharpness using gauges. Worn blades increase power consumption and reduce output quality, so timely rotation or replacement is essential. Rotating blades periodically—for instance, swapping positions between shafts—balances wear and extends overall life.

A structured rotation schedule, such as every 100 hours of operation, ensures that no blade becomes excessively worn. Data indicate that rotated blades last 30-40% longer than those left in place. When replacing blades, using matched sets maintains balance and prevents vibration. Proper torque during installation is critical to avoid loosening under load. These practices optimize cutting performance and minimize downtime for blade changes.

Long-Term Shutdown Procedures and Reactivation Steps

For extended shutdowns, such as seasonal breaks, the shredder must be prepared to prevent corrosion and component seizure. All material should be purged from the chamber to avoid hardening or attracting pests. Blades and internal surfaces should be cleaned and coated with anti-rust agents. Bearings and gears require fresh lubrication to protect against moisture.

Reactivation involves a thorough inspection to ensure no damage occurred during storage. Blades should be checked for rust, and motors tested at low speed before full operation. Starting with a light load, such as clean film plastic, helps recalibrate the system. These steps prevent unexpected failures and ensure the shredder resumes operation smoothly. Proper shutdown and reactivation protocols preserve equipment value and reliability over many years.