Industrial metal shredders have revolutionized the automotive recycling sector by enabling efficient processing of end-of-life vehicles while maximizing resource recovery. These powerful machines transform complete car bodies into valuable raw materials through advanced shredding technology, addressing both economic and environmental challenges in modern vehicle recycling operations. This comprehensive analysis explores how specialized shredding equipment handles the complex material composition of automobiles while delivering significant operational benefits.

Unique Characteristics of Automotive Metal Waste

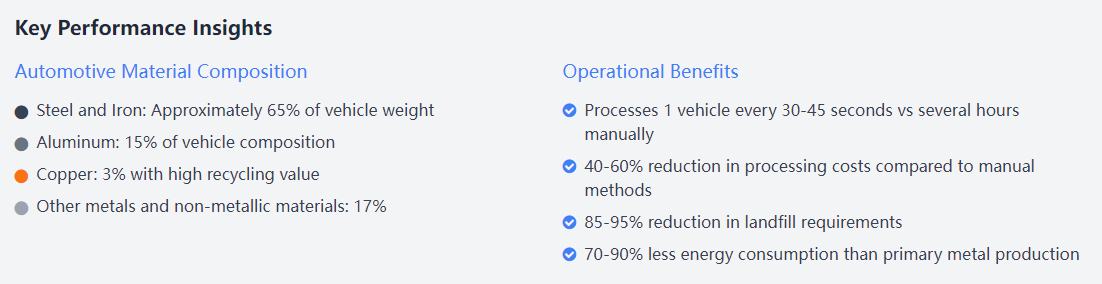

End-of-life vehicles present particularly challenging material characteristics that require specialized shredding solutions. The average automobile contains approximately 65% steel and iron, 15% aluminum, 3% copper, and various other metals alongside significant amounts of plastics, rubber, glass, and fluids. This complex material composition demands shredders capable of handling diverse material properties while maintaining operational efficiency and output quality.

The physical structure of vehicles adds another layer of complexity, with large, irregularly shaped components that vary significantly in density and strength. Modern vehicles incorporate advanced high-strength steels and aluminum alloys that require substantial cutting forces, while also containing fragile components that must be processed without excessive dust generation. This combination of material diversity and structural complexity makes automotive shredding particularly demanding compared to other recycling applications.

Diverse Metal Types and Configurations

Automotive metal waste encompasses an extraordinary variety of metal types, each with distinct processing requirements. The typical vehicle contains mild steel body panels, high-strength steel frame components, aluminum engine blocks, copper wiring systems, and various alloy elements. These materials exhibit different hardness levels, tensile strengths, and cutting characteristics that influence shredder selection and operation.

The configuration of automotive metals further complicates processing, with combinations of thin sheet metals, thick cast components, and complex fabricated structures. Modern double-shaft shredders excel at handling this diversity through their shear-based cutting action, which efficiently processes both thin materials and heavy sections without requiring pre-processing. This capability significantly reduces handling time and improves overall operational efficiency.

Mixed Material Composition Challenges

Automotive shredding must address the challenge of metal-nonmetal combinations that are integral to vehicle construction. Electrical systems combine copper wiring with plastic insulation, seats incorporate steel frames with fabric and foam, and dashboards blend various plastics with metal reinforcements. These combinations require shredding technology that can liberate materials for effective subsequent separation.

The presence of contaminants such as glass, fluids, and rubber affects both shredding performance and downstream processing. Modern shredding systems incorporate advanced dust extraction and contaminant management features that handle these mixed material streams effectively. Proper processing ensures that non-metallic materials are separated without compromising metal quality or recycling efficiency.

High-Value Recyclable Metal Content

Despite the challenges, automotive waste represents a significant source of high-value metals. The average end-of-life vehicle contains approximately 900 kg of recoverable metals, with current recovery rates reaching 95% in advanced recycling facilities. The economic value of these metals, particularly copper, aluminum, and high-grade steels, justifies investment in sophisticated shredding and separation technology.

The concentration of valuable metals varies significantly across vehicle types and ages, with modern vehicles typically containing more aluminum and electronics. Advanced shredding systems must accommodate these variations while maintaining consistent output quality. The ability to efficiently recover these valuable materials directly impacts the economic viability of automotive recycling operations.

Core Functions of Shredders in Vehicle Dismantling

Industrial shredders serve as the central processing technology in modern automotive recycling facilities, performing several critical functions that enable efficient material recovery. These machines transform complete vehicle hulks into processed materials ready for metallurgical recycling, typically reducing vehicles to fragments measuring 100-150 mm in size. This size reduction liberates materials for effective separation and prepares them for subsequent processing stages.

The shredding process typically follows initial depollution and component removal stages, where fluids, batteries, tires, and certain valuable components are extracted. Modern shredders handle the remaining vehicle hulks with minimal additional preparation, significantly reducing labor requirements compared to traditional dismantling methods. This streamlined approach has revolutionized automotive recycling economics while improving recovery rates and material quality.

Efficient Processing of Large Automotive Components

Modern automotive shredders demonstrate remarkable capability in processing complete vehicle bodies and large components. These machines typically feature massive hydraulic feed systems that can handle entire car bodies, with processing capacities ranging from 50-150 vehicles per hour depending on shredder size and configuration. The shredding process reduces vehicles to uniform fragments in seconds, enabling continuous high-volume operation.

The cutting systems in automotive shredders generate tremendous forces, often exceeding 10,000 horsepower in large installations. These systems employ specially designed cutting rotors with replaceable cutting elements that withstand the abrasive nature of automotive materials. Advanced monitoring systems ensure optimal operation by adjusting feed rates and cutting parameters based on real-time load conditions, maximizing throughput while protecting equipment from damage.

Effective Metal-Nonmetal Separation

Following shredding, advanced separation systems isolate metals from non-metallic materials with remarkable efficiency. Magnetic separation technology typically recovers 98-99% of ferrous metals, while eddy current separators achieve 90-95% recovery rates for non-ferrous metals. These separation processes rely on the uniform particle size produced by the shredder, highlighting the importance of consistent shredding performance.

The remaining non-metallic fraction, known as automotive shredder residue, undergoes further processing to recover additional materials and minimize landfill requirements. Modern facilities employ various technologies including air classification, density separation, and optical sorting to extract remaining metals and recyclable materials. This comprehensive approach maximizes resource recovery while minimizing environmental impact.

Enhanced Metal Recovery Rates and Purity

Advanced shredding systems significantly improve both the quantity and quality of recovered metals compared to traditional dismantling methods. Modern facilities achieve overall metal recovery rates exceeding 95%, compared to 75-85% with manual dismantling approaches. This improvement translates to substantial economic benefits, particularly given the rising value of recycled metals.

The quality of shredded metal directly impacts its market value and usability in metallurgical processes. Modern shredders produce clean, dense fragments with minimal contamination, meeting the stringent quality requirements of steel mills and foundries. This high-quality output commands premium prices in recycling markets, significantly improving the economics of automotive recycling operations.

Performance Analysis and Operational Benefits

The implementation of advanced shredding technology in automotive recycling has delivered measurable improvements in operational efficiency, economic performance, and environmental outcomes. Modern shredding facilities typically process 300,000-500,000 vehicles annually, with larger installations handling up to 1 million vehicles per year. This scale of operation generates significant economic benefits while addressing environmental challenges associated with end-of-life vehicle management.

The operational efficiency of automotive shredders continues to improve through technological advancements in cutting systems, drive technology, and control systems. Modern shredders achieve specific energy consumption of 15-25 kWh per ton of processed material, representing significant improvements over earlier generations of equipment. These efficiency gains contribute to both economic and environmental performance.

Efficiency Improvements in Automotive Recycling Facilities

The integration of modern shredding technology has transformed automotive recycling operations, typically increasing processing capacity by 200-300% compared to traditional methods. A typical automotive shredder installation can process a vehicle every 30-45 seconds, compared to several hours required for manual dismantling. This dramatic improvement in throughput has enabled the development of large-scale regional recycling centers that serve broad geographic areas.

Operational efficiency extends beyond sheer processing speed to include labor productivity, energy efficiency, and material recovery rates. Modern shredding facilities typically operate with 60-70% fewer direct labor hours per vehicle processed while achieving higher material recovery rates. This combination of factors significantly improves the economic viability of automotive recycling while ensuring environmental compliance.

Cost Reduction and Revenue Enhancement

The economic benefits of automotive shredding technology manifest through both cost reduction and revenue enhancement. Processing costs typically decrease by 40-60% compared to manual dismantling methods, primarily through reduced labor requirements and improved operational efficiency. Simultaneously, revenue increases through higher metal recovery rates and improved material quality that commands better market prices.

The economic analysis of automotive shredding operations must consider capital investment, operating costs, and revenue generation. Modern shredding installations represent significant investments ranging from $10-50 million depending on capacity and technology level. However, these investments typically achieve payback periods of 3-5 years through operational efficiencies and improved material recovery values.

Environmental Benefits and Sustainability Impact

Automotive shredding technology delivers substantial environmental benefits by reducing landfill requirements, conserving natural resources, and minimizing energy consumption in metal production. Recycling metals through shredding typically requires 70-90% less energy than primary metal production from ore, significantly reducing greenhouse gas emissions and other environmental impacts.

The comprehensive material recovery achieved through modern shredding operations reduces landfill requirements by 85-95% compared to disposal of complete vehicles. This reduction in waste generation addresses growing concerns about landfill capacity while recovering valuable materials for reuse. The environmental performance of automotive shredding continues to improve through technological advancements and process optimization.

Technological Advancements in Automotive Shredding

Recent technological developments have significantly enhanced the performance and efficiency of automotive shredding systems. These advancements address the evolving challenges presented by modern vehicle designs, which incorporate more diverse materials and complex construction techniques. Modern shredders incorporate sophisticated monitoring and control systems that optimize performance while extending equipment lifespan.

Material science innovations have dramatically improved the durability and performance of cutting components. Advanced alloy steels and specialized heat treatment processes extend component life while maintaining cutting efficiency. These improvements reduce maintenance requirements and downtime, significantly improving overall equipment effectiveness in demanding automotive shredding applications.

Intelligent Control and Monitoring Systems

Modern automotive shredders incorporate sophisticated PLC-based control systems that monitor and optimize shredding performance in real-time. These systems track numerous parameters including motor load, vibration levels, bearing temperatures, and hydraulic pressure, automatically adjusting operation to maintain optimal performance while preventing damage.

The control systems employ advanced algorithms that learn from operational data, continuously improving performance through adaptive control strategies. These intelligent systems can predict maintenance requirements, optimize energy consumption, and ensure consistent output quality despite variations in input material characteristics. The integration of these technologies has significantly improved the reliability and efficiency of automotive shredding operations.

Advanced Wear Protection and Maintenance Systems

The abrasive nature of automotive materials necessitates robust wear protection systems in shredding equipment. Modern shredders incorporate advanced wear-resistant materials in critical areas, significantly extending component life and reducing maintenance requirements. These materials include specialized alloy steels, ceramic composites, and advanced surface treatments that withstand extreme abrasive conditions.

Maintenance systems have evolved to minimize downtime and reduce labor requirements. Quick-change cutting elements, automated lubrication systems, and remote monitoring capabilities ensure that maintenance activities are performed efficiently and proactively. These advancements have increased equipment availability to 90-95% in modern automotive shredding facilities, significantly improving operational efficiency and economic performance.

Future Trends in Automotive Shredding Technology

The future of automotive shredding technology focuses on addressing emerging challenges including electric vehicle recycling, lightweight materials, and increasingly stringent environmental regulations. Electric vehicles present new recycling challenges due to their battery systems and different material compositions, requiring adaptations in shredding technology and safety systems.

Lightweighting trends in vehicle manufacturing are increasing the use of aluminum, composites, and advanced high-strength steels. These materials require different shredding approaches and separation technologies compared to traditional automotive materials. Future shredding systems will need to handle these material changes while maintaining high recovery rates and material quality.

Electric Vehicle Recycling Challenges

The growing adoption of electric vehicles presents both challenges and opportunities for automotive shredding operations. Lithium-ion batteries require special handling and safety precautions during shredding, including fire prevention systems and specialized processing techniques. However, these vehicles also contain valuable materials including copper, lithium, and cobalt that can be recovered through advanced recycling processes.

Future shredding technology will incorporate enhanced safety features for electric vehicle processing, including battery detection systems, fire suppression technology, and specialized processing chambers. These advancements will ensure safe and efficient recycling of electric vehicles while maximizing recovery of valuable materials.

Automation and Robotics Integration

The integration of automation and robotics represents the next frontier in automotive shredding technology. Automated feeding systems, robotic sorting technology, and artificial intelligence-based quality control will further improve efficiency and recovery rates. These technologies will reduce labor requirements while improving sorting accuracy and material quality.

Advanced sensor technology and machine learning algorithms will enable real-time material identification and sorting, maximizing recovery of valuable materials and improving output quality. These advancements will address the increasing complexity of automotive materials while maintaining economic viability in competitive recycling markets.