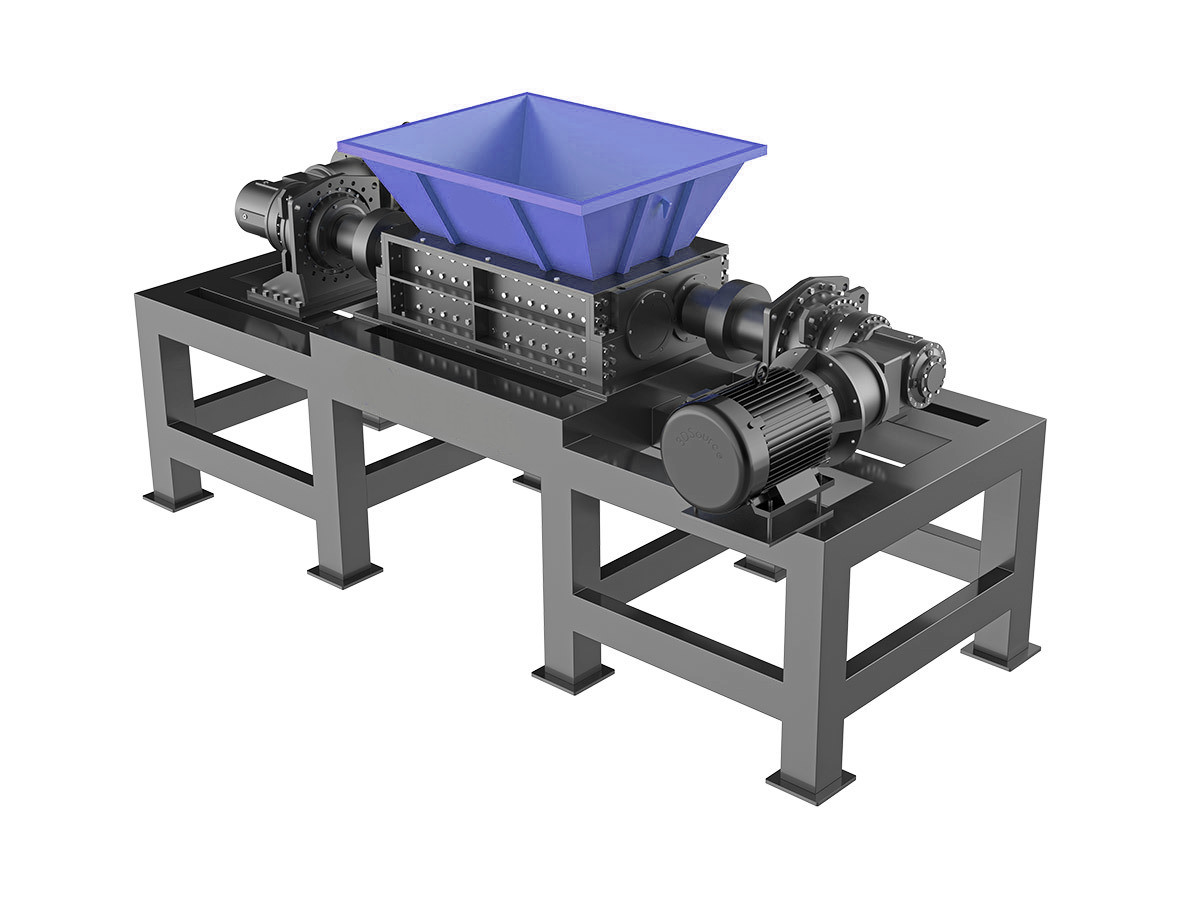

Scrap Metal Double Shaft Shredder

The scrap metal double shaft shredder is a powerful and efficient machine designed for processing various types of metal waste, including aluminum, steel, copper, and other ferrous and non-ferrous materials. It is widely used in metal recycling facilities, manufacturing plants, and waste processing centers.

Unlike single-shaft shredders, a double shaft shredder features two rotating shafts with heavy-duty blades that work together to tear, shear, and crush metal materials. This dual-shaft mechanism ensures efficient size reduction and high throughput capacity.

With its rugged design and advanced cutting technology, the scrap metal double shaft shredder is essential for reducing bulky metal waste into manageable fragments, making it easier to transport and recycle.

How a Scrap Metal Double Shaft Shredder Works

The shredding process begins when metal waste is fed into the cutting chamber. The two shafts, each equipped with sharp, wear-resistant blades, rotate in opposite directions, pulling the material in and breaking it down.

Unlike hammer mill shredders that rely on impact crushing, a double shaft shredder utilizes a low-speed, high-torque mechanism, which minimizes dust and noise while maximizing cutting efficiency.

The shredded metal pieces are discharged through a screen or grid, ensuring uniform output sizes suitable for further processing in smelting or refining operations.

Key Features of Scrap Metal Double Shaft Shredders

One of the key features of a double shaft shredder is its robust and durable construction, designed to withstand the demands of processing dense and abrasive metal materials.

The slow-speed, high-torque operation of the shredder reduces energy consumption while maintaining high cutting efficiency, making it a cost-effective solution for metal recycling.

Many scrap metal double shaft shredders come with an automatic overload protection system, preventing damage from unshreddable objects and ensuring smooth operation.

Applications of Scrap Metal Double Shaft Shredders

Scrap metal double shaft shredders are commonly used in recycling plants to process end-of-life vehicles, metal drums, and aluminum profiles, reducing them into smaller, recyclable fragments.

In the manufacturing industry, these shredders help in managing production scrap, cutting down waste materials into reusable sizes for remelting and repurposing.

Additionally, they are widely used in demolition waste processing, breaking down construction and industrial metal scrap for efficient recycling.

Advantages of Using a Scrap Metal Double Shaft Shredder

One of the primary advantages of using a double shaft shredder is its ability to handle a wide variety of metal waste types, from lightweight aluminum to heavy steel components.

The low-speed operation significantly reduces wear and tear, extending the machine’s lifespan while ensuring consistent performance and minimal downtime.

Furthermore, the high-efficiency shredding process enhances metal recovery rates, allowing recyclers to maximize material reuse and reduce overall environmental impact.