Industrial shredders serve as critical equipment across various sectors, each with unique requirements and operational challenges. This guide explores the specific needs of different industries and provides detailed insights into selecting the most appropriate shredding technology. Understanding these application-specific considerations ensures optimal performance, maximum efficiency, and return on investment for your shredding operations.

Recycling Industry Requirements for Metal Shredders

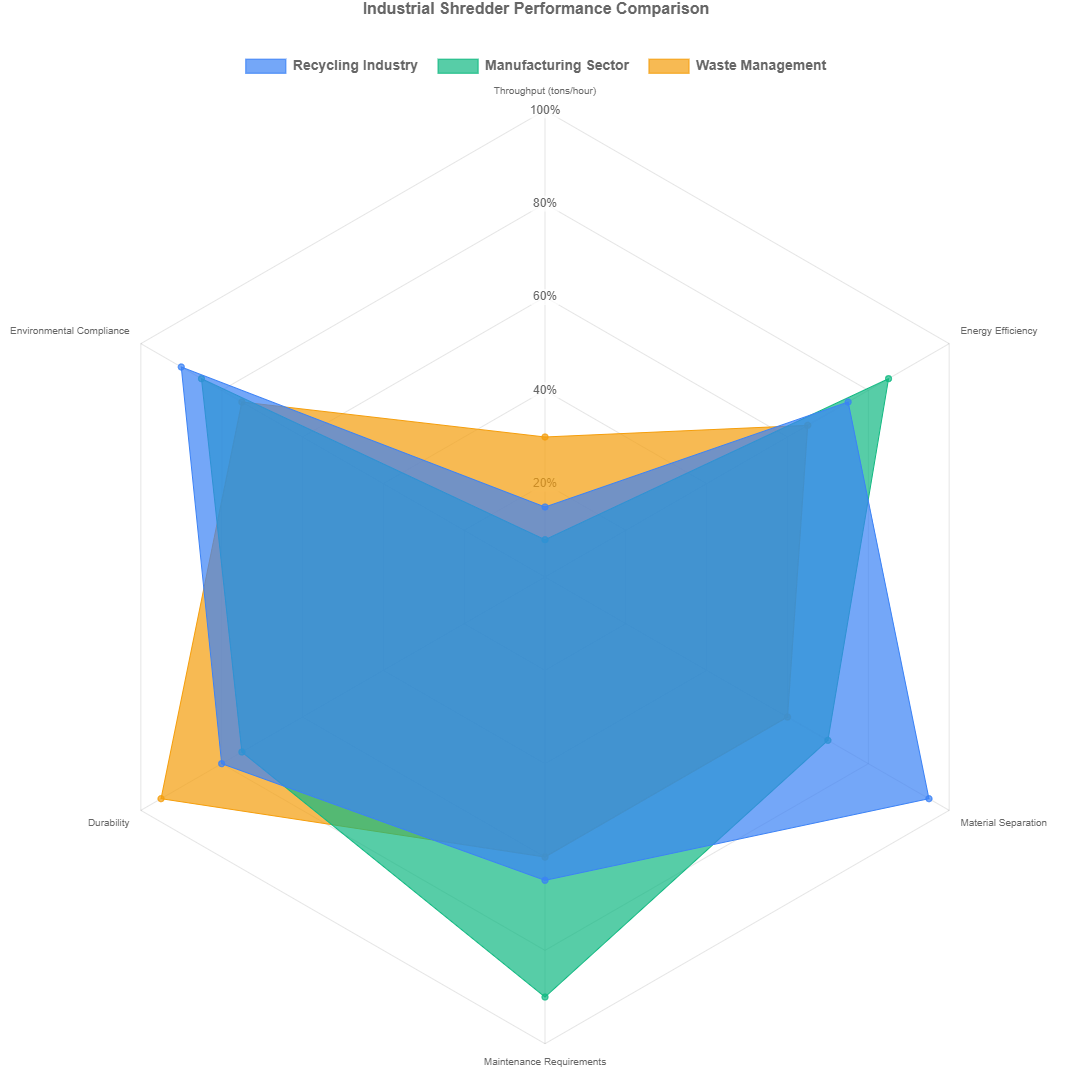

The recycling industry demands shredders capable of handling diverse metal streams while maintaining operational efficiency and output quality. Modern recycling facilities process an average of 5-20 tons of metal scrap per hour, requiring robust equipment that can withstand continuous operation. The choice of shredder technology significantly impacts the economic viability of recycling operations, affecting both processing costs and the quality of recycled materials.

Recycling operations typically utilize double-shaft shredders for their ability to process mixed metals efficiently. These machines employ counter-rotating shafts with interlocking cutters that generate tremendous shearing force, typically ranging from 100-500 tons depending on the model. The selection process must consider factors such as material composition, desired output size, and downstream separation requirements to ensure optimal system integration.

Mixed Metal Processing Capabilities

Modern recycling shredders must handle heterogeneous metal mixtures containing ferrous and non-ferrous materials. Advanced shredders incorporate intelligent sorting systems that can process mixed streams containing up to 30% non-metallic contaminants while maintaining operational efficiency. The cutting systems are designed with hardened steel blades that maintain sharpness even when processing abrasive materials like stainless steel or copper alloys.

The efficiency of mixed metal processing depends on the shredder's ability to maintain consistent output size despite variations in input material. Modern systems utilize hydraulic pressure monitoring and automatic reversal systems that prevent jamming when encountering difficult materials. This capability ensures continuous operation and minimizes downtime, which is crucial for recycling facilities operating 24/7.

Efficient Metal Separation for Value Enhancement

Value optimization in metal recycling requires precise separation of different metal types after shredding. Advanced shredding systems integrate magnetic separation technology that automatically separates ferrous metals from non-ferrous materials with efficiency rates exceeding 95%. This separation occurs immediately after the shredding process, maximizing material purity and market value.

Eddy current separators further enhance value recovery by separating non-ferrous metals based on their electrical conductivity. This technology can achieve separation efficiencies of up to 98% for aluminum, copper, and other valuable non-ferrous metals. The integration of these separation systems directly with the shredding process creates a streamlined operation that maximizes both throughput and material value.

Environmental Compliance and Emission Control

Modern shredding installations must comply with stringent environmental regulations regarding dust emissions, noise levels, and energy consumption. Advanced dust collection systems capture over 99% of particulate matter generated during shredding operations, ensuring compliance with air quality standards. These systems typically handle air volumes ranging from 10,000 to 50,000 cubic meters per hour, depending on the shredder size.

Noise reduction technologies incorporate acoustic enclosures and vibration damping systems that reduce operational noise levels below 85 decibels, meeting workplace safety standards. Energy efficiency is achieved through variable frequency drives that optimize power consumption based on processing requirements, typically reducing energy usage by 15-20% compared to conventional systems.

Manufacturing Sector Applications and Considerations

Manufacturing facilities utilize industrial shredders for various applications including production scrap management, quality control reject processing, and raw material preparation. The manufacturing environment demands shredders that integrate seamlessly with existing production lines while meeting specific operational requirements. These applications typically require precision shredding with consistent output quality and reliable performance.

Manufacturing shredders often need to process specific material types and shapes unique to the production process. The equipment must handle materials ranging from production off-cuts to rejected finished products while maintaining the cleanliness and purity requirements of manufacturing environments. Integration with material handling systems and compatibility with existing factory layouts are critical considerations in equipment selection.

Production Line Integration Capabilities

Successful integration of shredders into manufacturing lines requires careful consideration of material flow, space constraints, and operational synchronization. Modern shredders feature compact designs that minimize footprint while offering flexible configuration options. They typically include standardized interfaces for connection to pneumatic conveying systems and automated material handling equipment.

The control systems of manufacturing shredders must integrate with existing factory automation networks, supporting protocols such as PROFIBUS, Ethernet/IP, or Modbus. This integration enables real-time monitoring and control from central operation stations, allowing for seamless coordination with upstream and downstream processes. Advanced systems provide production data tracking and reporting capabilities for quality control and operational analysis.

Processing Specific Shapes and Sizes

Manufacturing applications often require shredding of specific product forms, including sheets, profiles, castings, or molded parts. Specialized shredders are available with customized feeding systems and cutting chamber designs that optimize processing for these specific shapes. The equipment must maintain consistent output quality regardless of variations in input material characteristics.

Size reduction ratios in manufacturing applications typically range from 10:1 to 30:1, depending on the material and subsequent processing requirements. The shredders must produce uniform particle sizes that meet the specifications for recycling or reuse in manufacturing processes. This consistency is achieved through precise engineering of cutting geometries and controlled feeding mechanisms.

Maintenance and Cleaning Accessibility

Manufacturing environments demand equipment that supports quick maintenance and thorough cleaning to minimize production interruptions. Modern shredders feature quick-access cutting chambers that allow for blade inspection and replacement without extensive disassembly. These designs typically reduce maintenance time by 40-50% compared to traditional configurations.

Hygienic design considerations include smooth surfaces, minimal crevices, and food-grade materials where applicable. Easy-clean features are particularly important in food processing, pharmaceutical, and electronic manufacturing applications where material contamination must be prevented. Many models offer CIP (Clean-in-Place) systems for automated cleaning cycles.

Waste Management Scenarios and Shredder Selection

Waste management operations require shredders capable of handling large volumes of diverse materials while operating under challenging conditions. These applications demand equipment with exceptional durability, high throughput capacity, and reliability. The shredders must process materials ranging from household appliances to industrial waste while maintaining operational efficiency and meeting environmental standards.

Waste management shredders typically feature heavy-duty construction with wear-resistant components that withstand abrasive materials and occasional contaminants. Throughput requirements often exceed 20 tons per hour for municipal solid waste applications, requiring powerful drives and robust cutting systems. The equipment must operate reliably in demanding environments with minimal supervision and maintenance.

Large Volume Metal Waste Processing

Waste management facilities process large metal items including appliances, vehicles, and industrial equipment. Heavy-duty shredders with hydraulic feed systems can process entire car bodies or large metal structures, reducing them to manageable fragments typically measuring 100-200 mm. These systems generate tremendous cutting forces, often exceeding 1000 tons in large industrial shredders.

The processing capacity for large metal waste typically ranges from 10-50 tons per hour, depending on the material density and shredder configuration. Advanced systems incorporate pre-shredding and fine-shredding stages to optimize energy consumption and output quality. Throughput monitoring and automatic load adjustment ensure efficient operation under varying feed conditions.

Durability and Long-Term Operational Stability

Waste management shredders are built for extended service life under continuous operation. Critical components including shafts, bearings, and cutting elements are manufactured from special alloy steels and undergo specialized heat treatment processes. These components typically achieve service lives of 10,000-20,000 operating hours between major overhauls.

The structural frames utilize heavy-grade steel plate construction with reinforced welding patterns that withstand dynamic loads and vibration. Vibration analysis and finite element analysis during design ensure structural integrity under worst-case operating conditions. Regular maintenance protocols and condition monitoring systems help maintain operational stability throughout the equipment's lifespan.

Operational Safety and User-Friendly Design

Modern waste shredders incorporate comprehensive safety systems that protect operators and prevent equipment damage. These include interlocked access doors, emergency stop systems, and overload protection mechanisms. Advanced monitoring systems track bearing temperatures, vibration levels, and power consumption, providing early warning of potential issues.

User interfaces feature intuitive controls with clear status indicators and diagnostic information. Automated operation modes optimize performance while minimizing operator intervention. Safety training requirements and operational procedures are integrated into the machine control systems, ensuring compliance with industry safety standards and regulations.

Advanced Control Systems and Automation Features

Modern industrial shredders incorporate sophisticated control systems that optimize performance, enhance safety, and simplify operation. These systems utilize programmable logic controllers (PLCs) and human-machine interfaces (HMIs) that provide comprehensive monitoring and control capabilities. The automation features significantly improve operational efficiency while reducing manpower requirements.

Advanced shredders feature self-diagnostic systems that monitor critical parameters including motor load, bearing temperatures, and hydraulic pressure. These systems can detect potential issues before they cause downtime, enabling predictive maintenance and reducing repair costs. The control systems typically store operational data for analysis and optimization of shredding processes.

Intelligent Load Management Systems

Modern shredders employ intelligent load management that automatically adjusts processing parameters based on material characteristics. These systems monitor motor current, hydraulic pressure, and vibration levels to optimize cutting efficiency while preventing overload conditions. The automation typically improves throughput by 15-25% while reducing energy consumption.

The load management systems can detect different material types and automatically adjust speed and feed rates accordingly. This capability is particularly valuable when processing mixed material streams with varying hardness and density. The systems maintain optimal performance while protecting the equipment from damage caused by unsuitable materials.

Remote Monitoring and Maintenance Capabilities

Advanced shredders feature remote connectivity that enables off-site monitoring and troubleshooting. These systems provide real-time access to operational data, performance metrics, and maintenance requirements. Technical support personnel can diagnose issues and often implement solutions without requiring physical presence at the facility.

The remote systems typically include automated alert functions that notify operators and maintenance teams of potential issues. These alerts can be configured based on predefined parameters and sent via multiple channels including email, SMS, or mobile applications. This capability significantly reduces response times and minimizes operational disruptions.

Environmental Considerations and Sustainability Aspects

Environmental performance has become a critical factor in shredder selection and operation. Modern equipment incorporates numerous features that minimize environmental impact while maximizing resource recovery. These considerations include energy efficiency, emission control, noise reduction, and water management.

Sustainable shredding operations focus on maximizing material recovery while minimizing waste generation and energy consumption. Advanced systems achieve recovery rates exceeding 95% for many materials, significantly reducing landfill requirements. The environmental performance of shredding operations is increasingly important for regulatory compliance and corporate sustainability reporting.

Energy Efficiency Optimization

Modern shredders incorporate energy-saving technologies that reduce power consumption while maintaining performance. Variable frequency drives optimize motor operation based on processing requirements, typically reducing energy usage by 20-30%. High-efficiency hydraulic systems and optimized cutting geometries further contribute to energy savings.

Energy recovery systems capture and reuse energy generated during the shredding process. Some advanced systems can recover up to 15% of the energy consumed through regenerative drives and heat recovery systems. These features significantly improve the overall energy efficiency of shredding operations.

Emission Control and Pollution Prevention

Advanced emission control systems capture dust, fumes, and other airborne contaminants generated during shredding operations. These systems typically achieve capture efficiencies exceeding 99%, ensuring compliance with stringent air quality regulations. The collected materials are often recovered and recycled, further enhancing the sustainability of the operation.

Noise abatement technologies reduce sound emissions to levels compliant with workplace and environmental regulations. Acoustic enclosures, vibration isolation, and silencers typically reduce noise levels by 20-30 decibels. Water management systems recycle process water and prevent contamination of local water sources.