Proper lubrication represents one of the most critical factors in ensuring reliable operation and extended service life for industrial shredding equipment. Bearings operating in scrap metal processing applications face extreme conditions that demand sophisticated lubrication strategies beyond conventional maintenance approaches. This comprehensive guide explores the scientific principles and practical methodologies for optimizing grease performance in demanding shredding environments.

Industrial statistics indicate that approximately 50% of bearing failures in continuous operation equipment result directly from lubrication deficiencies. The extreme conditions within scrap metal double shaft shredders accelerate lubricant degradation through thermal stress, mechanical shearing, and contamination, necessitating specialized maintenance protocols.

Operating Conditions and Lubrication Challenges for Double Shaft Shredder Bearings

Bearings in scrap metal shredders operate under some of the most severe conditions encountered in industrial machinery. The combination of extreme loads, contamination risks, and continuous operation creates a uniquely challenging environment for lubrication systems.

Understanding these specific operating conditions forms the foundation for developing effective lubrication strategies. The mechanical demands and environmental factors directly influence lubricant selection, application methods, and maintenance intervals.

Thermal Accumulation and Grease Aging Mechanisms Under Continuous Operation

Continuous shredding operations generate significant heat through mechanical friction and material deformation processes. Bearing temperatures typically range between 70-90°C during normal operation, with peak temperatures reaching 120°C during heavy loading conditions. These elevated temperatures accelerate the oxidation of base oils and degrade the thickener structure that gives grease its consistency.

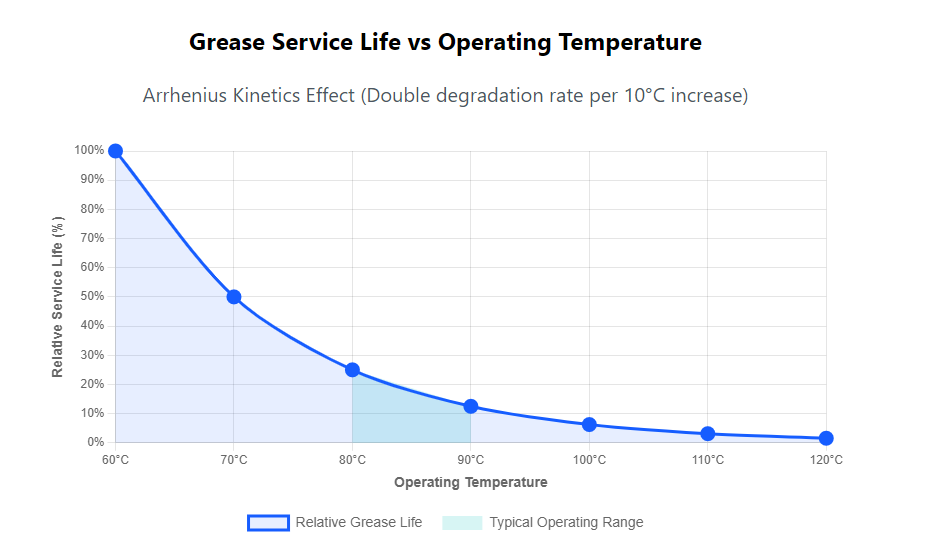

The thermal degradation follows Arrhenius kinetics, where the oxidation rate approximately doubles for every 10°C increase in operating temperature. This relationship means that bearings operating at 90°C experience lubricant degradation eight times faster than those at 60°C, significantly reducing effective service life.

Extreme Requirements for Grease Film Strength Under Impact Loading

Shredder bearings experience impact loads that can reach 3-5 times the average operating loads when processing irregular metal scrap. These sudden force spikes create extreme pressure conditions at the rolling element-raceway interfaces, demanding lubricants with exceptional film strength and load-carrying capacity.

High-quality greases for shredder applications typically demonstrate weld loads exceeding 3000N in four-ball extreme pressure tests. This performance level ensures the lubricant maintains protective films even under the most severe loading conditions, preventing metal-to-metal contact and subsequent surface damage.

Control Challenges of Metal Dust Contamination in Grease Systems

Metal particles measuring 3-20 micrometers generated during shredding operations present significant contamination risks. These hard particles can infiltrate bearing assemblies and become embedded in grease, creating three-body abrasive wear conditions that dramatically accelerate component deterioration.

Contamination levels as low as 0.5% by weight can reduce bearing life by up to 80% through abrasive wear mechanisms. Effective sealing systems and proper grease selection play crucial roles in mitigating this damage by excluding contaminants and safely encapsulating any particles that do enter the system.

Force Analysis and Grease Distribution Specifics in Shredder Bearings

Double shaft shredder bearings experience complex loading patterns combining radial forces from cutting actions and axial forces from material feeding pressures. These multidirectional loading conditions create unique challenges for maintaining proper lubricant distribution throughout the bearing contact zones.

The grease must demonstrate excellent mechanical stability to resist being pushed away from critical contact areas under high loads. Proper distribution ensures all rolling elements and raceways receive adequate lubrication, preventing localized starvation that can lead to premature failure.

Technical Specifications and Selection Criteria for High-Reliability Grease

Selecting the appropriate grease for shredder bearings requires careful consideration of multiple technical parameters that determine performance under specific operating conditions. The optimal lubricant must balance various properties to provide reliable protection throughout the intended service interval.

Modern grease formulations incorporate advanced base oils, thickener systems, and additive packages specifically engineered to address the challenges of heavy industrial applications. Understanding these components enables informed selection decisions.

Base Oil Type and Viscosity Selection Through Engineering Calculations

The base oil constitutes 80-95% of most grease formulations and primarily determines its lubricating properties. For shredder applications, synthetic hydrocarbon base oils with ISO viscosity grades between VG 150-220 provide optimal film formation under typical operating conditions. The specific viscosity selection depends on the bearing size and rotational speed, calculated using the dn value (bearing bore in mm × rpm).

Synthetic base oils offer advantages including higher viscosity indices, better oxidation stability, and lower volatility compared to mineral oils. These properties translate to longer service life and more consistent performance across the wide temperature ranges encountered in shredding operations.

Thickener System Compatibility and Mechanical Stability Relationships

Grease thickeners form the structural matrix that holds base oil and additives in a semi-solid state. Polyurea and complex lithium thickeners demonstrate superior mechanical stability in shredder applications, with shear stability indexes typically below 10%. This means the grease maintains its consistency and does not become excessively fluid under mechanical working.

The thickener system must remain stable throughout the grease service life, resisting both mechanical breakdown and chemical degradation. High-quality thickeners prevent oil separation during storage and operation while releasing oil appropriately to lubricate bearing surfaces.

Additive Package Design and Extreme Pressure Performance Requirements

Modern grease formulations incorporate sophisticated additive packages that enhance base oil performance and provide additional protection mechanisms. Extreme pressure additives typically contain sulfur, phosphorus, or boron compounds that form protective surface films under high-load conditions.

Performance testing validates additive effectiveness through standardized methods including the FZG gear test (requiring failure stage >12), four-ball weld test (>3000N), and Timken test (>45 pounds). These tests confirm the grease can withstand the extreme pressures generated during shredding operations.

Antioxidant Additives and High-Temperature Service Life Correlation

Oxidation represents the primary chemical degradation mechanism for lubricating greases in high-temperature applications. Antioxidant additives interrupt the free-radical chain reactions that cause base oil thickening and acid formation. High-performance greases typically demonstrate rotating pressure vessel oxidation test times exceeding 1000 minutes, indicating exceptional oxidation resistance.

The combination of synthetic base oils and advanced antioxidant packages enables service intervals of 2000 hours or more at typical operating temperatures. This extended service life reduces maintenance frequency while maintaining reliable equipment protection.

Scientific Methods for Determining Grease Replacement Intervals

Establishing optimal grease replacement intervals requires moving beyond fixed time-based schedules to condition-based approaches. Scientific methodologies incorporate multiple factors including operating conditions, lubricant analysis, and equipment monitoring to determine the precise point at which grease replacement becomes necessary.

Modern maintenance strategies employ predictive models that account for the specific variables affecting lubricant life in each application. This data-driven approach maximizes equipment protection while minimizing unnecessary maintenance activities.

Initial Time-Based Intervals and Adjustment Factors

Initial grease replacement intervals typically begin at 1000 operating hours for standard applications, serving as a conservative starting point. This baseline interval then undergoes adjustment through multiplication factors ranging from 0.5 to 2.0 based on specific operating conditions including load intensity, temperature extremes, and contamination levels.

Heavily loaded applications operating near capacity may require a 0.5 adjustment factor, reducing the interval to 500 hours. Conversely, lightly loaded applications in clean environments might justify a 2.0 factor, extending the interval to 2000 hours. These adjustments reflect the dramatic impact operating conditions have on lubricant life.

Grease Life Prediction Models and Key Influencing Factors

The Arrhenius equation provides the fundamental relationship between temperature and grease life, with the rate of chemical degradation doubling approximately every 10°C temperature increase. This mathematical relationship enables reasonably accurate predictions of grease service life based on operating temperature measurements.

Advanced models incorporate additional factors including mechanical shear rates, contamination levels, and moisture exposure to refine life predictions. These multifactor models typically achieve prediction accuracies within ±15% of actual service life, enabling precise maintenance planning.

Grease Condition Monitoring and Performance Degradation Indicators

Regular lubricant analysis provides objective data on grease condition and remaining useful life. Key parameters include viscosity changes (with increases exceeding 15% indicating advanced oxidation), acid number increases (above 0.5 mg KOH/g signaling degradation), and pentane insolubles (measuring contamination levels).

Trend analysis of these parameters establishes degradation patterns that predict when the grease will no longer provide adequate protection. This proactive approach enables replacement before bearing damage occurs, avoiding the costly consequences of lubricant failure.

Standard Operating Procedure for High-Reliability Grease Replacement

Consistent, proper execution of grease replacement procedures ensures reliable bearing operation and maximizes equipment life. Standardized protocols eliminate variability in maintenance quality and provide a reproducible framework for technicians to follow.

Well-documented procedures cover all aspects from initial preparation through final verification, addressing both technical requirements and safety considerations. This comprehensive approach ensures maintenance activities achieve their intended outcomes.

Pre-Job Safety Preparation and Equipment Isolation Measures

Comprehensive safety protocols begin with complete equipment isolation through lockout-tagout-tryout procedures. These measures ensure all energy sources including electrical, hydraulic, and potential energy are controlled before maintenance begins. Verification steps confirm zero energy state before technicians access bearing systems.

Additional safety measures include personal protective equipment requirements, confined space protocols when applicable, and emergency response planning. These precautions protect maintenance personnel from the significant hazards associated with heavy industrial equipment.

Thorough Old Grease Removal Methods and Cleaning Standards

Complete removal of degraded grease represents a critical step in the replacement process. Specialized cleaning tools and solvents effectively remove old lubricant and contamination from bearing housings. The cleaning process continues until the housing interior achieves a cleanliness level of NAS 8 or better, indicating minimal particulate contamination.

Proper cleaning prevents the mixing of new and old grease, which could compromise the performance of the fresh lubricant. It also removes abrasive particles and acidic oxidation products that could accelerate bearing wear if left in the system.

Precise Grease Quantity Calculation and Control Methods

Optimal grease quantity typically ranges between 30-40% of the bearing housing free volume, balancing adequate lubrication against the churning and heat generation caused by overfilling. Precise calculations based on bearing dimensions and housing geometry determine the exact required amount for each application.

Controlled filling techniques ensure the calculated quantity is accurately delivered to the bearing housing. Volume measurement or weight measurement methods provide the necessary precision, with documentation of the actual amount added to each bearing.

Contamination Control and Seal Integrity Management

Contamination exclusion represents the most effective strategy for extending bearing and lubricant life in harsh operating environments. Comprehensive sealing systems and contamination control practices significantly reduce the introduction of abrasive particles that accelerate component wear.

Modern sealing technologies have evolved to address the specific challenges of shredding applications, where fine metal dust presents persistent contamination threats. These systems combine multiple sealing principles to create effective barriers.

Metal Dust Ingestion Pathway Analysis and Blocking Strategies

Systematic analysis identifies primary contamination entry points including seal interfaces, housing breathers, and assembly joints. Seal design improvements focus on minimizing clearance gaps while maintaining necessary tolerances for shaft operation. Baffles and exclusion features redirect contaminant away from critical sealing surfaces.

Secondary protection methods include air purging systems that create positive pressure within bearing housings, preventing inward migration of contaminated air. These systems require careful pressure regulation to avoid seal damage while effectively excluding contaminants.

Seal System Selection and Combined Seal Applications

Labyrinth seals combined with lip seals provide highly effective contamination protection, typically reducing particle ingestion by 90% or more compared to single seal arrangements. The labyrinth section acts as a preliminary barrier that redirects and settles particles before they reach the primary lip seal.

Advanced sealing materials including filled PTFE and polyurethane compounds offer improved wear resistance and compatibility with the specific contaminants encountered in metal shredding applications. Material selection considers factors including temperature capability, chemical resistance, and mechanical properties.

Grease Storage and Application Process Contamination Prevention

Proper lubricant handling begins with sealed storage that protects grease from moisture, dust, and other contaminants during storage. Dedicated transfer equipment including grease guns, lines, and fittings prevents cross-contamination between different lubricant types.

Application equipment maintenance includes regular cleaning and verification of cleanliness levels. Storage and handling procedures target ISO 4406 cleanliness codes of 18/16/13 or better, ensuring lubricants enter bearing systems without introducing additional contamination.

Maintenance Quality Verification and Bearing Health Monitoring System

Verification processes confirm that maintenance activities have achieved their intended results and establish baseline conditions for ongoing monitoring. Comprehensive bearing health monitoring provides early warning of developing issues before they progress to equipment failure.

Advanced monitoring technologies enable continuous assessment of bearing condition and lubricant performance. This data-driven approach transforms maintenance from reactive to predictive, maximizing equipment reliability.

On-Site Rapid Verification Methods for Grease Application Quality

Visual inspection through purge ports confirms proper grease distribution by observing consistent, homogeneous grease flow from all discharge points. Uniform flow patterns indicate complete filling without air pockets or channeling that could leave areas improperly lubricated.

Initial operational checks include monitoring bearing temperatures during the first hours of operation. Properly lubricated bearings typically stabilize within 10-15°C of ambient temperature within 2-4 hours of operation, while abnormal temperature patterns may indicate installation issues.

Baseline Establishment for Initial Operating Parameters Post-Maintenance

Comprehensive data collection during the first 24 hours of operation following grease replacement establishes performance baselines for future comparison. Key parameters include vibration levels, temperature profiles, and acoustic emissions under various operating conditions.

These baselines enable trend analysis that detects subtle changes in bearing condition over time. Statistical process control methods establish normal operating ranges, with deviations triggering investigation before significant damage occurs.

Long-Term Performance Tracking and Lubrication Effectiveness Assessment

Continuous monitoring of bearing temperature, vibration, and acoustic emissions provides ongoing assessment of lubricant condition and bearing health. Advanced analysis techniques including envelope processing and peak value analysis detect early-stage damage that conventional monitoring might miss.

Periodic lubricant sampling and analysis validates continued lubricant effectiveness throughout the service interval. Trending of key parameters including viscosity, additive levels, and contamination provides objective data for determining optimal replacement timing.