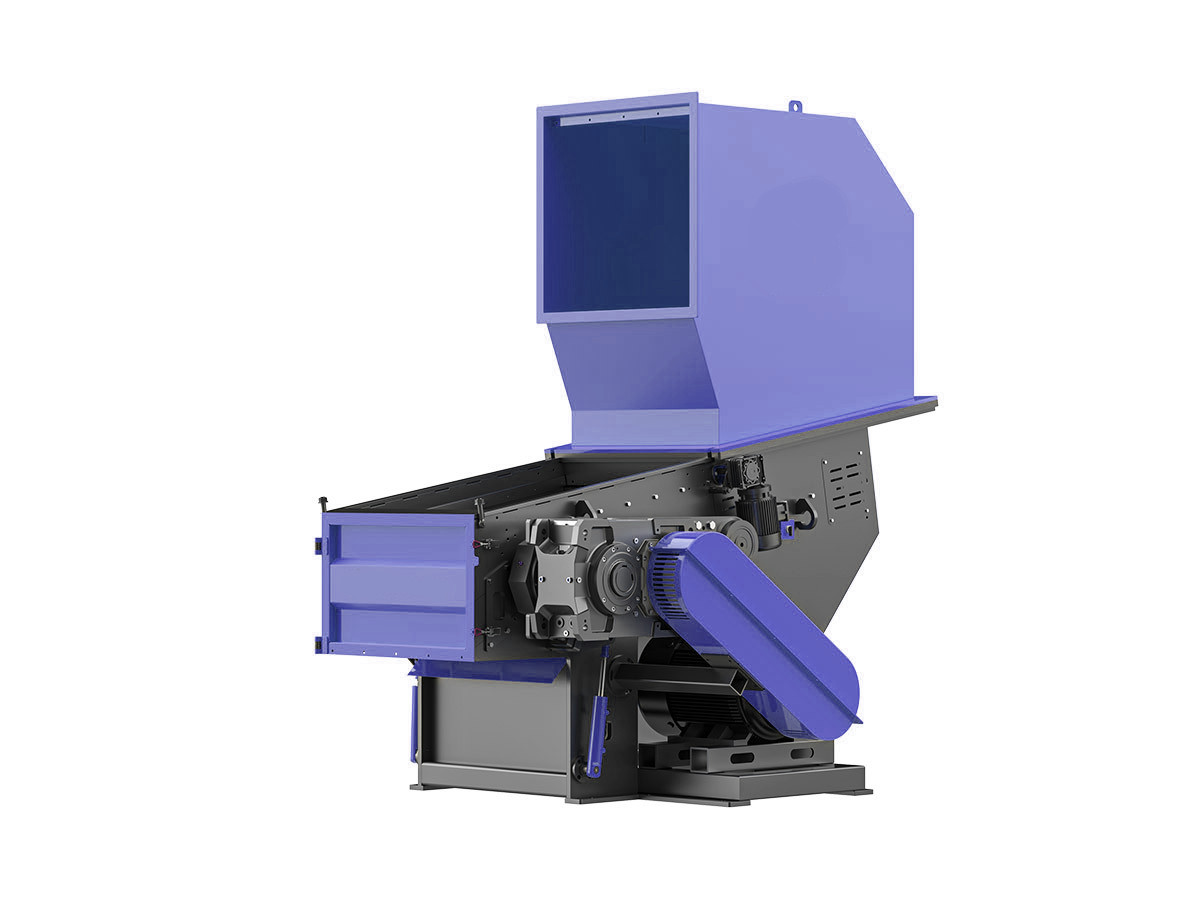

Solid Waste Single Shaft Shredder

A solid waste single shaft shredder is a powerful machine designed for processing various types of waste materials with a single rotating shaft equipped with cutting blades. This type of shredder is widely used in waste management and recycling industries due to its ability to efficiently break down bulky waste into smaller, uniform pieces.

Unlike dual-shaft shredders, which rely on interlocking blades, single shaft shredders use a single rotor to shred materials against a stationary counter knife. This mechanism provides precise control over output size, making it ideal for processing plastics, textiles, wood, and municipal solid waste.

Single shaft shredders are known for their high torque, low-speed operation, which ensures energy efficiency and reduced noise. Their versatility and durability make them a popular choice for industries looking to optimize waste reduction and material recovery.

How a Solid Waste Single Shaft Shredder Works

The shredding process in a single shaft shredder begins with waste being fed into the hopper, where it is gradually drawn toward the rotor. The rotor is fitted with replaceable cutting blades that shred the material against a fixed counter knife.

As the rotor spins at a controlled speed, the waste is progressively cut into smaller pieces until it reaches the desired size. A built-in screen beneath the rotor ensures that only properly shredded material exits the machine, while oversized pieces are recirculated for further processing.

Many single shaft shredders feature hydraulic or electric pushers that continuously feed material into the rotor. This automated system enhances shredding efficiency and prevents material from jamming, ensuring smooth and consistent operation.

Key Features of Solid Waste Single Shaft Shredders

Solid waste single shaft shredders are built with several advanced features to maximize efficiency, safety, and durability. One of the primary features is their robust rotor design, which ensures consistent shredding performance even when handling tough or abrasive materials.

Another essential feature is the adjustable screen, which allows operators to control the final particle size. Different screen sizes can be used to achieve varying degrees of material reduction, making the shredder highly adaptable for different waste processing needs.

Additionally, modern single shaft shredders come equipped with overload protection and automatic reverse functions. These safety mechanisms help prevent damage to the machine by reversing the rotor direction in case of a blockage, minimizing downtime and maintenance costs.

Applications of Solid Waste Single Shaft Shredders

Single shaft shredders are widely used in various industries for waste reduction and material recycling. Their ability to process a diverse range of materials makes them essential in many waste management and manufacturing applications.

In municipal waste processing, these shredders help reduce the size of household waste, making it easier to sort and transport for recycling. By breaking down bulky items like furniture, plastics, and textiles, they contribute to efficient waste handling.

Industrial applications include shredding production waste, rejected goods, and leftover packaging materials. Factories and warehouses use these machines to process materials such as rubber, paper, and wood, turning waste into reusable resources.

Advantages of Using a Solid Waste Single Shaft Shredder

Investing in a solid waste single shaft shredder provides multiple benefits for waste management facilities and industrial operations. One of the biggest advantages is improved waste volume reduction, which minimizes transportation and storage costs.

Another key advantage is the ability to achieve a uniform output size, thanks to the integrated screen system. This precision allows for easier downstream processing, whether for recycling, composting, or energy recovery.

Additionally, single shaft shredders are designed for energy efficiency and durability. Their low-speed, high-torque operation consumes less power while reducing wear and tear, making them a cost-effective solution for long-term waste processing needs.