Blade wear in waste tire shredders is a critical operational challenge that directly impacts efficiency, cost, and productivity. Industrial shredders processing tires face unique demands due to the abrasive nature of steel belts and rubber compounds. This guide provides a comprehensive overview of blade wear types, causes, detection methods, and replacement strategies, supported by industry data to help operators optimize maintenance schedules and reduce downtime. Understanding these aspects is essential for sustaining high performance in tire recycling operations.

Basic Types and Characteristics of Blade Wear

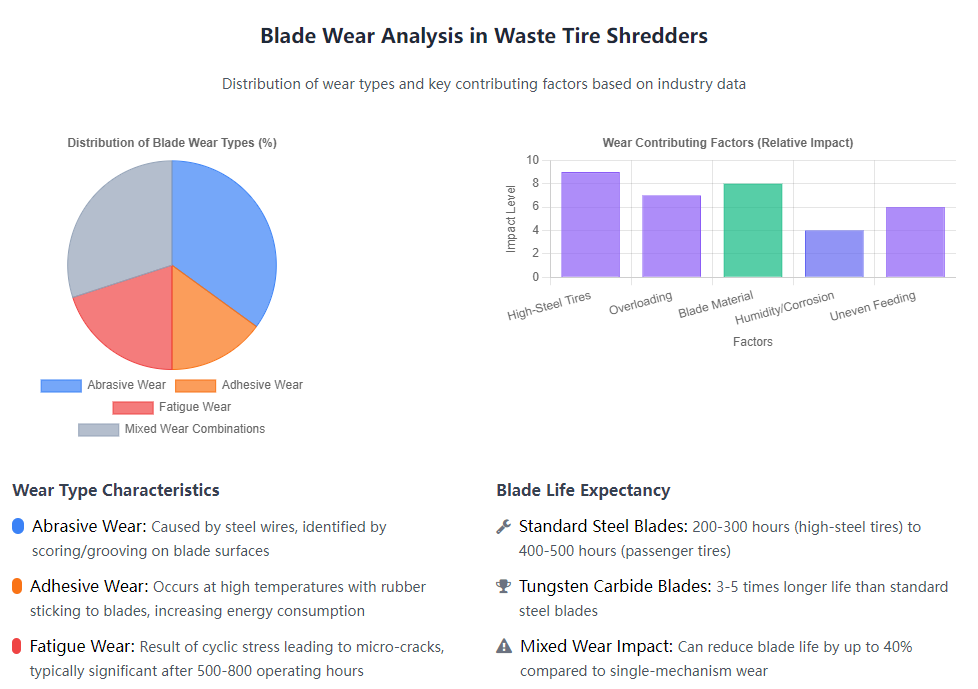

Blade wear in tire shredders manifests in several distinct forms, each with specific characteristics that affect cutting performance. Abrasive wear is the most common type, resulting from continuous contact with hard materials like steel wires embedded in tires. Adhesive wear occurs under high-stress conditions where rubber adheres to the blade surface, while fatigue wear develops from repeated cyclic loading during shredding operations. Recognizing these wear patterns early allows for proactive maintenance and prevents catastrophic failures.

The combination of these wear types is frequent in tire shredding due to the heterogeneous nature of waste tires. For instance, a blade may exhibit abrasive scratches from steel wires alongside adhesive rubber deposits, leading to accelerated deterioration. Industry studies indicate that improper identification of wear types can reduce blade life by up to 30%. Regular inspection protocols are necessary to distinguish between these mechanisms and apply appropriate corrective measures.

Causes and Identification of Abrasive Wear

Abrasive wear is primarily caused by the hard steel wires found in tire belts and beads, which act as grinding agents against the blade edges. This wear type is identified by visible scoring or grooving on the blade surface, along with a rounded edge profile that reduces cutting efficiency. The high hardness of steel wires, often exceeding 500 HV, accelerates material removal from the blade.

Operators can detect abrasive wear through routine visual checks for surface irregularities or by monitoring changes in shredding output quality. Quantitative analysis using microscopy reveals micro-scale material loss, which accumulates over time. Data from shredding facilities show that abrasive wear accounts for approximately 60% of all blade failures in tire processing applications.

Mechanism of Adhesive Wear under High Temperature

Adhesive wear occurs when localized high temperatures during shredding cause rubber compounds to soften and stick to the blade surface. This phenomenon is common in high-speed shredders where friction generates heat exceeding 150°C. The adhered rubber layers insulate the blade, leading to overheating and eventual coating delamination.

Identification involves examining blades for a built-up layer of carbonized rubber, which appears as a dark, rough coating. Thermal imaging cameras can detect hot spots during operation, signaling potential adhesive wear. Research indicates that adhesive wear can increase energy consumption by 15% due to reduced cutting efficiency, emphasizing the need for temperature control systems.

Long-term Effects of Fatigue Wear

Fatigue wear results from cyclic stress applied to blades during the shredding of tough materials like tires. This wear type initiates micro-cracks at stress concentration points, such as blade notches or edges, which propagate over time leading to fractures. The repetitive impact from steel wires exacerbates this process, reducing blade structural integrity.

Long-term effects include sudden blade failure, which can cause unplanned downtime and damage to other shredder components. Non-destructive testing methods like ultrasonic inspection are used to detect subsurface cracks before they become critical. Studies report that fatigue wear typically becomes significant after 500-800 operating hours, depending on blade material and operating conditions.

Analysis of Mixed Wear Practical Cases

Mixed wear scenarios involve the simultaneous occurrence of abrasive, adhesive, and fatigue mechanisms, often observed in blades processing varied tire types. For example, a blade may show abrasive grooves from steel wires, adhesive rubber deposits, and fatigue cracks at the base. This combination accelerates overall wear rates and complicates maintenance decisions.

Case analyses from recycling plants

demonstrate that mixed wear can reduce blade life by 40% compared to single-mechanism wear. Cross-sectional analysis of worn blades using scanning electron microscopy reveals

layered damage patterns. Addressing mixed wear requires integrated strategies, such as using multi-material blades and optimizing shredder settings for different tire

compositions.

In-depth Analysis of Wear Causes

Blade wear causes are multifaceted, involving material properties, operational parameters, and environmental factors. The composition of waste tires, particularly steel content and rubber hardness, plays a significant role in wear progression. Operational aspects like feed rate, load conditions, and shredder configuration directly influence wear rates. External factors such as humidity and temperature can exacerbate corrosion or adhesion issues.

Understanding these causes enables targeted interventions to extend blade life. For instance, adjusting feed consistency can minimize uneven wear, while selecting appropriate blade materials enhances durability. Data from industrial surveys indicate that operational errors contribute to 25% of premature blade failures, highlighting the importance of trained personnel and optimized processes.

Accelerating Effect of High-Steel Tires on Wear

High-steel tires, such as those from trucks or heavy equipment, contain up to 20-25% steel by weight, significantly accelerating blade wear. The continuous cutting of steel wires acts like a grinding process, rapidly dulling blade edges. This effect is quantified by wear rates, which can be 50% higher for high-steel tires compared to passenger tires.

Mitigation strategies include using blades made from tungsten carbide or other hard materials resistant to abrasion. Operational data show that processing high-steel tires may require blade replacements every 200-300 hours, whereas low-steel tires can extend life to 400-500 hours. Proper classification of tires before shredding helps in planning maintenance schedules.

Consequences of Operational Errors: Overloading and Improper Feeding

Operational errors like overloading the shredder or irregular feeding cause localized stress concentrations on blades, leading to accelerated wear. Overloading increases mechanical strain, while uneven feeding results in partial blade engagement, wearing specific sections faster than others. These practices can reduce blade life by up to 35% according to industry reports.

Monitoring systems integrated into modern shredders, such as load sensors on the shredder shaft, help prevent overloading by regulating feed rates. Training operators to maintain consistent feed patterns ensures even wear distribution. Implementing automated feed controls has been shown to reduce wear-related downtime by 20% in various facilities.

Blade Material Selection and Wear Resistance

Blade material selection is critical for wear resistance, with options ranging from high-carbon steel to advanced composites like ceramic-coated alloys. High-carbon steel offers good toughness but lower abrasion resistance, while tool steels with vanadium or chromium additives provide enhanced durability. Tungsten carbide blades exhibit superior performance in high-abrasion environments like tire shredding.

Comparative tests indicate that tungsten carbide blades can last 3-5 times longer than standard steel blades under identical conditions. The initial higher cost is offset by reduced replacement frequency and downtime. Material hardness, measured on the Rockwell C scale, should exceed 60 HRC for effective tire shredding applications to withstand steel wire abrasion.

Corrosive Wear Due to Environmental Factors like Humidity

Corrosive wear occurs in humid environments where moisture promotes rust formation on blade surfaces, weakening the material and accelerating abrasion. This type of wear is common in coastal areas or facilities without climate control. The combination of corrosion and mechanical wear can reduce blade thickness by 0.1-0.2 mm per month in severe cases.

Preventive measures include applying protective coatings or using stainless steel components for blades in corrosive environments. Regular cleaning and lubrication with anti-corrosion oils help maintain blade integrity. Data from field studies show that controlling relative humidity below 60% can extend blade life by 15% by minimizing corrosive effects.

Wear Detection and Monitoring Methods

Effective wear detection involves a combination of visual inspections, performance monitoring, and advanced technologies. Early identification of wear signs allows for planned interventions, avoiding unplanned shutdowns. Visual checks focus on blade edges and surfaces for obvious defects, while performance metrics like throughput and power consumption provide indirect wear indicators.

Advanced methods such as vibration analysis and IoT sensors enable predictive maintenance by detecting anomalies before they lead to failures. Implementing a comprehensive monitoring system can reduce maintenance costs by 25% according to industry analyses. Regular data collection and analysis help in trending wear patterns and optimizing inspection frequencies.

Daily Visual Inspection Checklist

Daily visual inspections are a frontline defense against excessive blade wear. Operators should examine blades for signs like edge rounding, visible cracks, or material buildup. A standardized checklist includes verifying blade alignment, checking for corrosion, and ensuring fasteners are tight. These inspections take only minutes but can prevent major issues.

Documenting inspection findings in a log helps track wear progression over time. For example, noting a 1-mm edge wear after 100 hours of operation provides a baseline for predicting future replacements. Facilities that implement daily visual reports have reported a 30% reduction in unexpected blade failures, enhancing operational reliability.

Correlation Between Performance Parameter Changes and Wear

Performance parameters such as shredding throughput, energy consumption, and product size distribution correlate directly with blade wear. As blades dull, throughput decreases because the shredder requires more time to process the same amount of material. Energy consumption often increases by 10-20% due to reduced cutting efficiency.

Monitoring these parameters through the shredder's control panel PLC/HMI allows for real-time wear assessment. For instance, a sustained 15% drop in throughput may indicate the need for blade inspection or replacement. Statistical process control charts can be used to set alert thresholds for proactive maintenance actions.

Application of Precision Measuring Tools

Precision measuring tools like calipers, micrometers, and laser scanners provide quantitative data on blade wear. Regular measurements of blade thickness, edge angle, and length reveal wear rates that are not visible to the naked eye. For example, a wear rate of 0.05 mm per 100 hours is typical for standard steel blades in tire applications.

Using these tools monthly establishes a wear trend database, enabling accurate life predictions. Digital calipers with data logging capabilities streamline this process by automatically recording measurements. Studies show that facilities using precision measurements achieve blade replacement accuracies within ±10 hours of optimal timing, minimizing waste.

Predictive Maintenance with IoT Sensors

IoT sensors enable predictive maintenance by continuously monitoring conditions like vibration, temperature, and acoustic emissions from the shredder. Abnormal vibration patterns often indicate blade imbalance or wear, while temperature spikes can signal adhesive wear. These sensors transmit data to cloud platforms for analysis using machine learning algorithms.

Implementing IoT systems can predict blade failures with over 90% accuracy, allowing replacements during planned downtime. For example, a vibration increase of 20% from baseline may trigger an alert for inspection. Industry adoption of IoT has reduced maintenance costs by up to 30% by transitioning from reactive to predictive strategies.

Basis for Replacement Cycle Formulation

Formulating a blade replacement cycle requires balancing operational data, economic factors, and material science principles. Fixed time-based cycles are often inefficient; instead, condition-based approaches using real-time monitoring data optimize resource use. Key factors include cumulative operating hours, tire types processed, and historical wear rates.

Economic considerations involve comparing the cost of blade replacement against potential losses from downtime or poor product quality. A well-designed cycle minimizes total cost of ownership while maintaining shredding performance. Research indicates that dynamic replacement cycles can extend average blade life by 15% compared to rigid schedules.

Life Estimation Formula and Examples

Blade life estimation can be calculated using formulas that incorporate base life values and adjustment factors. A simple formula is: Life (hours) = Base Life × (1 - Steel Content Factor) × (Operating Intensity Factor). Base life depends on blade material, e.g., 500 hours for tungsten carbide under standard conditions. The steel content factor adjusts for tire type, with high-steel tires reducing life by 0.3.

For example, a tungsten carbide blade processing tires with 20% steel content at high intensity may have a life of 500 × (1 - 0.2) × 0.8 = 320 hours. This formula helps in planning purchases and maintenance schedules. Field data validate that such calculations achieve within 10% accuracy when calibrated with local operating conditions.

Prioritization of Key Factors

Key factors influencing replacement cycles include tire hardness, operational hours, and environmental conditions. Tire hardness, measured by durometer, has the highest weight as it directly affects abrasion rates. Operational hours provide a straightforward metric, but intensity variations must be accounted for. Environmental factors like humidity have lower but significant impacts.

Prioritization tables assign weights to these factors based on statistical analysis of historical data. For instance, tire hardness may account for 50% of wear variance, while operational hours contribute 30%. This weighted approach allows for customized cycles per shredder unit, improving overall efficiency. Facilities using prioritized factors report 20% better resource allocation.

Calculation of Economic Replacement Point

The economic replacement point is determined when the cost of continued operation with worn blades exceeds the cost of replacement. Costs include energy overconsumption, downtime losses, and potential damage to other components. For example, if worn blades increase energy costs by $50 per day and replacement costs $2000, the economic point is reached when cumulative losses exceed $2000.

Calculations often use net present value models to account for time-based costs. Data from tire recycling plants show that optimizing economic points can save up to $5000 annually per shredder by avoiding unnecessary early replacements or delayed actions. Regular review of cost data ensures the model remains accurate under changing conditions.

Dynamic Cycle Adjustment Based on Real-time Data

Dynamic adjustment of replacement cycles uses real-time data from monitoring systems to update schedules continuously. IoT sensors feed information on blade condition, allowing algorithms to predict optimal replacement times. This approach adapts to variations in tire feed or operational intensity, which fixed cycles cannot accommodate.

For instance, if sensor data indicate slower wear due to processing softer tires, the system may extend the cycle by 50 hours. Implementation of dynamic adjustments has shown a 25% reduction in premature replacements and a 15% increase in blade utilization. Cloud-based platforms facilitate this by analyzing data across multiple shredders for benchmarking.

Detailed Steps for Blade Replacement

Blade replacement is a systematic process requiring careful preparation, execution, and testing to ensure safety and effectiveness. Preparation involves gathering tools, isolating energy sources, and reviewing safety protocols. The actual replacement includes removing old blades, installing new ones with precise alignment, and verifying installation through test runs.

Proper execution minimizes risks of injury or machine damage. Studies indicate that standardized replacement procedures reduce downtime by 30% compared to ad-hoc methods. Training personnel on these steps is essential for maintaining operational continuity and extending equipment lifespan.

Preparation: Safety Protocols and Tool Preparation

Safety protocols are critical during blade replacement to prevent accidents. Steps include locking out the shredder's power source using lockout-tagout (LOTO) procedures, wearing personal protective equipment (PPE) like gloves and goggles, and ensuring the work area is clear. Tools required include torque wrenches, hoists for heavy blades, and alignment instruments.

Preparation also involves reviewing the shredder's manual for specific blade specifications and torque settings. A pre-replacement checklist verifies that all safety measures are in place. Facilities implementing rigorous preparation report a 40% reduction in incidents during maintenance activities, highlighting the importance of protocol adherence.

Best Practices for Removing Old Blades

Removing old blades requires methodical steps to avoid damage to the shredder shaft or surrounding components. Start by loosening bolts in a cross pattern to evenly release tension, then use a pulling tool to detach the blade from the shredder shaft. Inspect the shaft for wear or corrosion during removal, as these issues can affect new blade performance.

Documenting the condition of removed blades aids in wear analysis for future cycles. For example, photographing worn edges helps in identifying recurring issues. Best practices include cleaning the shaft interface before installation to ensure proper seating. Data show that following structured removal procedures reduces rework rates by 20%.

New Blade Installation and Alignment Methods

Installing new blades involves aligning them precisely to ensure balanced operation and even wear. Use dial indicators or laser alignment tools to verify that blades are parallel to within 0.1 mm tolerance. Tighten bolts gradually in a star pattern to the manufacturer's specified torque, which typically ranges from 200 to 400 Nm for large shredders.

Alignment checks prevent vibrations that accelerate wear on bearings and other components. After installation, manually rotate the shaft to confirm free movement. Records from maintenance logs indicate that proper alignment extends blade life by up to 15% by reducing uneven stress distribution. Regular training on alignment techniques is recommended for maintenance teams.

Test Run and Performance Verification

After replacement, conduct a test run starting with no-load operation to check for unusual noises or vibrations. Then, gradually feed a small batch of tires to verify cutting efficiency and output quality. Monitor parameters like power draw and throughput to ensure they return to baseline levels.

Performance verification includes inspecting the shredded material for consistent size and absence of uncut pieces. Test runs should last at least 30 minutes to identify any issues. Facilities that implement thorough testing report a 25% decrease in post-replacement failures, ensuring that blades operate as intended before full-scale production resumes.

Preventive Maintenance and Life Extension Strategies

Preventive maintenance focuses on routine actions that delay blade wear and extend service life. Strategies include scheduled lubrication, operator training, and blade refurbishment options. A holistic approach integrates these measures with operational adjustments to maximize cost-effectiveness.

Life extension not only reduces direct costs but also enhances overall shredder reliability. Data indicate that a well-maintained shredder can achieve blade life increases of 20-30% compared to neglected systems. Investing in preventive measures yields long-term benefits through reduced downtime and lower spare part inventories.

Lubrication Schedule and Correct Lubricant Selection

Lubrication reduces friction between moving parts, minimizing wear on blades and associated components. A weekly schedule is typical, using high-temperature grease resistant to wash-off from rubber debris. The lubricant should have EP (extreme pressure) additives to withstand the heavy loads encountered in tire shredding.

Application points include blade bearings and shaft interfaces. Over-lubrication should be avoided as it can attract contaminants. Studies show that correct lubrication can reduce wear rates by 15% by maintaining smooth operation. Using automated lubrication systems ensures consistency and reduces manual errors.

Training Focus: Avoiding Improper Operations

Operator training emphasizes practices like even feeding and avoiding non-tire materials that cause shock loads. Training programs cover the importance of monitoring machine sounds and performance indicators for early wear detection. Simulated scenarios help operators recognize the effects of improper actions on blade life.

Certified training sessions have been shown to reduce operational errors by 35%, directly contributing to longer blade lifespan. Refresher courses every six months keep skills updated. Facilities with trained operators report fewer emergency shutdowns and more predictable maintenance schedules.

Blade Repair Techniques like Regrinding and Coating

Blade repair techniques such as regrinding restore sharp edges, while recoating applies new wear-resistant surfaces. Regrinding is feasible if wear is limited to the edge and does not exceed 10% of blade mass. Recoating with materials like tungsten carbide can rejuvenate blades at 50% of the cost of new ones.

Decisions on repair versus replacement depend on economic analysis; typically, blades can be reground 2-3 times before replacement is necessary. Quality checks after repair ensure hardness and dimensions meet specifications. Industry data suggest that repair programs can reduce blade expenses by 40% annually.

System Optimization such as Upgrading Materials or Design

System optimization involves upgrading to advanced blade materials or improving shredder design for better wear resistance. For example, switching from standard steel to carbide-tipped blades significantly extends life. Design changes might include modifying the cutting chamber geometry to reduce material recirculation.

Consulting with manufacturers for custom solutions tailored to specific tire types can yield substantial benefits. Retrofitting older shredders with modern components has been shown to improve overall efficiency by 20%. Lifecycle cost analyses justify these investments by demonstrating payback periods of under two years through reduced maintenance and downtime.