The transformation of waste tires into high-performance infill material for artificial turf represents a remarkable achievement in sustainable manufacturing. Industrial shredders serve as the cornerstone technology in this process, enabling the efficient conversion of discarded rubber into valuable, engineered products. This article examines the specialized shredding techniques that facilitate this transformation, highlighting the operational advantages and environmental benefits derived from using tire-derived material. The integration of advanced shredding technology allows manufacturers to meet rigorous performance standards while supporting circular economy principles through material recovery and reuse.

Technical Principles and Core Functions of Waste Tire Shredders

Industrial shredders designed for tire processing employ sophisticated mechanical systems to break down the complex structure of automotive and truck tires. These machines must overcome the challenging combination of flexible rubber and embedded steel reinforcement, requiring specifically engineered cutting mechanisms. The shredding process transforms whole tires into consistent granular material suitable for further refinement into turf infill products, making it a critical first step in the value-added recycling chain.

Modern tire shredders incorporate multiple technological innovations to handle the tough, abrasive nature of tire material. They feature reinforced cutting chambers, specialized wear-resistant tooling, and powerful drive systems capable of generating the tremendous forces necessary to shear through steel-belted radial tires. These engineering solutions ensure continuous operation under demanding conditions while maintaining consistent output quality essential for downstream processing into premium infill material.

Integrated Mechanism of Shearing, Tearing and Crushing

Tire shredders utilize a combination of mechanical actions to dismantle the complex structure of waste tires. The primary cutting mechanism involves shearing action between counter-rotating shafts equipped with intermeshing cutters that grab and tear apart tire sections. This approach differs fundamentally from impact-based crushing methods, as it produces controlled particle sizes with minimal heat generation, preserving the desirable elastic properties of the rubber material.

The cutting geometry is specifically designed to handle the heterogeneous nature of tires, which combine flexible rubber with rigid steel cord and textile reinforcement. The staggered arrangement of cutting discs creates a scissor-like action that cleanly severs the steel wires while tearing the rubber matrix into progressively smaller fragments. This integrated approach ensures efficient size reduction while minimizing energy consumption and wear on cutting components.

Progressive Material Processing Through Multi-Stage Shredding Systems

Advanced tire recycling operations typically employ two or three-stage shredding systems to achieve the precise particle size distribution required for turf infill. The primary shredder reduces whole tires to rough chunks of 100-150mm, which are then conveyed to secondary grinding equipment. This staged approach allows each machine to operate at optimal efficiency for its specific size reduction task, minimizing overall energy consumption while maximizing throughput.

The secondary processing stage further reduces material to the 2-6mm range suitable for turf infill applications. This stage often utilizes granulators or fine shredders with screen systems to control maximum particle size. The multi-stage approach also facilitates the removal of steel and fiber contaminants between processing stages, resulting in cleaner rubber product with higher market value for synthetic turf applications.

Intelligent Screening Technology Ensuring Particle Size Uniformity

Precise particle size distribution is critical for artificial turf infill, as it directly impacts playing characteristics and long-term performance. Modern shredding facilities incorporate automated screening systems that continuously classify output material according to size specifications. These systems use vibrating screens with precisely sized apertures to separate oversize particles for further processing while allowing correctly sized material to proceed to downstream operations.

The screening process is typically integrated with the shredding operation through closed-loop systems that automatically return oversize material for additional processing. This ensures consistent product quality without manual intervention. Advanced facilities employ laser scanning technology to continuously monitor particle size distribution, providing real-time data to operators and automatically adjusting shredder parameters to maintain product specifications within tight tolerances.

Dust Collection and Noise Reduction Designs Enhancing Environmental Friendliness

Tire shredding operations generate significant amounts of dust and noise, requiring comprehensive environmental control systems. Modern shredders incorporate integrated dust collection systems that capture airborne particles at source points throughout the material handling process. These systems typically use cyclone separators followed by baghouse filters to achieve collection efficiencies exceeding 99.9%, ensuring compliance with workplace air quality standards.

Noise suppression represents another critical design consideration, particularly for facilities located near residential areas. Shredders are equipped with acoustic enclosures, vibration isolation mounts, and sound-dampening materials that reduce operational noise levels below 85 decibels at operator stations. These environmental controls make tire shredding facilities better neighbors while protecting workers from occupational health hazards associated with dust and noise exposure.

Performance Requirements and Material Standards for Artificial Turf Infill

Artificial turf infill must meet rigorous performance specifications to ensure satisfactory playing characteristics and long service life. The material serves multiple functions, providing cushioning for athletes, supporting turf fibers, and facilitating proper drainage. Tire-derived infill must demonstrate consistent physical properties and environmental safety to gain acceptance in the highly regulated synthetic turf market.

Material specifications for turf infill address both mechanical performance and environmental compatibility. The rubber granules must maintain their elastic properties through extreme temperature variations, prolonged UV exposure, and mechanical compaction from use. Simultaneously, they must not leach harmful substances or contain heavy metals above regulatory limits, ensuring safety for users and the environment.

Requirements for Elasticity, Wear Resistance and UV Protection

The elastic properties of tire-derived infill directly impact player safety and comfort on synthetic sports fields. High-quality infill material exhibits consistent rebound characteristics, typically maintaining 60-70% energy return after compression. This elasticity provides necessary shock absorption while allowing athletes to perform cutting movements without excessive energy loss. The material must retain these properties through years of exposure to weather and mechanical stress.

Wear resistance is equally important, as infill particles experience constant abrasion from cleats, turf fibers, and maintenance equipment. Premium tire-derived infill demonstrates minimal degradation even after equivalent of 5-7 years of intensive use. UV stabilization is achieved through specialized compounding during tire manufacturing and can be enhanced with surface treatments during the recycling process, ensuring the material maintains its color and physical properties despite prolonged sun exposure.

Environmental Regulations Limiting Heavy Metals and Harmful Substances

Stringent regulations govern the chemical composition of materials used in synthetic turf applications, particularly those derived from recycled sources. The European REACH regulation and various national standards establish maximum permissible concentrations for heavy metals including lead, cadmium, mercury, and chromium. High-quality tire-derived infill typically contains these elements at levels below 10% of regulatory limits, ensuring broad market acceptance.

Polycyclic aromatic hydrocarbons (PAHs) represent another regulated substance category of concern for tire-derived products. Advanced shredding and cleaning processes reduce PAH content to levels compliant with the European Union's strict 0.1% limitation. Manufacturers implement rigorous quality control protocols, including batch testing and certification, to verify compliance with these environmental standards before products reach the market.

Impact of Particle Shape and Size Distribution on Turf Performance

The geometric characteristics of infill particles significantly influence playing surface behavior. Irregularly shaped particles with rough surfaces provide better interlocking and stability, reducing particle migration during use. This stability maintains consistent playing characteristics and prevents uneven settling that can create hard spots on the field. The shredding process can be adjusted to produce particles with optimal geometry for specific applications.

Particle size distribution affects both mechanical performance and player experience. A well-graded mixture containing particles between 1-4mm provides the ideal balance of stability, drainage, and cushioning. Larger particles may be used in base layers for improved drainage, while smaller particles in the surface layer enhance comfort and ball roll characteristics. The shredding and screening processes must therefore be precisely controlled to deliver the required size distribution for each application.

Key Advantages of Shredder Technology in Infill Manufacturing

The application of specialized shredding technology in tire-derived infill production offers numerous advantages over alternative materials and processing methods. These benefits span economic, environmental, and performance dimensions, making tire-derived infill an increasingly preferred choice for synthetic turf installations worldwide. The efficiency of modern shredding systems continues to improve, further enhancing these advantages through technological innovation.

Shredder-based processing enables manufacturers to transform waste material into high-value products with consistent quality and predictable performance. This value creation supports the economic viability of tire recycling operations while addressing environmental concerns associated with tire stockpiling. The resulting infill material offers performance characteristics that equal or exceed those of virgin alternatives, creating a compelling case for its widespread adoption.

Efficient Resource Conversion: Transforming Waste Tires into High-Value Products

Advanced shredding technology enables the recovery of approximately 70-75% of a waste tire's mass as usable rubber granulate for infill applications. This represents a significant valorization of material that would otherwise require disposal in landfills or through energy recovery. The shredding process preserves the valuable elastic properties of the rubber, allowing it to serve performance functions rather than merely serving as filler material.

The economic value created through this transformation helps support comprehensive tire recycling programs. A single passenger tire can yield approximately 1.5-2.0 kilograms of infill material with a market value substantially higher than alternative recycling outcomes. This economic incentive drives investment in improved shredding technology and collection infrastructure, creating a virtuous cycle of continuous improvement in tire recycling rates and product quality.

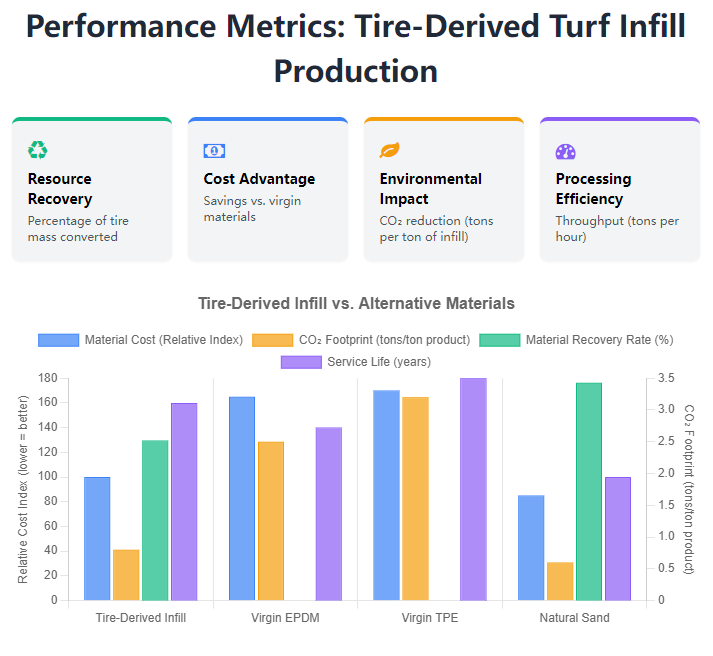

Cost Advantage: Reducing Production Costs by Over 30% Compared to Traditional Materials

Tire-derived infill typically costs 30-40% less than virgin synthetic alternatives such as EPDM or TPE granules, providing significant savings for turf installers and owners. This cost advantage stems primarily from the utilization of waste material as feedstock rather than petroleum-based raw materials. The difference becomes particularly substantial for large installations such as sports fields, where infill requirements often exceed 100 tons.

The shredding process itself has benefited from efficiency improvements that have reduced processing costs by approximately 25% over the past decade. These gains result from increased automation, improved wear resistance of cutting components, and better energy efficiency in modern shredding systems. The combination of low-cost feedstock and efficient processing creates a compelling economic proposition that continues to drive market adoption of tire-derived infill materials.

Environmental Benefits: Reducing Pollution from Tire Landfilling and Incineration

The diversion of waste tires from landfills and illegal dumping represents a significant environmental achievement made possible by shredding technology. Approximately 90% of tires processed through shredding operations avoid disposal in landfills, where they pose fire hazards and create breeding grounds for mosquitoes. The conversion to turf infill provides a beneficial use pathway that extends the material's service life by decades.

Shredding-based recycling also avoids the air emissions associated with tire-derived fuel applications, which remain a common disposal method in some regions. The production of turf infill from shredded tires reduces greenhouse gas emissions by approximately 1.5-2.0 tons of CO2 equivalent per ton of rubber compared to virgin production. This carbon footprint advantage, combined with resource conservation benefits, makes tire-derived infill an environmentally preferable choice for synthetic turf applications.

Complete Process Analysis from Tires to Infill Material

The transformation of whole waste tires into consistent, high-quality turf infill involves a series of precisely controlled processing stages. Each step must be carefully optimized to ensure final product quality while maintaining economic viability. Modern recycling facilities employ integrated processing lines that minimize material handling between stages, reducing energy consumption and opportunities for contamination.

The complete process typically requires 4-6 hours from whole tire intake to finished infill product, depending on the specific equipment configuration and product specifications. Throughout this process, quality control measures ensure that the material meets all relevant specifications for size, cleanliness, and chemical composition. The efficiency of this transformation demonstrates how advanced shredding technology enables large-scale valorization of challenging waste materials.

Pretreatment Stage: Wire Removal, Sorting and Cleaning Technologies

Whole tires undergo initial processing to remove non-rubber components that could compromise final product quality. Bead wires are typically removed using specialized cutting equipment that severs the steel reinforcement around the tire's circumference. This preliminary step significantly reduces the metal content before shredding, protecting cutting equipment from excessive wear and simplifying subsequent metal separation processes.

Tires are then sorted by type and size to optimize shredding efficiency and product consistency. Passenger tires, truck tires, and off-road tires may be processed separately or in controlled blends to achieve specific product characteristics. Thorough cleaning removes dirt, sand, and other contaminants that could affect final product quality. This pretreatment stage is essential for producing infill material that meets the stringent quality standards required for synthetic turf applications.

Primary Shredding: Reducing Tires to 50-100mm Pieces

The first size reduction stage typically employs a double shaft shredder with hydraulically powered feed ram to process whole tires into manageable chunks. These primary shredders feature massive cutting rotors with wear-resistant knives specifically designed to handle the tough combination of rubber and steel reinforcement. The output from this stage consists of irregularly shaped pieces ranging from 50-100mm in largest dimension.

Primary shredders operate at relatively low rotational speeds (20-40 RPM) to generate high torque for cutting through the toughest sections of truck and off-road tires. The cutting chamber design includes replaceable wear plates that protect the machine structure from abrasion. This stage typically reduces whole tires to approximately 30-40% of their original volume, creating material that can be efficiently handled by downstream processing equipment.

Fine Grinding: Secondary Processing to 2-6mm Target Size

Secondary processing further reduces tire chunks to the granular size required for turf infill applications. This stage typically utilizes granulators or fine shredders equipped with screen systems to control maximum particle size. The grinding process generates heat that must be carefully managed to prevent degradation of the rubber's elastic properties. Modern systems incorporate temperature monitoring and controlled cooling to maintain optimal processing conditions.

The selection of screen size determines the final product specification, with different applications requiring different size distributions. Sports field infill typically utilizes particles between 1-3mm, while landscape applications may accept slightly larger granules. The secondary grinding process represents the most energy-intensive stage of production, accounting for approximately 40-50% of total processing energy requirements. Efficiency improvements in this area therefore have significant impact on overall process economics.

Equipment Selection and Production Capacity Matching Strategies

Selecting appropriate shredding equipment requires careful analysis of feed material characteristics, desired output specifications, and production volume requirements. The choice between single-shaft, double-shaft, and multi-shaft configurations depends on the specific application, with each design offering distinct advantages for different processing scenarios. Proper equipment selection ensures optimal processing efficiency, product quality, and return on investment.

Production capacity planning must consider both peak and average processing rates, accounting for maintenance requirements and potential feedstock variations. Modern shredding facilities typically design for 85-90% utilization rates, allowing capacity for maintenance and unexpected disruptions. The integration of shredding equipment with downstream processing and material handling systems is equally important for achieving overall line efficiency.

Selecting Single-Shaft or Double-Shaft Shredders Based on Daily Processing Volume

Single-shaft shredders typically process 2-5 tons per hour and are suitable for smaller operations or specialized applications requiring precise control over particle geometry. These machines excel at producing uniform output with controlled particle shape characteristics, making them ideal for premium infill products. Their simpler design facilitates maintenance and operation, though they may require more frequent knife changes when processing steel-belted radial tires.

Double-shaft shredders offer higher throughput capacity, typically handling 5-20 tons per hour depending on model size and configuration. The intermeshing cutting rotors provide positive feed action and superior grabbing capability for whole tires, making them ideal for primary shredding applications. Their higher torque capability better handles the irregular feeding of mixed tire sizes and types, providing more consistent operation in high-volume recycling facilities.

Power System Configuration and Energy Optimization Solutions

Modern tire shredders typically utilize electric drive systems ranging from 100-1000 horsepower, depending on processing capacity requirements. These systems incorporate sophisticated power management features that optimize energy consumption based on load conditions. Soft-start systems reduce in-rush current during startup, while power factor correction equipment minimizes reactive power losses during operation.

Energy recovery systems represent an emerging innovation in shredding technology, capturing and reusing energy from the braking action of massive cutting rotors. Some advanced systems utilize regenerative drive technology similar to that employed in hybrid vehicles, improving overall energy efficiency by 15-20%. These improvements significantly impact operational costs, as energy typically represents 30-40% of total processing expenses in tire shredding operations.

Industry Application Cases and Market Outlook

The use of tire-derived infill has gained substantial acceptance across multiple market segments, driven by performance advantages and environmental benefits. Sports facilities represent the largest application, with synthetic turf fields now outnumbering natural grass installations in many regions. The consistent playing characteristics and all-weather capability of synthetic turf with rubber infill have made it the preferred choice for schools, municipalities, and professional sports organizations.

Landscape applications represent another growing market, particularly for golf courses, playgrounds, and residential landscaping. In these applications, the cushioning properties of rubber infill provide safety benefits while the material's durability ensures long service life with minimal maintenance. The market continues to expand as product quality improves and awareness of environmental benefits increases.

Procurement Trends for High-Performance Fillers in Sports Venues

Sports field designers increasingly specify tire-derived infill for its superior shock absorption properties and consistent playing characteristics. The material provides critical injury prevention benefits while maintaining ball roll and bounce characteristics comparable to natural grass. Professional sports organizations have led adoption, with over 75% of synthetic fields in professional stadiums now utilizing tire-derived infill.

The procurement process for major sports facilities increasingly emphasizes sustainability credentials alongside performance characteristics. Life cycle assessment data demonstrating the environmental advantages of tire-derived infill has become a important factor in specification decisions. This trend supports continued market growth despite competition from alternative materials, particularly in regions with strong environmental policies and recycling infrastructure.

Innovation Directions: Intelligent, Low-Energy Shredder Development

Shredder manufacturers are focusing development efforts on intelligence and energy efficiency improvements. Next-generation systems incorporate IoT connectivity for real-time performance monitoring and predictive maintenance, reducing downtime and improving overall equipment effectiveness. These smart systems automatically adjust operating parameters based on feed material characteristics, optimizing energy consumption and product quality.

Energy reduction remains a primary focus, with developments in motor technology, cutting geometry, and drive systems targeting 20-30% reductions in specific energy consumption. Some innovative designs utilize high toughness material shredding solutions that minimize friction and heat generation during size reduction. These advancements will further improve the economic and environmental performance of tire-derived infill production, supporting continued market expansion.