The global disposal of waste tires poses significant environmental challenges, with over 1 billion tires reaching the end of their life annually. Efficient separation of steel and rubber components is critical for recycling, and industrial shredders play a pivotal role in this process. This article explores the technical methods for separating steel wire and rubber from tires using specialized shredding equipment, highlighting principles, equipment setup, and utilization pathways to enhance resource recovery and minimize waste.

Tire Composition Analysis: Structural Characteristics of Steel and Rubber

Understanding the composition of a tire is fundamental to developing effective separation strategies. A typical tire is a complex composite material comprising multiple layers, each with distinct properties. The primary components include the tread, carcass ply, and bead rings, which integrate steel wire for strength and rubber for flexibility.

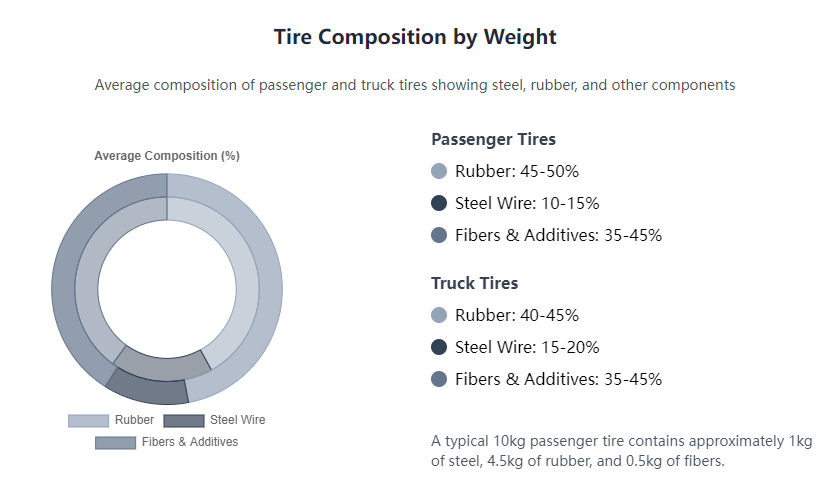

Steel wire, often embedded in the bead and belt areas, provides structural integrity and accounts for approximately 15-20% of a truck tire's weight. Rubber, comprising both natural and synthetic variants, offers elasticity and constitutes the bulk of the tire mass. The presence of textile fibers in the carcass layer adds complexity, requiring additional steps for pure separation. A material balance model shows that a standard passenger tire consists of about 10-15% steel, 45-50% rubber, and the remainder as fibers and additives.

Distribution and Content of Steel Wire in Tires

Steel wire is strategically placed in tires to reinforce critical areas such as the bead and steel belts. In passenger tires, steel content ranges from 10% to 15%, while heavy-duty truck tires can contain up to 20% steel by weight. This concentration influences the design of shredding systems, as higher steel content demands robust separation mechanisms.

The distribution pattern affects separation efficiency; for instance, bead wires are thicker and require coarse shredding, whereas belt wires are finer. Modern tire designs often use high-tensile steel, which retains magnetic properties after shredding, facilitating recovery through magnetic separation techniques.

Types of Rubber and Recycling Potential

Tire rubber is a blend of natural rubber derived from latex and synthetic rubber like styrene-butadiene rubber (SBR). Natural rubber exhibits superior elasticity, while synthetic variants offer better abrasion resistance. The recycling potential is high, as shredded rubber can be repurposed into products such as athletic tracks or asphalt modifiers.

Challenges in rubber recycling include contamination from steel and fibers, which must be minimized to meet industry standards. Advances in devulcanization technology allow for the breakdown of cross-linked polymers, enhancing the value of recycled rubber for high-end applications. Market analyses indicate that recycled rubber demand is growing at an annual rate of 5-7% globally.

Challenges and Handling of Fiber Impurities

Textile fibers from the carcass layer, typically polyester or nylon, complicate the separation process by entangling with rubber and steel fragments. These impurities can reduce the purity of output materials if not addressed. Effective handling involves integrated screening systems post-shredding to isolate fibers.

Technologies like air classifiers or vibrating screens are employed to separate lightweight fibers from denser rubber and steel. In some setups, fibers are collected and used as fuel or in composite materials, though this requires additional processing. Data shows that fiber content in tires averages 5-10%, necessitating efficient removal for quality control.

Material Balance Model of Whole Tires

A material balance model provides a quantitative framework for tire recycling, illustrating the proportions of steel, rubber, and other components. For example, a typical car tire weighing 10 kg contains about 1 kg of steel, 4.5 kg of rubber, and 0.5 kg of fibers. This model aids in optimizing shredder configurations for maximum recovery.

By analyzing input and output streams, operators can track separation efficiency, aiming for steel recovery rates above 95% and rubber purity exceeding 99%. The model also highlights the environmental benefit, as recycling one ton of tires saves approximately 700 kg of carbon emissions compared to incineration.

Separation Technology Principles and the Role of Shredders

Shredders are central to the separation process, utilizing mechanical forces to break down tires into manageable fragments. The principle involves shear and tear mechanisms that disintegrate the tire while preserving the integrity of steel wires for easy extraction. Integrated systems, such as magnetic separators, work in tandem with shredders to achieve high-purity outputs.

Separation efficiency is measured by purity and recovery rates, with industrial targets set at less than 1% steel contamination in rubber and over 90% steel recovery. Shredders like the double-shaft tire shredder excel in this role due to their controlled cutting action, which minimizes wire fragmentation. Multi-stage processes combining shredders with secondary equipment enhance overall performance.

Impact of Shredder Cutting Mechanisms on Separation Efficiency

The cutting mechanism of a shredder directly influences the quality of separation. Low-speed, high-torque shredders apply gradual shear forces, which prevent excessive fragmentation of steel wires. This preservation of wire length improves the effectiveness of subsequent magnetic separation, as longer wires are more easily captured.

In contrast, high-speed shredders may pulverize wires, reducing magnetic recovery rates. Studies indicate that optimized shredder settings can increase steel purity by up to 15% compared to conventional methods. The choice of cutter geometry, such as hook-shaped blades, also plays a role in minimizing rubber-steel adhesion.

Design Points for Integrating Magnetic Separation Systems into Shredders

Magnetic separators are often integrated at the discharge end of shredders to automate steel extraction. Permanent magnets are commonly used due to their low maintenance, while electromagnetic variants offer adjustable strength for handling varying wire sizes. Proper placement ensures that shredded material passes directly under the magnetic field for efficient capture.

Design considerations include the angle of the conveyor and the distance between the magnet and the material stream. For instance, an overband magnet installed 10-15 cm above the conveyor can achieve recovery rates of 98%. Regular cleaning of the magnet surface is essential to prevent clogging and maintain performance.

Evaluation Standards and Methods for Separation Purity

Separation purity is assessed through laboratory tests that measure the residual steel content in rubber output. Standard protocols involve sieving and magnetic susceptibility tests to quantify contamination levels. The goal is to achieve less than 1% steel by weight in the rubber fraction, as specified by industries like rubberized asphalt production.

Advanced methods include X-ray fluorescence (XRF) analysis for precise elemental detection. Regular monitoring helps identify issues such as blade wear or magnet degradation, allowing for timely adjustments. Data from operational plants show that consistent purity checks can reduce waste by 20% annually.

Optimization of Multi-Stage Separation Processes

Multi-stage separation involves combining primary shredding with secondary processing units like vibratory screens or air separators. This approach addresses limitations of single-stage systems by removing fines and fibers step-by-step. For example, a primary shredder reduces tires to 50-100 mm chips, followed by a secondary shredder for finer size reduction.

Optimization focuses on throughput and energy efficiency; adding a screening stage can improve rubber purity by 10% without significant cost increases. Process simulations indicate that three-stage systems achieve the highest material recovery, making them suitable for large-scale recycling facilities.

Equipment Configuration and Optimization Strategies

Selecting and configuring the right equipment is crucial for efficient tire recycling. Shredder choice depends on factors like throughput requirements and desired output purity. Auxiliary devices, including conveyors and automated controls, integrate with shredders to create a seamless operation.

Optimization strategies balance energy consumption with maintenance needs. For instance, using high-efficiency motors can reduce power usage by 15-20%, while predictive maintenance schedules minimize downtime. The integration of PLC systems allows for real-time adjustments, enhancing the adaptability of the recycling line to different tire types.

Shredder Selection Based on Separation Objectives

Shredder selection is guided by the intended use of the output materials. For high-purity rubber production, double-shaft shredders are preferred due to their precise cutting action. These machines handle whole tires efficiently, reducing them to uniform chips that facilitate easy steel separation.

When processing tires with high steel content, such as truck tires, four-shaft shredders offer enhanced durability and finer control. Performance data indicate that double-shaft models achieve throughputs of 2-5 tons per hour, while four-shaft variants can process up to 10 tons per hour with higher energy input.

Selection and Installation Techniques for Magnetic Separation Equipment

Choosing between permanent and electromagnetic separators depends on operational requirements. Permanent magnets are cost-effective for continuous operation, whereas electromagnets provide flexibility for processing mixed waste streams. Installation tips include positioning the magnet close to the shredder discharge to capture wires immediately after size reduction.

For optimal results, the magnetic field should cover the entire width of the conveyor belt. Maintenance involves periodic checks for demagnetization, which can reduce efficiency by up to 30%. Field tests show that proper installation can extend equipment lifespan by 25% compared to ad-hoc setups.

Enhancing Separation Continuity with Automation Systems

Automation systems, such as PLC-based controls, enable continuous operation by regulating feed rates and separator functions. Sensors monitor material flow, adjusting shredder speed to prevent overloads. This reduces manual intervention and improves safety.

Automated systems can increase overall efficiency by 20% by maintaining consistent throughput. For example, integrated PLC control panels allow operators to set parameters for different tire sizes, ensuring adaptive performance. Data logging features help track performance metrics for ongoing optimization.

Energy Management: Efficient Motors and Process Optimization

Energy management focuses on reducing the carbon footprint of tire recycling. High-efficiency IE3 or IE4 motors lower electricity consumption by 10-15% compared to standard models. Process optimizations, such as sequential startup of equipment, avoid idle running and peak demand charges.

Energy audits reveal that optimizing motor sizes and using variable frequency drives (VFDs) can cut energy use by up to 25%. For instance, a shredder line processing 10 tons per hour may consume 150-200 kWh, but with optimized controls, this can be reduced to 120-160 kWh, yielding significant cost savings.

Recycling and Utilization Pathways for Steel Wire

After separation, steel wire enters the scrap metal market, where it is valued for its high iron content. Recycling pathways include remelting in electric arc furnaces to produce new steel products. Environmental regulations mandate proper handling to prevent contamination.

Innovative uses, such as incorporating steel fibers into concrete, add value beyond traditional recycling. The global scrap steel market processes millions of tons annually, with tire-derived steel contributing to circular economy goals. Proper management ensures compliance with standards like ISO 14001 for environmental safety.

Market Analysis and Sales Strategies for Scrap Steel

The scrap steel market is influenced by global demand, with prices fluctuating based on industrial activity. Tire-derived steel typically commands prices 5-10% lower than prime scrap due to potential contaminants. Sales strategies involve building relationships with local steel mills to ensure steady offtake.

Market data indicate that scrap steel prices range from $200 to $400 per ton, depending on purity. By enhancing separation quality, recyclers can achieve premium pricing. Long-term contracts with consumers provide stability, reducing market volatility risks.

Brief on Steel Wire Reprocessing Technologies

Reprocessing involves melting scrap steel in furnaces at temperatures exceeding 1600°C to remove impurities. The molten steel is then cast into billets or rods for manufacturing. Quality control ensures the output meets industry specifications for tensile strength and composition.

Advanced techniques like arc furnace refining improve efficiency, with modern plants achieving recovery rates of 95%. Environmental measures, such as fume extraction systems, minimize emissions during melting. Reprocessed steel from tires can be used in construction, reducing the need for virgin materials.

Environmental Compliance: Avoiding Pollution and Proper Handling

Compliance with regulations requires safe storage and transportation of steel wire to prevent rust and leaching. Guidelines from agencies like the EPA mandate containment measures for scrap yards. Regular inspections ensure adherence to laws governing hazardous waste.

Best practices include covering steel piles to avoid water runoff and using lined storage areas. Non-compliance can result in fines or operational shutdowns. Data show that proper handling reduces environmental incidents by over 50% in regulated facilities.

Innovative Applications: Steel Wire in Concrete Reinforcement

Recycled steel wire can be used as fiber reinforcement in concrete, enhancing durability and crack resistance. This application diverts wire from landfills and supports green building initiatives. Tests demonstrate that steel-fiber concrete improves load-bearing capacity by 15-20%.

Adoption in infrastructure projects, such as bridges or pavements, is growing. Standards like ASTM A820 specify requirements for fiber-reinforced concrete, ensuring safety and performance. This innovative use adds economic value while promoting sustainability.

Utilization Solutions and Value Enhancement for Rubber

Separated rubber is processed into various products, from crumb rubber for sports surfaces to tire-derived fuel (TDF). Value enhancement involves refining rubber quality through grinding and purification. Certification to standards like ISO 9001 ensures market acceptance.

High-end applications, such as synthetic turf infill, require strict control over particle size and cleanliness. The global recycled rubber market is projected to reach $6 billion by 2025, driven by demand for sustainable materials. Efficient shredding is the first step in unlocking this value.

Production Processes and Equipment for Rubber Powder

Rubber powder production involves grinding shredded rubber into fine particles using granulators or mills. Equipment like cryogenic mills achieve sizes below 1 mm by freezing rubber to make it brittle. The powder is used in asphalt modification or molded products.

Production rates vary; a standard line can yield 1-3 tons of powder per hour. Quality depends on initial shredding, with uniform chips resulting in higher-grade powder. Market analysis shows that rubber powder prices range from $0.10 to $0.50 per kg, based on purity.

Key Points and Combustion Efficiency for TDF Preparation

Tire-derived fuel (TDF) is produced by shredding tires to specific sizes, typically 50-100 mm, for use in cement kilns or power plants. Combustion efficiency relies on consistent chip size and low moisture content. TDF has a high calorific value of 30-35 MJ/kg, comparable to coal.

Preparation involves removing metals to avoid furnace damage. Shredder settings influence TDF quality; for instance, controlled cutting reduces fines that can cause emissions. Regulations limit contaminants to less than 1% steel, ensuring safe combustion.

Manufacturing High-End Products: Example of Artificial Turf Filling

Rubber granules from shredded tires are used as infill for artificial turf, providing cushioning and durability. The process involves washing and grading granules to meet size specifications of 1-3 mm. Quality checks ensure absence of metals or fibers.

This application accounts for 20% of recycled rubber use in some regions. Standards like FIFA Quality Concept for turf require rigorous testing. Value addition through coloring or coating can increase profitability by 30%.

Importance of Quality Certifications such as ISO Standards

Certifications validate the quality and safety of recycled rubber products. ISO 9001 for quality management and ISO 14001 for environmental management are common. Certification involves audits of processes from shredding to final product.

Certified products often command price premiums of 10-15%. For example, rubber mulch with ISO certification is preferred for playgrounds. Compliance demonstrates commitment to sustainability, enhancing brand reputation and market access.

Operational Best Practices and Troubleshooting

Daily operations require adherence to maintenance and safety protocols to ensure shredder reliability. Best practices include scheduled inspections and operator training. Troubleshooting common issues like jams or purity drops minimizes downtime.

Performance monitoring through data collection enables continuous improvement. Safety measures protect workers from hazards like moving parts or wire fragments. A well-maintained system can operate at over 90% efficiency, maximizing resource recovery.

Maintenance Schedule: Regular Checks for Magnetic Separators and Shredders

A maintenance schedule includes weekly tasks such as cleaning magnet surfaces and inspecting shredder blades for wear. Monthly checks might involve lubricating bearings and testing electrical systems. Predictive maintenance using vibration analysis can prevent failures.

Documented schedules reduce unplanned downtime by 25%. For instance, blade replacement every 500 operating hours maintains cutting efficiency. Records of maintenance activities aid in troubleshooting and warranty claims.

Troubleshooting Issue 1: Causes and Solutions for Low Separation Purity

Low purity often results from dull blades or weakened magnetic fields. Inspection may reveal blade gaps exceeding tolerances or magnet contamination. Solutions include sharpening blades or replacing magnets to restore performance.

Data analysis can pinpoint trends, such as purity drops after processing wet tires. Adjusting feed rates or pre-drying tires may resolve the issue. Regular calibration of sensors ensures accurate monitoring.

Troubleshooting Issue 2: Prevention and Handling of System Blockages

Blockages occur due to overfeeding or foreign objects in tires. Prevention involves using regulated feed conveyors and pre-sorting tires. Clearing jams requires shutdown and manual removal, emphasizing safety.

Installation of metal detectors before shredders reduces blockage risks. Operational logs show that trained operators can reduce blockage frequency by 40%. Emergency stop systems protect equipment during incidents.

Safety Protocols: Operator Training and Protective Equipment

Safety protocols mandate training on shredder operation and hazard awareness. Protective gear like gloves and goggles shields against wire splinters. Lockout-tagout procedures ensure machinery is safe during maintenance.

Accident rates decrease by 60% with comprehensive training. Regular drills reinforce protocols. Compliance with OSHA standards minimizes legal risks and promotes a culture of safety.