Selecting the appropriate industrial shredder for waste tires is a critical decision that directly impacts operational efficiency, cost-effectiveness, and the quality of the final output. The physical volume of the tires is the primary determinant in this selection process, influencing the required machine size, power, cutting mechanism, and overall system design. This guide provides a comprehensive analysis of the relationship between tire volume and shredder specifications, offering a systematic approach to matching equipment capabilities with specific material characteristics. A thorough understanding of these principles ensures a processing line that maximizes throughput, minimizes downtime, and delivers consistently sized tire derived fuel or crumb rubber.

Understanding the Foundational Relationship Between Tire Volume and Shredder Selection

The volume of a waste tire dictates the fundamental mechanical stresses that will be placed upon a shredding system. Larger tires possess greater structural integrity and contain more material, requiring significantly more force to shear and tear apart. This relationship is not linear; doubling the tire volume often requires more than double the power and a more robust cutting chamber to accommodate the larger size and resist the increased forces. The selection process must therefore begin with a precise understanding of the incoming tire stream's volumetric characteristics.

Ignoring this foundational relationship leads to several operational challenges. An undersized shredder will experience frequent jamming, accelerated wear on its cutters, and potential motor burnout from constant overloading. Conversely, an excessively large machine for a small volume of tires represents a poor capital investment, consuming more floor space and energy than necessary. The goal is to achieve a precise match where the shredder operates consistently within its designed capacity, ensuring smooth processing and economic viability.

Basic Processing Capacity Requirements Dictated by Tire Volume

Tire volume directly determines the necessary hourly processing capacity of a shredder. A machine intended for passenger car tires, which average approximately 0.07 cubic meters, will have vastly different requirements than one processing off-the-road (OTR) tires exceeding 5 cubic meters. The shredder's cutting chamber must be physically large enough to accept the largest tire in the feedstock without requiring excessive pre-processing, which adds time and labor costs.

The required motor power scales with volume. Processing a high volume of large tires demands a powerful drive system, often exceeding 200 horsepower for heavy-duty applications, to provide the necessary torque to the cutting shafts. This power ensures the rotors can maintain their speed under load, cleanly shearing the rubber and steel cord rather than stalling, which is a common cause of inefficiency and equipment damage in mismatched systems.

Common Processing Challenges for Different Tire Volumes

Different tire sizes present unique challenges. Smaller tires, while less voluminous, can be processed in high quantities, leading to potential overheating of the shredder if its cooling systems are inadequate. They may also nest or intertwine on a conveyor, causing irregular feed rates into the machine. This inconsistent feeding can create a pulsed load on the motor and drive train, reducing efficiency and increasing mechanical stress.

Large-volume tires, such as those from trucks and heavy equipment, present challenges of pure mass and strength. Their thick steel bead wires and rugged radial plies are designed to withstand immense pressure, making them exceptionally resistant to tearing. A shredder must exert tremendous focused force to initiate a cut, and its blades must be made from specialized alloys, like tungsten carbide, to resist the abrasive nature of the steel and rubber composite. The sheer bulk of these tires also demands robust material handling equipment, like hydraulic pusher rams, to force them into the cutting chamber consistently.

Matching Principles for Volume and Shredder Model

The primary rule for matching tire volume to a shredder model is ensuring the physical dimensions of the cutting chamber exceed the dimensions of the largest tire. There must be sufficient clearance for the tire to enter the chamber and be engaged by the rotating cutters without obstruction. For a double shaft shredder, the distance between the shafts must be considered to allow the tires to be grabbed and pulled into the cutting action effectively.

Another critical principle is selecting a shredder with a torque and power profile that matches the volumetric load. High-volume, large-tire applications benefit from high-torque, low-speed shredders that can exert tremendous shearing force without bogging down. For lower volumes of smaller tires, a higher-speed system might prioritize throughput. The choice between single-shaft, double-shaft, and four-shaft models is also a function of volume, with multi-shaft systems generally offering higher throughput and better handling of bulky, difficult-to-grip materials.

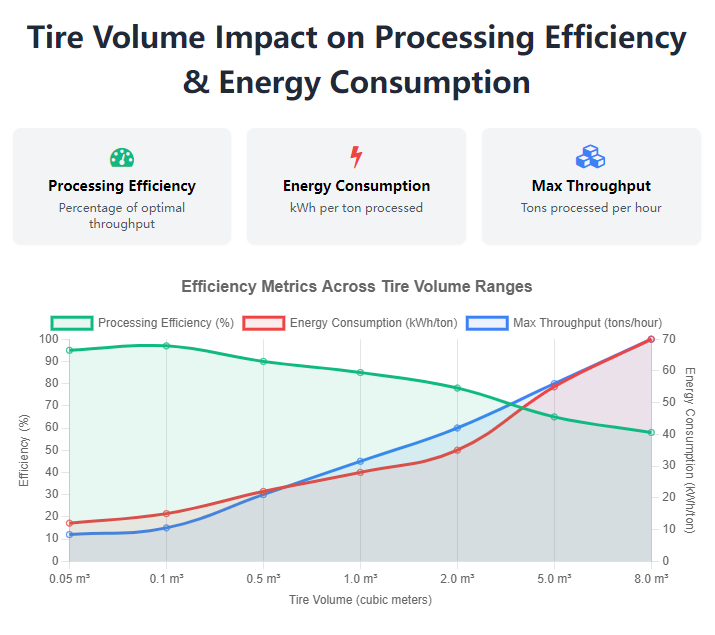

Impact of Volume on Processing Efficiency and Energy Consumption

Tire volume has a direct and significant correlation with energy consumption. Processing a single large OTR tire can consume as much energy as processing hundreds of passenger tires. This is due to the prolonged high-power demand required to break down the dense, reinforced structure. Therefore, understanding the average volumetric input is essential for accurately forecasting operational electricity costs and evaluating the environmental footprint of the recycling operation.

Efficiency peaks when a shredder operates consistently near its designed volumetric capacity. Underloading a large machine is inefficient, as it cycles on and off, never reaching its optimal operating temperature and consuming energy disproportionately to its output. Overloading causes frequent emergency stops, unplanned maintenance, and high energy draws during jam recovery. The most efficient systems use automated feeding mechanisms that regulate the flow of material into the shredder based on its real-time power consumption, maintaining an ideal load regardless of variations in individual tire volume.

Precise Methods for Assessing Waste Tire Volume

Accurately determining the volume of waste tires is a prerequisite for informed shredder selection. Volume assessment goes beyond simple physical dimensions; it requires an understanding of the tire's deformable nature and the variability within a batch. Professional operations employ a combination of direct measurement and statistical estimation to build a reliable profile of their feedstock, ensuring the selected equipment can handle the full range of expected material.

This assessment is not a one-time activity. The composition of a waste tire stream can change based on source, season, and market conditions. A continuous evaluation process helps operators adapt their processing strategies and provides critical data for planning maintenance cycles and forecasting wear on consumable parts like cutter blades and screen meshes. Precision in volume assessment translates directly to predictability in operation.

Using Professional Measurement Tools to Obtain Volume Data

For critical applications and unique tire types, professional tools provide the most accurate volume data. Laser scanning systems can create a detailed 3D point cloud model of a tire, from which software can calculate its exact volume, including the void space in the center. This method is highly accurate but is typically reserved for engineering studies or when designing a completely new processing line for a specific, high-value tire type.

More commonly, operators use a combination of manual measurements and displacement techniques. Measuring the overall diameter, section width, and rim diameter provides the data needed to use standardized formulas for estimating tire volume. For irregularly worn or damaged tires, the water displacement method offers a practical, though more labor-intensive, way to determine actual volume. This involves submerging the tire in a tank of known dimensions and measuring the rise in water level, which directly corresponds to the tire's volume.

Estimation Techniques for Bulk Tire Volumes

In a practical industrial setting, measuring every single tire is impractical. Instead, operators rely on bulk estimation techniques. A common method involves calculating the pile density. A known number of tires of a specific type are loaded into a container of known volume. The total volume of the tires is then the container's volume minus the remaining air space. This provides an average volume per tire for that specific type, which can be used to estimate the total volume of a large pile by counting.

Another technique involves using historical data and standardized classification. Tires are categorized into standard groups: passenger (P), light truck (LT), truck and bus (TB), and off-the-road (OTR). Each category has well-documented average volume ranges. By weighing a load of tires and knowing the approximate mix of categories, an operator can estimate the total volumetric load. For instance, a metric ton of passenger tires represents a much larger volume than a metric ton of dense OTR tires.

Considering Tire Compression and Expansion Factors

Tires are highly elastic and compressible, a factor that significantly complicates volume assessment. A tire under compression in a stack has a much lower apparent volume than when it is free-standing. This is crucial for designing feed systems and hoppers; the equipment must be sized for the expanded volume of the tire as it enters the shredder, not its compressed state in storage.

The expansion factor must be accounted for when sizing shredder feed openings and conveyors. A hydraulic ram feeder can compress a tire to force it into a smaller opening, but this requires additional energy and places different stresses on the shredder. Understanding this behavior helps in selecting a shredder with a feed mechanism that can effectively manage the material's tendency to spring back, ensuring a consistent and reliable flow into the cutting chamber.

Key Parameters for Selecting a Shredder Based on Volume

Selecting the correct shredder involves analyzing several interconnected parameters that are all influenced by the volume of the tires. These parameters form a technical specification that ensures the machine can handle the physical size, material strength, and desired output of the feedstock. A holistic view of these factors prevents the common mistake of over-emphasizing a single feature, such as motor power, while neglecting other critical elements like cutting chamber design or discharge handling.

The evaluation process should balance immediate processing needs with long-term operational goals. A shredder is a significant capital investment, and its specifications must support not only the current feedstock but also potential future changes in the volume or type of tires being processed. Flexibility, durability, and ease of maintenance are as important as pure processing capacity in achieving a satisfactory return on investment.

Adaptability of Cutting Chamber Size to Tire Volume

The cutting chamber is the heart of the shredder, and its dimensions are the first and most critical parameter to check against tire volume. The chamber must be wide enough to accept the largest tire's cross-section and tall enough so that the tire does not bridge at the throat of the machine. For very large tires, the chamber may also need to be longer to allow the material to be fully engaged and processed before being discharged.

The design of the chamber, particularly in a solid waste shredder adapted for tires, must facilitate a smooth flow of material. Restrictive or poorly designed chambers can cause blockages, especially with tires that tend to rebound or twist. The geometry of the chamber, the placement of the cutting shafts, and the design of the counter-knives all work together to ensure that once a tire enters, it is effectively drawn in, shredded, and pushed out to make room for the next feed cycle.

Relationship Between Power System and Processing Volume

The motor power, measured in kilowatts or horsepower, must be matched to the volumetric throughput and the density of the material. A high volume of large, heavy tires requires a high-torque drive system capable of delivering consistent power under extreme load. Electric motors are common, often coupled with a heavy-duty gearbox that provides the necessary reduction to achieve high torque at low rotor speeds, typically between 20 and 60 RPM for high-volume tire shredding.

Energy efficiency is directly tied to proper power matching. An underpowered motor will draw excessive current, overheat, and fail prematurely when faced with a large volumetric load. Modern shredders often incorporate programmable logic controllers (PLCs) that monitor motor amperage and automatically adjust the feed rate to maintain an optimal load, maximizing energy efficiency and protecting the drive system from damage. This is a standard feature in a well-designed metal shredder system, which faces similar challenges with voluminous scrap.

Matching Cutting Tool Design to Tire Material

The cutting tools are the components that directly interact with the tire, and their design is paramount. For the high-volume processing of tires, which contain abrasive rubber and tough steel cord, the tools must be made from exceptionally wear-resistant materials. Hardened tool steel or tungsten carbide tips are standard. The geometry of the knives is also crucial; hook-shaped or sickle-shaped knives are often used to better grab and pull the elastic tire material into the shear zone between the rotors.

The arrangement of the knives on the shaft also influences volumetric capacity. Staggered knife patterns create a scissor-like shearing action that is more efficient for processing large volumes than a crushing action. The clearance between the rotary knives and the stationary bed knives must be precisely adjustable to maintain cutting efficiency as the knife edges wear down over time. This ensures consistent output particle size throughout the life of the tools, which is vital for downstream processing steps.

Recommended Shredder Types for Different Tire Volumes

The market offers a variety of shredder configurations, each with strengths suited to particular volume ranges. There is no universal solution; the optimal choice depends on a careful analysis of the feedstock. Generally, shredder systems progress from simpler, single-shaft designs for lower volumes and smaller tires to complex, multi-stage systems with automated feeding for high-volume, large-tire applications.

Beyond the basic shredder type, auxiliary equipment plays a significant role in handling volume. Conveyors, pre-compactors, and post-shredding separation systems (like magnetic separators for steel wire) are integral to a efficient processing line. The shredder itself is the core, but its effectiveness is determined by how well it is integrated into a system designed for the specific volumetric characteristics of the material.

Suitable Models for Small Tires

Passenger car and light truck tires, representing the smallest common volumes, are often processed efficiently using single-shaft or compact double-shaft shredders. These machines typically have cutting chambers with intake widths ranging from 600mm to 1000mm. They are designed for continuous feeding of a high quantity of smaller items. A single-shaft shredder with a hydraulic ram feeder can effectively process these tires, often producing a strip-like output that may require secondary shredding for smaller chips.

For operations focusing exclusively on a high volume of small tires, a system incorporating a granulator after the primary shredder is common. The primary shredder reduces whole tires into manageable strips, which are then fed into a high-speed granulator for size reduction into clean rubber chips. This two-stage approach is highly efficient for this volume class, allowing for high throughput and controlled output sizing with manageable power consumption per ton of material processed.

Recommended Choices for Medium and Large Tires

Medium-volume tires from trucks and buses require more robust machinery. Double-shaft shear-type shredders are the industry standard for this application. Their intermeshing rotors equipped with hardened steel cutters provide a powerful shearing and tearing action that effectively handles the thicker rubber and heavier steel cord. These machines feature larger cutting chambers and more powerful motors, typically in the 75-200 kW range, to maintain productivity.

For the high-volume processing of large tires, such as those from mining and agricultural equipment, dedicated heavy-duty systems are essential. These often involve a primary shredder, which performs the initial size reduction, followed by a secondary shredder or granulator to refine the material into the final product. The primary shredder in such a system is a massive piece of equipment, with a large feed opening, a extremely powerful drive system, and components designed for maximum uptime and ease of maintenance, such as those found in a tire shredder built for OTR applications.

Practical Techniques for Optimizing Shredder Processing Results

Achieving optimal results from a tire shredder extends beyond selecting the right machine; it involves implementing best practices throughout the operation. Optimization focuses on maximizing throughput, minimizing wear and energy costs, and ensuring a consistent, high-quality output. These techniques are often operational nuances learned through experience and are critical for maintaining profitability in a competitive recycling market.

A proactive approach to optimization, centered on data collection and analysis, yields the best long-term results. Monitoring key performance indicators like tons per hour, kWh per ton, blade wear rates, and downtime provides a factual basis for making adjustments. This data-driven strategy allows operators to move from reactive maintenance to predictive and preventive schedules, significantly improving overall equipment effectiveness.

The Impact of Preprocessing Steps on Effective Volume

Preprocessing can dramatically alter the effective volume of tires entering the shredder, leading to significant gains in efficiency. The most common preprocessing step is bead ring removal. Removing the stiff steel bead wires from the tire's inner rim before shredding reduces the overall material strength and eliminates a major source of wear and potential damage to the shredder's cutting tools. While it adds a process step, it often increases overall system throughput and reduces maintenance costs.

For very large tires, primary cutting with a guillotine or saw is another effective preprocessing technique. Reducing an OTR tire into two or three smaller sections makes it easier to handle and feed into the shredder. This prevents the shredder from having to process the entire massive volume at once, reducing peak power demands and minimizing the risk of jamming. This step effectively transforms a single, voluminous, and difficult-to-process item into several more manageable ones, smoothing the feed rate into the primary shredder.

Monitoring Tool Wear and Timely Replacement

Cutting tools are consumable items in tire shredding, and their condition directly impacts processing efficiency and output quality. Dull or worn knives require more power to pull material into the chamber and result in a ragged, irregular tear instead of a clean cut. This increases energy consumption, generates more heat, and produces an inconsistent output size. Establishing a regular schedule for inspecting and rotating or replacing knives is essential.

Modern monitoring systems use sensors to track motor current and vibration patterns. A gradual increase in amperage draw for the same feed rate often indicates that the knives are dulling and require attention. By tracking this data, operators can schedule knife changes during planned maintenance downtime, avoiding unplanned stoppages and ensuring the shredder always operates with sharp, efficient cutting tools. This predictive maintenance approach is far superior to waiting for a noticeable drop in performance or a machine jam.

Case Studies: Successful Selection and Application Examples

Real-world applications provide the most compelling evidence for the importance of volume-based shredder selection. Analyzing these cases offers valuable insights into the decision-making process, the challenges encountered, and the solutions implemented to achieve operational success. These examples span different scales and feedstock profiles, illustrating the adaptability of well-chosen shredding technology.

Common themes in successful case studies include thorough initial feedstock analysis, investment in appropriately sized equipment (often erring on the side of slightly larger capacity for future growth), and the integration of ancillary systems for feeding and material handling. The long-term financial benefits, including reduced downtime, lower maintenance costs, and higher-quality output, consistently justify the upfront investment in precision-matched equipment.

Case Study: Integrated System for Mixed Volumes

A large recycling facility faced the challenge of processing a mixed stream of tires, ranging from passenger car to light truck tires. Their initial single-shredder system was frequently jammed by the larger tires, while it was inefficient for the high volume of smaller ones. The solution involved installing a two-stage system centered around a robust double-shaft primary shredder sized for the largest tires in the stream.

The primary shredder reduced all incoming tires to a rough 100mm output. A series of screens and conveyors then separated the material. The correctly sized material proceeded to storage, while the oversized chunks were recirculated back to the primary hopper. This closed-loop system allowed a single shredder to efficiently handle the mixed volumetric load, maximizing throughput and producing a consistent final product without the need for manual sorting of the input stream. The operational principles are similar to those used in a high toughness material shredding solution.