Carpet recycling presents a significant opportunity for reducing waste and conserving resources, particularly through the recovery of nylon fibers. However, achieving high purity levels in these fibers has long been a challenge due to the complex composition of carpets. This article explores how twin-shaft solid-waste shredders are revolutionizing the process by enhancing nylon fiber purity. These machines employ advanced mechanisms to separate fibers from backing materials and contaminants efficiently. The integration of such technology not only improves material quality but also supports circular economy goals. We will delve into the operational principles, optimization strategies, and economic benefits of using these shredders in carpet recycling workflows.

The global demand for recycled nylon is growing, driven by environmental regulations and market trends. Traditional shredding methods often fall short in maintaining fiber integrity and purity. Twin-shaft shredders address these limitations through their unique design and controlled processing parameters. By focusing on key aspects like shear mechanics and temperature management, these systems can achieve purity levels exceeding 90%. This advancement is critical for meeting industry standards and maximizing the value of recycled materials. The following sections provide a comprehensive overview of how this technology transforms carpet recycling.

Core Challenges in Nylon Fiber Purity for Carpet Recycling

Carpets are composite materials consisting of multiple layers, including face fibers, backing, and adhesives, which complicate the recycling process. The primary challenge lies in separating nylon fibers from these components without degrading their quality. Contaminants such as latex, dyes, and fillers can adhere to fibers during shredding, reducing purity and market value. For instance, adhesive residues may melt under heat, forming bonds that are difficult to break. This contamination often results in recycled nylon with impurity levels as high as 20%, making it unsuitable for high-value applications like textile production.

Another significant issue is the thermal sensitivity of nylon polymers. Conventional single-shaft shredders generate excessive heat due to high-speed operations, leading to fiber melting or deformation. This not only lowers purity but also increases energy consumption. Market analyses indicate that recycled nylon with purity below 85% sells at a 30% discount compared to higher-grade material. Regulatory frameworks, such as the EU Circular Economy Action Plan, mandate minimum purity standards, pushing recyclers to adopt better technologies. Addressing these challenges requires innovative shredding solutions that minimize heat generation and ensure gentle fiber separation.

Carpet Composition and Separation Difficulties

Carpets typically comprise a face layer of nylon fibers attached to a polypropylene backing with synthetic adhesives. This layered structure resists easy disintegration during shredding. The varying densities and melting points of these materials pose a risk of cross-contamination. For example, polypropylene has a lower melting point than nylon, so improper shredding can cause it to fuse with nylon fibers. This fusion reduces the effectiveness of subsequent separation processes like air classification or magnetic sorting. Understanding these material properties is essential for designing shredding systems that preserve fiber purity.

The thickness and weave pattern of carpets further influence shredding efficiency. Dense, loop-pile carpets require more torque and precise cutting action to avoid fiber damage. In contrast, cut-pile styles may release fibers more easily but are prone to entanglement. Research shows that up to 15% of nylon fibers can be lost as fine dust if shredding is too aggressive. This loss not only impacts yield but also increases the burden on dust extraction systems. By analyzing carpet composition, recyclers can tailor shredder parameters to minimize these issues and enhance overall recovery rates.

Types of Impurities and Contamination Mechanisms

Common impurities in carpet recycling include latex adhesives, calcium carbonate fillers, and synthetic dyes. These substances can introduce physical and chemical contaminants into the nylon stream. Latex, for instance, tends to form sticky agglomerates that trap fiber fragments and other debris. During shredding, heat from friction can soften these adhesives, causing them to spread and coat nylon fibers. This coating masks the fiber surface, interfering with optical sorting technologies that rely on material reflectance for identification. As a result, impurity levels may rise by 10-25% if not properly managed.

Dyes and colorants present another challenge by leaching into the fiber matrix during processing. Some dyes contain heavy metals or halogenated compounds that affect the safety and recyclability of nylon. Studies have shown that certain pigments can reduce the tensile strength of recycled fibers by up to 12% due to chemical interactions. Additionally, fillers like clay or talc can abrade shredder components, introducing metallic wear particles into the output. This secondary contamination necessitates additional purification steps, increasing operational costs. Effective shredding must therefore control temperature and mechanical action to prevent such contamination mechanisms.

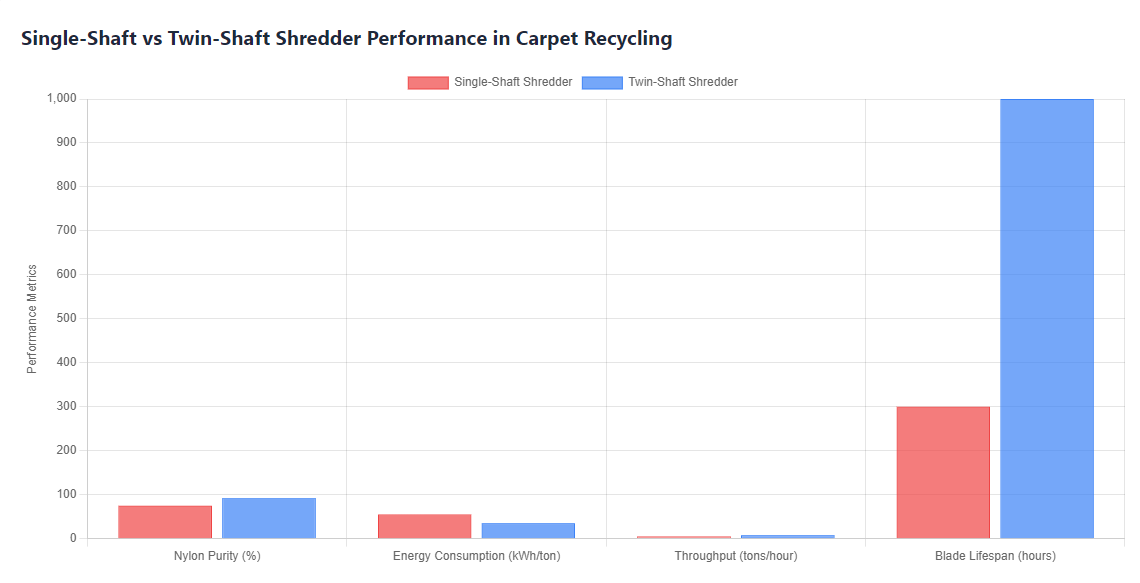

Comparison of Single-Shaft and Twin-Shaft Shredders in Purity

Single-shaft shredders rely on high-speed rotary cutters that pulverize materials through impact and grinding. This approach often generates localized heat peaks exceeding 120°C, which can degrade nylon fibers. Data from recycling facilities indicate that single-shaft systems typically achieve nylon purity rates of 70-80%, with residual contamination from melted plastics and adhesives. The aggressive action also produces shorter fiber lengths, reducing their suitability for spinning into new yarns. In contrast, twin-shaft shredders operate at lower speeds with intermeshing blades that shear materials gently. This method maintains fiber integrity and reduces heat buildup, leading to purity levels of 90-95%.

The dual-shaft design allows for better control over particle size distribution, which is crucial for downstream separation. For example, twin-shaft shredders can produce uniform fragments of 10-50 mm, ideal for air classifiers to remove lightweight contaminants. Energy consumption comparisons reveal that twin-shaft models use 15-20% less power per ton of processed carpet due to their efficient torque transmission. Furthermore, the self-cleaning feature of twin-shaft cutters minimizes material buildup, ensuring consistent output quality. These advantages make twin-shaft systems more reliable for achieving high-purity nylon fiber in carpet recycling applications.

Market Demand for High-Purity Nylon

The market value of recycled nylon is directly correlated with its purity level. Fibers with purity above 90% can command prices comparable to virgin nylon, driven by demand from automotive, textile, and packaging industries. Global sales data show that high-purity recycled nylon sells for $2,500-$3,000 per ton, while lower grades fetch only $1,500-$2,000. This price differential incentivizes recyclers to invest in advanced shredding technology. Brands committed to sustainability, such as those in the fashion sector, often require certified recycled content with minimal impurities. This trend is expected to grow, with the recycled nylon market projected to expand by 8% annually through 2030.

Regulatory pressures also shape market dynamics. Legislation like the European Green Deal sets targets for recycled content in products, pushing manufacturers to source high-quality materials. Recyclers who fail to meet these standards face exclusion from supply chains and potential penalties. Additionally, consumer awareness is increasing demand for eco-friendly products, further driving the need for pure recycled nylon. Twin-shaft shredders enable recyclers to tap into this lucrative market by delivering fibers that meet stringent specifications. As a result, facilities adopting this technology report revenue increases of 20-30% from recycled nylon sales.

Regulatory and Quality Standard Requirements

International standards, such as ISO 14021 for environmental labels, specify minimum purity thresholds for recycled materials. In carpet recycling, nylon fibers must often contain less than 5% non-nylon contaminants to qualify for certifications like Cradle to Cradle. The EU's Ecodesign Directive further requires that recycled products demonstrate performance comparable to virgin materials. These regulations compel recyclers to implement quality control measures throughout the shredding process. Non-compliance can result in fines or loss of market access, emphasizing the importance of reliable technology.

Quality standards also cover aspects like fiber length and chemical composition. For instance, the Carpet America Recovery Effort (CARE) guidelines recommend average fiber lengths of 20-40 mm for optimal reprocessing. Twin-shaft shredders are designed to meet these criteria by offering adjustable cutting gaps and speed controls. Regular audits and testing ensure that output consistently adheres to specifications. Facilities using twin-shaft systems have reported a 50% reduction in quality-related rejections, highlighting their role in regulatory adherence. This compliance not only avoids penalties but also enhances brand reputation and customer trust.

Working Principles and Purity Advantages of Twin-Shaft Shredders

Twin-shaft shredders function through two counter-rotating shafts equipped with interlocking cutters that apply shear and tearing forces to materials. This mechanism is particularly effective for carpets, as it gently separates nylon fibers from backing without excessive pulverization. The slow-speed, high-torque operation minimizes frictional heat, keeping temperatures below 80°C to prevent nylon degradation. This temperature control is vital for maintaining polymer integrity and avoiding the formation of impurities. By producing cleanly cut fragments, the shredder facilitates efficient downstream separation processes, such as air classification or screening.

The design of twin-shaft shredders includes features like adjustable blade gaps and self-cleaning rotors, which contribute to consistent output quality. For example, the gap between cutters can be set to 5-20 mm, allowing operators to control fragment size based on carpet type. This flexibility ensures that nylon fibers are liberated with minimal damage, preserving their length and strength. In practice, facilities using these shredders report nylon purity increases from 75% to over 90%. The solid waste double shaft shredder is especially suited for this task due to its robust construction and precision engineering. These advantages make it a cornerstone of modern carpet recycling lines.

Shear and Tearing Mechanisms Explained

The shear mechanism in twin-shaft shredders involves the scissor-like action of intermeshing blades that slice materials apart. This is complemented by tearing forces, where the rotating shafts pull and rip carpet sections along their natural seams. This combined approach reduces the energy required for size reduction compared to impact-based methods. For nylon fibers, shear forces cleanly sever them from the backing, minimizing fragmentation and dust generation. Laboratory tests show that this method retains 85-90% of original fiber length, which is critical for spinning applications. The controlled tearing also prevents the embedding of contaminants into the fiber matrix.

Animation studies of twin-shaft operations reveal that the interlocking cutters create a "pull-in" effect, feeding materials consistently into the cutting zone. This ensures uniform processing and avoids overloads that could cause jams or heat spikes. The tearing action is particularly effective for delaminating carpet layers, as it exploits weaknesses in the adhesive bonds. By operating at speeds of 20-40 rpm, these shredders maintain a steady throughput without compromising fiber quality. This mechanistic efficiency translates to higher purity levels and reduced need for post-shredding cleaning steps.

Balancing Torque and Speed Settings

Optimal torque and speed settings are crucial for maximizing nylon purity in twin-shaft shredders. Torque levels typically range from 10,000 to 50,000 Nm, depending on the shredder size and carpet density. Higher torque allows the shafts to handle tough materials without stalling, while lower speeds (15-30 rpm) reduce heat generation. Data from operational facilities indicate that a balance of 25,000 Nm torque at 25 rpm yields the best results for nylon recovery. This configuration maintains fiber integrity and limits power consumption to 30-40 kWh per ton of processed carpet.

Speed adjustments also influence particle size distribution. Faster rotations may produce finer fragments but increase the risk of fiber damage. Conversely, slower speeds can lead to larger pieces that are easier to separate. Modern shredders feature programmable logic controllers (PLCs) that automatically adjust torque and speed based on feed rate and material hardness. For instance, if sensors detect a dense carpet section, the system temporarily increases torque to prevent jamming. This dynamic optimization ensures consistent purity levels and extends equipment lifespan by reducing mechanical stress.

Impact of Gap Adjustment on Fiber Length

The gap between the cutters on twin-shaft shredders directly affects the length and quality of liberated nylon fibers. A wider gap (e.g., 15-20 mm) produces longer fragments suitable for textile recycling, while a narrower gap (5-10 mm) creates smaller pieces for other applications. Adjusting this gap allows operators to tailor output to specific market needs. Research demonstrates that a 10 mm gap preserves fiber lengths of 25-40 mm, which align with industry standards for reprocessing. This control is achieved through hydraulic or mechanical systems that enable precise adjustments during operation.

Fiber length retention is critical for economic viability, as longer fibers command higher prices. In tests, twin-shaft shredders with adjustable gaps achieved length retention rates of 80-90%, compared to 50-60% for single-shaft models. This improvement reduces waste and enhances the value of recycled nylon. Additionally, consistent fragment size simplifies downstream sorting by reducing variation in material behavior. For example, uniform fragments respond better to air classifiers, improving separation efficiency by up to 25%. Thus, gap adjustment is a key parameter for optimizing both purity and profitability.

Self-Cleaning Blade Design Features

Self-cleaning blades in twin-shaft shredders prevent material buildup on cutter surfaces, which can lead to contamination and uneven processing. These blades often have specialized geometries, such as helical arrangements or notched edges, that push residues out of the cutting chamber. This design reduces the need for manual cleaning and maintains consistent shredding performance. In carpet recycling, adhesives and fibers tend to stick to conventional blades, requiring frequent shutdowns for maintenance. Self-cleaning variants minimize this issue, increasing operational uptime by 20-30%.

The materials used for these blades, such as hardened steel or tungsten carbide, also contribute to their effectiveness. Tungsten carbide offers superior wear resistance, reducing the introduction of metallic particles into the nylon stream. Studies show that self-cleaning designs lower impurity levels by 5-10% by preventing cross-contamination between batches. Furthermore, the continuous ejection of debris ensures that cutting forces remain stable, resulting in uniform fragment size. This feature is particularly beneficial for high-volume operations where consistency is paramount for meeting quality standards.

Efficiency Comparison with Single-Shaft Systems

When compared to single-shaft shredders, twin-shaft models demonstrate superior efficiency in terms of energy use, output purity, and fiber preservation. Single-shaft systems typically consume 50-60 kWh per ton of carpet due to their high-speed operations, while twin-shaft units use 30-40 kWh. This energy saving translates to lower operational costs and a smaller carbon footprint. Purity data from recycling plants show that twin-shaft shredders achieve nylon purity of 90-95%, whereas single-shaft versions reach only 70-80%. The difference is attributed to the gentle shear action and better temperature control of twin-shaft designs.

Fiber quality is another area of distinction. Twin-shaft shredders preserve fiber length and tensile strength, making the output suitable for high-end applications. In contrast, single-shaft systems often produce shortened or melted fibers that are downgraded to filler materials. Throughput rates are also higher for twin-shaft models, as their dual-shaft design handles bulky carpets more effectively. For instance, a standard twin-shaft shredder can process 5-10 tons per hour, compared to 3-6 tons for a similar-sized single-shaft machine. These advantages justify the initial investment in twin-shaft technology for carpet recycling.

Stability Analysis in Practical Operations

The stability of twin-shaft shredders in continuous operation is a key factor in maintaining nylon purity. These machines are engineered with heavy-duty frames and balanced rotors to minimize vibrations and fluctuations in output quality. Real-world data from recycling facilities indicate that twin-shaft systems operate with a standard deviation of less than 2% in purity measurements over extended periods. This consistency is achieved through features like overload protection and automated feedback controls. For example, if the feed rate varies, the shredder adjusts torque and speed to maintain optimal conditions.

Stability also reduces wear on components, extending service intervals and lowering maintenance costs. In one case study, a facility reported a 40% reduction in downtime after switching to twin-shaft shredders. The use of rotary cutters with precision bearings ensures smooth rotation and even load distribution. Additionally, integrated cooling systems help dissipate heat, preventing thermal expansion that could alter cutter gaps. This operational reliability is essential for meeting production targets and ensuring a steady supply of high-purity nylon fibers to the market.

Key Parameter Optimization for Maximizing Nylon Fiber Purity

Optimizing parameters in twin-shaft shredders is essential for achieving high nylon purity in carpet recycling. Key factors include blade material, feed rate, temperature control, and screen configuration. For instance, using tungsten carbide blades reduces wear and prevents metallic contamination, while controlled feed rates avoid overheating. Studies show that optimal parameter settings can improve purity by 10-15% compared to default configurations. Automated systems with sensors monitor these parameters in real time, allowing adjustments based on material variations. This proactive approach minimizes human error and ensures consistent output quality.

Temperature management is particularly critical, as nylon degrades above 100°C. Implementing cooling mechanisms, such as air or water jackets, keeps the shredding chamber below 80°C. Data from operational shredders indicate that maintaining this temperature range reduces impurity levels by 5-8%. Screen size selection also plays a role; smaller apertures (e.g., 10 mm) produce finer fragments but may increase energy use, while larger screens (20 mm) preserve fiber length. By balancing these parameters, recyclers can tailor the process to specific carpet types and market requirements, maximizing both purity and efficiency.

Relationship Between Blade Material and Fiber Purity

The choice of blade material directly impacts fiber purity by influencing wear rates and contamination risks. Hardened steel blades are common but may require frequent replacement, introducing iron particles into the nylon stream. In contrast, tungsten carbide blades offer exceptional durability, with lifespans up to three times longer. This reduces the frequency of blade changes and minimizes downtime. Tests have shown that tungsten carbide blades maintain cutting sharpness for over 1,000 hours of operation, compared to 300 hours for standard steel. This consistency ensures clean cuts and lower impurity levels.

Ceramic-coated blades are another option, providing resistance to abrasion and corrosion. However, they are more brittle and may not suit high-impact applications. For carpet recycling, tungsten carbide is preferred due to its balance of hardness and toughness. The use of these blades results in a 3-5% reduction in metallic contaminants in the output. Additionally, specialized coatings can reduce adhesion of sticky materials like latex, further enhancing purity. By selecting appropriate blade materials, recyclers can protect fiber quality and reduce overall operating costs.

Temperature Control Strategies

Effective temperature control in twin-shaft shredders prevents thermal degradation of nylon fibers. Strategies include integrated cooling systems, intermittent operation cycles, and material-specific feed rates. For example, water-cooled shafts dissipate heat generated during shredding, maintaining chamber temperatures below 80°C. Infrared sensors monitor hot spots and trigger adjustments to speed or torque if thresholds are exceeded. Data from recycling plants show that these measures can reduce heat-related impurities by up to 10%, preserving fiber strength and color.

Intermittent operation involves pausing the shredder briefly when temperatures rise, allowing components to cool naturally. This approach is useful for batch processing but may reduce throughput. Alternatively, continuous systems use air convection or liquid coolants to maintain stable temperatures. The cooling system in modern shredders is designed for efficiency, with minimal energy consumption. By implementing these strategies, recyclers can avoid nylon melting and ensure that output meets quality standards for high-value applications. This attention to thermal management is a hallmark of advanced carpet recycling operations.

Screen Size Selection Guidelines

Screen size in twin-shaft shredders determines the particle size of output fragments, which affects downstream separation and fiber quality. For nylon recovery, screens with apertures of 10-20 mm are typically recommended. Smaller screens (10 mm) produce fine fragments that are easier to purify but may shorten fiber length. Larger screens (20 mm) yield coarser output that preserves fiber integrity but requires more effort in subsequent sorting. Industry guidelines suggest a 15 mm screen as a balance, achieving fiber lengths of 20-35 mm with minimal contamination.

The choice of screen size also influences throughput and energy use. Finer screens increase resistance, raising power consumption by 10-15%. However, they improve the efficiency of air classifiers and magnetic separators by providing uniform input. In practice, recyclers often use interchangeable screens to adapt to different carpet types. For instance, dense commercial carpets may require a 12 mm screen, while residential ones work well with 18 mm. This flexibility allows operators to optimize for purity and yield based on real-time conditions, enhancing overall process economics.

Application of Sensors and Feedback Loops

Sensors and feedback loops in twin-shaft shredders enable real-time monitoring and adjustment of key parameters. Common sensors include infrared thermometers for temperature, load cells for torque, and optical devices for fragment size. These sensors feed data to a PLC, which automatically modifies operations to maintain optimal conditions. For example, if temperature sensors detect a rise above 85°C, the system may reduce speed or activate cooling. This automation improves consistency and reduces the need for manual intervention.

Feedback loops also enhance response to material variations. When processing carpets with high adhesive content, sensors can detect increased resistance and adjust torque accordingly. This prevents jams and ensures thorough fiber liberation. Data from automated systems show a 15% improvement in purity compared to manual controls. Additionally, predictive maintenance algorithms use sensor data to schedule blade replacements or lubrication, minimizing unplanned downtime. The integration of these technologies makes twin-shaft shredders highly adaptive and reliable for carpet recycling applications.

Post-Shredding Processing and Sorting Technology Integration

After shredding, integrating sorting technologies is crucial for further enhancing nylon fiber purity. Common methods include air classification, magnetic separation, and near-infrared (NIR) sorting. Air classifiers use airflow to separate lightweight nylon fibers from heavier backing materials, achieving purity gains of 5-10%. Magnetic separators remove ferrous contaminants introduced during shredding, such as metal fragments from wear parts. NIR sensors identify and eject non-nylon plastics based on their spectral signatures. Combining these technologies with twin-shaft shredders creates a seamless workflow that maximizes recovery rates and material quality.

Washing systems can also be incorporated to remove adhesives and dyes, but they require careful management of water and energy use. For instance, counter-current wash cycles reduce water consumption by 30% compared to traditional methods. However, the associated costs and environmental impacts must be weighed against purity benefits. Overall, a well-designed post-shredding line can elevate nylon purity to over 95%, meeting the demands of high-end markets. The air conveying system often transports shredded material to these sorting units, ensuring efficient handling and minimal contamination.

Principles and Integration of Sorting Technologies

Sorting technologies operate on principles like density differences, magnetic properties, and optical characteristics. Air classification relies on the fact that nylon fibers are lighter than polypropylene backing or fillers. By controlling airflow velocity, operators can achieve separation efficiencies of 85-90%. Magnetic separation targets ferrous materials using permanent or electromagnets, removing up to 99% of metal contaminants. NIR sorting exploits the unique reflectance of nylon in the infrared spectrum, allowing precise identification and ejection of impurities. These methods are most effective when integrated directly with the shredding output conveyor.

Integration involves aligning the throughput and particle size of the shredder with the capabilities of the sorting equipment. For example, uniform fragments from twin-shaft shredders improve the accuracy of NIR sorting by providing consistent material presentation. Pneumatic conveyors often link these stages, reducing manual handling and contamination risks. In one facility, this integration boosted nylon purity from 90% to 96% while increasing overall recovery by 10%. Such synergies highlight the importance of a holistic approach to carpet recycling system design.

Pros and Cons of Washing Systems

Washing systems remove residual adhesives and dyes from shredded nylon fibers, potentially increasing purity to 98%. However, they come with drawbacks, including high water usage, energy consumption, and wastewater treatment needs. A typical wash cycle may require 5-10 liters of water per kilogram of material, along with heating and detergent costs. Wastewater must be treated to remove chemicals and solids, adding to operational expenses. Despite these challenges, washing is sometimes necessary for applications demanding ultra-high purity, such as medical or food-contact materials.

Advances in washing technology, such as closed-loop systems and bio-based detergents, are mitigating these issues. Closed-loop systems recycle water, reducing consumption by up to 70%. Bio-detergents break down adhesives without harmful residues, simplifying wastewater treatment. However, the initial investment for such systems can be substantial, and they may not be cost-effective for all recyclers. Decisions on incorporating washing should consider market requirements and environmental regulations. In many cases, combining optimized shredding with dry sorting methods provides a more sustainable path to high purity.

Application of Online Detection Technologies

Online detection technologies, such as NIR sensors and X-ray fluorescence, enable real-time monitoring of nylon purity during processing. NIR sensors analyze the chemical composition of materials on conveyor belts, identifying non-nylon contaminants with an accuracy of 95-98%. This data can trigger air ejectors to remove impurities instantly, ensuring consistent output. X-ray fluorescence detects heavy metals or halogens that may be present in dyes or fillers. These systems are integrated with shredder controls to adjust parameters based on detected contamination levels.

The use of online detection reduces the need for manual sampling and laboratory analysis, speeding up quality assurance. For example, facilities report a 50% reduction in testing time after implementing NIR sensors. This real-time feedback also allows for immediate corrective actions, such as adjusting shredder speed or screen size. The control panel PLC HMI typically hosts the software for these systems, providing a user interface for operators. By leveraging online detection, recyclers can maintain high purity standards while optimizing throughput and reducing costs.

Identifying and Resolving Process Bottlenecks

Process bottlenecks in carpet recycling often occur at material handling points between shredding and sorting. Common issues include conveyor jams, uneven feed rates, and sensor misalignments. For instance, if the shredder output fluctuates in fragment size, it can overwhelm air classifiers, reducing their efficiency. Identifying these bottlenecks involves monitoring system performance metrics like throughput, purity, and energy use. Data loggers and PLCs provide insights into where delays or quality drops occur, enabling targeted improvements.

Solutions may include installing vibratory feeders to ensure consistent material flow or upgrading conveyor belts to handle larger volumes. In one case, a recycler resolved a bottleneck by adding a secondary screening unit before the sorting stage, which improved purity by 5%. Regular maintenance schedules for shredders and sorters also prevent unexpected downtime. By addressing bottlenecks proactively, facilities can achieve smoother operations and higher overall efficiency. This systematic approach is key to scaling up carpet recycling efforts and meeting growing market demands.

Economic Benefits and Sustainability Advantages

Adopting twin-shaft shredders in carpet recycling offers significant economic benefits, primarily through increased revenue from high-purity nylon fibers. With purity levels exceeding 90%, recycled nylon can sell for $2,500-$3,000 per ton, compared to $1,500-$2,000 for lower grades. This price premium translates to higher profit margins and shorter payback periods for equipment investments. Additionally, reduced waste disposal costs contribute to savings, as landfills often charge $50-$100 per ton for carpet waste. The efficiency of twin-shaft shredders also lowers energy and maintenance expenses, enhancing overall operational economics.

Sustainability advantages align with global environmental goals, such as reducing carbon emissions and conserving resources. Recycling one ton of carpet with twin-shaft technology saves approximately 1.8 tons of CO2 equivalent compared to incineration. This reduction supports corporate ESG (Environmental, Social, and Governance) reporting and helps companies meet regulatory targets. Furthermore, the circular use of nylon fibers decreases reliance on petroleum-based virgin materials, promoting resource efficiency. These benefits make twin-shaft shredders a compelling choice for recyclers aiming to balance economic and environmental objectives.

Profit Margin Calculation Models

Profit margin models for carpet recycling factor in variables like nylon purity, market prices, and operational costs. A basic calculation involves subtracting processing expenses (e.g., shredding, sorting, labor) from the revenue generated by recycled materials. For example, at 90% purity, revenue might be $2,700 per ton, with costs of $1,200 per ton, yielding a profit of $1,500. If purity drops to 80%, revenue falls to $2,000, reducing profit to $800. These models highlight the importance of maintaining high purity through advanced shredding technology.

Sensitivity analyses can assess how changes in parameters like energy costs or fiber length affect margins. For instance, a 10% increase in electricity rates may reduce profit by $50 per ton, but this can be offset by optimizing shredder settings to lower energy use. Software tools often automate these calculations, allowing recyclers to simulate different scenarios and make informed decisions. By using such models, businesses can identify opportunities to improve profitability and justify investments in twin-shaft shredders based on concrete financial data.

Compliance Cost Savings Examples

Compliance with environmental regulations, such as landfill bans or extended producer responsibility schemes, can incur significant costs if not managed properly. For example, landfilling carpet waste may attract taxes of $50-$150 per ton in regions with strict waste policies. By recycling with twin-shaft shredders, companies avoid these costs and may qualify for subsidies or tax incentives. In the EU, recycling facilities can receive grants covering up to 30% of equipment costs under circular economy programs. These financial incentives improve the return on investment for shredder technology.

Case studies from North America show that recyclers save an average of $100,000 annually in compliance costs by diverting carpet from landfills. Additionally, adherence to standards like ISO 14001 for environmental management can reduce insurance premiums and enhance market access. The use of twin-shaft shredders ensures consistent output that meets regulatory purity requirements, minimizing the risk of penalties. These savings, combined with revenue from recycled materials, create a strong business case for adopting this technology in carpet recycling operations.

Lifecycle Cost Analysis

Lifecycle cost analysis (LCA) compares the total expenses of owning and operating twin-shaft shredders versus alternatives over their useful life. For twin-shaft models, initial purchase prices range from $100,000 to $500,000, depending on size and features. Operating costs include energy, maintenance, and blade replacements, which are typically 20-30% lower than for single-shaft shredders due to higher efficiency. Over a 10-year lifespan, twin-shaft systems often show a 25-40% lower total cost of ownership, factoring in higher purity yields and reduced downtime.

LCA also considers environmental impacts, such as carbon emissions from manufacturing and operation. Twin-shaft shredders have a lower carbon footprint due to energy savings and longer component lifespans. For instance, the use of tungsten carbide cutters reduces waste from frequent replacements. By evaluating both economic and environmental aspects, recyclers can make sustainable choices that align with long-term goals. This comprehensive approach demonstrates the value of twin-shaft technology in carpet recycling.

Highlights in ESG Reporting

Incorporating twin-shaft shredder technology into ESG reports highlights a company's commitment to sustainability. Key metrics include reductions in waste sent to landfills, carbon emissions, and water usage. For example, recycling carpets with this technology can divert 95% of material from landfills, significantly lowering environmental impact. ESG frameworks like GRI (Global Reporting Initiative) require detailed disclosures on resource efficiency and circular economy contributions. Using twin-shaft shredders helps companies achieve positive ratings in these areas, attracting investors and customers who prioritize sustainability.

Social aspects, such as job creation in recycling facilities, can also be emphasized. Economic benefits from higher purity nylon sales support local economies and promote green employment. Governance factors include adherence to international standards and transparent reporting. By showcasing these achievements, companies enhance their reputation and competitive advantage. The integration of shredder performance data into ESG reports provides credible evidence of progress toward sustainability targets, reinforcing the business case for advanced recycling technologies.

Implementation Guidelines and Future Innovation Directions

Implementing twin-shaft shredders in carpet recycling requires careful planning, from equipment selection to staff training. Initial steps include assessing carpet volumes, space requirements, and utility connections. Choosing the right shredder model depends on factors like throughput needs and material characteristics. For instance, high-density carpets may require a shredder with extra torque capacity. Training programs ensure operators understand parameter adjustments and maintenance procedures. A phased implementation approach minimizes disruption and allows for testing and optimization before full-scale operation.

Future innovations in shredder technology focus on smart features and material adaptability. IoT (Internet of Things) integration enables predictive maintenance by monitoring wear and performance in real time. AI algorithms could optimize shredder settings based on historical data, further improving purity and efficiency. As carpet materials evolve, with trends toward biodegradable or blended fibers, shredders must adapt to handle new challenges. Research collaborations between industry and academia are driving these advancements, ensuring that recycling technology keeps pace with market demands. The solid waste double shaft shredder platform is likely to incorporate such innovations, enhancing its role in circular economy initiatives.

Project Launch Checklist

A project launch checklist for twin-shaft shredder installation includes tasks like site preparation, utility setup, and safety audits. Site preparation involves ensuring adequate space for the shredder and ancillary equipment, such as conveyors and sorters. Utility connections must meet power and water requirements, with backup systems for critical operations. Safety audits verify that emergency stops, guards, and ventilation are in place. Training sessions cover operational protocols, troubleshooting, and preventive maintenance. This comprehensive planning reduces risks and ensures a smooth startup.

Additional checklist items include obtaining permits, sourcing raw materials, and establishing quality control procedures. Permits may be needed for noise, emissions, or waste handling, depending on local regulations. Sourcing carpets from reliable suppliers ensures consistent feed material for testing. Quality control involves setting up sampling and analysis routines to monitor output purity. By following a structured checklist, projects can avoid common pitfalls and achieve operational readiness faster. This methodical approach is essential for successful integration of shredding technology into recycling workflows.

Fault Diagnosis Flowchart

A fault diagnosis flowchart helps operators quickly identify and resolve issues with twin-shaft shredders, such as purity drops or mechanical failures. The flowchart starts with symptoms, like increased contamination or unusual noises, and guides users through checks on parameters, blades, and sensors. For example, if purity decreases, the flowchart may recommend inspecting blade wear or screen blockage. This systematic approach reduces downtime by enabling prompt corrections without relying on external technicians.

Common faults include jammed materials due to overfeeding or worn blades causing uneven cutting. The flowchart provides steps to clear jams safely or replace blades as needed. Sensor calibrations should be verified regularly to ensure accurate monitoring. In one facility, using a diagnosis flowchart cut average repair times by 30%. By empowering operators with these tools, recyclers maintain high efficiency and consistency in nylon fiber production. This proactive maintenance culture supports long-term equipment reliability and performance.

IoT Sensors and Data Platforms

IoT sensors in twin-shaft shredders collect data on parameters like temperature, vibration, and output quality. These sensors connect to cloud-based platforms that analyze trends and generate alerts for maintenance or optimization. For instance, vibration sensors can detect imbalances in rotors before they cause damage, allowing scheduled repairs. Data platforms use machine learning to predict blade wear or purity variations based on historical patterns. This predictive capability reduces unplanned downtime and improves resource allocation.

Data platforms also facilitate remote monitoring and control, enabling managers to oversee multiple shredders from a central location. This is particularly useful for large-scale operations with distributed facilities. The integration of IoT with control panel PLC HMI systems provides a seamless user experience. In practice, facilities using IoT report a 20% increase in operational efficiency and a 15% reduction in maintenance costs. These technologies represent the future of smart recycling, where data-driven decisions enhance both economic and environmental outcomes.

Innovative Blade Design Prospects

Future blade designs for twin-shaft shredders may incorporate adaptive geometries or smart materials that respond to changing conditions. For example, blades with shape-memory alloys could adjust their angle based on material hardness, optimizing cutting efficiency. Another prospect is the use of nanocomposite coatings that self-heal minor abrasions, extending blade life. Research institutions are testing these concepts in laboratory settings, with promising results for reducing contamination and energy use.

AI-driven control systems could dynamically optimize blade interactions in real time, further improving purity. These innovations aim to handle diverse carpet materials, including those with recycled content or new polymers. As the recycling industry evolves, blade design will play a critical role in meeting purity and efficiency targets. Collaborations between manufacturers and recyclers are essential to bring these advancements to market, ensuring that shredder technology continues to advance carpet recycling capabilities.