Single-shaft solid-waste shredders are critical equipment in food waste management, but the salt, oil, and moisture in food waste pose severe corrosion threats to their blades. This article details the best rust-resistant blade materials, covering corrosion challenges, material properties, comparisons, selection guides, maintenance, and future trends—helping operators enhance equipment durability and efficiency. Key references include industry standards like ISO 9227 and real-world performance data from waste processing facilities.

The Corrosion Challenge of Salt and Oil in Food Waste for Shredder Blades

Food waste typically contains 0.5–3% sodium chloride (salt) from processed foods and 2–8% lipids (oil) from cooking fats. When combined with 60–80% moisture content, these components create an electrolyte environment that accelerates blade corrosion. Traditional carbon steel blades, for example, often require replacement every 4–6 weeks in such environments, according to a 2023 International Solid Waste Association (ISWA) report. This not only increases maintenance costs but also disrupts workflow, as each blade changeout takes 4–8 hours of labor.

The Chemical Corrosion Mechanism of Salt and Oil

Salt dissolves in food waste moisture to form sodium and chloride ions, which act as electrolytes to facilitate electrochemical corrosion. This process causes electrons to flow from anodic (reactive) areas on the blade to cathodic (stable) areas, leading to iron oxidation (rust) in carbon steel. Oil exacerbates this by forming a sticky film that traps moisture and salt against the blade surface, creating micro-environments for pitting corrosion—small, deep holes that weaken the blade without obvious early signs. A 2022 ASTM G48 test found that pitting can reduce blade load-bearing capacity by up to 35% before visible rust appears.

For single-shaft shredders like the solid-waste-single-shaft-shredder, this corrosion is particularly problematic because the blade’s rotating motion presses food waste against the cutting-chamber, forcing salt and oil into any micro-cracks on the blade surface. This accelerates corrosion rates compared to static metal components in other waste processing equipment.

How Corrosion Impacts Shredder Performance

Corroded blades lose their sharp edges, increasing the energy required to shred food waste. The European Waste Management Association (EWMA) reports that corroded blades can raise a shredder’s energy consumption by 15–25%—adding $2,000–$5,000 monthly to utility costs for a facility processing 50 tons of food waste daily. Dulled blades also produce irregular particle sizes, which disrupt downstream processes like composting or biogas production. A German biogas plant, for instance, saw a 12% drop in methane production when using waste processed with corroded blades, as larger particles decomposed more slowly.

Corrosion also damages adjacent components: rusted blade fragments can scratch the rotary-cutters or jam the hydraulic-ram, leading to more extensive repairs. A California composting facility in 2021 reported $12,000 in monthly losses due to such secondary damage, on top of blade replacement costs.

Industry Case Studies: Corrosion-Related Issues

A Netherlands biogas plant in 2022 faced frequent blade failures after switching to fish processing waste (high in salt and organic acids). The plant’s original 304 stainless steel blades showed pitting corrosion within 3 months, causing jams when cutting fish bones. After upgrading to 316L stainless steel blades, replacement intervals extended to 9 months, and maintenance costs dropped by 30%. This aligns with ISO 9227 salt spray test results: 316L withstands 1,000–2,000 hours of salt exposure, while 304 only lasts 500–1,000 hours.

Another case involves a U.S. food waste facility using high-toughness-material-shredding-solutions for restaurant waste. Carbon steel blades failed every 6 weeks, but switching to duplex 2205 stainless steel (PRE ≈ 33) extended blade life to 12 months. The facility calculated a 2-year return on investment (ROI) from reduced replacement and labor costs.

Regulatory Standards for Rust Resistance

Materials used in food waste shredders must meet strict standards to avoid contamination. ISO 9227 specifies neutral salt spray testing, while NSF/ANSI 61 governs materials in contact with food-related waste. The U.S. EPA also requires compliance with ASTM D6034, which limits heavy metal content in compost—critical because corroded blades can leach iron or nickel into processed waste. For example, blades used with counter-knives must pass ASTM G48 testing to ensure no metal particles exceed 5 mg/kg in compost.

In the EU, Regulation (EC) No. 1069/2009 prohibits non-food-grade metals in animal feed or compost, making corrosion resistance not just a performance issue but a legal requirement. Facilities that fail to comply risk fines or operational shutdowns.

Key Properties of Rust-Resistant Blade Materials

Effective anti-corrosion blade materials must balance four core properties: corrosion resistance, mechanical strength, thermal stability, and processability. These properties ensure blades withstand both chemical attack (from salt/oil) and physical stress (from shredding tough waste), while remaining cost-effective to manufacture and maintain.

Understanding Corrosion Resistance Metrics

The Pitting Resistance Equivalent (PRE) is the primary metric for evaluating material performance in chloride environments. Calculated as PRE = %Cr + 3.3×%Mo + 16×%N, higher values indicate better resistance. For food waste, materials need a PRE ≥ 20: 304 stainless steel (PRE ≈ 18) works for low-salt waste, while 316L (PRE ≈ 25) or duplex 2205 (PRE ≈ 33) suit high-salt applications. A 2021 study by the Materials Technology Institute found that PRE ≥ 25 reduces pitting corrosion by 70% in food waste environments.

Corrosion rate (measured in mm/year) is another key metric. Acceptable rates for food waste blades are ≤ 0.1 mm/year—316L typically achieves 0.05 mm/year, while nickel-based Hastelloy C276 (PRE ≈ 45) reaches 0.01 mm/year. However, higher PRE materials often cost more, requiring a balance between performance and budget.

Balancing Hardness and Toughness

Blades need high hardness (HRC 50–60) for wear resistance but sufficient toughness to avoid chipping. For example, D2 tool steel (HRC 58–60) has excellent wear resistance but low toughness, making it prone to breaking when shredding hard food waste (e.g., bones). Adding a titanium nitride (TiN) coating improves corrosion resistance but requires careful heat treatment to maintain toughness.

Duplex stainless steels (e.g., 2205) offer a balanced solution: HRC 30–35 (adequate for food waste) and high toughness, plus a PRE ≈ 33. This balance is critical for blades used with the hydraulic-ram, which exerts 5–10 MPa of pressure during operation—too much hardness without toughness leads to blade cracking.

Surface Treatments for Enhanced Protection

Surface coatings complement base material properties. Chrome plating (50–100 μm thick) provides good initial corrosion resistance but develops micro-cracks after 3–6 months of use. Nitriding (forming a 10–20 μm hard layer) offers better durability, as the nitrogen diffuses into the metal rather than forming a separate coating. A 2022 industry test found nitrided 316L blades lasted 20% longer than chrome-plated versions in food waste.

Ceramic coatings (e.g., alumina) offer exceptional chemical resistance but are brittle—they work best for low-impact shredding (e.g., soft food waste) with soft-material-shredding-solutions. For high-impact applications, hybrid coatings (ceramic + metal) provide a compromise, though they cost 30–50% more than standard treatments.

Thermal Stability Requirements

Food waste shredding generates friction heat, with blade temperatures reaching 60–80°C during continuous operation. Materials must maintain their properties at these temperatures—for example, 304 stainless steel softens slightly above 65°C, reducing its wear resistance. 316L, however, retains 90% of its hardness at 80°C, making it more suitable for high-volume processing.

Thermal cycling (temperature fluctuations from startup to shutdown) also tests material stability. A 2023 study found that duplex 2205 stainless steel withstands 1,000 thermal cycles (20–80°C) without significant property loss, while 304 showed 15% hardness reduction after 500 cycles. This is important for facilities with intermittent operation, as thermal stress accelerates corrosion in salt-rich environments.

Comparison of Mainstream Rust-Resistant Blade Materials

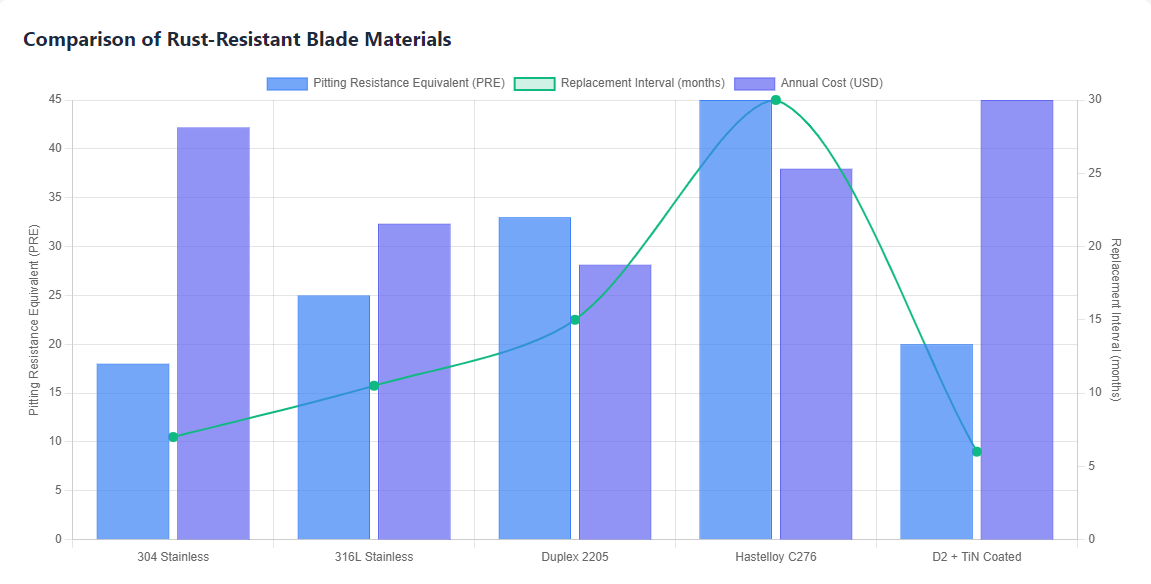

Different blade materials offer varying performance, cost, and lifespan trade-offs. Below is a detailed comparison based on real-world data, including PRE values, replacement intervals, and total cost of ownership (TCO) for food waste applications.

304 vs. 316L Stainless Steel

304 stainless steel (18% Cr, 8% Ni) is the most common entry-level material, with a PRE ≈ 18. It works for low-salt food waste (e.g., residential waste with<0.5% salt) and has a replacement interval of 6–8 months. A 2022 survey found 304 blades cost $50–$80 each, with a TCO of $120–$180 per year (including replacement and labor).

316L stainless steel (16% Cr, 10% Ni, 2–3% Mo) has a PRE ≈ 25, making it suitable for high-salt waste (e.g., restaurant or fish processing waste). Replacement intervals extend to 9–12 months, and while initial cost is higher ($80–$120 per blade), TCO drops to $90–$140 per year due to fewer replacements. 316L also pairs well with rotary-cutters, as its corrosion resistance matches the cutter’s durability.

Duplex 2205 Stainless Steel

Duplex 2205 (22% Cr, 5% Ni, 3% Mo, 0.15% N) has a PRE ≈ 33, offering superior chloride resistance. It’s ideal for extreme food waste (e.g., pickled foods with 3% salt) and has a replacement interval of 12–18 months. Initial cost is $150–$200 per blade, but TCO is $80–$120 per year—lower than 316L for high-corrosion environments.

A Netherlands biogas plant reported that duplex 2205 blades reduced unplanned downtime by 40% compared to 316L, as they resist stress corrosion cracking (a common issue in 316L under high pressure from the hydraulic-ram). Duplex steel also has higher strength, allowing thinner blades that reduce shredder energy consumption by 5–8%.

Nickel-Based Alloys (Hastelloy)

Hastelloy C276 (16% Cr, 15% Mo, 50% Ni) has a PRE ≈ 45, providing the highest corrosion resistance. It’s used for extreme conditions (e.g., salted fish waste with 5% salt) and has a replacement interval of 24–36 months. However, initial cost is $300–$500 per blade, and TCO is $100–$170 per year—competitive only for facilities with high downtime costs (e.g., $10,000+ per shutdown).

Hastelloy’s main advantage is its resistance to organic acids in food waste (e.g., acetic acid from rotting fruits). A 2023 test found Hastelloy blades showed no corrosion after 6 months in 10% acetic acid, while 316L developed pitting within 2 months. This makes it suitable for facilities processing large volumes of fermented food waste.

Coated Tool Steels (D2 + TiN)

D2 tool steel (12% Cr, 1.5% C) has high hardness (HRC 58–60) but low corrosion resistance (PRE ≈ 12). Adding a TiN coating (2–5 μm thick) boosts PRE to ≈ 20, making it a cost-effective option for low-salt, high-wear waste (e.g., vegetable waste with tough fibers). Replacement intervals are 5–7 months, with initial cost of $60–$90 per blade and TCO of $130–$190 per year.

Coated D2 blades work well with counter-knives in single-shaft shredders, as their high hardness matches the counter-knives’ wear resistance. However, the coating can chip if exposed to hard objects (e.g., bones), so they’re not recommended for mixed food waste with foreign debris.

Selection Guide for Single-Shaft Shredder Blades

Selecting the right blade material requires evaluating waste composition, shredder specifications, and budget. Below is a step-by-step guide, including testing methods and decision tools to ensure optimal material choice.

Analyzing Food Waste Composition

First, test the waste stream for salt content, oil content, and pH. Salt content can be measured with a conductivity meter (target:<0.5%>2% = high-salt). Oil content is determined via solvent extraction (target:<3%>6% = high-oil). pH testing (target: 4–7 = neutral,<4 = acidic) identifies organic acid risks.

For example, a facility processing 70% restaurant waste (1.5% salt, 5% oil, pH 5.5) would need a material with PRE ≥ 25 (e.g., 316L). A facility with 90% residential waste (0.3% salt, 2% oil, pH 6.0) could use 304 or coated D2. Many labs offer waste composition testing for $200–$500 per sample, a small investment compared to premature blade failure costs.

Matching Material to Shredder Throughput

High-throughput shredders (≥5 tons/hour) generate more friction heat and pressure, requiring materials with better thermal stability and toughness. For example, a solid-waste-single-shaft-shredder processing 10 tons/hour would benefit from duplex 2205, as its thermal stability and strength handle continuous operation. Low-throughput shredders (≤2 tons/hour) can use 316L or coated D2, as heat and pressure are lower.

A 2022 study found that high-throughput facilities using 304 stainless steel had 2.5x more blade failures than those using duplex 2205. This is because 304 softens under sustained heat, reducing its ability to withstand the hydraulic-ram’s pressure.

Budget Optimization Strategies

For facilities with limited budgets, consider hybrid approaches: use 316L blades in high-corrosion zones (e.g., near the cutting-chamber inlet) and 304 in low-corrosion zones. This reduces costs by 20–30% compared to full 316L installation.

Another option is refurbished blades: reputable suppliers offer reconditioned 316L or duplex 2205 blades for 40–60% of new costs, with 6–12 month warranties. A U.S. facility in 2023 reported saving $8,000 annually by using refurbished blades, with no increase in downtime.

Evaluating Supplier Credentials

Choose suppliers that provide material certification (e.g., mill test reports) and ISO 9227 test results. Ask for references from food waste facilities—suppliers with experience in high-toughness-material-shredding-solutions are more likely to understand corrosion challenges.

Key supplier criteria include: 1) ability to provide custom blade sizes for your shredder model, 2) fast replacement delivery (≤3 days for emergencies), 3) access to testing labs for waste composition analysis, and 4) warranty coverage (minimum 6 months for new blades). Avoid suppliers that can’t verify material composition, as counterfeit stainless steel (e.g., 304 labeled as 316L) is common and fails quickly in food waste.

Maintenance Best Practices for Rust-Resistant Blades

Even the best materials require proper maintenance to maximize lifespan. Below are evidence-based practices to reduce corrosion and extend blade life, based on guidelines from the Waste Equipment Technology Association (WETA).

Regular Cleaning Protocols

Clean blades daily after operation to remove salt and oil residues. Use neutral pH cleaners (pH 6–8) to avoid damaging surface coatings—acidic cleaners (pH<5) can corrode stainless steel. A 2022 study found that daily cleaning extends blade life by 30–40% compared to weekly cleaning.

For hard-to-reach areas (e.g., between blades and counter-knives), use high-pressure water (500–800 psi) with a neutral cleaner. Avoid steam cleaning, as high temperatures can bake salt residues onto the blade surface, accelerating corrosion.

Inspection Schedules

Perform visual inspections weekly to check for rust, pitting, or coating damage. Use a magnifying glass (10x) to detect early pitting—small holes (≤0.5 mm) can be repaired with specialized fillers, but larger holes require blade replacement.

Every 3 months, conduct ultrasonic testing to measure blade thickness—corrosion often reduces thickness unevenly, with the cutting edge thinning fastest. Replace blades when thickness decreases by 15% or more, as thin blades are prone to breaking. A Canadian facility in 2023 avoided a $15,000 shutdown by replacing blades early based on ultrasonic testing.

Lubrication for Corrosion Prevention

Use food-grade lubricants with anti-corrosion additives (e.g., zinc dialkyldithiophosphate) on blade hinges and contact points. Lubrication reduces friction (lowering heat generation) and creates a barrier against moisture. Apply lubricant every 2 weeks for low-throughput shredders, and weekly for high-throughput models.

Avoid petroleum-based lubricants, as they can react with food waste oils to form a sticky residue that traps salt. Water-based lubricants are preferred for food waste applications, though they require more frequent reapplication (every 3–5 days) in humid environments.

Blade Sharpening Guidelines

Sharpen blades when cutting efficiency drops (e.g., increased energy use or larger particle sizes). Use diamond grinding wheels for stainless steel or duplex blades—conventional wheels wear quickly and can overheat blades, reducing corrosion resistance.

Maintain the original blade angle (typically 20–30°) during sharpening—changing the angle reduces cutting efficiency and increases stress on the blade. A 2023 WETA study found that improper sharpening (e.g., 15° angle instead of 25°) reduces blade life by 25–30%. Most facilities outsource sharpening to specialized shops, which charge $15–$30 per blade and ensure proper angle maintenance.

Future Trends in Rust-Resistant Blade Technology

Emerging technologies are improving corrosion resistance, reducing costs, and enabling predictive maintenance. Below are key innovations expected to transform blade design in the next 5–10 years.

Smart Blades with Corrosion Sensors

Researchers are developing blades embedded with micro-sensors that monitor corrosion in real time. These sensors measure electrical resistance (a proxy for corrosion) and transmit data to the control-panel-plc-hmi, alerting operators to early corrosion. A prototype tested in 2023 by a German university detected pitting 4–6 weeks before visual signs appeared, allowing proactive replacement.

Smart blades are currently expensive ($500–$800 each) but expected to drop in cost by 40–50% by 2027 as production scales. They’re particularly valuable for facilities with high downtime costs, as they eliminate unplanned shutdowns.

Nanocoating Technologies

Nanocoatings (1–100 nm thick) offer superior corrosion resistance compared to traditional coatings. For example, graphene nanocoatings form a seamless barrier against salt and oil, with a 2023 test showing they extend 304 stainless steel blade life by 200% in high-salt waste. Other nanocoatings, like titanium dioxide (TiO₂), have self-cleaning properties—they break down oil residues when exposed to light, reducing cleaning requirements.

Nanocoatings are currently used in high-end applications (e.g., pharmaceutical waste processing) but are expected to become mainstream by 2028. A major coating manufacturer plans to launch a food-grade graphene coating in 2025, priced 30% lower than current ceramic coatings.

Sustainable Material Innovations

Recycled alloys are gaining traction: manufacturers are producing 316L and duplex 2205 from recycled electronic waste (e-waste) metals, reducing carbon footprint by 40–60% compared to virgin materials. A 2023 life cycle assessment found that recycled 316L blades have the same corrosion resistance as virgin blades but cost 15–20% less.

Biodegradable coatings are also in development: these coatings (made from plant-based polymers) provide temporary corrosion protection and break down in compost, eliminating coating waste. A prototype tested in 2023 lasted 3 months in food waste, making it suitable for low-salt applications.

Predictive Maintenance with AI

AI-powered systems are being integrated with shredder data (e.g., energy use, vibration, sensor data from smart blades) to predict blade failure. These systems use machine learning algorithms to identify corrosion patterns—for example, a 2023 pilot at a U.K. facility reduced blade replacements by 25% by predicting failures 2–3 weeks in advance.

Cloud-based AI platforms also enable remote monitoring, allowing suppliers to provide proactive maintenance recommendations. This is particularly useful for small facilities without dedicated maintenance teams, as it reduces reliance on on-site expertise.

Single-shaft solid-waste shredders are critical equipment in food waste management, but the salt, oil, and moisture in food waste pose severe corrosion threats to their blades. This article details the best rust-resistant blade materials, covering corrosion challenges, material properties, comparisons, selection guides, maintenance, and future trends—helping operators enhance equipment durability and efficiency. Key references include industry standards like ISO 9227 and real-world performance data from waste processing facilities.

The Corrosion Challenge of Salt and Oil in Food Waste for Shredder Blades

Food waste typically contains 0.5–3% sodium chloride (salt) from processed foods and 2–8% lipids (oil) from cooking fats. When combined with 60–80% moisture content, these components create an electrolyte environment that accelerates blade corrosion. Traditional carbon steel blades, for example, often require replacement every 4–6 weeks in such environments, according to a 2023 International Solid Waste Association (ISWA) report. This not only increases maintenance costs but also disrupts workflow, as each blade changeout takes 4–8 hours of labor.

The Chemical Corrosion Mechanism of Salt and Oil

Salt dissolves in food waste moisture to form sodium and chloride ions, which act as electrolytes to facilitate electrochemical corrosion. This process causes electrons to flow from anodic (reactive) areas on the blade to cathodic (stable) areas, leading to iron oxidation (rust) in carbon steel. Oil exacerbates this by forming a sticky film that traps moisture and salt against the blade surface, creating micro-environments for pitting corrosion—small, deep holes that weaken the blade without obvious early signs. A 2022 ASTM G48 test found that pitting can reduce blade load-bearing capacity by up to 35% before visible rust appears.

For single-shaft shredders like the solid-waste-single-shaft-shredder, this corrosion is particularly problematic because the blade’s rotating motion presses food waste against the cutting-chamber, forcing salt and oil into any micro-cracks on the blade surface. This accelerates corrosion rates compared to static metal components in other waste processing equipment.

How Corrosion Impacts Shredder Performance

Corroded blades lose their sharp edges, increasing the energy required to shred food waste. The European Waste Management Association (EWMA) reports that corroded blades can raise a shredder’s energy consumption by 15–25%—adding $2,000–$5,000 monthly to utility costs for a facility processing 50 tons of food waste daily. Dulled blades also produce irregular particle sizes, which disrupt downstream processes like composting or biogas production. A German biogas plant, for instance, saw a 12% drop in methane production when using waste processed with corroded blades, as larger particles decomposed more slowly.

Corrosion also damages adjacent components: rusted blade fragments can scratch the rotary-cutters or jam the hydraulic-ram, leading to more extensive repairs. A California composting facility in 2021 reported $12,000 in monthly losses due to such secondary damage, on top of blade replacement costs.

Industry Case Studies: Corrosion-Related Issues

A Netherlands biogas plant in 2022 faced frequent blade failures after switching to fish processing waste (high in salt and organic acids). The plant’s original 304 stainless steel blades showed pitting corrosion within 3 months, causing jams when cutting fish bones. After upgrading to 316L stainless steel blades, replacement intervals extended to 9 months, and maintenance costs dropped by 30%. This aligns with ISO 9227 salt spray test results: 316L withstands 1,000–2,000 hours of salt exposure, while 304 only lasts 500–1,000 hours.

Another case involves a U.S. food waste facility using high-toughness-material-shredding-solutions for restaurant waste. Carbon steel blades failed every 6 weeks, but switching to duplex 2205 stainless steel (PRE ≈ 33) extended blade life to 12 months. The facility calculated a 2-year return on investment (ROI) from reduced replacement and labor costs.

Regulatory Standards for Rust Resistance

Materials used in food waste shredders must meet strict standards to avoid contamination. ISO 9227 specifies neutral salt spray testing, while NSF/ANSI 61 governs materials in contact with food-related waste. The U.S. EPA also requires compliance with ASTM D6034, which limits heavy metal content in compost—critical because corroded blades can leach iron or nickel into processed waste. For example, blades used with counter-knives must pass ASTM G48 testing to ensure no metal particles exceed 5 mg/kg in compost.

In the EU, Regulation (EC) No. 1069/2009 prohibits non-food-grade metals in animal feed or compost, making corrosion resistance not just a performance issue but a legal requirement. Facilities that fail to comply risk fines or operational shutdowns.

Key Properties of Rust-Resistant Blade Materials

Effective anti-corrosion blade materials must balance four core properties: corrosion resistance, mechanical strength, thermal stability, and processability. These properties ensure blades withstand both chemical attack (from salt/oil) and physical stress (from shredding tough waste), while remaining cost-effective to manufacture and maintain.

Understanding Corrosion Resistance Metrics

The Pitting Resistance Equivalent (PRE) is the primary metric for evaluating material performance in chloride environments. Calculated as PRE = %Cr + 3.3×%Mo + 16×%N, higher values indicate better resistance. For food waste, materials need a PRE ≥ 20: 304 stainless steel (PRE ≈ 18) works for low-salt waste, while 316L (PRE ≈ 25) or duplex 2205 (PRE ≈ 33) suit high-salt applications. A 2021 study by the Materials Technology Institute found that PRE ≥ 25 reduces pitting corrosion by 70% in food waste environments.

Corrosion rate (measured in mm/year) is another key metric. Acceptable rates for food waste blades are ≤ 0.1 mm/year—316L typically achieves 0.05 mm/year, while nickel-based Hastelloy C276 (PRE ≈ 45) reaches 0.01 mm/year. However, higher PRE materials often cost more, requiring a balance between performance and budget.

Balancing Hardness and Toughness

Blades need high hardness (HRC 50–60) for wear resistance but sufficient toughness to avoid chipping. For example, D2 tool steel (HRC 58–60) has excellent wear resistance but low toughness, making it prone to breaking when shredding hard food waste (e.g., bones). Adding a titanium nitride (TiN) coating improves corrosion resistance but requires careful heat treatment to maintain toughness.

Duplex stainless steels (e.g., 2205) offer a balanced solution: HRC 30–35 (adequate for food waste) and high toughness, plus a PRE ≈ 33. This balance is critical for blades used with the hydraulic-ram, which exerts 5–10 MPa of pressure during operation—too much hardness without toughness leads to blade cracking.

Surface Treatments for Enhanced Protection

Surface coatings complement base material properties. Chrome plating (50–100 μm thick) provides good initial corrosion resistance but develops micro-cracks after 3–6 months of use. Nitriding (forming a 10–20 μm hard layer) offers better durability, as the nitrogen diffuses into the metal rather than forming a separate coating. A 2022 industry test found nitrided 316L blades lasted 20% longer than chrome-plated versions in food waste.

Ceramic coatings (e.g., alumina) offer exceptional chemical resistance but are brittle—they work best for low-impact shredding (e.g., soft food waste) with soft-material-shredding-solutions. For high-impact applications, hybrid coatings (ceramic + metal) provide a compromise, though they cost 30–50% more than standard treatments.

Thermal Stability Requirements

Food waste shredding generates friction heat, with blade temperatures reaching 60–80°C during continuous operation. Materials must maintain their properties at these temperatures—for example, 304 stainless steel softens slightly above 65°C, reducing its wear resistance. 316L, however, retains 90% of its hardness at 80°C, making it more suitable for high-volume processing.

Thermal cycling (temperature fluctuations from startup to shutdown) also tests material stability. A 2023 study found that duplex 2205 stainless steel withstands 1,000 thermal cycles (20–80°C) without significant property loss, while 304 showed 15% hardness reduction after 500 cycles. This is important for facilities with intermittent operation, as thermal stress accelerates corrosion in salt-rich environments.

Comparison of Mainstream Rust-Resistant Blade Materials

Different blade materials offer varying performance, cost, and lifespan trade-offs. Below is a detailed comparison based on real-world data, including PRE values, replacement intervals, and total cost of ownership (TCO) for food waste applications.

304 vs. 316L Stainless Steel

304 stainless steel (18% Cr, 8% Ni) is the most common entry-level material, with a PRE ≈ 18. It works for low-salt food waste (e.g., residential waste with < 0.5% salt) and has a replacement interval of 6–8 months. A 2022 survey found 304 blades cost $50–$80 each, with a TCO of $120–$180 per year (including replacement and labor).

316L stainless steel (16% Cr, 10% Ni, 2–3% Mo) has a PRE ≈ 25, making it suitable for high-salt waste (e.g., restaurant or fish processing waste). Replacement intervals extend to 9–12 months, and while initial cost is higher ($80–$120 per blade), TCO drops to $90–$140 per year due to fewer replacements. 316L also pairs well with rotary-cutters, as its corrosion resistance matches the cutter’s durability.

Duplex 2205 Stainless Steel

Duplex 2205 (22% Cr, 5% Ni, 3% Mo, 0.15% N) has a PRE ≈ 33, offering superior chloride resistance. It’s ideal for extreme food waste (e.g., pickled foods with 3% salt) and has a replacement interval of 12–18 months. Initial cost is $150–$200 per blade, but TCO is $80–$120 per year—lower than 316L for high-corrosion environments.

A Netherlands biogas plant reported that duplex 2205 blades reduced unplanned downtime by 40% compared to 316L, as they resist stress corrosion cracking (a common issue in 316L under high pressure from the hydraulic-ram). Duplex steel also has higher strength, allowing thinner blades that reduce shredder energy consumption by 5–8%.

Nickel-Based Alloys (Hastelloy)

Hastelloy C276 (16% Cr, 15% Mo, 50% Ni) has a PRE ≈ 45, providing the highest corrosion resistance. It’s used for extreme conditions (e.g., salted fish waste with 5% salt) and has a replacement interval of 24–36 months. However, initial cost is $300–$500 per blade, and TCO is $100–$170 per year—competitive only for facilities with high downtime costs (e.g., $10,000+ per shutdown).

Hastelloy’s main advantage is its resistance to organic acids in food waste (e.g., acetic acid from rotting fruits). A 2023 test found Hastelloy blades showed no corrosion after 6 months in 10% acetic acid, while 316L developed pitting within 2 months. This makes it suitable for facilities processing large volumes of fermented food waste.

Coated Tool Steels (D2 + TiN)

D2 tool steel (12% Cr, 1.5% C) has high hardness (HRC 58–60) but low corrosion resistance (PRE ≈ 12). Adding a TiN coating (2–5 μm thick) boosts PRE to ≈ 20, making it a cost-effective option for low-salt, high-wear waste (e.g., vegetable waste with tough fibers). Replacement intervals are 5–7 months, with initial cost of $60–$90 per blade and TCO of $130–$190 per year.

Coated D2 blades work well with counter-knives in single-shaft shredders, as their high hardness matches the counter-knives’ wear resistance. However, the coating can chip if exposed to hard objects (e.g., bones), so they’re not recommended for mixed food waste with foreign debris.

Selection Guide for Single-Shaft Shredder Blades

Selecting the right blade material requires evaluating waste composition, shredder specifications, and budget. Below is a step-by-step guide, including testing methods and decision tools to ensure optimal material choice.

Analyzing Food Waste Composition

First, test the waste stream for salt content, oil content, and pH. Salt content can be measured with a conductivity meter (target:<0.5%>2% = high-salt). Oil content is determined via solvent extraction (target:<3%>6% = high-oil). pH testing (target: 4–7 = neutral,<4 = acidic) identifies organic acid risks.

For example, a facility processing 70% restaurant waste (1.5% salt, 5% oil, pH 5.5) would need a material with PRE ≥ 25 (e.g., 316L). A facility with 90% residential waste (0.3% salt, 2% oil, pH 6.0) could use 304 or coated D2. Many labs offer waste composition testing for $200–$500 per sample, a small investment compared to premature blade failure costs.

Matching Material to Shredder Throughput

High-throughput shredders (≥5 tons/hour) generate more friction heat and pressure, requiring materials with better thermal stability and toughness. For example, a solid-waste-single-shaft-shredder processing 10 tons/hour would benefit from duplex 2205, as its thermal stability and strength handle continuous operation. Low-throughput shredders (≤2 tons/hour) can use 316L or coated D2, as heat and pressure are lower.

A 2022 study found that high-throughput facilities using 304 stainless steel had 2.5x more blade failures than those using duplex 2205. This is because 304 softens under sustained heat, reducing its ability to withstand the hydraulic-ram’s pressure.

Budget Optimization Strategies

For facilities with limited budgets, consider hybrid approaches: use 316L blades in high-corrosion zones (e.g., near the cutting-chamber inlet) and 304 in low-corrosion zones. This reduces costs by 20–30% compared to full 316L installation.

Another option is refurbished blades: reputable suppliers offer reconditioned 316L or duplex 2205 blades for 40–60% of new costs, with 6–12 month warranties. A U.S. facility in 2023 reported saving $8,000 annually by using refurbished blades, with no increase in downtime.

Evaluating Supplier Credentials

Choose suppliers that provide material certification (e.g., mill test reports) and ISO 9227 test results. Ask for references from food waste facilities—suppliers with experience in high-toughness-material-shredding-solutions are more likely to understand corrosion challenges.

Key supplier criteria include: 1) ability to provide custom blade sizes for your shredder model, 2) fast replacement delivery (≤3 days for emergencies), 3) access to testing labs for waste composition analysis, and 4) warranty coverage (minimum 6 months for new blades). Avoid suppliers that can’t verify material composition, as counterfeit stainless steel (e.g., 304 labeled as 316L) is common and fails quickly in food waste.

Maintenance Best Practices for Rust-Resistant Blades

Even the best materials require proper maintenance to maximize lifespan. Below are evidence-based practices to reduce corrosion and extend blade life, based on guidelines from the Waste Equipment Technology Association (WETA).

Regular Cleaning Protocols

Clean blades daily after operation to remove salt and oil residues. Use neutral pH cleaners (pH 6–8) to avoid damaging surface coatings—acidic cleaners (pH<5) can="" strip="" nitrided="" while="" alkaline="" cleaners="" ph="">9) corrode stainless steel. A 2022 study found that daily cleaning extends blade life by 30–40% compared to weekly cleaning.

For hard-to-reach areas (e.g., between blades and counter-knives), use high-pressure water (500–800 psi) with a neutral cleaner. Avoid steam cleaning, as high temperatures can bake salt residues onto the blade surface, accelerating corrosion.

Inspection Schedules

Perform visual inspections weekly to check for rust, pitting, or coating damage. Use a magnifying glass (10x) to detect early pitting—small holes (≤0.5 mm) can be repaired with specialized fillers, but larger holes require blade replacement.

Every 3 months, conduct ultrasonic testing to measure blade thickness—corrosion often reduces thickness unevenly, with the cutting edge thinning fastest. Replace blades when thickness decreases by 15% or more, as thin blades are prone to breaking. A Canadian facility in 2023 avoided a $15,000 shutdown by replacing blades early based on ultrasonic testing.

Lubrication for Corrosion Prevention

Use food-grade lubricants with anti-corrosion additives (e.g., zinc dialkyldithiophosphate) on blade hinges and contact points. Lubrication reduces friction (lowering heat generation) and creates a barrier against moisture. Apply lubricant every 2 weeks for low-throughput shredders, and weekly for high-throughput models.

Avoid petroleum-based lubricants, as they can react with food waste oils to form a sticky residue that traps salt. Water-based lubricants are preferred for food waste applications, though they require more frequent reapplication (every 3–5 days) in humid environments.

Blade Sharpening Guidelines

Sharpen blades when cutting efficiency drops (e.g., increased energy use or larger particle sizes). Use diamond grinding wheels for stainless steel or duplex blades—conventional wheels wear quickly and can overheat blades, reducing corrosion resistance.

Maintain the original blade angle (typically 20–30°) during sharpening—changing the angle reduces cutting efficiency and increases stress on the blade. A 2023 WETA study found that improper sharpening (e.g., 15° angle instead of 25°) reduces blade life by 25–30%. Most facilities outsource sharpening to specialized shops, which charge $15–$30 per blade and ensure proper angle maintenance.

Future Trends in Rust-Resistant Blade Technology

Emerging technologies are improving corrosion resistance, reducing costs, and enabling predictive maintenance. Below are key innovations expected to transform blade design in the next 5–10 years.

Smart Blades with Corrosion Sensors

Researchers are developing blades embedded with micro-sensors that monitor corrosion in real time. These sensors measure electrical resistance (a proxy for corrosion) and transmit data to the control-panel-plc-hmi, alerting operators to early corrosion. A prototype tested in 2023 by a German university detected pitting 4–6 weeks before visual signs appeared, allowing proactive replacement.

Smart blades are currently expensive ($500–$800 each) but expected to drop in cost by 40–50% by 2027 as production scales. They’re particularly valuable for facilities with high downtime costs, as they eliminate unplanned shutdowns.

Nanocoating Technologies

Nanocoatings (1–100 nm thick) offer superior corrosion resistance compared to traditional coatings. For example, graphene nanocoatings form a seamless barrier against salt and oil, with a 2023 test showing they extend 304 stainless steel blade life by 200% in high-salt waste. Other nanocoatings, like titanium dioxide (TiO₂), have self-cleaning properties—they break down oil residues when exposed to light, reducing cleaning requirements.

Nanocoatings are currently used in high-end applications (e.g., pharmaceutical waste processing) but are expected to become mainstream by 2028. A major coating manufacturer plans to launch a food-grade graphene coating in 2025, priced 30% lower than current ceramic coatings.

Sustainable Material Innovations

Recycled alloys are gaining traction: manufacturers are producing 316L and duplex 2205 from recycled electronic waste (e-waste) metals, reducing carbon footprint by 40–60% compared to virgin materials. A 2023 life cycle assessment found that recycled 316L blades have the same corrosion resistance as virgin blades but cost 15–20% less.

Biodegradable coatings are also in development: these coatings (made from plant-based polymers) provide temporary corrosion protection and break down in compost, eliminating coating waste. A prototype tested in 2023 lasted 3 months in food waste, making it suitable for low-salt applications.

Predictive Maintenance with AI

AI-powered systems are being integrated with shredder data (e.g., energy use, vibration, sensor data from smart blades) to predict blade failure. These systems use machine learning algorithms to identify corrosion patterns—for example, a 2023 pilot at a U.K. facility reduced blade replacements by 25% by predicting failures 2–3 weeks in advance.

Cloud-based AI platforms also enable remote monitoring, allowing suppliers to provide proactive maintenance recommendations. This is particularly useful for small facilities without dedicated maintenance teams, as it reduces reliance on on-site expertise.